A kind of preparation method of graphene composite lubricating grease

A graphene composite and graphene technology, applied in the field of lubricating grease, can solve the problems of poor uniformity of lubricating grease, poor oxidation resistance, poor dispersion uniformity, etc., and achieve excellent anti-friction performance and anti-oxidation performance, and good colloidal stability , The effect of high dropping point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

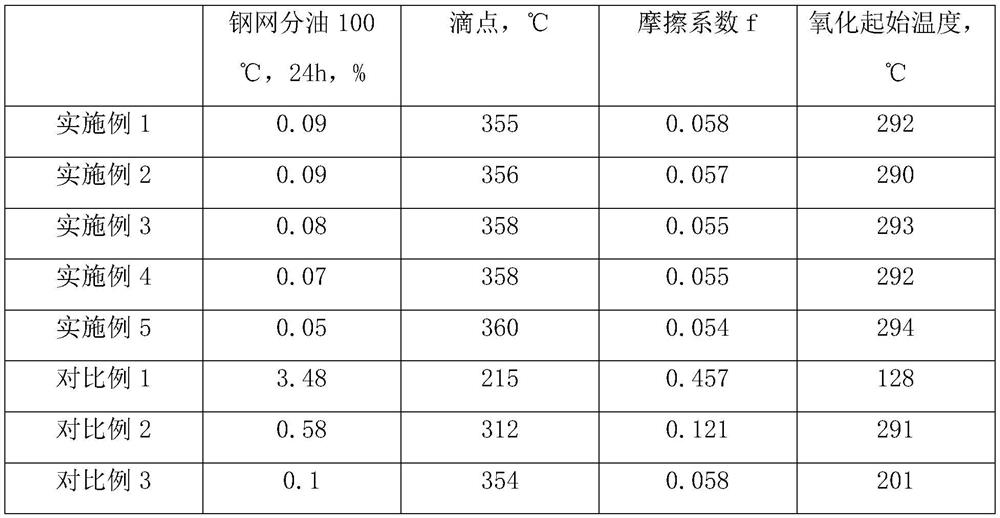

Examples

Embodiment 1

[0031] A method of preparing a graphene composite grease, first partially graphene, a first portion base oil, a high molecular acid, and a suspension of calcium hydroxide with water, performing a first saponified reaction, then add a low molecule Acid and lithium hydroxide for the second saponified reaction, refining, adding a second portion of the base oil, cooling, adding a modified second part of graphene, stir well, ground, and alteration of a graphite Ethylene compound grease; wherein the modified treatment method of the second portion of the graphene is as follows: the second portion of graphene, epoxy resin, vinyl triethoxysilane, organic solvent is added to the ball mill, the first ball milling treatment , Then add an antioxidant, second ball milling treatment, a calcium borate suspension, and the third ball milling treatment, and then processed.

[0032] The base oil is a 500 SN base oil, and the high molecule acid is 12-hydroxyglycanic acid, and the low molecular acid is...

Embodiment 2

[0045] A method of preparing a graphene composite grease, first partially graphene, a first portion base oil, a high molecular acid, and a suspension of calcium hydroxide with water, performing a first saponified reaction, then add a low molecule Acid and lithium hydroxide for the second saponified reaction, refining, adding a second portion of the base oil, cooling, adding a modified second part of graphene, stir well, ground, and alteration of a graphite Ethylene compound grease; wherein the modified treatment method of the second portion of the graphene is as follows: the second portion of graphene, epoxy resin, vinyl triethoxysilane, organic solvent is added to the ball mill, the first ball milling treatment , Then add an antioxidant, second ball milling treatment, a calcium borate suspension, and the third ball milling treatment, and then processed.

[0046] The base oil is 150 bar of base oil, and the polymeric acid is a lauric acid, and the low molecular acid is a terephtha...

Embodiment 3

[0059] A method of preparing a graphene composite grease, first partially graphene, a first portion base oil, a high molecular acid, and a suspension of calcium hydroxide with water, performing a first saponified reaction, then add a low molecule Acid and lithium hydroxide for the second saponified reaction, refining, adding a second portion of the base oil, cooling, adding a modified second part of graphene, stir well, ground, and alteration of a graphite Ethylene compound grease; wherein the modified treatment method of the second portion of the graphene is as follows: the second portion of graphene, epoxy resin, vinyl triethoxysilane, organic solvent is added to the ball mill, the first ball milling treatment , Then add an antioxidant, second ball milling treatment, a calcium borate suspension, and the third ball milling treatment, and then processed.

[0060] The base oil is a 500sn base oil, and the polymer acid is a lauric acid, and the low molecular acid is a sebacic acid. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com