Worm wheel worm rod lubricating oil composition and preparation method thereof

A lubricating oil composition and worm gear technology, applied in the field of lubricating oil, can solve the problems of poor extreme pressure wear resistance, short oil change interval, increased operating cost, etc., and achieve good anti-foaming, excellent corrosion resistance and rust resistance, The effect of good oil-water separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a preparation method of the worm gear lubricating oil composition described in the above technical solution, comprising the following steps:

[0042] Under vacuum conditions, polyalphaolefin, oil-soluble polyether, antioxidant, metal passivator, corrosion inhibitor, extreme pressure antiwear agent and antifoaming agent are mixed to obtain a worm gear lubricating oil composition.

[0043] In the present invention, the types and sources of the polyα-olefins, oil-soluble polyethers, antioxidants, metal passivators, corrosion inhibitors, extreme pressure antiwear agents and antifoaming agents are the same as those described in the above technical solutions. The types and sources of alpha-olefins, oil-soluble polyethers, antioxidants, metal passivators, corrosion inhibitors, extreme pressure antiwear agents and antifoaming agents are the same, and will not be repeated here.

[0044] Under the condition of vacuum, the present invention preferabl...

Embodiment 1

[0051] 55g PAO40, 37g OSP220, 1.5g 2,4-dimethyl-6-tert-butylphenol, 1.5g N-phenyl-α-naphthylamine, 0.5g N,N'-dialkylaminomethylene Benzenetriazole, 2.0g tricresyl phosphate, 0.5g dodecenylsuccinic acid, 2.0g barium dinonylnaphthalene sulfonate and 0.0001g 5000# methyl silicone oil at 130°C and vacuum degree of 350Pa at 60r / min stirring rate for 2.5h to obtain a worm gear and worm lubricating oil composition.

