Lubricating grease with long service life, extreme pressure and high-temperature resistance and preparation method thereof

A high-temperature-resistant grease and long-life technology, used in lubricating compositions, petroleum industry, etc., can solve the problem of unsatisfactory stencil oil separation and water leaching loss indicators, high content of grease thickener, and inability to meet heavy loads requirements, etc., to facilitate large-scale industrial production, improve extreme pressure wear resistance and high temperature resistance, and improve high temperature adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

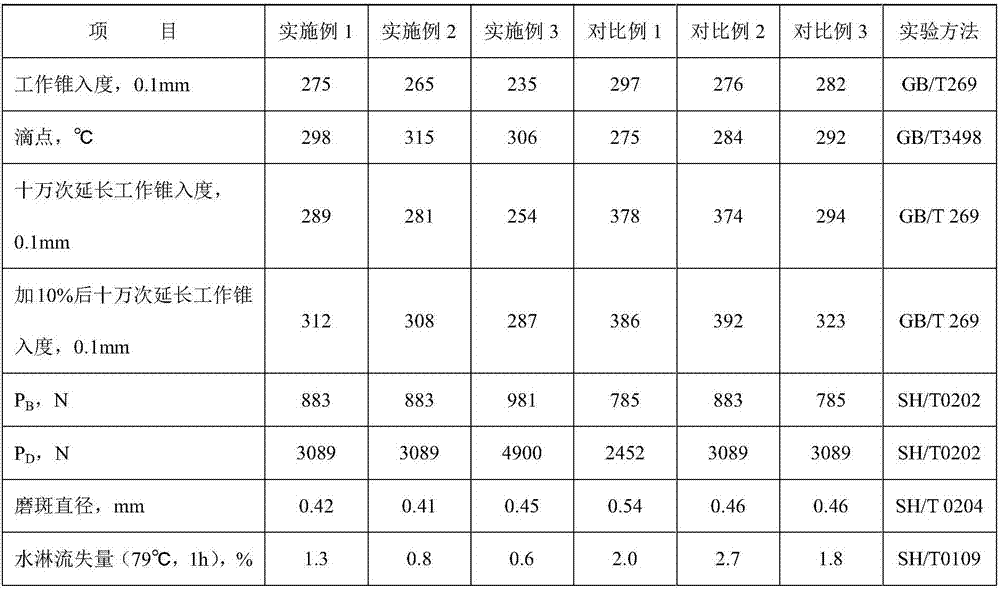

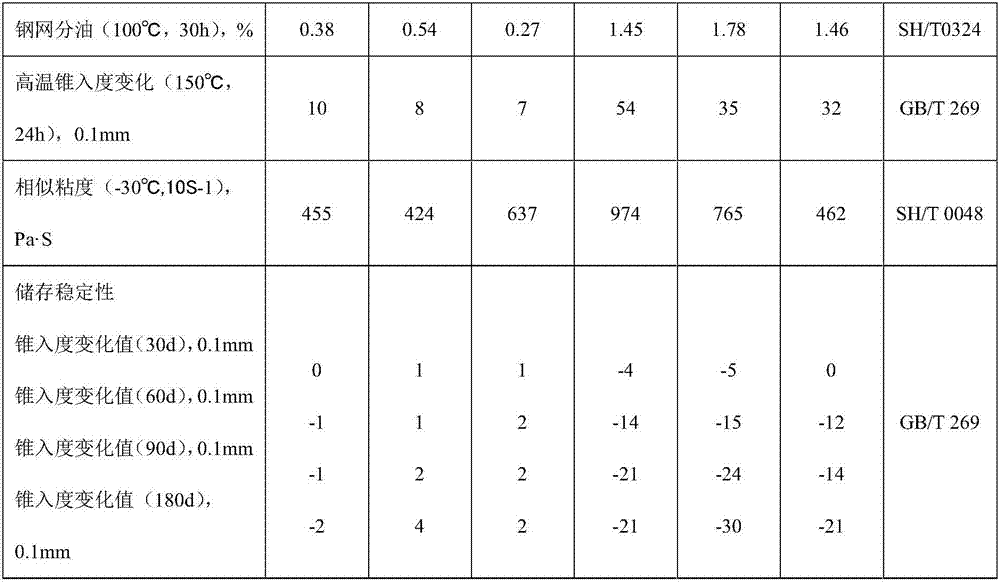

Examples

Embodiment 1

[0014] The base oil selected in this embodiment is a mixed oil of 150BS and alkylnaphthalene Synesstic 12, and the kinematic viscosity at 40°C after mixing is 160mm 2 / s, the total amount of base oil is 485kg.

