Nano core-shell type copper-nickel bimetal powder body and preparing method and application thereof

A nano-core-shell and bimetallic technology, applied in the direction of coating, etc., can solve the problems of simple nano-copper powder being easily oxidized and not easily oxidized, and achieve significant social benefits, friction reduction, energy saving, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, 4 grams of nano-spherical copper powder was prepared by using the technology reported by Liu Zhijie, Zhao Bin, etc. on pages 55-58 of the 10th issue of the document "Chemical Bulletin" in 1996, and the copper powder was stirred and dispersed evenly with 100 ml of water;

[0025] Polymer protection agent PVP content is 16g / L, nickel sulfate hexahydrate content is 13.3g / L (theoretical content of nickel in powder is 10%), copper complexing agent thiourea content is 120ml of the mixed solution of 67g / L, Mix it with the copper powder suspension at 80 degrees with stirring. The reaction time is 15 minutes, and the reaction product is filtered, washed and dried. The so-called core-shell copper-nickel bimetal nanopowder can be obtained.

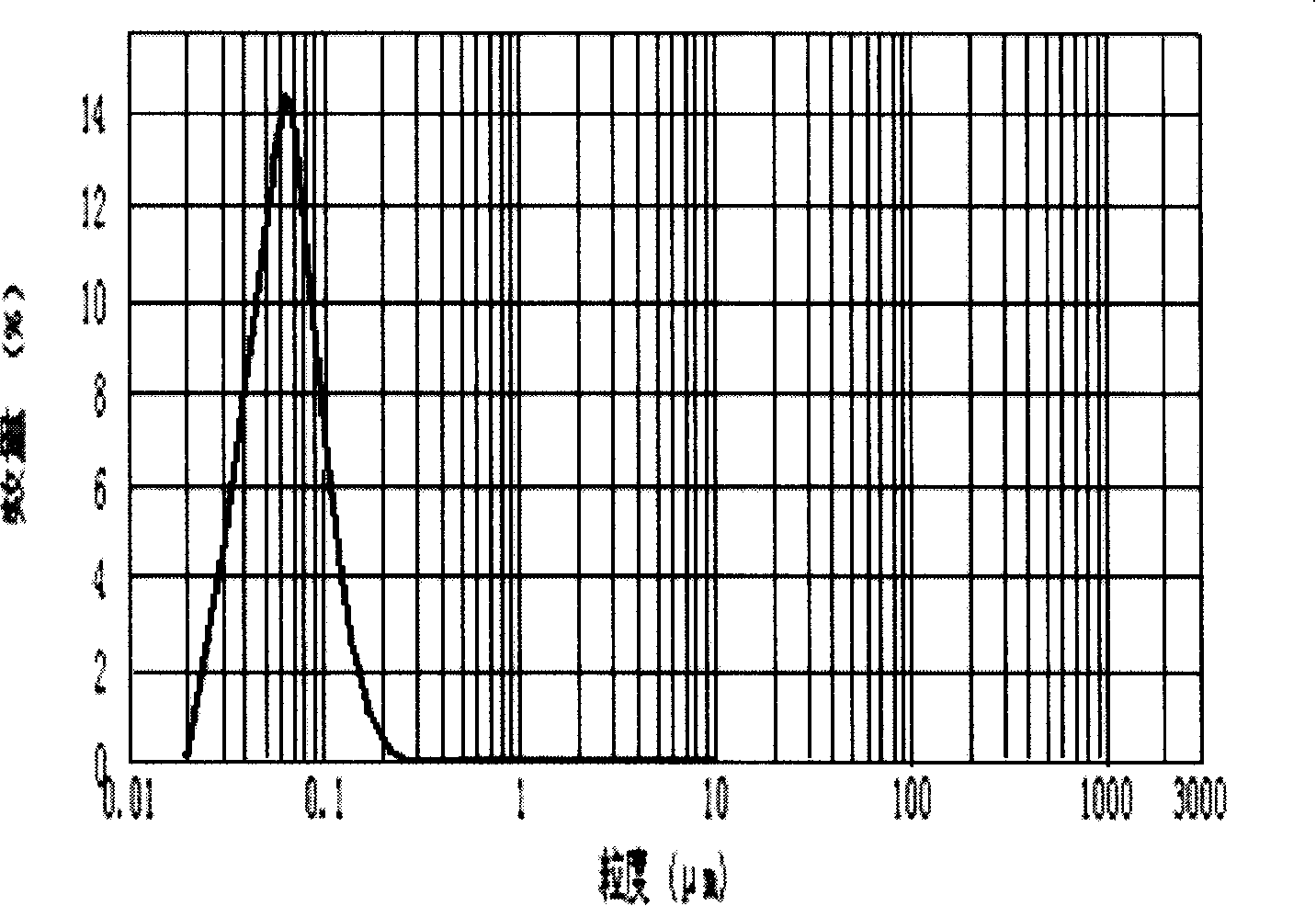

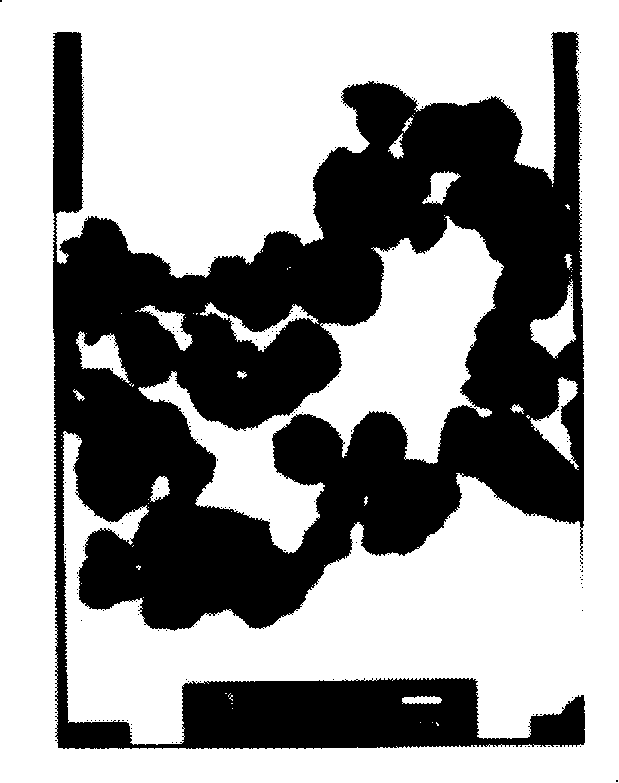

[0026] Depend on figure 1 , 2 The comparison shows that spherical or near-nano-spherical copper-nickel bimetallic powder can be prepared by using nano-spherical copper powder as raw material, and the particles of the latter are sligh...

Embodiment 2