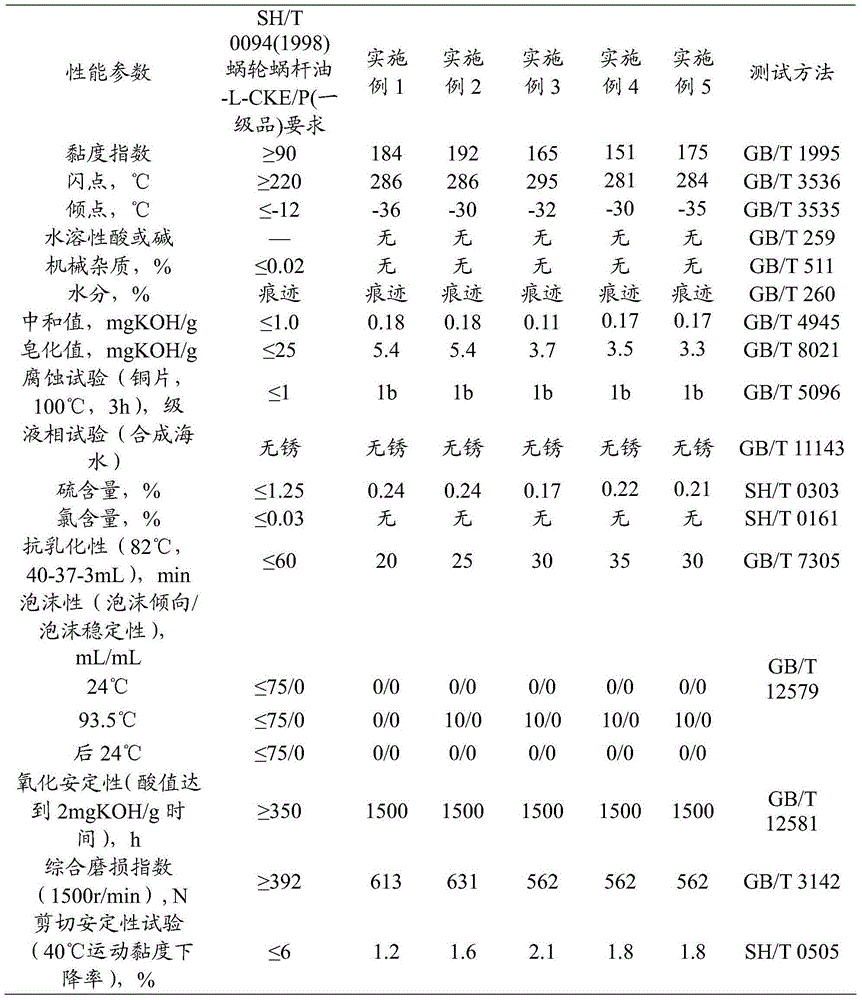

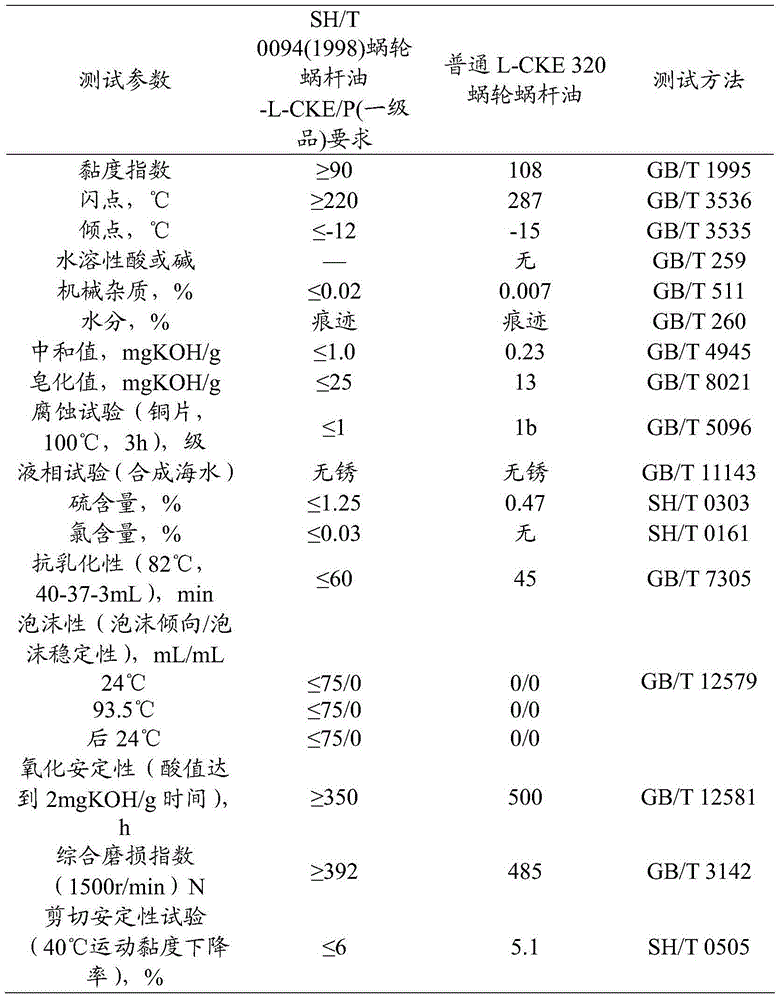

[0052] The present invention tests the performance of the obtained worm gear lubricating oil composition according to the test method described in the above technical solution, and the test results are shown in Table 1. Table 1 shows the worm gear and worm lubricating oil compositions obtained in Examples 1 to 5 of the present invention. performance test results.

Embodiment 2

[0054] 45g PAO20, 47g OSP680, 1.5g 2,4-dimethyl-6-tert-butylphenol, 1.5g diisooctyldiphenylamine, 0.5g N,N'-dialkylaminomethylenebenzenetriazole , 2.0g tricresyl phosphate, 0.5g dodecenyl succinic acid, 2.0g barium dinonylnaphthalene sulfonate and 0.001g 5000# methyl silicone oil at 100°C and vacuum degree of 250Pa at 80r / min The speed was stirred for 1.5h to obtain a worm gear and worm lubricating oil composition.

[0055] The present invention tests the performance of the obtained worm gear lubricating oil composition according to the test method described in the above technical solution, and the test results are shown in Table 1. Table 1 shows the worm gear and worm lubricating oil compositions obtained in Examples 1 to 5 of the present invention. performance test results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com