Hydraulic oil composition with high extreme pressure performance

A hydraulic oil composition, composition technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem that the extreme pressure property cannot meet its index requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

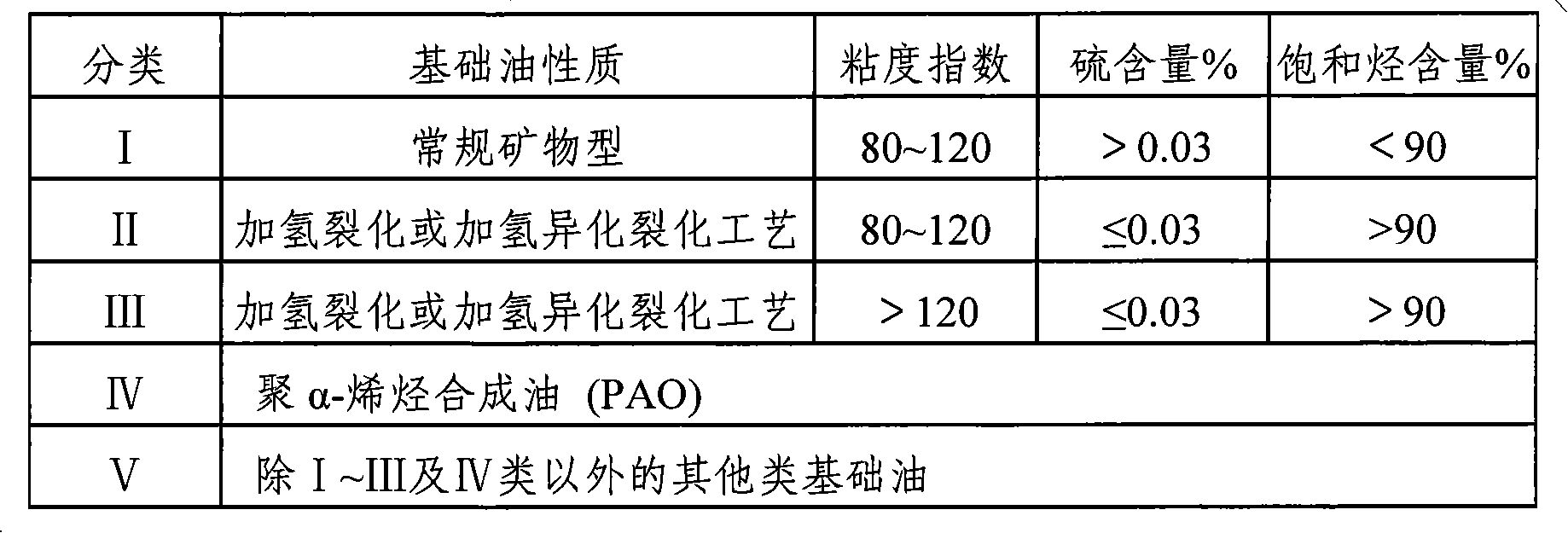

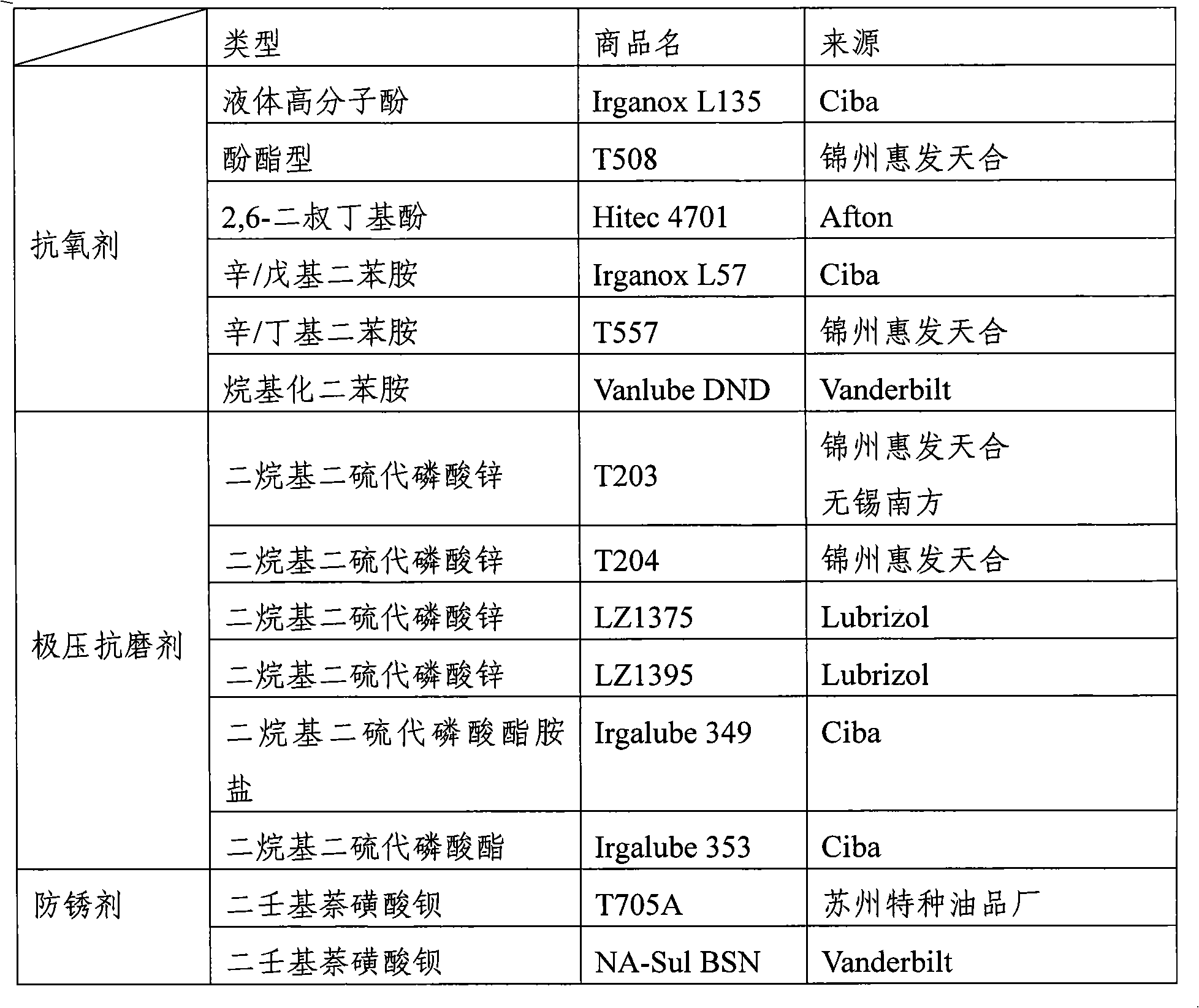

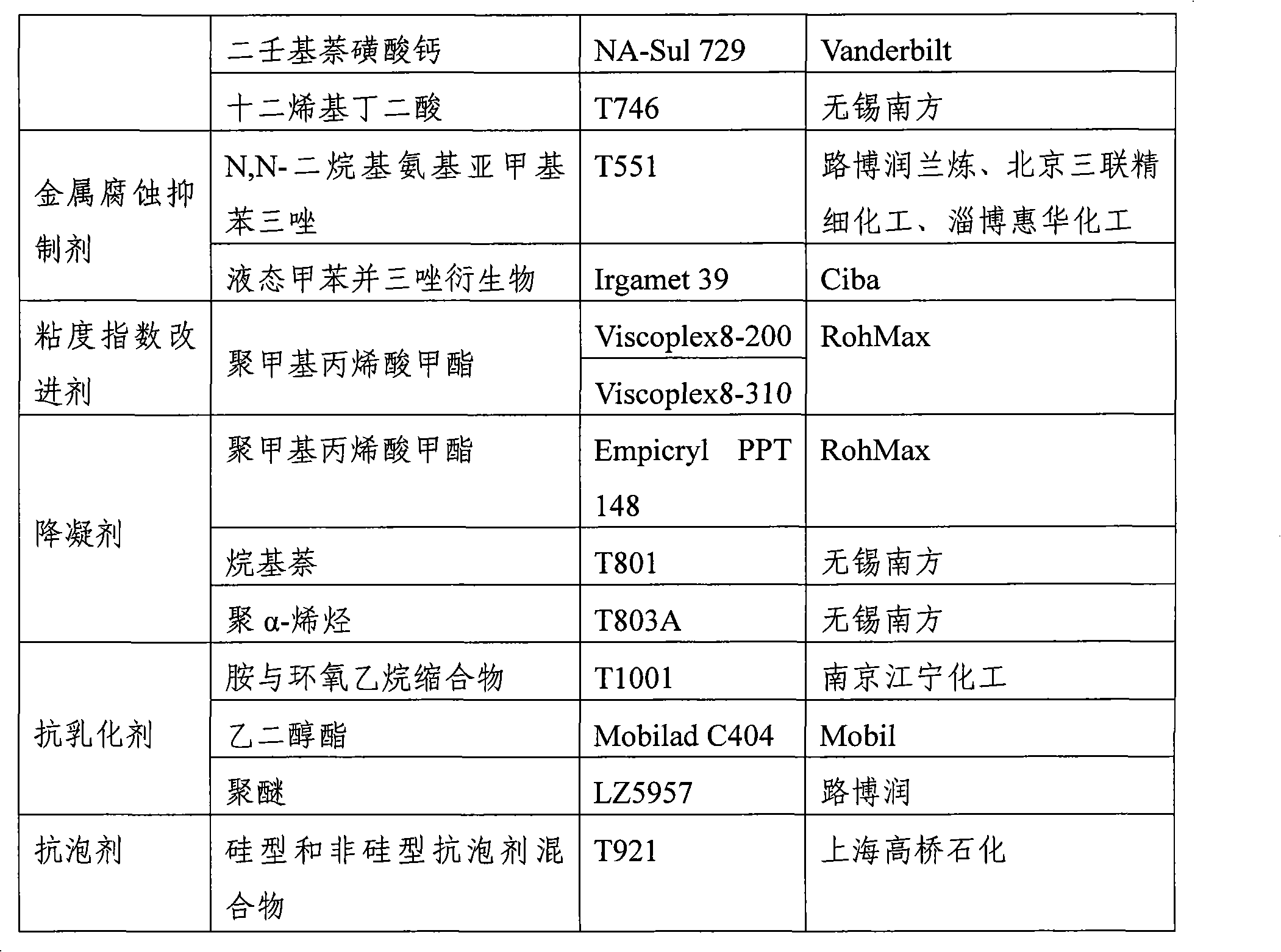

Method used

Image

Examples

Embodiment 1

[0029] Take 0.3kg of zinc dialkyl dithiophosphate (T203, alkyl is C4~C8), 0.05kg of dialkyl dithiophosphate amine salt (Irgalube 349, alkyl is C10~C14), dialkyl dithiophosphate Phosphorothioate (Irgalube 353, alkyl is C4) 0.05kg, 4-octyl-4'-butyldiphenylamine (T557) 0.1kg, dinonyl naphthalene sulfonate calcium (NA-Sul 729) 0.06kg, Then add successively