[0015] Preparation:

[0016] (1) Preparation of thickener: dissolve 11.5kg of octadecylamine and 12kg of cyclohexylamine in 55°C, 100kg of the above-mentioned base oil and 22kg of diphenylmethane diisocyanate (hereinafter referred to as MDI) in 75°C, 300kg of base oil , then pour the amine solution into the MDI solution, stir and heat up to 100°C, and saponify at this temperature for 1.5 hours to obtain a thickener.

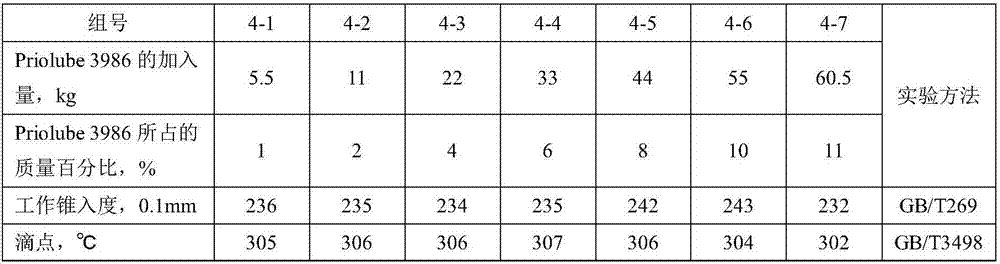

[0017] (2) Preparation of lubricating grease: Add 2.5kg of stearyl alcohol to the thickener prepared in step (1) and continue mixing and stirring for 20 minutes, then heat up to 190°C for high-temperature refining for 40 minutes, transfer to the cooling tank, add the remaining base Cool the oil to 100 ℃, then add 11.3kg Priolube3986, 2.0kg alkyl dipheny...

Embodiment 2

[0019] The base oil used in this example is a mixed oil of 500SN and alkylnaphthalene Synesstic 12, and the kinematic viscosity at 40°C after mixing is 100mm 2 / s, the total amount of base oil is 366kg.

[0020] Preparation:

[0021] (1) Preparation of thickener: Dissolve 20.60kg n-octylamine and 22.4kg aniline in 50°C, 100kg of the above base oil and 55kg of MDI in 80°C and 200kg of the above mixed base oil, then pour the amine solution into MDI In the solution, stir and heat up to 105°C, and saponify at this temperature for 2 hours to obtain a thickener.

[0022] (2) Preparation of lubricating grease: Add 3.0 kg of stearyl alcohol to the thickener prepared in step (1) and continue mixing and stirring for 30 minutes, then raise the temperature to 195°C for high-temperature refining for 30 minutes, transfer to the cooling kettle, add the remaining base Cool the oil to 95°C, then add 40kg of Ketjenlube 135, 3.0kg of phenyl-α-naphthylamine, 15kg of Additin RC8400 and 2.5kg of ...

Embodiment 3

[0024] The base oil selected in this embodiment is a mixed oil of poly-alpha olefin PAO40 and alkylnaphthalene Synesstic 12, and the kinematic viscosity of the mixed oil at 40°C is 220mm 2 / s, the total amount of base oil is 409kg.

[0025] Preparation:

[0026] (1) Preparation of thickener: Dissolve 19.5kg octadecylamine, 24.5kg aniline in 55°C, 100kg of the above base oil and 45kg of MDI in 75°C, 250kg of the above mixed base oil, then pour the amine solution into the MDI In the solution, stir and heat up to 115°C, and saponify at this temperature for 1.5 hours to obtain a thickener.

[0027] (2) Preparation of lubricating grease: Add 3.0kg of stearyl alcohol to the thickener prepared in step (1) and continue mixing and stirring for 20 minutes, then heat up to 190°C for high-temperature refining for 30 minutes, transfer to the cooling tank, add the remaining base Cool the oil to 110°C, then add 16.5kg Priolube3986, 2.75kg phenyl-α-naphthylamine, 27.25kg Additin RC8400 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com