Oil-soluble light-colored nano copper preparation as well as preparation method and application thereof

A nano-copper, oil-soluble technology, used in additives, petroleum industry, lubricating compositions, etc., can solve problems such as limiting the application of nano-copper powder, and achieve the effects of significant social benefits, increased stability, and narrow particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Firstly, the technology reported by Liu Zhijie, Zhao Bin and others was used in the document "Chemical Bulletin" No. 10, 1996, pages 55-58, to prepare 100 grams of polymer aqueous dispersion containing 1 gram of nano-spherical copper powder; the content of polymer protective agent PVP It is 16g / L, and the reaction time is 15 minutes.

Embodiment 2

[0027] Referring to Example 1, 100 grams of aqueous dispersion of 1 gram of nano-copper was prepared, and mixed with 6 grams of phosphobisoctyl zinc salt and 100 grams of xylene as a solvent at 65° C. while stirring. The reaction time is 20 minutes, the oil-water phase of the reaction product is separated, and the oil phase is subjected to vacuum distillation to obtain the oil-soluble light-colored nano-copper preparation.

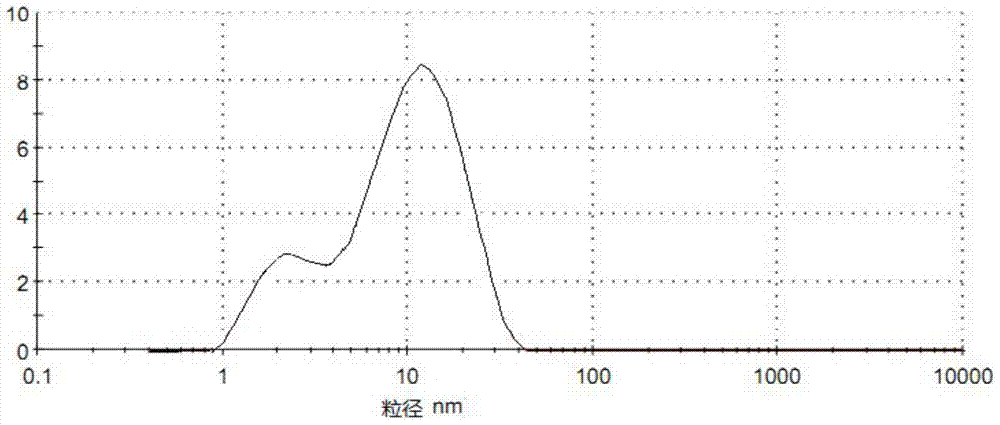

[0028] The particle size of the prepared preparation was tested by a laser particle size analyzer, and the average particle size of the particles was less than 10nm.

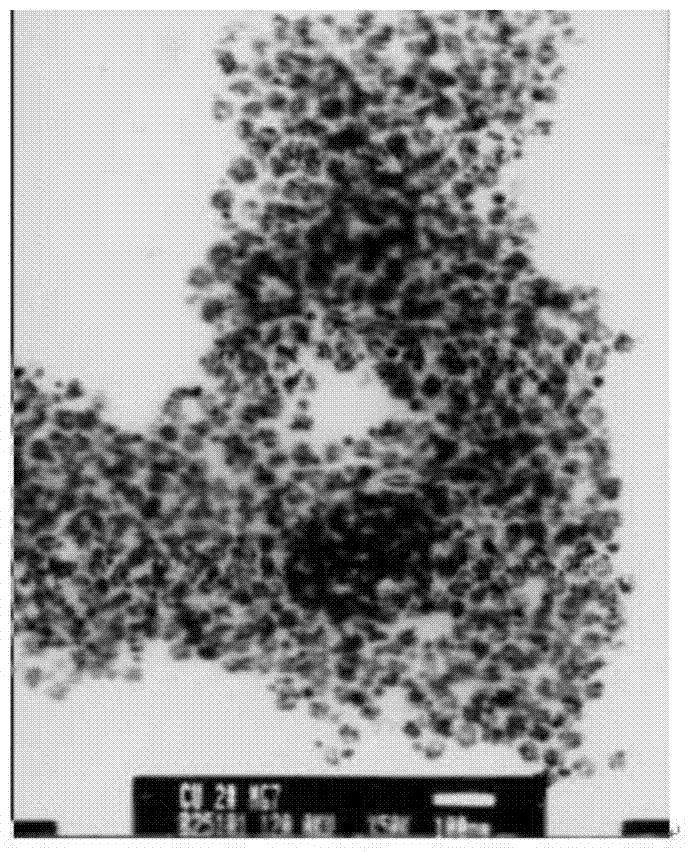

[0029] Particle size distribution see figure 1 , see electron microscope photo figure 2 .

Embodiment 3

[0031] With reference to Example 1, prepare 100 grams of aqueous dispersion of 1 gram of nano-copper, mix it with 7 grams of aqueous zinc stearate and 100 grams of solvent undecane under the condition of stirring at 70 ° C, and the reaction time is 30 minutes. The product oil-water phase is separated, and the oil phase is subjected to vacuum distillation. The said oil-soluble light-colored nano-copper preparation can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com