Ceramic alloy lubricating oil special for dredging workboat engine and preparation method thereof

A ceramic alloy and lubricating oil technology, applied in the field of lubrication, can solve problems such as easy precipitation, phosphorus content cannot be reached, sulfur content cannot be lower than 1%, and achieve excellent lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

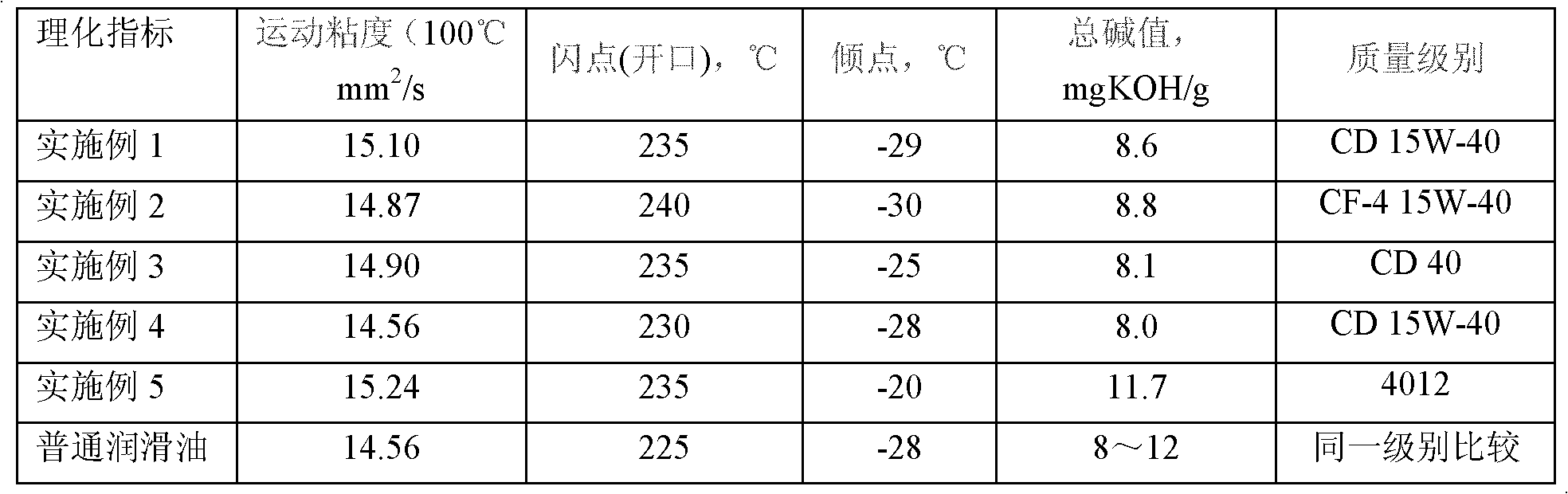

Examples

Embodiment 1

[0033] Mix and stir 250kg of ceramic alloy coupling agent, 1500kg of 150N, 2750kg of 500N, 20kg of pour point depressant V382, 495kg of viscosity index improver T614, 250kg of compound 1185 and 200ppm of antifoaming agent, and control the mixing temperature to be 75 ℃, the stirring time is 120 minutes, and the special ceramic alloy lubricating oil for dredging engineering ship engines that meets the national standard is prepared.

Embodiment 2

[0035] 200kg of ceramic alloy coupling agent, 1400kg of 150N, 2800kg of 500N, 15kg of pour point depressant V385, 510kg of viscosity index improver T614, 250kg of compound agent 1185, 400ppm of anti-foaming agent, control the mixing temperature to 65℃, stir The time is 150 minutes, and the special ceramic alloy lubricating oil for dredging engineering ship engines that meets the national standard is prepared.

Embodiment 3

[0037] 150kg of ceramic alloy coupling agent, 1500kg of 150N, 2750kg of 500N, 20kg of pour point depressant V382, 495kg of viscosity index improver Infineum SV261, 250kg of compound agent 1185, 200ppm of anti-foaming agent, controlled stirring and mixing temperature of 60 ℃, the stirring time is 60 minutes, and the special ceramic alloy lubricating oil for dredging engineering ship engines that meets the national standard is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com