Oil-air lubricating grease and production method thereof

A production method and grease technology, applied in the field of grease, can solve problems such as environmental pollution, non-biodegradability, unsatisfactory use temperature range, etc., and achieve good biodegradation performance, great economic and social benefits, and good biodegradation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

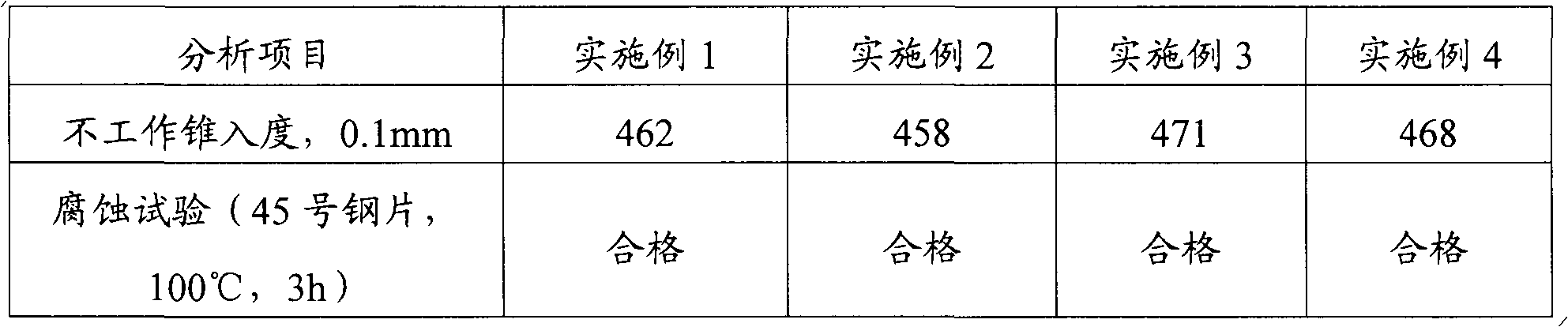

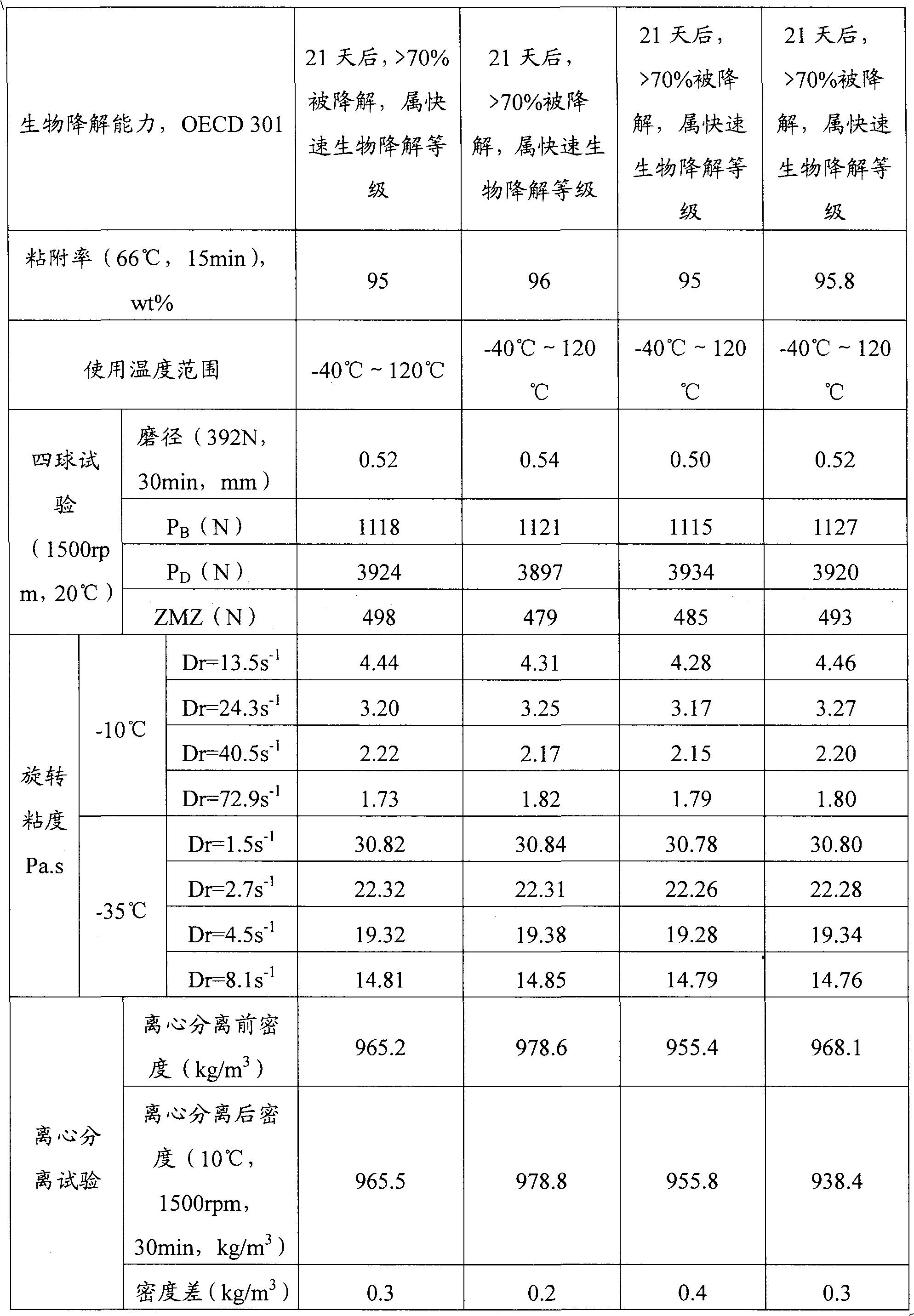

Embodiment 1

[0055] Step a) put 86% trimethylolpropane oleate and 6% bentonite into the kettle and mix them without heating and stirring for 20 minutes;

[0056] Step b) adding 2% ethanol by weight and stirring for 60 minutes without heating;

[0057] Step c) heating and stirring the mixture obtained above, raising the temperature to 160° C. for 60 minutes at a constant temperature, then adding 0.3% by weight of diphenylamine, 0.7% of benzotriazole and 3% of colloidal graphite, and stirring for 10 minutes;

[0058] Step d) cooling the mixture obtained in step c) to 50° C., adding 2% by weight of zinc dialkyldithiophosphate, and then stirring for 10 min;

[0059] Step e) Homogenizing the mixture obtained in step d) in a colloid mill for 60 min, with a gap of 40 mm, taking samples during the cycle to measure the consistency of the mixture, and finally the non-working penetration of the mixture is 462;

[0060] Step f) Under 15MPa, the oil-gas lubricating grease obtained after homogenization...

Embodiment 2

[0062] Step a) Put 87% by weight trimethylolpropane oleate and 4% silica gel into the kettle and mix them without heating and stirring for 18 minutes;

[0063] Step b) adding 2% acetic acid by weight, and stirring for 55 minutes without heating;

