Treatment method of high-speed steel roller surface cracks

A roll surface and processing method technology, applied in the field of hot roll defect detection, can solve problems such as threats to rolling mill equipment, roll accidents, cost increase, etc., and achieve the effect of reducing product cost and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: On the 1700 production line of Benxi Iron and Steel Hot Rolling Plant, there were four imported high-speed steel rolls worth 2.4 million yuan on August 17, 2008 and November 30, 2009. Due to a steel jamming accident during the rolling process, the rolls Surface cracks appeared, and the depth of the cracks was detected to be 12mm and 15mm in the radial direction. After on-site inspection by foreign experts, it was determined that the 4 rolls were unusable and scrapped ahead of schedule.

[0030] Due to the high price of the rolls, 4 rolls were kept. After many tests and researches, this method was finally invented.

[0031] In May 2010, it was decided to grind the opening of the crack to the closed state. At first, it was carefully tracked and used, and finally the feasibility of the method of the present invention was determined. Wherein 06YS02G01 and G06 two rolls after grinding Φ4.15mm, use according to the method of the present invention, during from May 2...

Embodiment 2

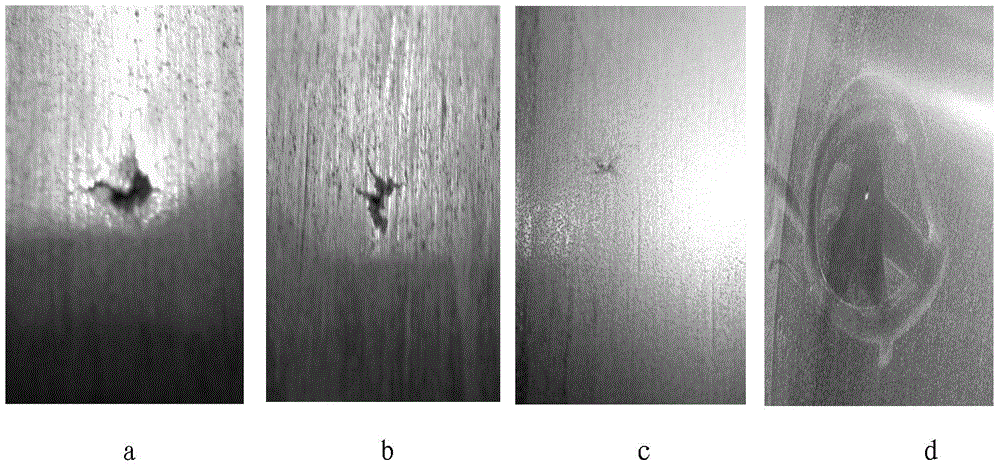

[0033] Example 2: During the use of domestic high-speed steel rolls in September 2012, it was found that Φ6mm equivalent irregular open defects occurred on the roll body. The ultrasonic detection depth was 35mm, and the defects reached the effective use radius of the roll. If the roll is scrapped, it will lose 760,000 yuan. After several inspections, it is considered that the defect is hole-like in appearance and generally regular in appearance, but there is no obvious ring crack, and the inside is narrow crack-like, slightly inclined, and the overall stability is relatively stable. The non-destructive testing method can be used to monitor its surface crack shape and internal shape, and it can be used safely, and finally the roll can be used safely to the scrapped diameter. Such as figure 2 a, figure 2 b, figure 2 c, figure 2 As shown in d, the defect gradually decreases until it is eliminated with the normal wear of the roll during use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com