Catalytic low-energy-consumption waste gas treatment equipment

A treatment equipment and catalytic technology, which is applied in the field of catalytic low-energy consumption treatment equipment for exhaust gas, can solve the problems of insufficient contact between catalyst and organic waste gas, insufficient exhaust gas treatment, failure to meet emission standards, etc., and achieve superior kinetic performance , Improve combustion treatment efficiency and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

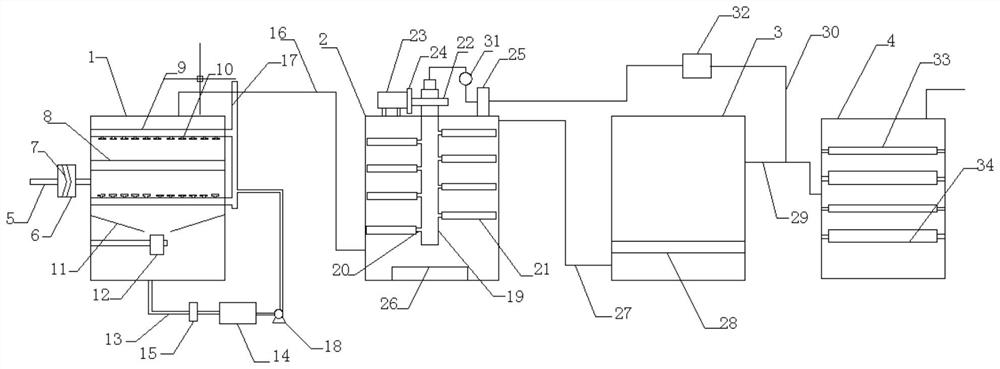

[0019] This embodiment provides a catalytic low-energy processing equipment for exhaust gas, the structure of which is as follows: figure 1 As shown, it includes a spray chamber 1, an adsorption chamber 2, a combustion chamber 3 and a photocatalytic chamber 4. The air inlet provided on one side of the spray chamber is connected with an exhaust gas intake pipe 5, and a filter device 6 is arranged on the exhaust gas intake pipe. The filter device comprises at least two layers of filter assembly 7 arranged vertically, the filter assembly is composed of two filter screens connected end to end, and the connection ends are at an angle of 30°, and the filter screen is a glass fiber filter screen with a grid-like structure, At least one group of spraying devices and packing layer 8 are arranged in the spraying chamber, and each group of spraying devices is composed of two upper and lower spraying assemblies opposite to the spraying direction. It consists of several spray heads 10 abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com