A beneficiation process for separating garnet and rutile based on composite flotation agents

A flotation agent, garnet technology, applied in the chemical and metallurgical fields, can solve the problems such as few, flotation to obtain garnet concentrate, can not fully obtain garnet concentrate, etc., to achieve low cost and reduced saponification time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

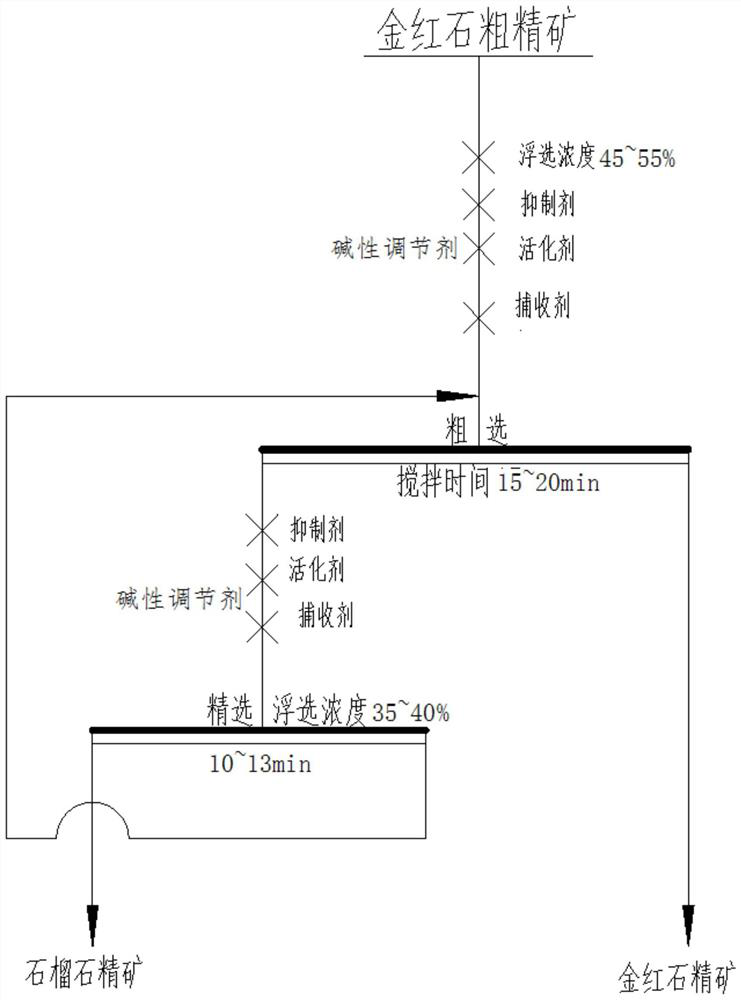

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1-a kind of preparation method of garnet composite collector, comprises the steps:

[0030] (1) according to the ratio of parts by weight, get the following components and raw materials: 20 parts of tar oil, 30 parts of oxidized paraffin soap, 20 parts of palm oil and 12 parts of sodium fatty acid methyl ester sulfonate are mixed to obtain mixed raw materials; The oil is a palm oil hydrolysis mixture subjected to acid-catalyzed hydrolysis, that is, using 3% concentrated sulfuric acid of palm oil quality, with an oil-water ratio of 1:1, the palm oil is subjected to acid-catalyzed hydrolysis at 70 ° C to obtain a palm oil hydrolysis mixture;

[0031] (2) Microwave pre-activation: microwave pre-activation of the mixed raw materials, the microwave treatment time is 6min, and the microwave frequency is 1850MH Z , the microwave power is 5kg / kw;

[0032] (3) High temperature saponification reaction: Add 13 parts by weight of flake alkali to the pre-activated mixed ...

