Collecting agent for separating garnet and ilmenite and flotation process of collecting agent

A technology of garnet and ilmenite, which is applied in the fields of chemical industry and metallurgy, can solve the problems of not getting enough garnet concentrate, achieve the effects of improving harvesting effect, reducing material input, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

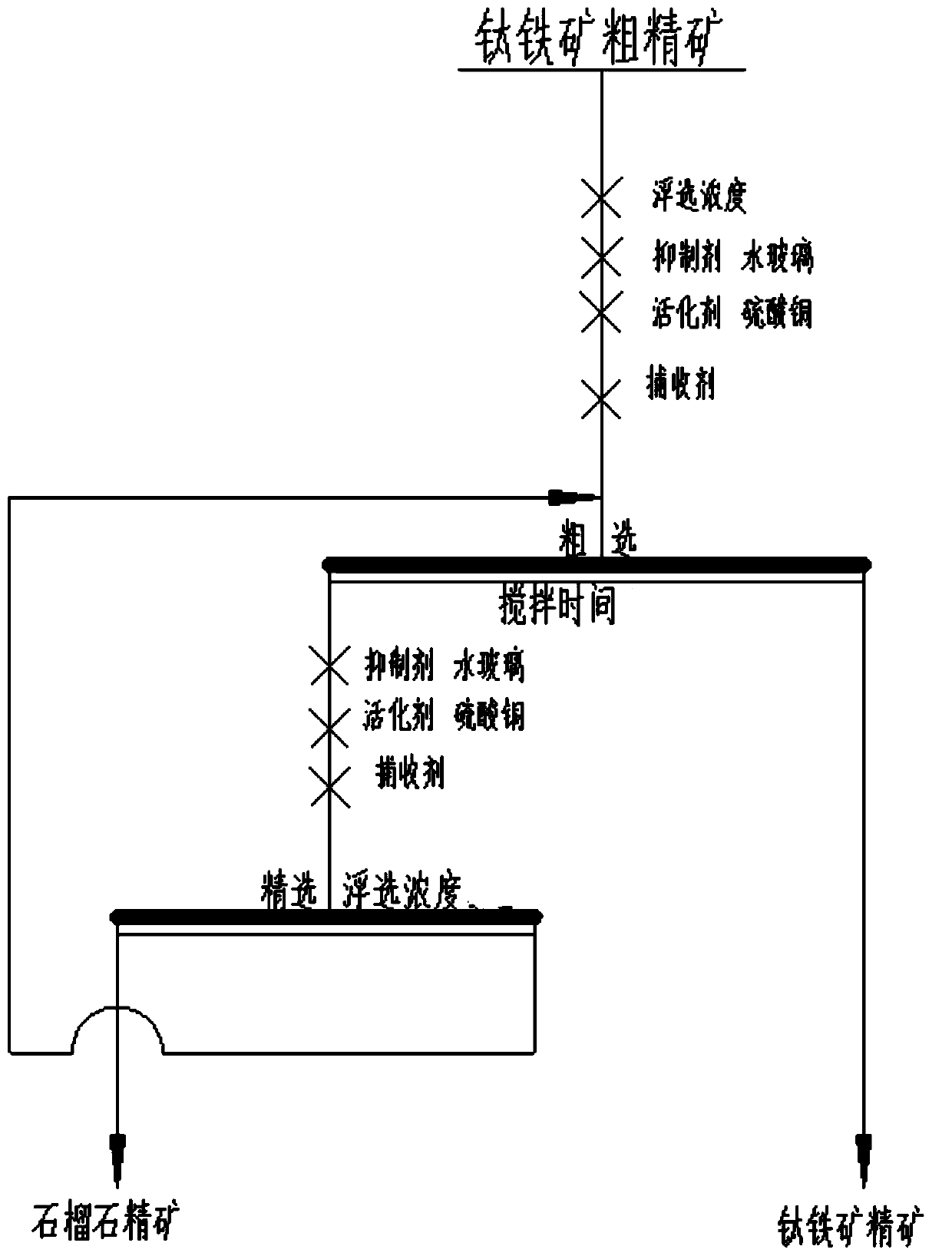

Method used

Image

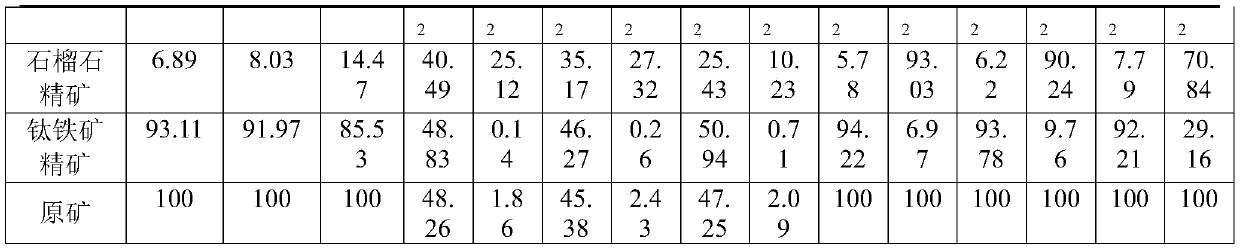

Examples

Embodiment 1

[0021] A collector for sorting garnet and ilmenite: the collector includes the following raw materials in parts by weight: 10 parts of tall oil, 25 parts of oxidized paraffin wax soap, 40 parts of palm oil, 10 parts of sodium fatty acid methyl ester sulfonate parts, 10 parts of sodium hydroxide.

Embodiment 2

[0023] A collector for sorting garnet and ilmenite: the collector includes the following raw materials in parts by weight: 15 parts of tall oil, 35 parts of oxidized paraffin wax soap, 50 parts of palm oil, 15 parts of sodium fatty acid methyl ester sulfonate Parts, 15 parts of sodium hydroxide.

Embodiment 3

[0025] A collector for sorting garnet and ilmenite: the collector includes the following raw materials in parts by weight: 10 parts of tall oil, 25 parts of oxidized paraffin wax soap, 50 parts of palm oil, 15 parts of sodium fatty acid methyl ester sulfonate part, 15 parts of sodium hydroxide;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com