A gold-coated silver-graphene-based aqueous ink and its application in inkjet printing transparent patterned conductive electrodes

An alkenyl water-based, graphene technology, applied to the conductive layer on the insulating carrier, application, printing, etc., can solve the problem of silver being easily oxidized, and achieve high practical application value, controllable products, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

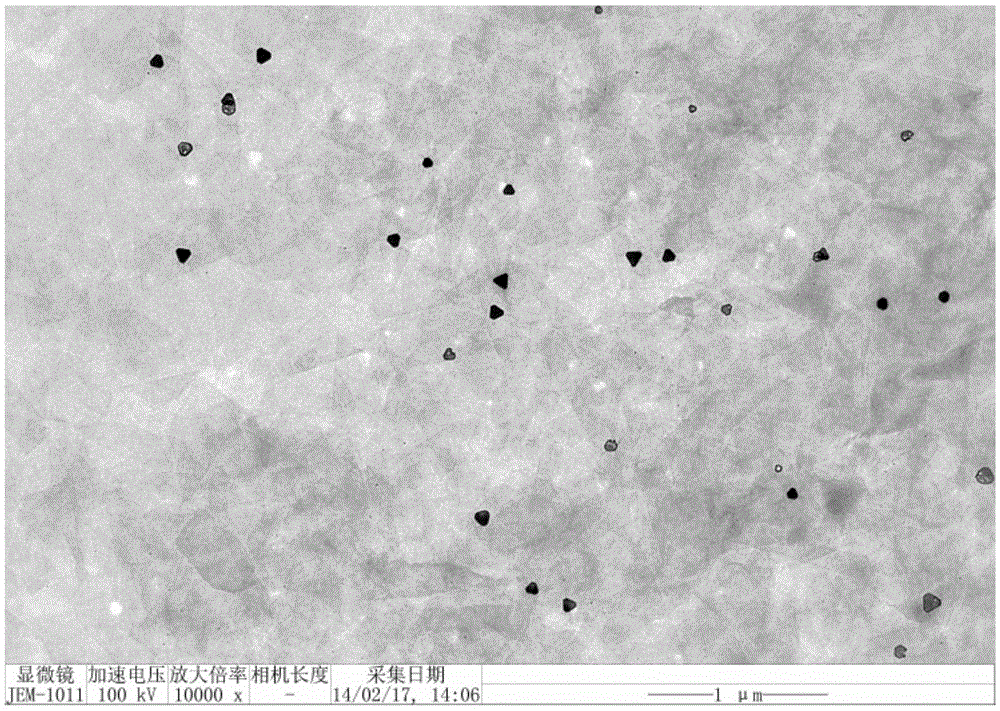

[0025] The composition of gold-coated silver-graphene-based water-based ink includes ink active components and solvents; the mass of ink active components accounts for 2.4% of the total mass, and is composed of graphene oxide and sheet-shaped gold-coated silver nanoparticles with a mass ratio of 0.5; solvent for water.

[0026] Synthesis of graphene oxide: the graphene oxide prepared by the improved Hummer method is a golden yellow product; the product is treated with an ultrasonic crusher at 200W for 2 hours, and then passed through a 1 μM filter membrane to remove large-sized graphene oxide; the obtained solid Vacuum dried at room temperature overnight to obtain the obtained product.