Embodiment 2

[0033] Embodiment 2-a kind of beneficiation process based on composite flotation reagent sorting garnet and rutile, comprising the following steps:

[0034] (1) Preparation of garnet composite collector:

[0035] A. according to the ratio of parts by weight, get the following components and raw materials: 25 parts of tar oil, 35 parts of oxidized paraffin soap, 30 parts of palm oil and 18 parts of sodium fatty acid methyl ester sulfonate are mixed to obtain mixed raw materials; the palm oil It is the palm oil hydrolysis mixture subjected to acid-catalyzed hydrolysis; that is, using 6% concentrated sulfuric acid of palm oil quality, with an oil-water ratio of 1:1, the palm oil is subjected to acid-catalyzed hydrolysis at 85 ° C to obtain a palm oil hydrolysis mixture;

[0036] b. Microwave pre-activation: microwave pre-activation of the mixed raw materials, the microwave treatment time is 8min, and the microwave frequency is 2050MH Z , the microwave power is 10kg / kw;

[0037]...

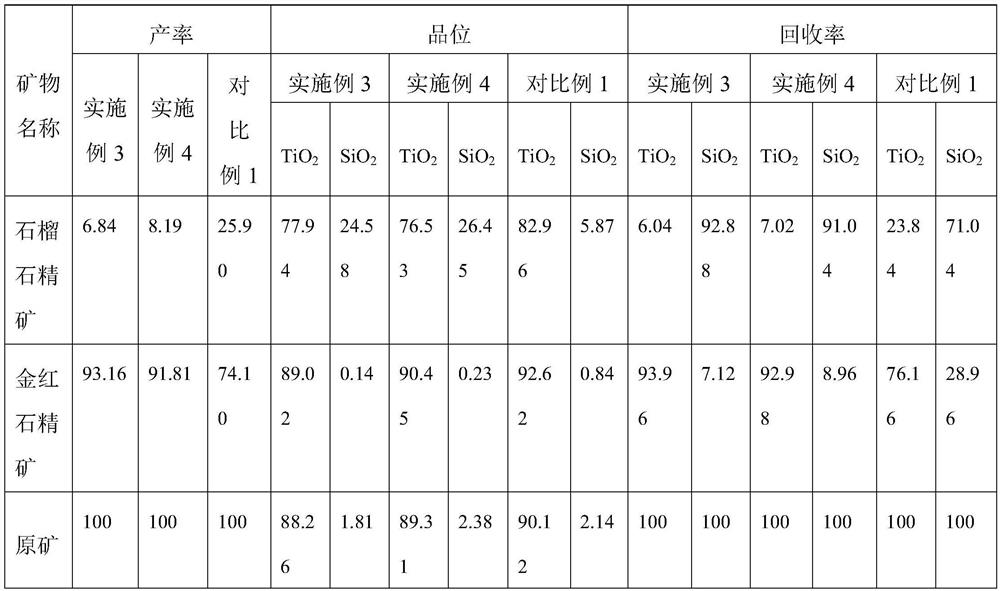

Embodiment 3

[0042] Embodiment 3-a kind of beneficiation process based on composite flotation reagent sorting garnet, rutile, comprising the steps:

[0043] (1) Preparation of garnet composite collector:

[0044] A. according to the ratio of parts by weight, get the following components and raw materials: 23 parts of tar oil, 33 parts of oxidized paraffin soap, 25 parts of palm oil and 15 parts of sodium fatty acid methyl ester sulfonate are mixed to obtain mixed raw materials; the palm oil It is the palm oil hydrolysis mixture subjected to acid-catalyzed hydrolysis; that is, the palm oil is subjected to acid-catalyzed hydrolysis at 80° C. by using 5% concentrated sulfuric acid of palm oil quality and the oil-water ratio is 1:1 to obtain the palm oil hydrolysis mixture;

[0045] b. Microwave pre-activation: microwave pre-activation of the mixed raw materials, the microwave treatment time is 7min, and the microwave frequency is 1950MH Z , the microwave power is 8kg / kw;

[0046] c. High te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com