Three-dimensional structure graphene composite intermediate layer assisted brazing method

A technology of graphene composite and three-dimensional structure, which is applied in the direction of coating, welding equipment, metal material coating process, etc., can solve the problems of poor mechanical properties of brazed joints such as joint residual stress, improve dispersion, avoid agglomeration, repeat strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

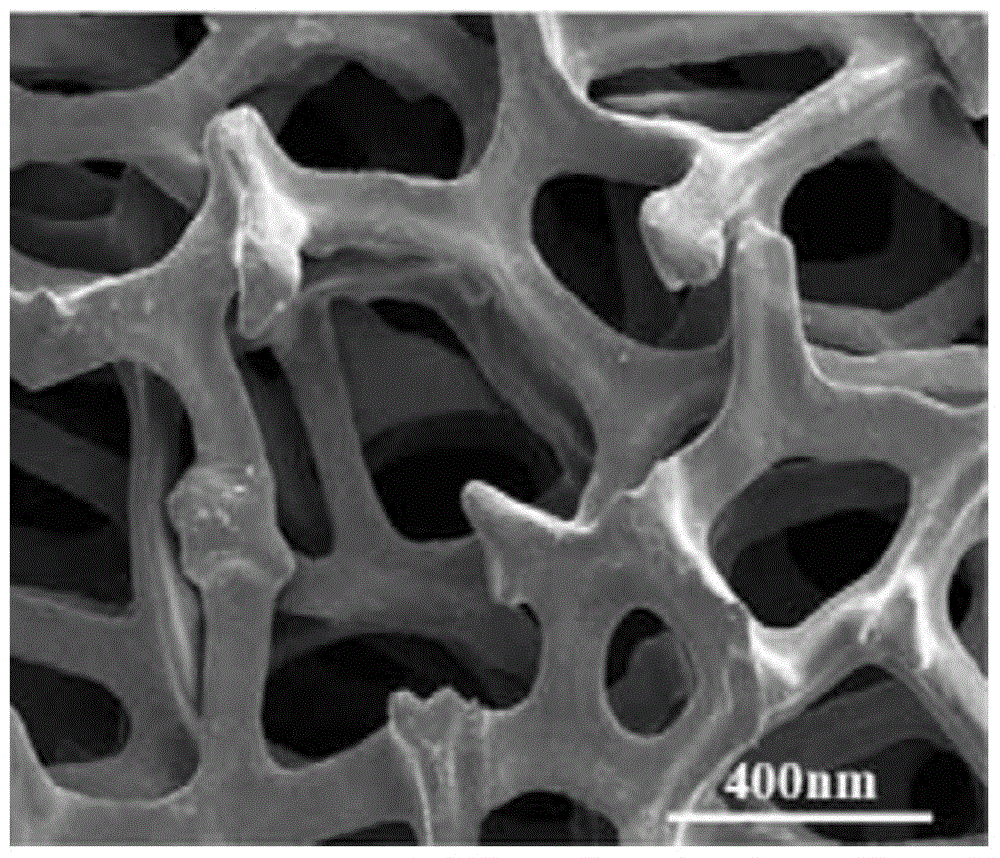

Image

Examples

specific Embodiment approach 1

[0019] Specific embodiment one: the method for assisted brazing of the three-dimensional structure graphene composite intermediate layer described in the present embodiment is specifically carried out according to the following steps:

[0020] 1. Ultrasonic pretreatment of the metal foam with acetone for 10 to 20 minutes to obtain a metal foam with impurities removed from the surface;

[0021] The metal foam is Ni foam or Cu foam;

[0022] 2. Put the metal foam from which impurities have been removed from the surface in a chemical vapor deposition device, evacuate until the pressure is below 20Pa, pass in argon gas, adjust the flow rate of argon gas to 10sccm~50sccm, and adjust the pressure in the chemical vapor deposition device to 50Pa~ 300Pa, and under the pressure of 50Pa~300Pa and argon atmosphere, the temperature is raised to 800℃~1200℃;

[0023] 3. Feed methane, adjust the gas flow rate of methane to 5 sccm to 40 sccm, adjust the gas flow rate of argon to 60 sccm to 95...

specific Embodiment approach 2

[0034] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the material to be welded described in step 4 is a metal material or ceramic material; the described material to be welded is polished with sandpaper, and then ultrasonically pretreated in acetone 5min~10min. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the brazing filler metal described in Step 4 is AgCuTi brazing filler metal or TiNi brazing filler metal. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com