Production process of octacosanol

A technology of octadecanol and production process, applied in the field of production technology of fatty alcohol, can solve problems such as long operation time, environmental pollution, complicated process, etc., and achieve the effects of fully and complete reaction, reduction of production cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

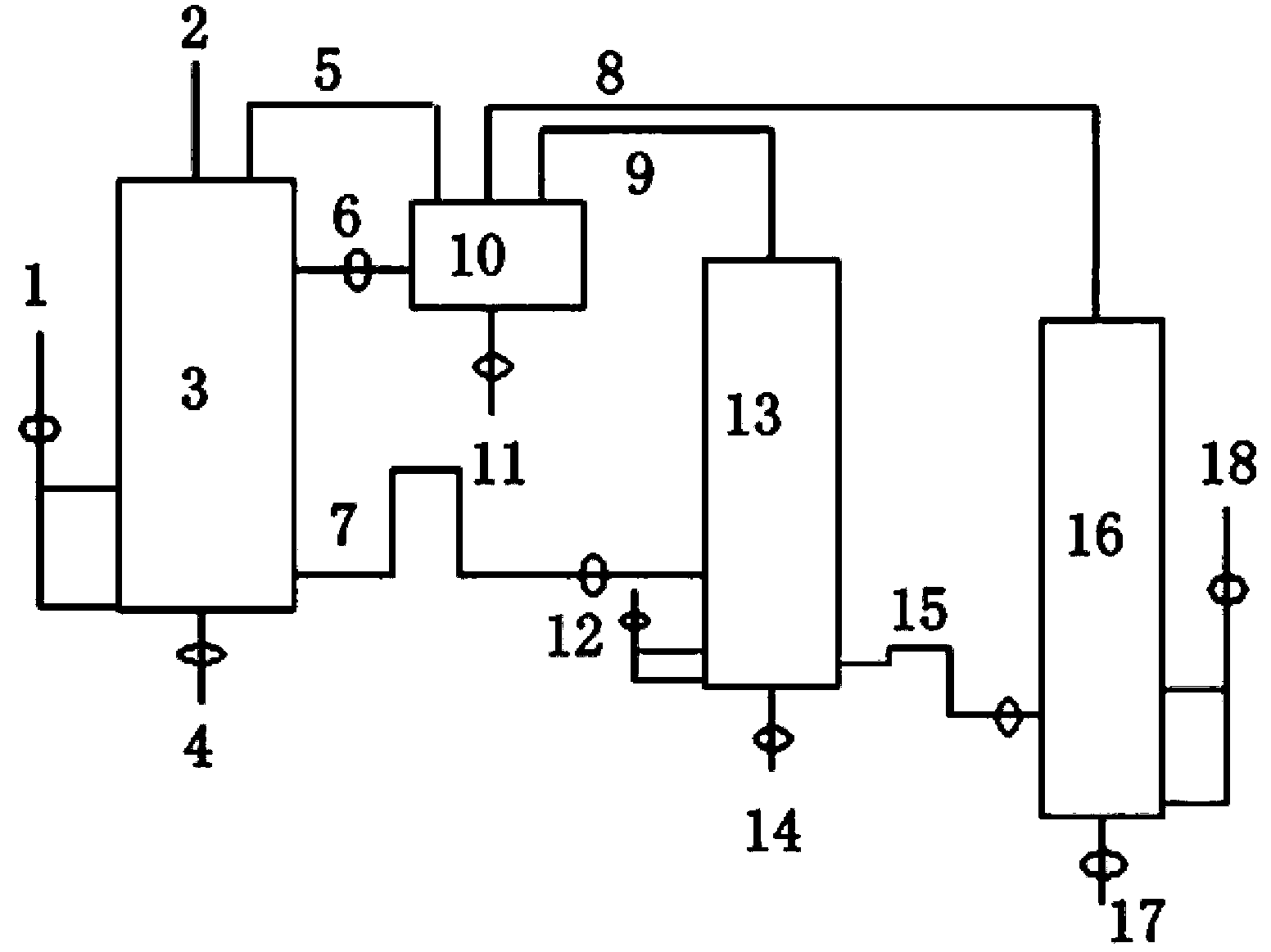

[0033]Example 1. The production process of octacosanol involves saponification, washing, dehydration, drying, pulverization, extraction, filtration, precipitation of hair bran wax to obtain fatty alcohol, and vacuum distillation to obtain octacosanol.

[0034] Preferably, the production process of octacosanol includes the following steps: ①Put the hair bran wax into the saponification tank, heat it to 95°C with indirect steam, and stir at a stirring speed of 60r / min at the same time. Add caustic soda solution with a mass fraction of 4.5% to 6% and benzyltriethylammonium chloride, start the ultrasonic radiation with a power of 200 watts for 30 minutes to fully saponify it, and obtain product A;

[0035] ② Put the product A in the saponification tank into the filter car and wash it with water until the product A becomes neutral, then dehydrate, dry and crush the washed material into granules to obtain product B;

[0036] ③ Put product B and alcohol solvent into the extraction t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com