Patents

Literature

78results about How to "Lower distillation temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

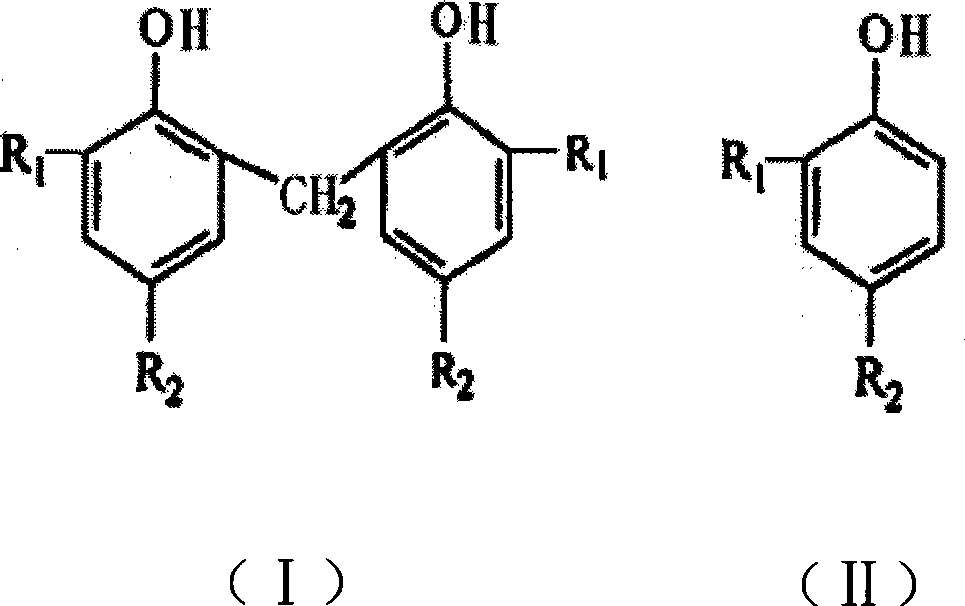

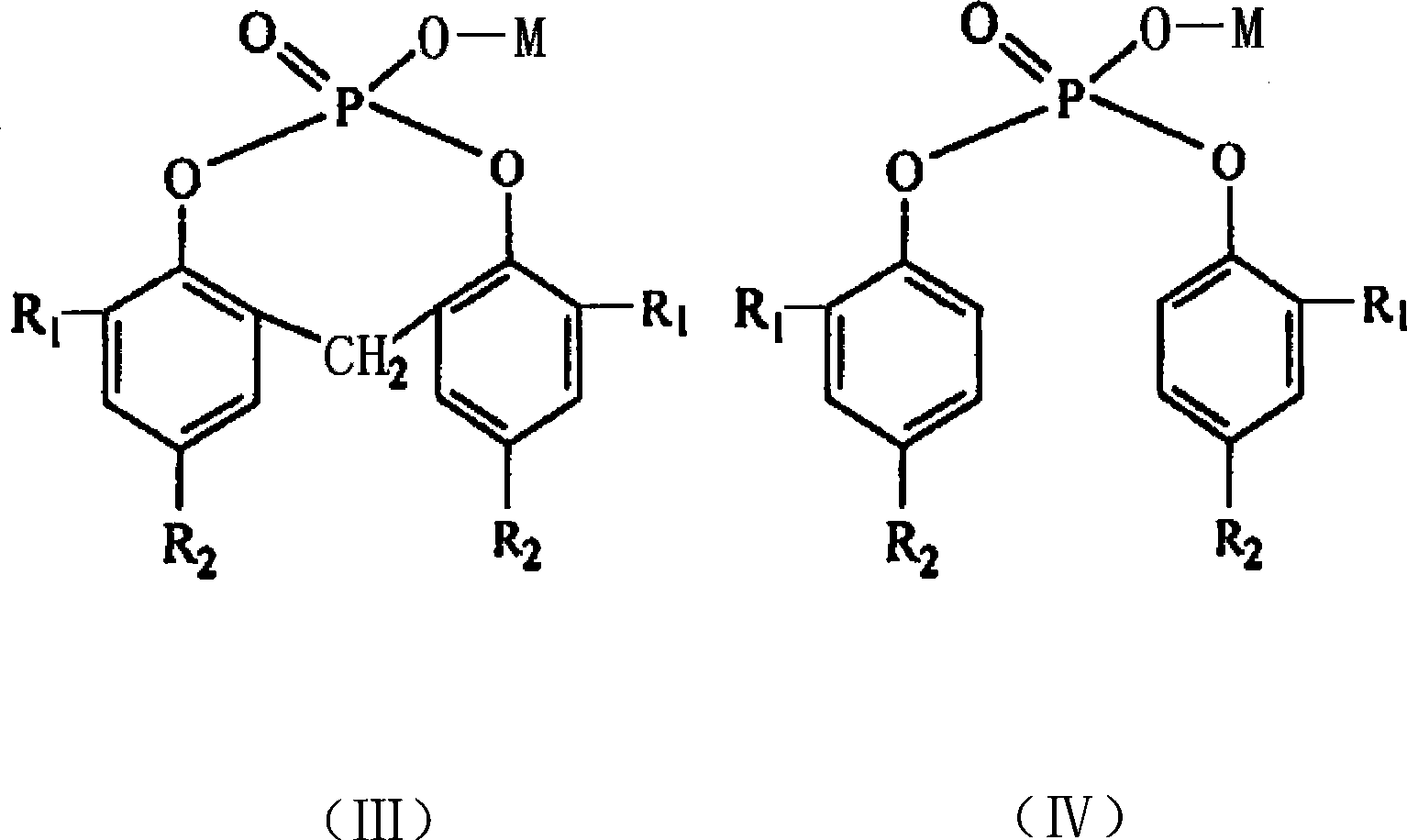

Preparation method for organic phosphate nucleating agent

The present invention relates to a method for preparing an organic compound, in particular to a method for preparing an organic phosphate nucleator, which includes the following steps: phosphorylation reaction, hydrolyzation and salification. Since the solvent for the phosphorylation reaction adopts halogenated hydrocarbon instead of benzene series compounds, which is cheap, the cost