[0064] Step c) heat up and stir the mixture obtained above, raise the temperature to 162° C. and keep the temperature for 55 minutes, then add 0.5% by weight of diisooctyldiphenylamine, 0.5% of barium dinonylnaphthalenesulfonate and 5% of aluminum powder, Stir for 12 minutes;

[0065] Step d) cooling the mixture obtained in step c) to 60° C., adding 1% by weight tricresyl phosphate, and then stirring for 10 min;

[0066] Step e) Homogenizing the mixture obtained in step d) in a colloid mill for 65 minutes, with a gap of 45 mm, taking samples during the cycle to measure the consistency of the mixture, and finally the non-working penetration of the mixture is 458;

[0067] Step f) Under 20MPa, the homogenized oil-gas lubricating grea...

Embodiment 3

[0069] Step a) put 90% trimethylolpropane oleate and 2% graphite into the kettle and mix them without heating and stirring for 16 minutes;

[0070] Step b) adding 3% glycerin by weight, and stirring for 65 minutes without heating;

[0071] Step c) heat up and stir the mixture obtained above, raise the temperature to 155° C. and keep the temperature for 65 minutes, then add 0.2% by weight of phenyl-α-naphthylamine, 0.8% of benzotriazole and 1% of colloidal graphite, and stir 15min;

[0072] Step d) cooling the mixture obtained in step c) to 50° C., adding molybdenum dialkyldithiocarbamate at a weight percentage of 3%, and then stirring for 10 min;

[0073] Step e) Homogenize the mixture obtained in step d) in a colloid mill for 60 min, with a gap of 35 mm, take a sample during the cycle to measure the consistency of the mixture, and finally the non-working penetration of the mixture is 471;

[0074] Step f) Under 18MPa, the homogenized oil-gas lubricating grease is discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com