High-vacuum vacuum pump oil

A high-vacuum pump and vacuum technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of limited improvement in anti-oxidation performance, affect the vacuum performance of vacuum oil, and cannot meet the needs of high-vacuum pump oil, and achieve extreme pressure and anti-wear performance The effect of high and excellent antioxidant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

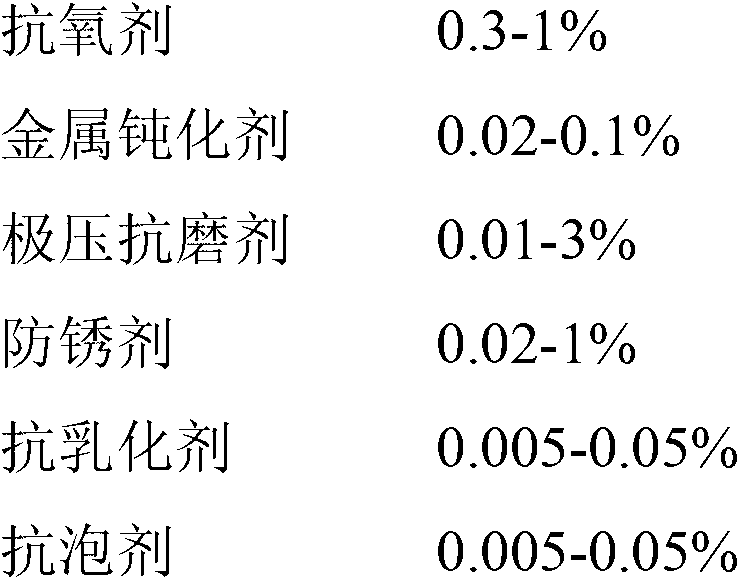

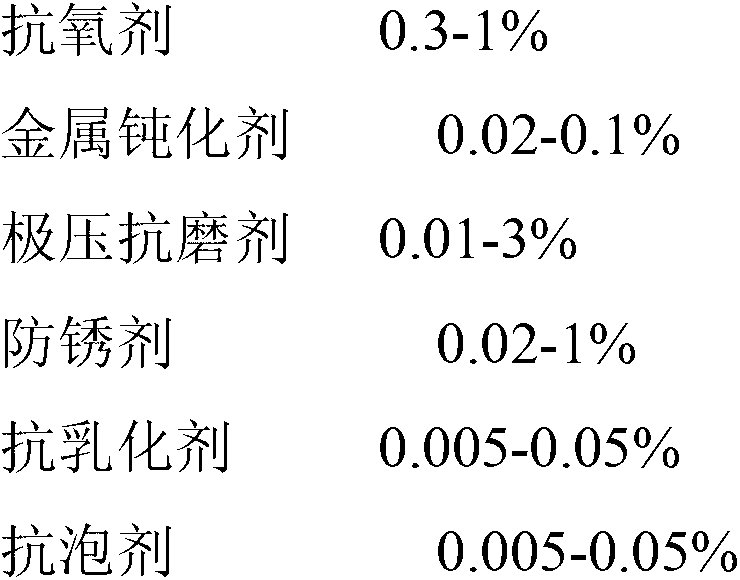

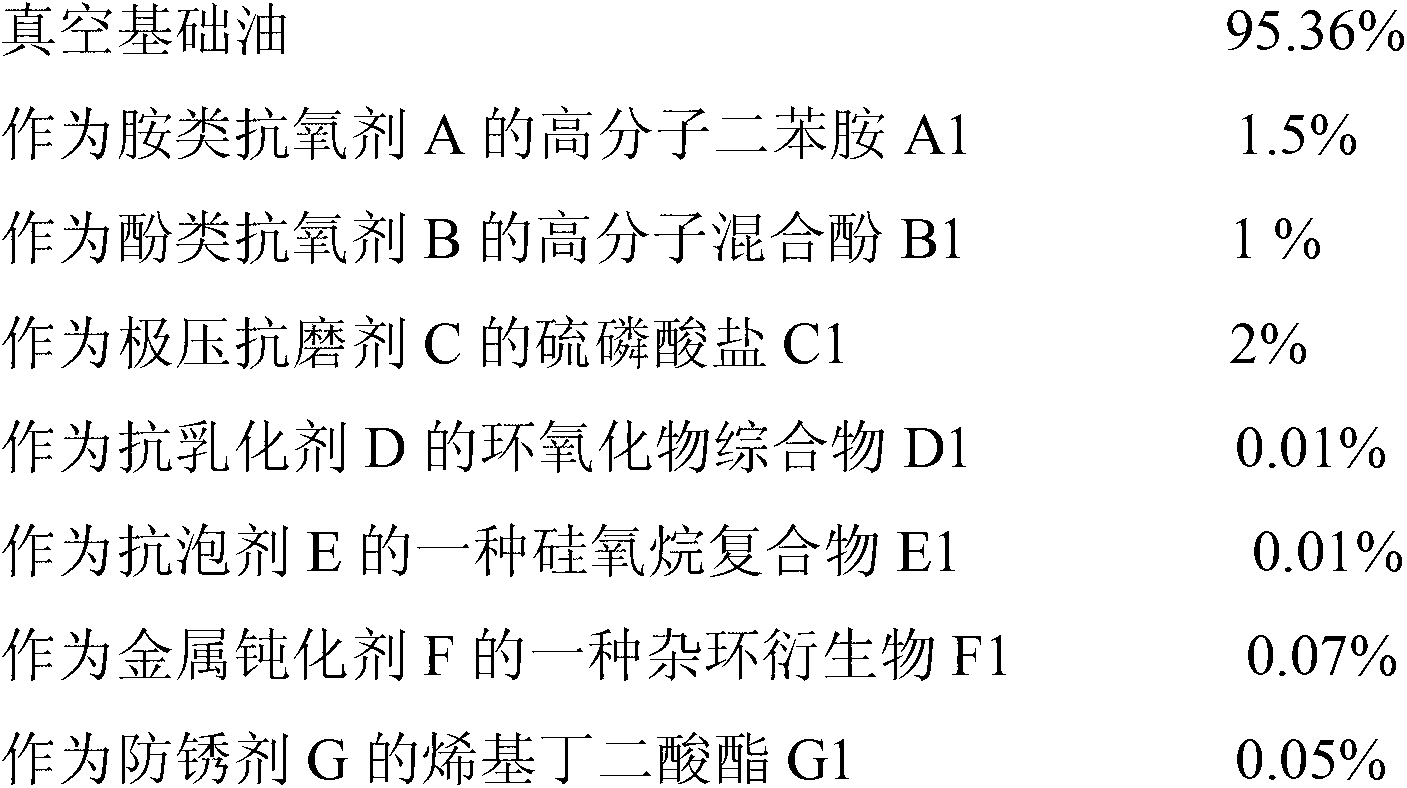

[0034] The mass percentage content of vacuum base oil and each additive in this high vacuum pump oil is as follows:

[0035]

[0036] The preparation process of the high vacuum pump oil can be as follows: in the blending kettle, add vacuum base oil, antioxidant, extreme pressure antiwear agent, metal passivator, antirust agent, reduce pressure, stir for 60min, and keep the temperature at 60°C. After dissolving, add antifoaming agent, antiemulsifying agent, etc., and after stirring, high vacuum pump oil is obtained (refer to Table 1).

[0037] The high vacuum pump oil has a high ultimate vacuum (1×10 -4 kPa), excellent anti-oxidation performance and extrusion anti-wear performance, is a high temperature resistant ashless high vacuum pump oil, especially suitable for more severe application conditions such as high temperature, high pressure or high load working conditions. The high vacuum pump oil can still maintain a good vacuum state under high temperature, high pressure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com