in API I type base oil (viscosity index 82, sulfur content 0.07%, saturated hydrocarbon 85%) 9.44kg and API II type base oil (viscosity index 106, sulfur content 0.01%, saturated hydrocarbon 99%) in 90kg, Mixing and stirring were carried out at 50° C. for 3 hours to prepare a hydraulic oil composition.

Embodiment 2

[0031] Take 0.2kg of zinc dialkyldithiophosphate (T204, alkyl is C4~C8), 0.6kg of dialkyldithiophosphate (Irgalube 353, alkyl is C4), 2,6-di-tert-butyl p-cresol (Hitec 4701) 0.1kg, polymethacrylate (16 carbon atoms) 0.1kg, and then added to API Group I base oil (viscosity index 85, sulfur content 0.08%, saturated hydrocarbon 87%) 23.5 kg and 75 kg of API II group base oil (viscosity index 105, sulfur content 0, saturated hydrocarbon 95%), mixed and stirred at 40° C. for 5 hours to prepare a hydraulic oil composition.

Embodiment 3

[0033] Take 0.4kg of zinc dialkyl dithiophosphate (T203, alkyl is C4~C8), 0.2kg of dialkyl dithiophosphate amine salt (Irgalube 349, alkyl is C10~C14), dialkyl dithiophosphate Phosphorothioate (Irgalube 353, alkyl is C4) 0.05kg, 4-octyl-4'-butyldiphenylamine (T557) 0.2kg, polymethacrylate (carbon number is 12) 0.3kg, two Calcium nonylnaphthalene sulfonate (NA-Sul 729) 0.1kg, compound antifoam agent (T921) 0.1kg, and then added to API Group I base oil (viscosity index 82, sulfur content 0.07%, saturated hydrocarbon 85%) 35kg 63.74kg of API II base oil (viscosity index 106, sulfur content 0.01%, saturated hydrocarbon 99%) was mixed and stirred at 70°C for 2 hours to prepare a hydraulic oil composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com