Lubricating grease for hub bearing of heavy load truck and preparation method thereof

A technology for automobile wheels and lubricating grease, which is applied in lubricating compositions, petroleum industry, thickeners, etc., can solve the problems of complex production process of polyurea-based lubricating grease, poor colloidal stability, and high production investment cost, and achieve improvement Colloidal stability and mechanical stability, the effect of improving the efficiency of saponification reaction and shortening the production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

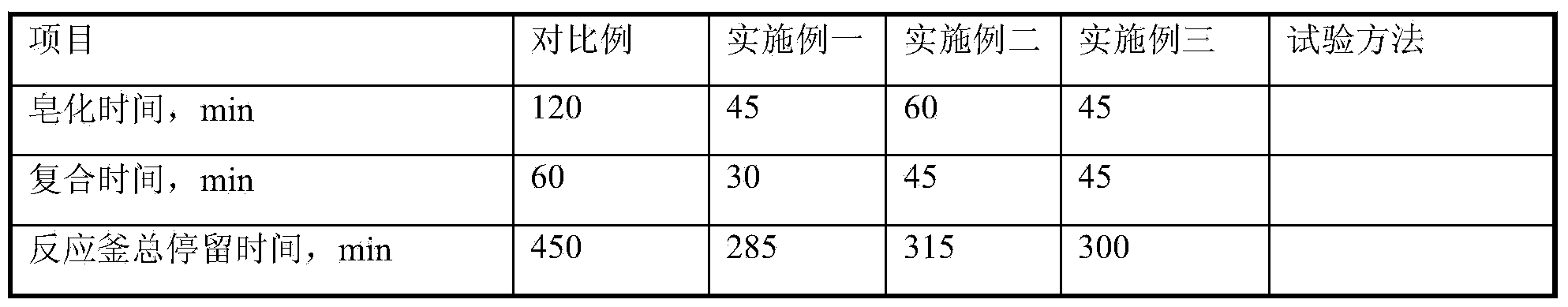

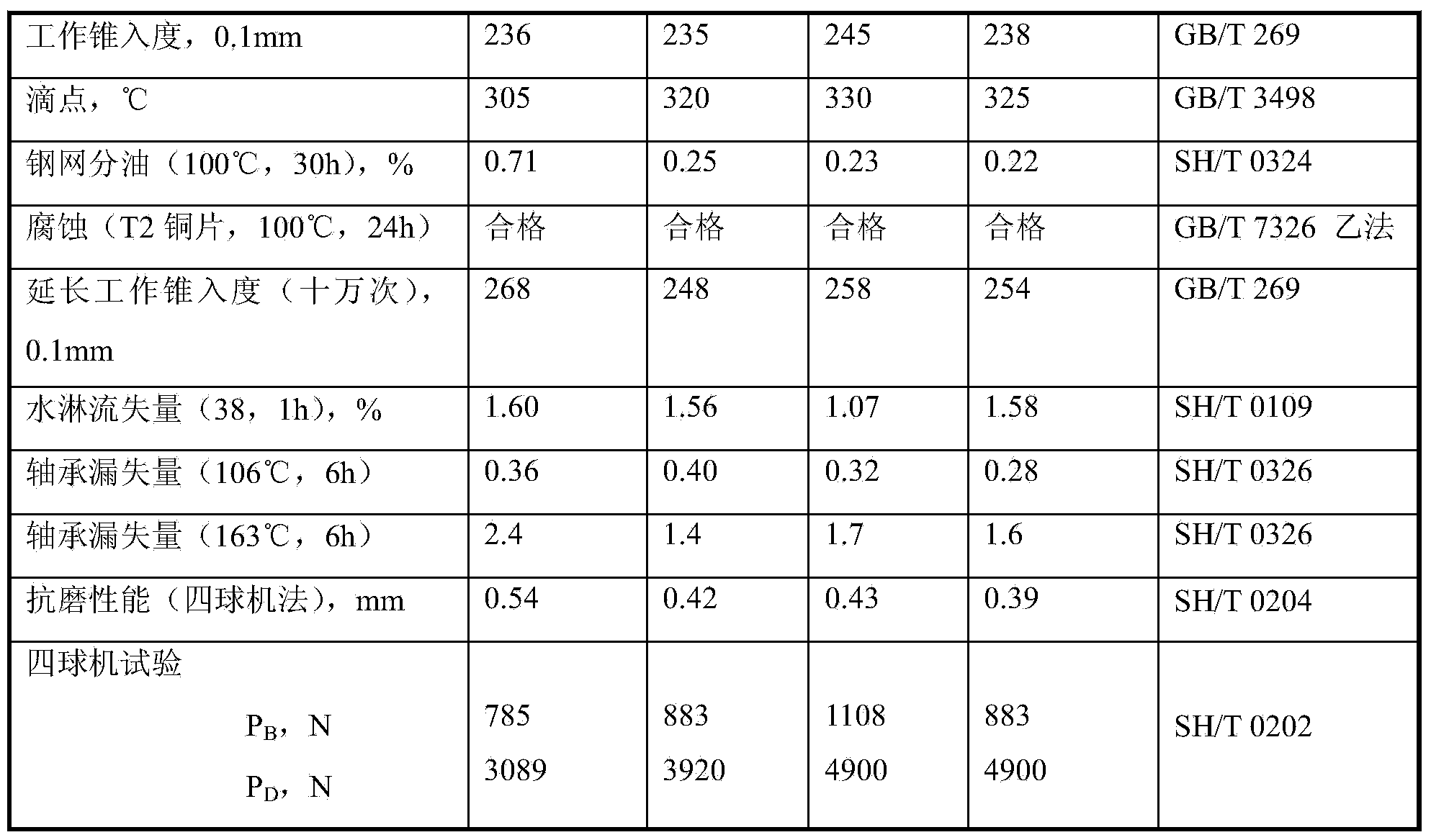

Embodiment 1

[0027] Take mineral base oil 150BS1800kg and 400SN1300kg and mix it as the test base oil. Take 1000kg of mixed base oil and 48.8kg of sebacic acid into the saponification reaction kettle, stir and heat up to 134°C, after the sebacic acid is completely dissolved, add 415.3kg of 12-hydroxystearic acid to completely dissolve, then add 1000kg of The above-mentioned mixed base oil lowers the temperature in the kettle to 85°C, then adds 167kg of lithium hydroxide oil solution, and after saponification reaction for 45 minutes, the temperature is rapidly raised to 110°C, and 30kg of boric acid dissolved in 3 times of water is added, and the compound reaction is stirred at constant temperature for 30 Minutes, finally raise the temperature to 225°C, keep the temperature for 3 minutes, then transfer to the blending kettle, add 1100kg of mixed base oil to cool down, homogenize at 115°C, 22MPa pressure for 2h, wait until the temperature in the blending kettle drops to 95°C, add octane Base...

Embodiment 2