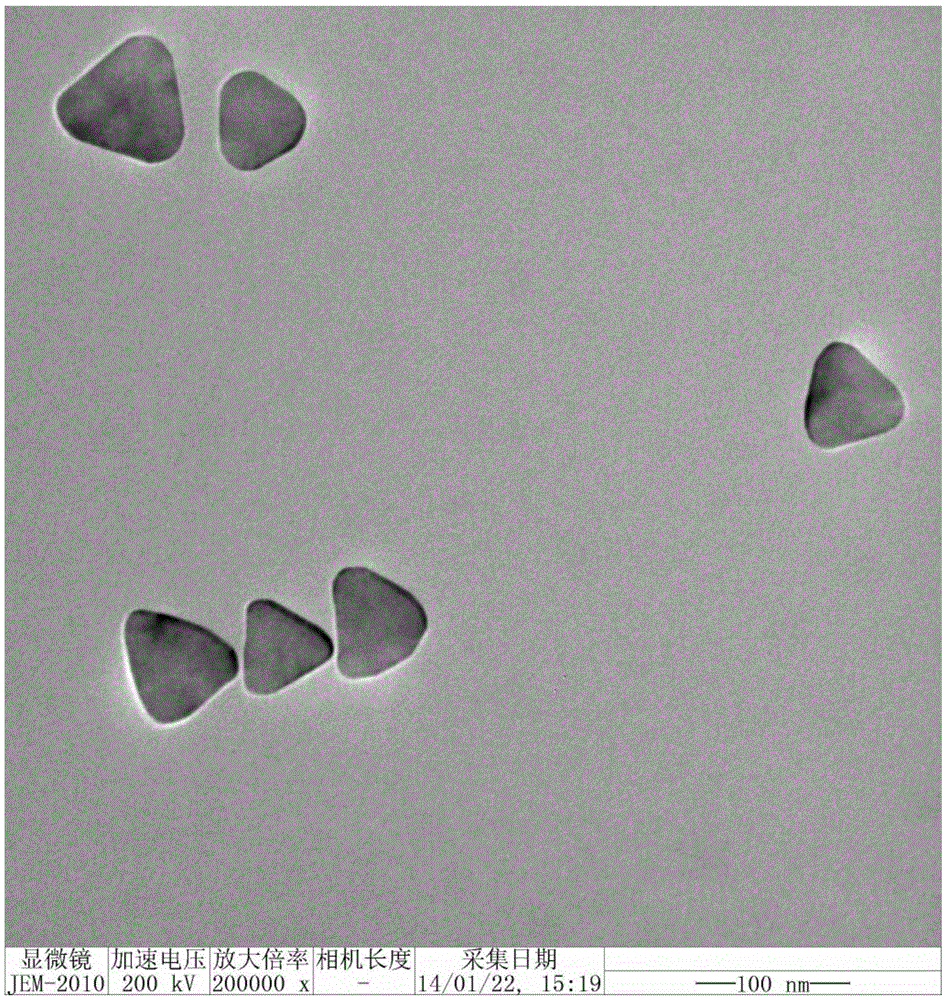

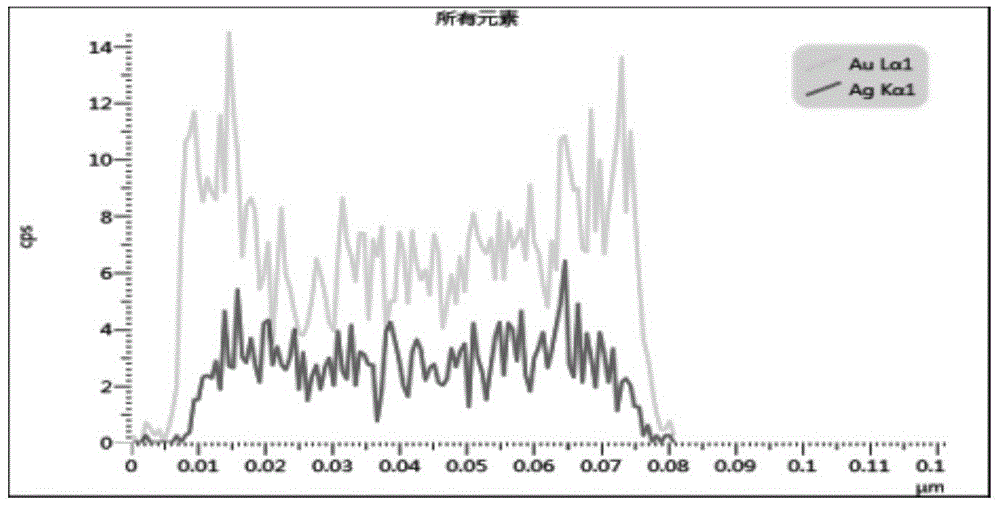

[0027] Synthesis of flaky gold-coated silver nanoparticles: Dissolve 100 μL of 0.1mol / L sodium citrate solution and 45 μL of 0.1mol / L silver nitrate solution in 50 mL of water, then add 100 μL of 30 wt% hydrogen peroxide solution, Stir vigorously, then inject 2500 μL of 0.1mol / L iced sodium bor...

Embodiment 2

[0032] The composition of gold-coated silver-graphene-based water-based ink includes ink active components and solvents; the quality of ink active components accounts for 4.5% of the total mass, and is composed of graphene oxide and gold-coated silver nanoparticles with a mass ratio of 0.2; the ink solvent is 20% volume concentration of acetone solution.

[0033] Synthesis of graphene oxide: the graphene oxide prepared by the improved Hummer method is a golden yellow product; the product is treated with an ultrasonic crusher at 200W for 2 hours, and then passed through a 1 μM filter membrane to remove large-sized graphene oxide; the obtained solid Vacuum-dried overnight at room temperature to obtain the obtained product.

[0034] Synthesis of gold-coated silver nanoparticles: 100 μL of 10 wt% sodium citrate solution and 50 μL of 10 wt% silver nitrate solution were added to 1 mL of water, and stirred at room temperature until the color changed from white to colorless to obtain ...

Embodiment 3

[0038] The composition of gold-coated silver-graphene-based water-based ink includes ink active components, solvents and additives; the mass of ink active components accounts for 10% of the total mass, and the graphene and gold-coated silver obtained by the liquid phase exfoliation method with a mass ratio of 0.15 Composition of nanoparticles; ink solvent is ethyl acetate saturated aqueous solution at 30°C; additive is 5wt% polyvinylpyrrolidone solution, accounting for 1% of the total ink volume.

[0039] Synthesis of gold-coated silver nanoparticles: 100 μL of 10wt% tartaric acid solution and 50 μL of 10wt% silver nitrate solution were added to 1 mL of water, and stirred at room temperature until the color changed from white to colorless to obtain a mixed solution A; 49 μL of 0.1mol Mix / L ascorbic acid and 49 μL 5mmol / L potassium iodide, add it into water at 80°C whose volume is 1000 times that of the ascorbic acid solution, stir evenly to obtain mixed solution B; inject mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com