High-viscosity repair type engine anti-wear agent capable of reducing exhaust and preparing method of engine anti-wear agent

An engine, high-viscosity technology, applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of high viscosity of lubricating oil, change of oil viscosity, unfavorable fuel economy, etc., achieve low phosphorus content, reduce exhaust emissions, and good resistance The effect of grinding and repairing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

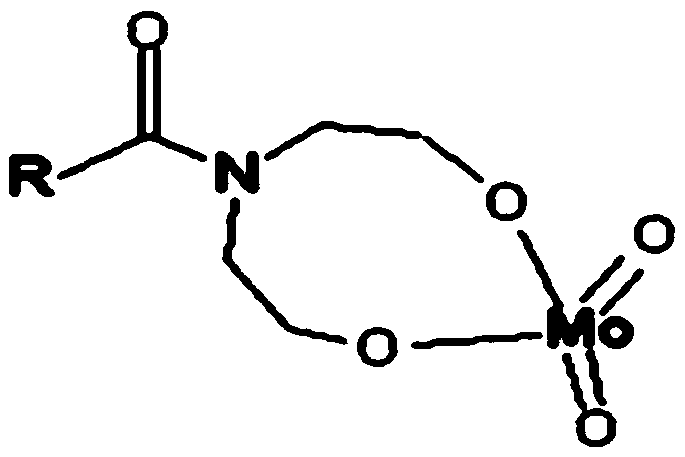

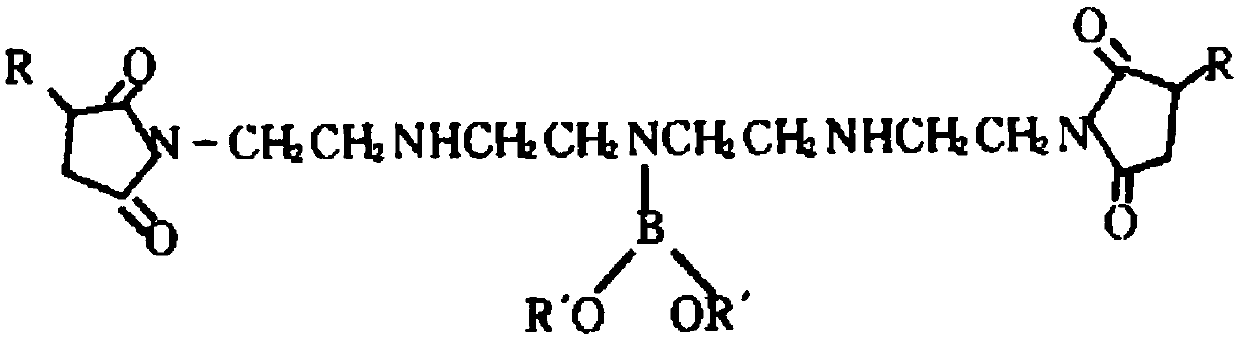

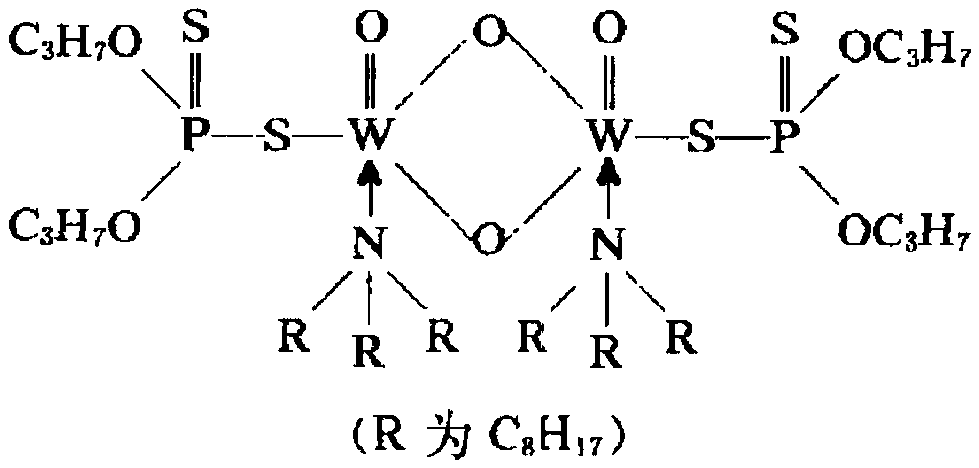

[0064] High-viscosity repair type engine anti-wear agent for reducing exhaust gas Raw materials: 8kg of molybdenum N,N-di(tridecyl)alkyldithiocarbamate, 8kg of aminodiisopropyldithiophosphate tungsten, nitrogen-containing borate 7.8kg, long carbon chain alkyl calcium borate 3kg, borated polyisobutylene succinimide 20kg, polymethacrylate 15kg, polydodecanedibasic acid 1,3-butylene glycol ester 15kg, alkyl di Benzyltoluene 23.2kg.

[0065] The nitrogen-containing borate is formed by mixing 2.6kg of lauric acid diethanolamide borate, 2.6kg of stearic acid diethanolamide borate and 2.6kg of oleic acid diethanolamide borate.

[0066] Preparation method of high-viscosity repair type engine anti-wear agent for reducing exhaust gas:

[0067] Add polymethacrylate, polydodecanedibasic acid 1,3-butylene glycol ester, and alkyl dibenzyltoluene into the mixing tank, stir and heat to 65°C, keep the temperature at 65°C, and then add borated poly Isobutylene succinimide, Nitrogen-containing...

Embodiment 2

[0069] Prepare the engine anti-wear agent of high-viscosity repairing type reducing tail gas according to the raw material ratio and method of Example 1, the difference is only: the nitrogen-containing borate is composed of 3.9kg lauric acid diethanolamide borate, 3.9kg hard Fatty acid diethanolamide borate blend. Obtain the high-viscosity repair type engine antiwear agent that reduces exhaust gas of embodiment 2.

Embodiment 3

[0071] Prepare the engine anti-wear agent of high-viscosity repairing type reducing tail gas by the raw material proportioning and method of embodiment 1, difference is only: described nitrogen-containing borate is made of 3.9kg lauric acid diethanolamide borate, 3.9kg oil Acid diethanolamide borate mixture. Obtain the high-viscosity repair type engine antiwear agent that reduces exhaust gas of embodiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com