[0028] Prepare 4g of nano-spherical copper powder with reference to Example 1, and add 100ml of water to the copper powder to stir and disperse evenly; another polymer protective agent PVP content is 16g / L, copper complexing agent thiourea content is 67g / L, sulfuric acid hexahydrate 120ml of a mixed solution with a nickel content of 20g / L (the theoretical content of nickel in the powder is 15%) is mixed with the copper powder suspension under stirring at 80°C. The reaction time is 15 minutes, and the reaction product is filtered, washed and dried. The so-called core-shell copper-nickel bimetal nanopowder can be obtained.

[0029] The particle size of the prepared powder was tested by a laser particle size analyzer, and the average particle size of the particles was 70nm. The particles are clad structures.

Embodiment 3

[0031] Referring to Example 1, prepare 4 g of nano-spherical copper powder, and add 100 ml of water to the copper powder to stir and disperse evenly; another polymer protective agent PVP content is 16 g / L, copper complexing agent thiourea content is 67 g / L, sulfuric acid hexahydrate Nickel content is 26.6g / L (theoretical content of nickel in powder is 20%) mixed solution 120ml, under the condition of stirring at 80 ℃, it is mixed with copper powder suspension. The reaction time is 20 minutes, and the reaction product is filtered, washed and dried. The so-called nano-core-shell copper-nickel bimetallic powder can be obtained.

[0032] The particle size of the prepared powder was tested by a laser particle size analyzer, and the average particle size of the particles was 60nm. The particles are clad structures.

[0033] The same method can produce nano-copper-nickel powder with nickel content of 30%, 40%, etc. in the powder

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com