[0029] Take mineral base oil 150BS1500kg and 500SN1200kg and mix it as the test base oil. Take 1000kg of mixed base oil and 112kg of sebacic acid and add them to the saponification reactor, stir and heat up to 136°C, after the sebacic acid is completely dissolved, add 330kg of 12-hydroxystearic acid to completely dissolve, then add 1200kg of the above mixed For a good base oil, lower the temperature in the kettle to 80°C, then add 188kg of lithium hydroxide oil solution, and quickly heat up to 115°C after 60 minutes of saponification, add 34kg of boric acid dissolved in 4 times the water, and stir at a constant temperature for 45 minutes. Finally, heat up to 220°C, keep the temperature for 5 minutes, then transfer to the blending kettle, add 800kg of mixed base oil to cool down, homogenize at 120°C, 25MPa pressure for 1.5h, wait until the temperature in the blending kettle drops to 90°C, add octyl in turn / Butyl diphenylamine 10kg, 2,6-di-tert-butyl-p-cresol 10kg, dinonylnapht...

Embodiment 3

[0031]Take mineral base oil 150BS2000kg and PAO101000kg and mix it as the test base oil. Take 1000kg of mixed base oil and 102kg of sebacic acid into the saponification reactor, stir and heat up to 135°C, after the sebacic acid is completely dissolved, add 300kg of 12-hydroxystearic acid to completely dissolve, then add 1000kg of the above mixed For a good base oil, lower the temperature in the kettle to 90°C, then add 172kg of lithium hydroxide oil solution, and quickly heat up to 120°C after saponification reaction for 60 minutes, add 30.4kg of boric acid dissolved in 4 times of water, and stir for 45 minutes at a constant temperature. , and finally raise the temperature to 230°C, keep the temperature for 3 minutes, then transfer to the blending kettle, add 1000kg of mixed base oil to cool down, homogenize at 115°C, 20MPa pressure for 2h, wait until the temperature in the blending kettle drops to 100°C, add octyl in turn / Butyl diphenylamine 12kg, dinonyl naphthalene barium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com