Method for preparing grafted modified starch

A technology of modified starch and starch, applied in the textile field, can solve the problems that the hydrophobicity cannot be very good, the warp hairiness is not easy to adhere to, the grafting efficiency is low, etc., and achieves good operability and stability, shortened saponification time, and water solubility. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of preparation method of grafted starch, its steps are:

[0019] (1) Add 60kg of ordinary starch with water to make starch milk containing 30% starch, add 0.5L, 2% sulfuric acid, and heat up to 40°C for 2 hours of acidification;

[0020] (2) Nitrogen is fed into the acidified starch milk to get rid of the oxygen in the system, while the temperature is lowered to 20°C, and then 2kg manganese dihydrogen pyrophosphate and 3kg graft monomer acrylic acid, 2kg methyl acrylate, 3kg ethyl acrylate, 2kg vinyl acetate carry out graft copolymerization reaction, and the reaction time is 5 hours, forms starch copolymer;

[0021] (3) add 2kg caustic soda, 3kg sodium hypochlorite in the starch copolymer and carry out saponification aftertreatment, processing time 3 hours;

[0022] (4) Neutralize with sulfuric acid to make the pH value 7, then dehydrate, dry, pulverize, sieve, pack, and measure to obtain the finished product—grafted modified starch.

Embodiment 2

[0024] (1) Add water to 90kg of ordinary starch to make starch milk containing 35% starch, add 0.8L, 4% sulfuric acid, and heat up to 50°C for acidification for 3 hours;

[0025] (2) In the starch milk after the acidification, pass nitrogen to get rid of the oxygen in the system, simultaneously lower the temperature to 27 ℃, then add 3kg manganese dihydrogen pyrophosphate and 3kg graft monomer acrylic acid, 2kg methyl acrylate, 4 ethyl acrylates, 3kg vinyl acetate carry out graft copolymerization reaction, and the reaction time is 3 hours, forms starch copolymer;

[0026] (3) add 4kg caustic soda, 4kg sodium hypochlorite in the starch copolymer and carry out saponification aftertreatment, processing time 3.5 hours;

[0027] (4) Neutralize with sulfuric acid to make the pH value 6-8, then dehydrate, dry, pulverize, sieve, pack, and measure to obtain the finished product—grafted modified starch.

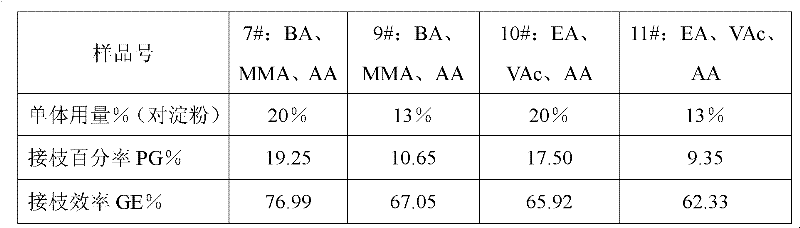

[0028] Further verify the advancement of the grafted modified starch product of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com