Sludge treatment apparatus for water conservancy project

A technology for sludge treatment and water conservancy engineering, which is applied in the field of sludge treatment devices for hydraulic engineering, and can solve the problem of heavy metal elements re-entering underground water bodies and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

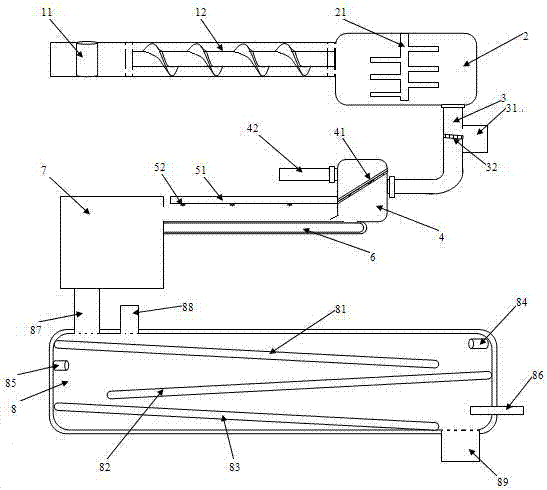

[0035] Such as figure 1 Shown:

[0036] A sludge treatment device for water conservancy projects, comprising a conveying device, a stirring chamber, a conveying pipeline part, a sludge filtering chamber, a mud mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber.

[0037] The conveying device includes a mud inlet, a dredge pump arranged at the mud inlet, and a crushing and conveying shaft arranged at the rear end of the dredge pump. The crushing and conveying shaft is in the form of a single helical knife arranged on a rotating shaft. The sludge delivered by the pump is broken up and conveyed to the inlet of the mixing chamber.

[0038] The inside of the stirring chamber is provided with a vertically penetrating stirring shaft and high-pressure water nozzles arranged at the entrance of the stirring chamber and at both ends of the stirring shaft, and the outlet of the stirring chamber is arranged at the bottom of the stirring chamber.

[00...

Embodiment 2

[0058] A sludge treatment device for water conservancy projects, comprising a conveying device, a stirring chamber, a conveying pipeline part, a sludge filtering chamber, a mud mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber.

[0059] The conveying device includes a mud inlet, a dredge pump arranged at the mud inlet, and a crushing and conveying shaft arranged at the rear end of the dredge pump. The crushing and conveying shaft is in the form of a single helical knife arranged on a rotating shaft. The sludge delivered by the pump is broken up and conveyed to the inlet of the mixing chamber.

[0060] The inside of the stirring chamber is provided with a vertically penetrating stirring shaft and high-pressure water nozzles arranged at the entrance of the stirring chamber and at both ends of the stirring shaft, and the outlet of the stirring chamber is arranged at the bottom of the stirring chamber.

[0061] The conveying pipe part include...

Embodiment 3

[0078] A sludge treatment device for water conservancy projects, comprising a conveying device, a stirring chamber, a conveying pipeline part, a sludge filtering chamber, a mud mixing and drying part, a mixing and granulating chamber and a ceramsite heating chamber.

[0079] The conveying device includes a mud inlet, a dredge pump arranged at the mud inlet, and a crushing and conveying shaft arranged at the rear end of the dredge pump. The crushing and conveying shaft is in the form of a single helical knife arranged on a rotating shaft. The sludge delivered by the pump is broken up and conveyed to the inlet of the mixing chamber.

[0080] The inside of the stirring chamber is provided with a vertically penetrating stirring shaft and high-pressure water nozzles arranged at the entrance of the stirring chamber and at both ends of the stirring shaft, and the outlet of the stirring chamber is arranged at the bottom of the stirring chamber.

[0081] The conveying pipe part include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com