Universal nonferrous metal and stainless steel cold rolling oil composite additive and preparation method thereof

A compound additive and non-ferrous metal technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of mixed formula types, inconvenience for users, etc., and achieve the effects of inhibiting catalysis, preventing corrosion, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

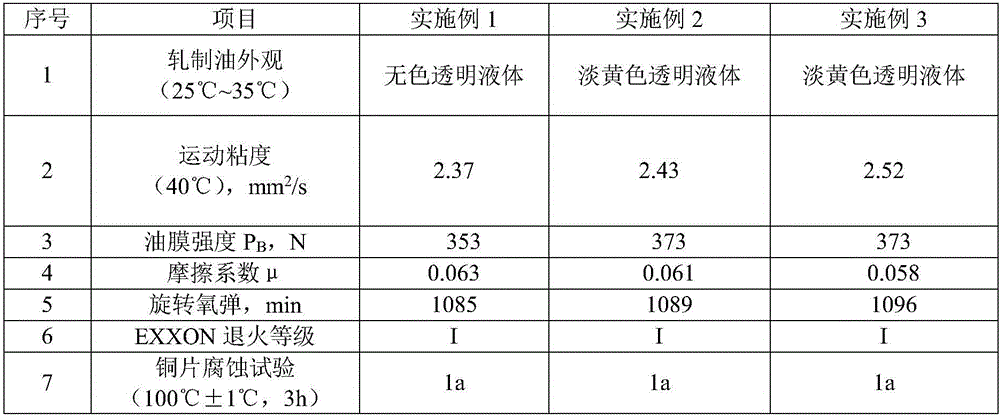

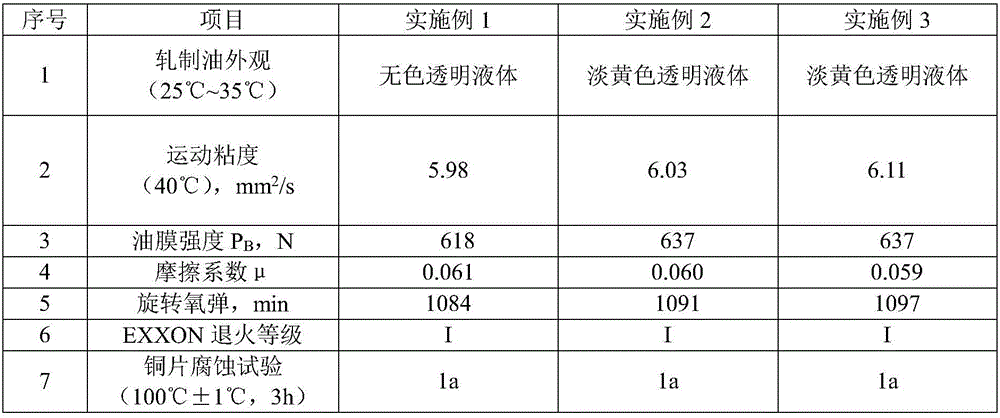

Examples

Embodiment 1

[0026] Embodiment 1 formula (by total mass 100g) is shown in Table 1:

[0027] Table 1

[0028] serial number component name mass (g) 1 Lauryl Alcohol 28.0 2 Butyl stearate 16.8 3 pentaerythritol oleate 25.2 4 Lauric acid 2.0 5 2,6-di-tert-butyl-p-cresol 0.5 6 Benzotriazole 0.3 7 Thiadiazole Derivatives 0.9 8 dialkyl dithiophosphate 0.5 9 Hydrogenated base oil 25.8

[0029] According to the mass formula of each component in the above table, a general-purpose nonferrous metal and stainless steel cold rolling oil composite additive is prepared. Dodecyl alcohol (28.0g), butyl stearate (16.8g), pentaerythritol oleate (25.2g), lauric acid (2.0g), 2,6-di-tert-butyl p-cresol (0.5g) , benzotriazole (0.3g), thiadiazole derivatives (0.9g), dialkyl dithiophosphate (0.5g) and hydrogenated base oil (25.8g), add to the container in the order specified in the instructions Finally, put it on a constant temperatu...

Embodiment 2

[0031] Embodiment 2 formula (by total mass 100g) is shown in Table 2:

[0032] Table 2

[0033] serial number component name mass (g) 1 Lauryl Alcohol 35.0 2 Butyl stearate 17.5 3 pentaerythritol oleate 17.5 4 Lauric acid 3.0 5 2,6-di-tert-butyl-p-cresol 0.7 6 Benzotriazole 0.5 7 Thiadiazole Derivatives 0.5 8 dialkyl dithiophosphate 1.0 9 Hydrogenated base oil 24.3

[0034] According to the mass formula of each component in the above table, a general-purpose nonferrous metal and stainless steel cold rolling oil composite additive is prepared. Dodecyl alcohol (35.0g), butyl stearate (17.5g), pentaerythritol oleate (17.5g), lauric acid (3.0g), 2,6-di-tert-butyl p-cresol (0.7g) , benzotriazole (0.5g), thiadiazole derivatives (0.5g), dialkyl dithiophosphate (1.0g) and hydrogenated base oil (24.3g), add to the container in the order specified in the instructions Finally, put it on a constant temperatu...

Embodiment 3

[0036] Embodiment 3 formula (according to total mass 100g meter) is shown in Table 3:

[0037] table 3

[0038] serial number component name mass (g) 1 Lauryl Alcohol 42.0 2 Butyl stearate 16.8 3 pentaerythritol oleate 11.2 4 Lauric acid 5.0 5 2,6-di-tert-butyl-p-cresol 1.0 6 Benzotriazole 0.9 7 Thiadiazole Derivatives 0.3 8 dialkyl dithiophosphate 2.0 9 Hydrogenated base oil 20.8

[0039] According to the mass formula of each component in the above table, a general-purpose nonferrous metal and stainless steel cold rolling oil composite additive is prepared. Dodecyl alcohol (42.0g), butyl stearate (16.8g), pentaerythritol oleate (11.2g), lauric acid (5.0g), 2,6-di-tert-butyl p-cresol (1.0g) , benzotriazole (0.9g), thiadiazole derivatives (0.3g), dialkyl dithiophosphate (2.0g) and hydrogenated base oil (20.8g), add to the container in the order specified in the instructions Finally, put it on a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com