A kind of handmade soap with shortened saponification time and preparation method thereof

A handmade soap and saponification technology, applied in chemical instruments and methods, skin care preparations, alkali soap/ammonium soap composition, etc., can solve the problems of environmental protection, skin damage, etc., and achieve short saponification time and biocompatibility The effect of good performance and wide source of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

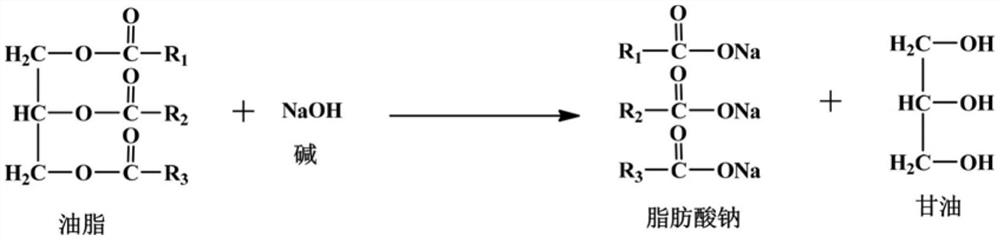

Problems solved by technology

Method used

Image

Examples

Embodiment 1

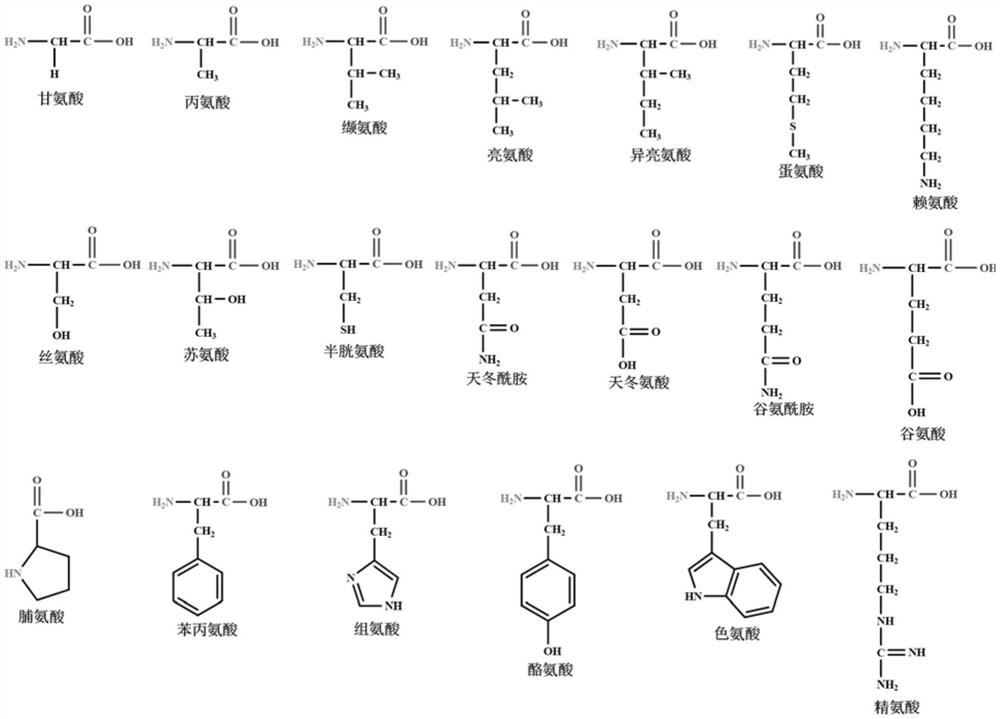

[0031] The raw material components used in this embodiment are by mass percentage: 60% of olive oil, 18% of sodium glycinate, 20% of distilled water, and 2% of lavender essential oil.

[0032] Proceed as follows:

[0033] S1: Put olive oil into the reactor and preheat it to 40±0.5°C in a water bath;

[0034] S2: Dissolve sodium glycinate (purchased directly in the market) in distilled water, configure sodium glycinate aqueous solution, control the temperature at 40±0.5°C,

[0035] S3: Add the sodium glycinate aqueous solution obtained in S2 into the olive oil in 3 times, stir quickly and mix evenly, and control the temperature at 40±0.5°C and continue stirring for 50 minutes until the saponification liquid is viscous;

[0036] S4: Add lavender essential oil to the above saponified liquid, stir evenly, then transfer the saponified liquid into the mold, and carry out the aging reaction for 48 hours;

[0037] S5: Demould the aged primary soap, cut the soap, and then place it in...

Embodiment 2

[0040] The raw material components used in this embodiment are by mass percentage: 58% of palm oil, 20% of sodium alanine, 19% of distilled water, 1% of Roman chamomile essential oil, and 2% of blue gum eucalyptus essential oil.

[0041] Preparation of sodium alanine: After mixing equal volumes of 1.0 mol / L alanine and 1.0 mol / L NaOH solution evenly, remove the solvent by a rotary evaporator to prepare sodium alanine.

[0042] S1: Put the palm oil into the reactor and preheat it to 40±0.5°C in a water bath;

[0043] S2: Dissolve the required sodium alanine in distilled water, prepare an aqueous solution of sodium alanine, control the temperature at 40±0.5°C,

[0044] S3: Add the sodium alanine aqueous solution obtained in S2 into the olive oil in 3 times, stir quickly and mix evenly, and control the temperature at 40±0.5°C and continue stirring for 50 minutes until the saponification liquid is viscous;

[0045] S4: Add Roman chamomile essential oil and blue gum eucalyptus ess...

Embodiment 3

[0049] The used raw material component of present embodiment is by mass percent: base oil 55% (olive oil 20%, coconut oil 20%, palm oil 15%), disodium glutamate 20%, distilled water 20%, honey 4%, Lavender essential oil 1%.

[0050] Preparation of disodium glutamate: Mix 1.0 mol / L glutamic acid and 2.0 mol / L NaOH solution in equal volumes, and remove the solvent by rotary evaporator to prepare disodium glutamate.

[0051] S1: Put the base oil into the reactor and preheat it to 40±0.5°C in a water bath;

[0052] S2: Dissolve the required disodium glutamate in distilled water, prepare disodium glutamate aqueous solution, control the temperature at 40±0.5°C,

[0053] S3: Add the disodium glutamate aqueous solution obtained in S2 into the base oil in 3 times, stir quickly and mix evenly, and control the temperature at 40±0.5°C and continue stirring for 50 minutes until the saponification liquid is viscous;

[0054]S4: Add honey and lavender essential oil to the above saponified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com