An electrocatalytic oxidation anode material and treatment method for preferential removal of nonylphenol

An electrocatalytic oxidation and anode material technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. Excellent electrocatalytic performance, overcoming easy oxidation, and improving electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

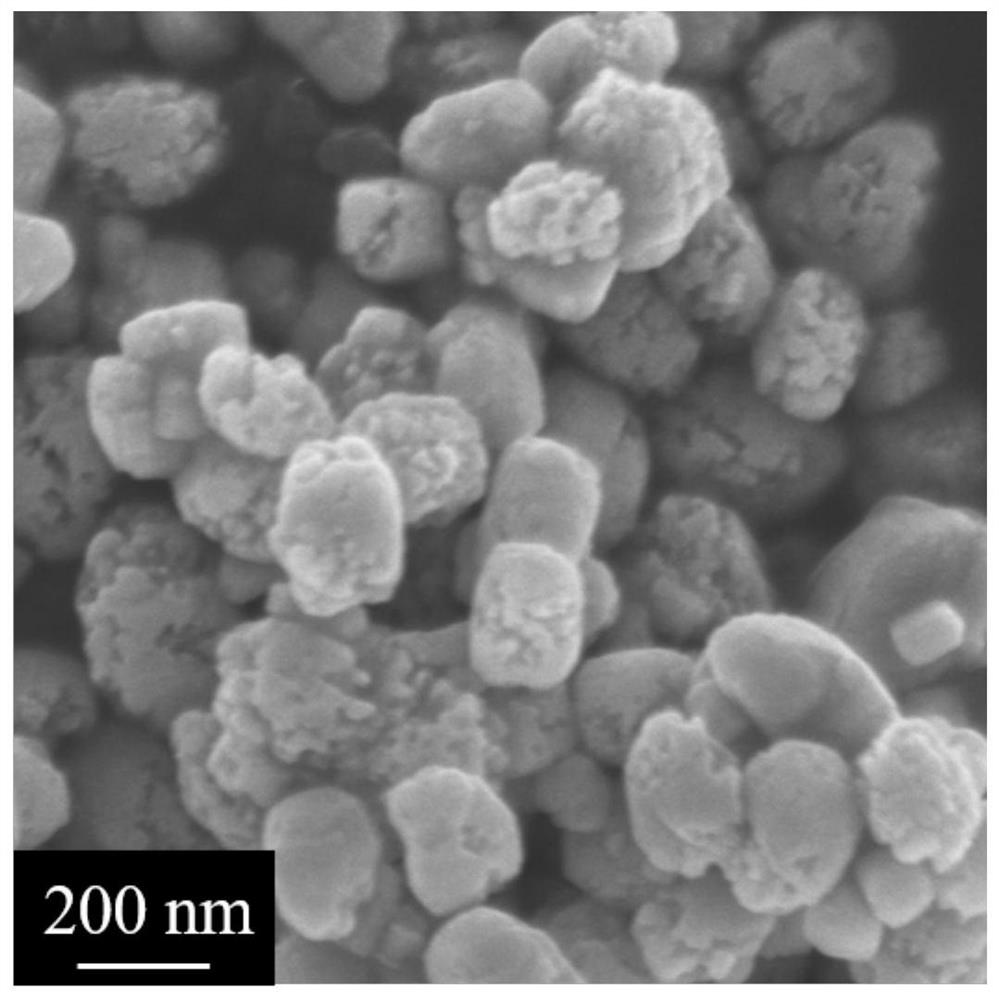

[0033] An electrocatalytic oxidation anode material that preferentially removes nonylphenol. The electrocatalytic oxidation anode material is an imprinted high-index crystal surface tin dioxide electrode, which is prepared by the following method: first prepare 4-(9-aminononyl)- The phenol template molecule is modified on the surface of silica through condensation reaction to form the inner core, and then the high-index crystal facet tin dioxide crystal is grown on the inner core surface for many times to obtain the molecular imprinted material precursor, which is removed from the inner core and fixed on the On the substrate electrode, the MI-SnO 2,HIF electrode.

[0034] MI-SnO 2,HIF The electrode is specifically prepared by the following method:

[0035] (a) In an inert gas atmosphere, add palladium (II), triphenylphosphine and triethanolamine to the reactor to obtain a mixed solution, add 4-bromophenol and 9-bromo-1-nonene to the mixed solution , after the reaction, a re...

