Cold heading oil composition and application thereof

A composition and technology of cold heading oil, applied in lubricating compositions, petroleum industry, etc., can solve the problem of whether the extreme pressure and anti-wear performance and copper corrosion resistance of cold heading oil can meet the requirements of use at the same time, transmission gear shaft corrosion, workpiece surface Problems such as pulling hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

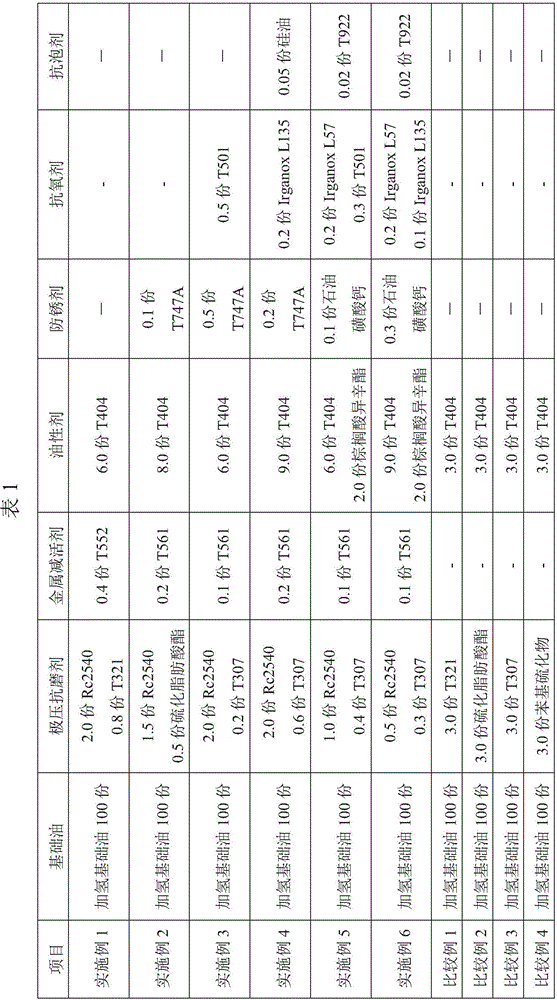

[0031] According to the parts by weight in Table 1, weigh the required amount of metal deactivator, antioxidant, oily agent, rust inhibitor, detergent dispersant and antifoaming agent into the base oil (68 viscosity grade). Heat and stir at 70°C until it is completely uniform, then lower the temperature to 60°C, add an extreme pressure anti-wear agent, and stir until it is completely uniform to obtain the cold heading oil composition for cold heading and lubrication. The types and amounts of each component in the composition are shown in Table 1.

[0032] Among them, Rc2540 is sulfurized olefin; T321 is sulfurized isobutylene; T307 is phosphorothioate double ester amine salt; T404 is sulfurized cottonseed oil; T501 is 2,6-di-tert-butyl-p-cresol; Irganox L135 is mixed shielding component; Irganox L57 is alkylated diphenylamine; T552 is benzenetriazole, aldehyde and amine condensate; T561 is 2,5-dimercapto-1,3,4-thiadiazole derivative; T747A is alkenyl succinic acid half ester ; T...

Embodiment 7

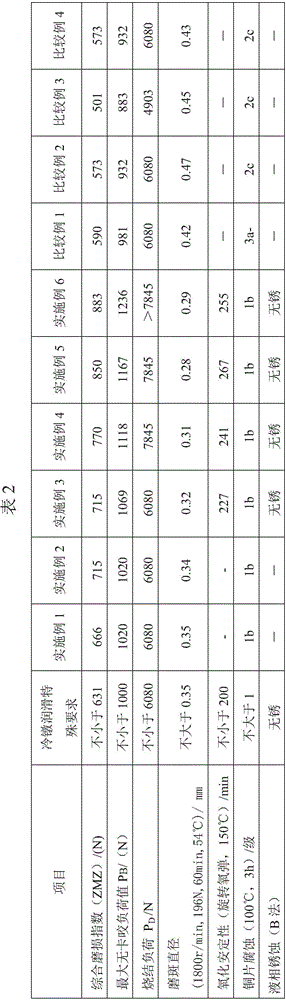

[0034] The extreme pressure and anti-wear properties (comprehensive wear index, maximum seizure-free coincidence, sintering load, wear scar diameter), corrosion resistance (corrosion of copper flakes), and oxidation stability of the composition in [Examples 1 to 6] Rotating oxygen bomb value) and rust resistance (liquid phase corrosion B method) were tested. The test results are shown in Table 2.

Embodiment 6

[0035] Extreme pressure and wear resistance is one of the most important properties of cold heading oil. The various compositions in [Examples 1 to 6] were tested for indicators such as comprehensive wear index, maximum seizure-free coincidence, sintering load, and wear scar diameter. The larger the comprehensive wear index, maximum seizure-free coincidence, sintering load, wear scar diameter, etc., the better the extreme pressure and wear resistance performance of cold heading oil; the smaller the wear scar diameter, the lower the extreme pressure and wear resistance performance of the oil. The better. [Examples 1 to 6] In the extreme pressure and anti-wear properties of each composition, the comprehensive wear index is greater than 631N, the sintering load is not less than 6080N, the wear scar diameter is not greater than 0.35mm, and in [Examples 4 to 6] The maximum non-jamming load value of each composition is not less than 1100N, indicating that each composition can simult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com