Lubricating grease composition for heavy-loading roller press bearing and preparation method thereof

A grease composition, a technology of a loaded roller press, applied in the directions of lubricating compositions, petroleum industry, etc., can solve the problems of increasing production difficulty and cost, numerous raw materials, complicated processes, etc., and achieve excellent extreme pressure and wear resistance, product The effect of stable performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Add 90 parts of lauryl hydroxystearic acid and 26.5 parts of sebacic acid to 640 parts of 150BS base oil (Jiangsu Yinglong Petrochemical Co., Ltd., the same below), stir, heat up to 80°C, and then add 12.2 parts of lithium hydroxide (Lithium hydroxide is diluted with deionized water in advance, the quality of deionized water is 13.42 parts, and the quality of deionized water is not included in the total mass of lithium-calcium complex grease) and 4 parts of calcium hydroxide (calcium hydroxide is used in advance Dilute with deionized water, the quality of deionized water is 4.4 parts, and the quality of deionized water is not included in the total mass of lithium-calcium complex grease), continue to stir and heat up to 110°C, dehydrate for 30 minutes, heat up to 210°C, add 227.3 parts 150BS base oil, cooled, homogenized and degassed to obtain complex lithium-calcium grease.

[0046] Add 100 parts of the above-mentioned lithium-calcium complex grease to the pre-cleaned n...

Embodiment 2

[0052] Add 100 parts of complex lithium-calcium-based grease (same as Example 1) into the pre-cleaned normal pressure reactor, heat up and stir, mix well, add 13 parts of ethylene-propylene polymer T612, 1.5 parts of potassium triborate neutral Oil dispersion Octopol PTB, 1.5 parts zinc diamyl dithiocarbamate Vanlube AZ, 2 parts vulcanized olefin cottonseed oil T405 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd.), 0.5 parts butyl / octyl diphenylamine Vanlube961, 13 parts Colloidal graphite 00#, mixed and stirred, then heated to 70°C, stirred at constant temperature for 2 hours, cooled out of the kettle, homogeneously ground and packaged to obtain bearing grease composition IV for heavy-duty roller presses.

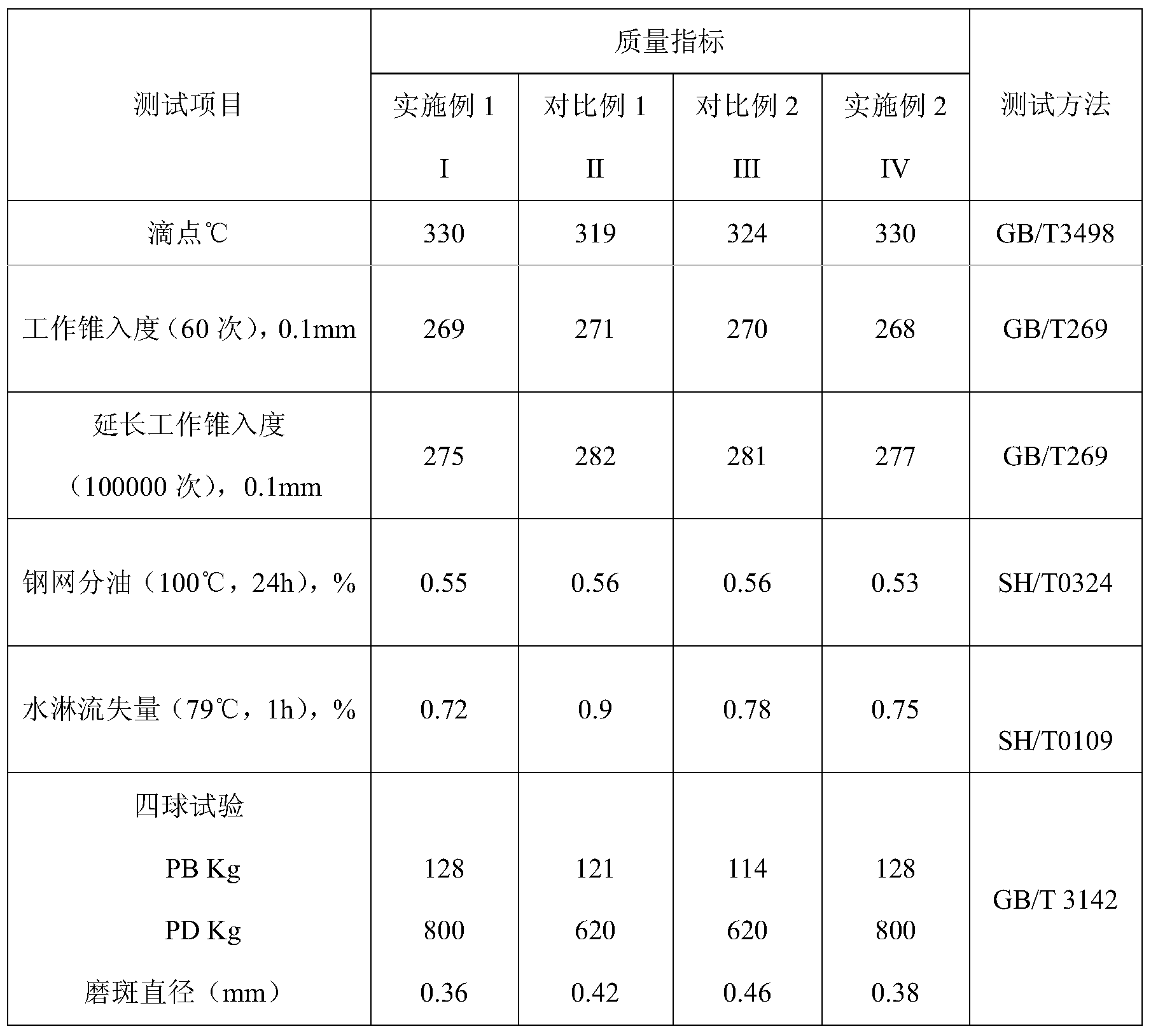

[0053] Table 1 shows the performance test data of the above grease compositions I, II, III and IV.

[0054] Table 1 heavy-duty rolling machine bearing grease composition I, II, III and IV performance test data

[0055]

[0056] As can be seen from Table 1, grease c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com