Embodiment 2

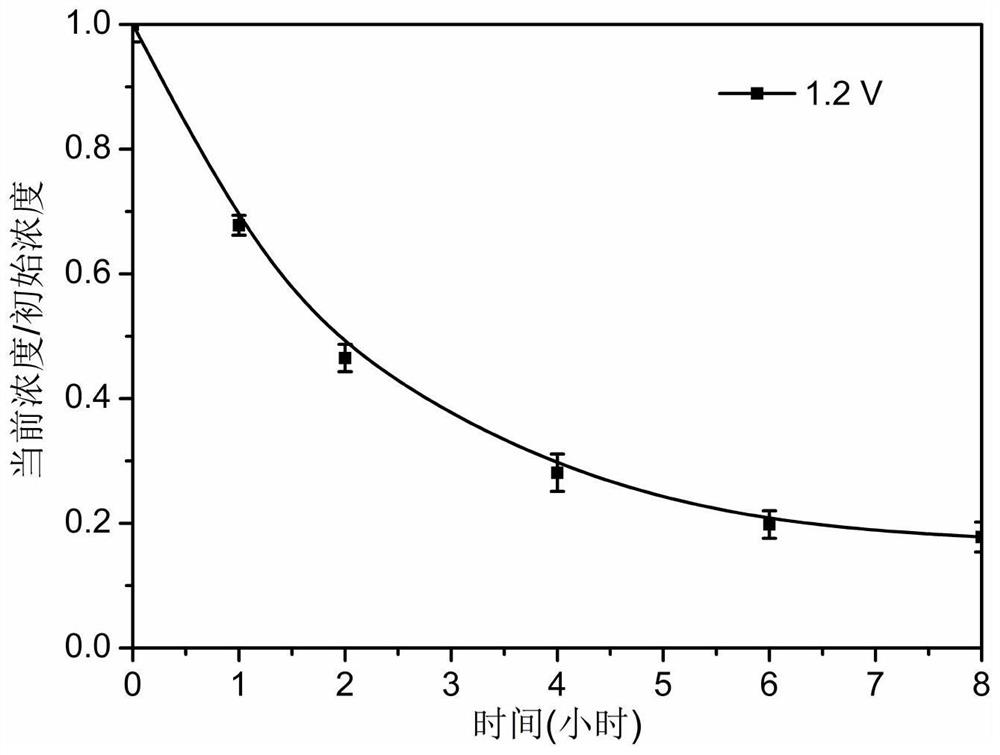

[0040] A treatment method for an electrocatalytic oxidation anode material that preferentially removes nonylphenol, the treatment method is specifically: the NP solution to be degraded (with a concentration of 4.5 μmol L -1 NP solution containing 0.1mol L -1 Na 2 SO 4 solution) is placed in a circular degradation cell with a single-layer quartz surface light transmission, and the MI-SnO prepared in Example 1 is taken 2,HIF The electrode is used as a working anode (the effective area of the electrode is 4.5cm 2 ), the platinum sheet is the counter electrode, and the saturated calomel electrode is the reference electrode to form a three-electrode system. A bias voltage of 1.2V is applied to the three-electrode system, and the degradation solution volume is 100mL. The temperature of the reaction system was maintained at 25° C. using a super constant temperature water bath. Take the concentration at this time as the initial concentration C of NP 0 . The sampling interval w...

Embodiment 3

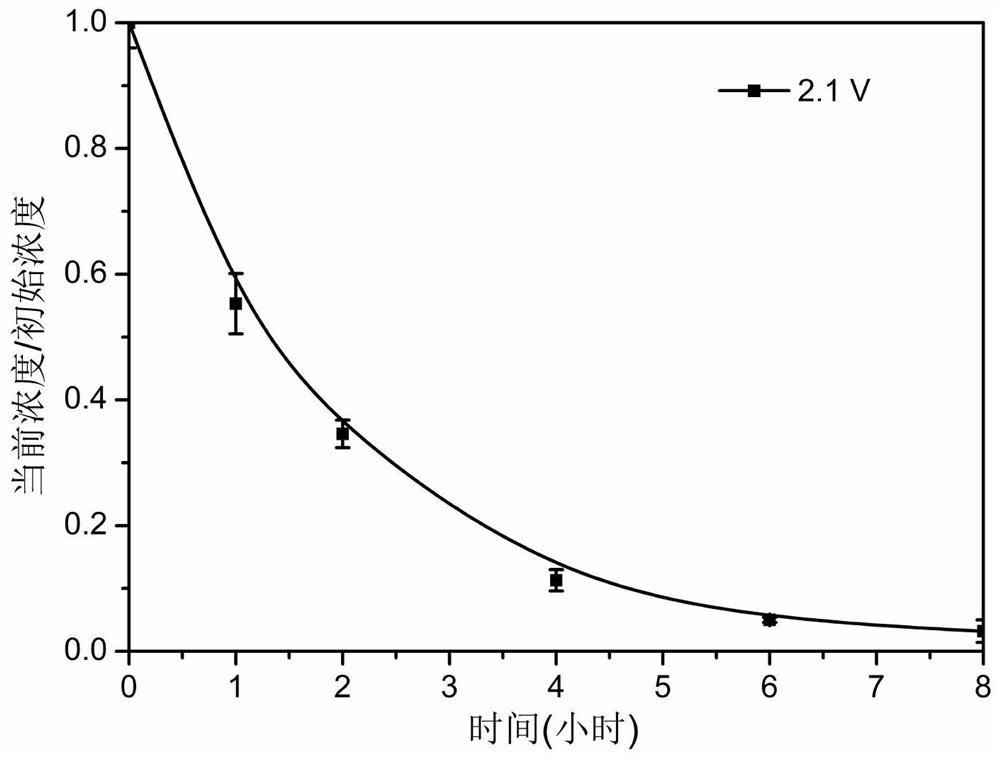

[0042] A treatment method for an electrocatalytic oxidation anode material that preferentially removes nonylphenol, the treatment method is specifically: the NP solution to be degraded (concentration is 8 μmol L -1 NP solution containing 0.8mol L -1 Na 2 SO 4 solution) is placed in a circular degradation cell with a single-layer quartz surface light transmission, and the MI-SnO prepared in Example 1 is taken 2,HIF The electrode is used as a working anode (the effective area of the electrode is 6cm 2 ), stainless steel is the counter electrode, forming a two-electrode system, the tank voltage of the two-electrode system is 5V, and the degradation solution volume is 100mL. The temperature of the reaction system was maintained at 25° C. using a super constant temperature water bath. Take the concentration at this time as the initial concentration C of NP 0 . The sampling interval was 30min, and the samples were filtered through a 0.22μm aqueous needle filter membrane. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com