Borate anti-abrasion extreme pressure additive and preparing method thereof

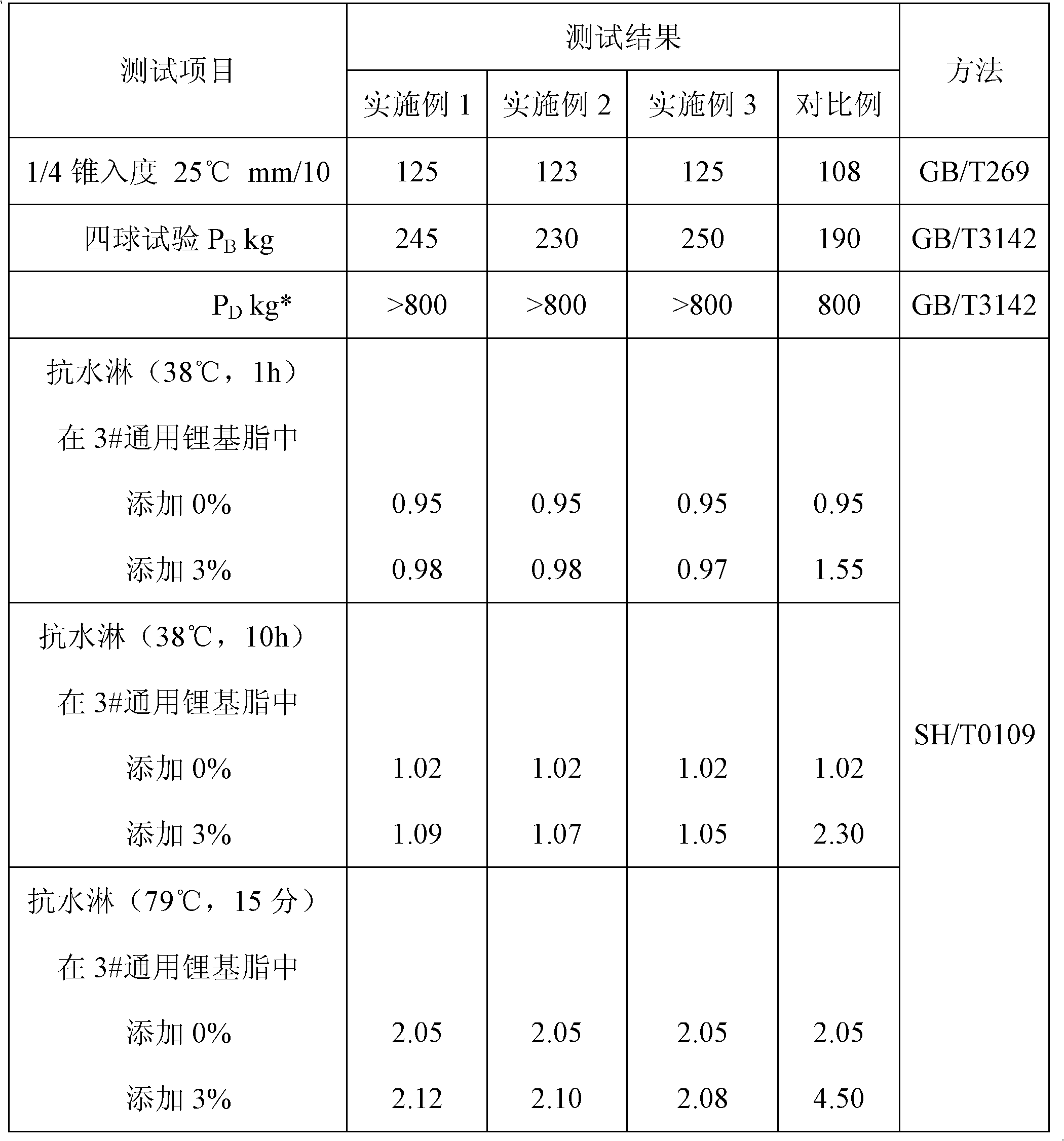

An extreme pressure additive, borate technology, applied in additives, petroleum industry, lubricating compositions, etc., can solve the problems of poor water resistance, anti-wear and compression resistance and cone penetration that can not fully meet market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Add 80kg of water, 649.2kg of boric acid and 59kg of potassium hydroxide into the reactor, stir, heat up to 60°C, react for 60 minutes, add 5kg of poly-a-olefin base oil, stir, heat up to 150°C, dehydrate for 10 minutes, and then Raise the temperature to 190°C, carry out high-temperature polymerization for 60 minutes, cool down to 150°C, add 5kg of aluminum stearate, stir for 30 minutes, continue to cool down to 100°C, take out the kettle, grind on a three-roll mill, and disperse homogeneously to obtain a finished product.

Embodiment 2

[0058] Add 40kg of water, 37kg of boric acid and 67kg of potassium hydroxide into the reactor, stir, heat up to 95°C, react for 10 minutes, add 42kg of poly-a-olefin base oil, stir, heat up to 100°C, dehydrate for 90 minutes, and then heat up To 250°C, carry out high-temperature polymerization for 20 minutes, cool down to 190°C, add 8 kg of lithium stearate, stir for 30 minutes, continue to cool down to 120°C, take out the kettle, grind on a three-roll mill, homogeneously disperse, and obtain a finished product.

Embodiment 3

[0060] Add 40kg of water, 293.7kg of boric acid and 53.3kg of potassium hydroxide into the reactor, stir, heat up to 80°C, react for 40 minutes, add 19.9kg of poly-a-olefin base oil, stir, heat up to 115°C, and dehydrate for 60 minutes , then raise the temperature to 220°C, carry out high-temperature polymerization for 50 minutes, cool down to 175°C, add 0.1kg of sodium stearate, stir for 30 minutes, continue to cool down to 110°C, take out the kettle, grind on a three-roll mill, and disperse homogeneously. finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com