Preparation method of in-situ growth carbon nanotube/graphene composite sponge

A graphene composite and graphene sponge technology, applied in the field of material science, can solve the problems of low density, high modulus, and the internal space of the sponge is not used, and achieve the effect of improving electrical conductivity, improving mechanical properties, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

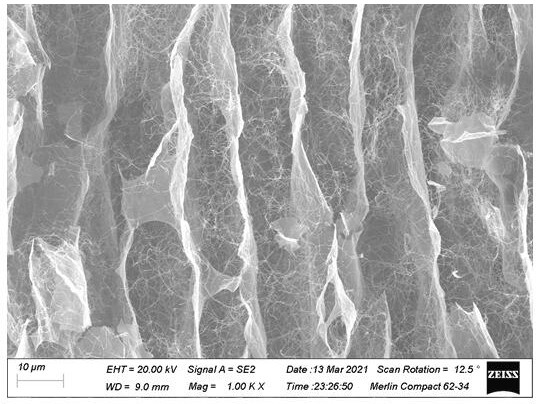

Image

Examples

Embodiment 1

[0023] The preparation method of the in-situ growth carbon nanotube / graphene composite sponge provided by this embodiment is realized according to the following steps:

[0024] 1. Preparation of oriented graphene sponge: Pour the dispersed graphene oxide aqueous solution with a concentration of 5 mg / ml into a cuboid mold with aluminum at the bottom and polytetrafluoroethylene around it, and place the bottom of the mold at a low temperature cold source -80°C Freeze on the surface, and then use the freeze-drying method to obtain the oriented porous graphene oxide sponge. Finally, the aligned graphene sponge was prepared by heat treatment at 1000 °C for 2 h under nitrogen atmosphere.

[0025] 2. Preparation of graphene sponge loaded with nickel nitrate: immerse the oriented graphene sponge obtained in step 1 in a nickel nitrate ethanol solution with a concentration of 30 mg / ml, and vacuum the oven to a vacuum with a vacuum pump for 30 minutes, so that the solution is filled with ...

Embodiment 2

[0029] The preparation method of the in-situ growth carbon nanotube / graphene composite sponge provided by this embodiment is realized according to the following steps:

[0030] 1. Preparation of oriented graphene sponge: Pour the dispersed graphene oxide aqueous solution with a concentration of 5 mg / ml into a cuboid mold with aluminum at the bottom and polytetrafluoroethylene around it, and place the bottom of the mold at a low temperature cold source -80°C Freeze on the surface, and then use the freeze-drying method to obtain the oriented porous graphene oxide sponge. Finally, chemical reduction was carried out at a temperature of 90° C. for 24 hours using excess hydrazine hydrate to obtain an aligned graphene sponge.

[0031] 2. Preparation of graphene sponge loaded with nickel nitrate: immerse the oriented graphene sponge obtained in step 1 in a nickel nitrate ethanol solution with a concentration of 30 mg / ml, and vacuum the oven to a vacuum with a vacuum pump for 30 minute...

Embodiment 3

[0034] A kind of preparation method of growing carbon nanotube / graphene composite sponge in situ, realize according to the following steps:

[0035] 1. Preparation of oriented graphene sponge: Pour the dispersed graphene oxide aqueous solution with a concentration of 5 mg / ml into a cuboid mold with aluminum at the bottom and polytetrafluoroethylene around it, and place the bottom of the mold at a low temperature cold source -80°C Freeze on the surface, and then use the freeze-drying method to obtain the oriented porous graphene oxide sponge. Finally, the aligned graphene sponge was prepared by heat treatment at 1000 °C for 2 h under nitrogen atmosphere.

[0036] 2. Preparation of graphene sponge loaded with nickel nitrate: immerse the oriented graphene sponge obtained in step 1 in a nickel nitrate ethanol solution with a concentration of 60 mg / ml, and vacuum the oven to a vacuum with a vacuum pump for 30 minutes, so that the solution is filled with graphite After drying in an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com