Special lubrication oil for heavy-load LNG (liquefied natural gas) engine

A technology for liquefied natural gas and engine, which is used in lubricating compositions, petroleum industry, etc., can solve the problems of poor engine adaptability to temperature changes, excessive drop in viscosity at high temperature, etc., and achieves the effect of satisfying low temperature performance, reducing dosage and reducing sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

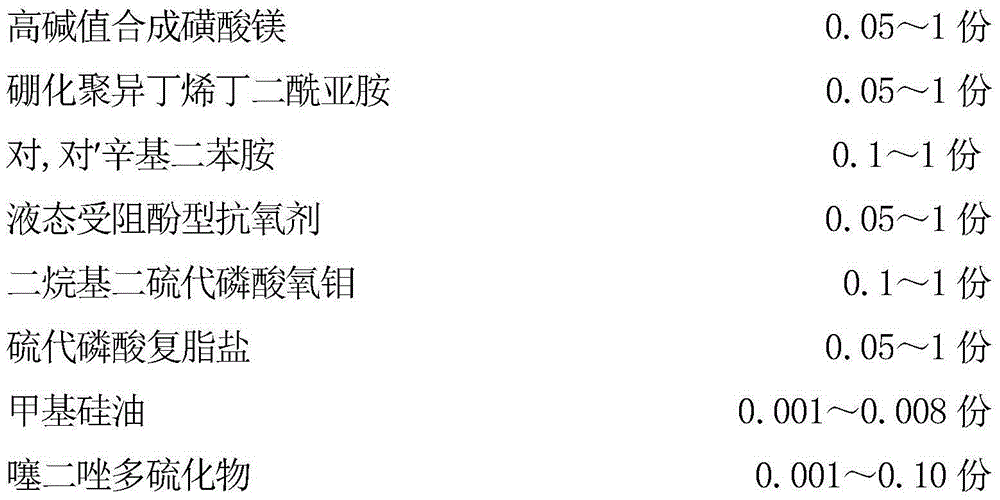

[0021] Taking the deployment of 10W / 40 synthetic LNG engine lubricating oil as an example, the raw materials used and their quality composition are as follows:

[0022]

Embodiment 2

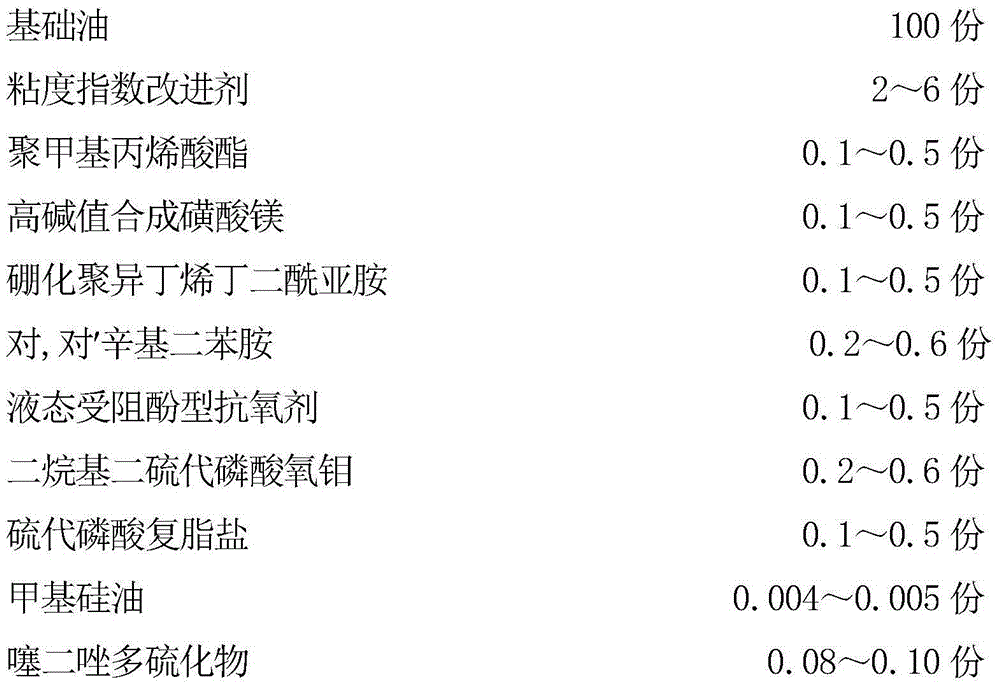

[0028] Taking the deployment of 10W / 40LNG engine lubricating oil as an example, the raw materials used and their quality composition are as follows:

[0029]

Embodiment 3

[0031] Taking the deployment of 10W / 40LNG engine lubricating oil as an example, the raw materials used and their quality composition are as follows:

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com