can be reduced, and since the yield of the organic phosphate synthesized with the halogenated hydrocarbon used as the solvent is higher, the yield of the final product, the organic phosphate, is greatly increased. Moreover, since the solvent does not adopt the benzene series compounds, toxicity is low, non-burning operation is safe, environment can be protected, recycling is convenient, and the diaryl-substituted organophosphate metal salt used as nucleator prepared by the method has obvious effect in the improvement of the processing property of resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

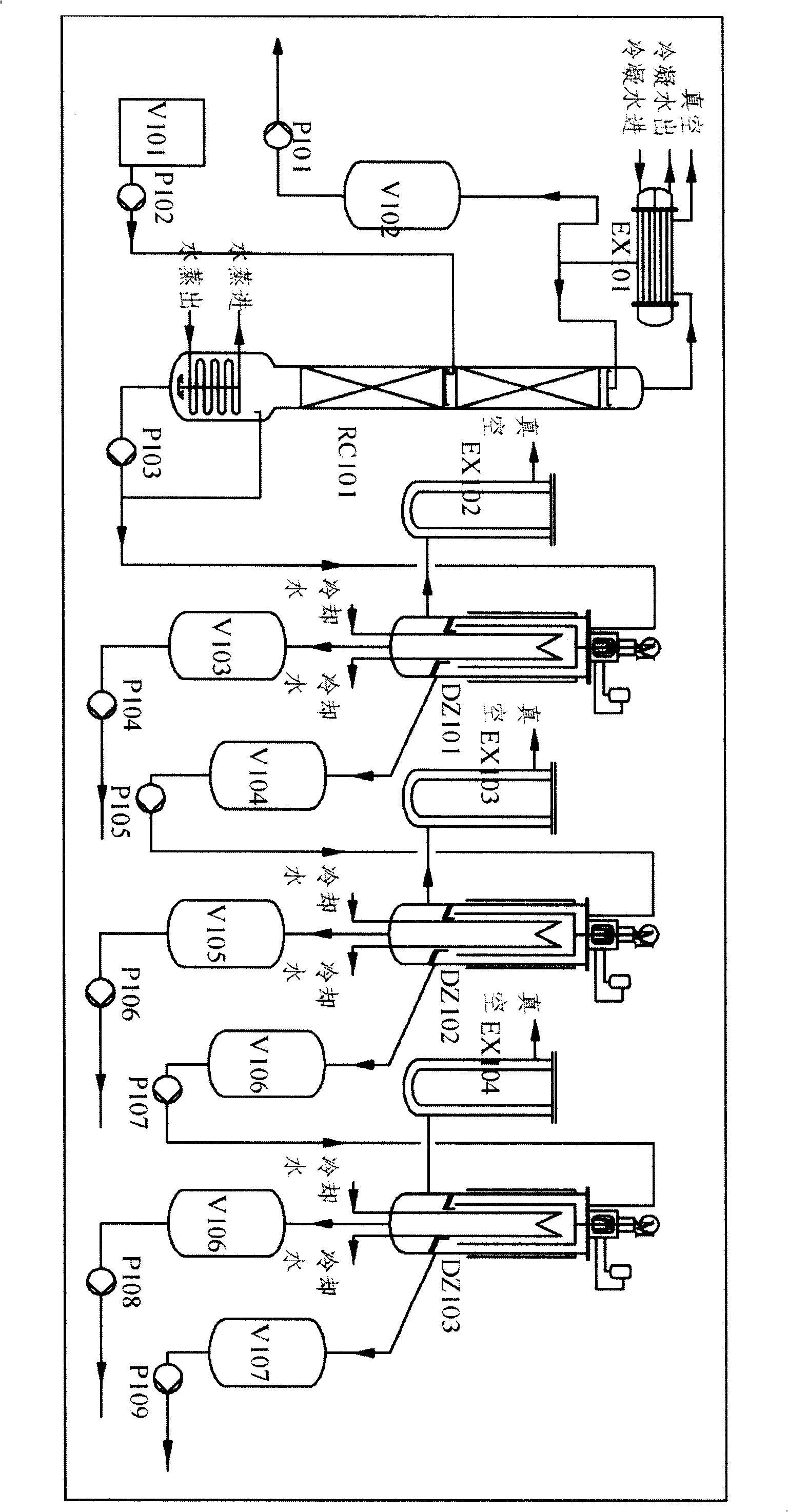

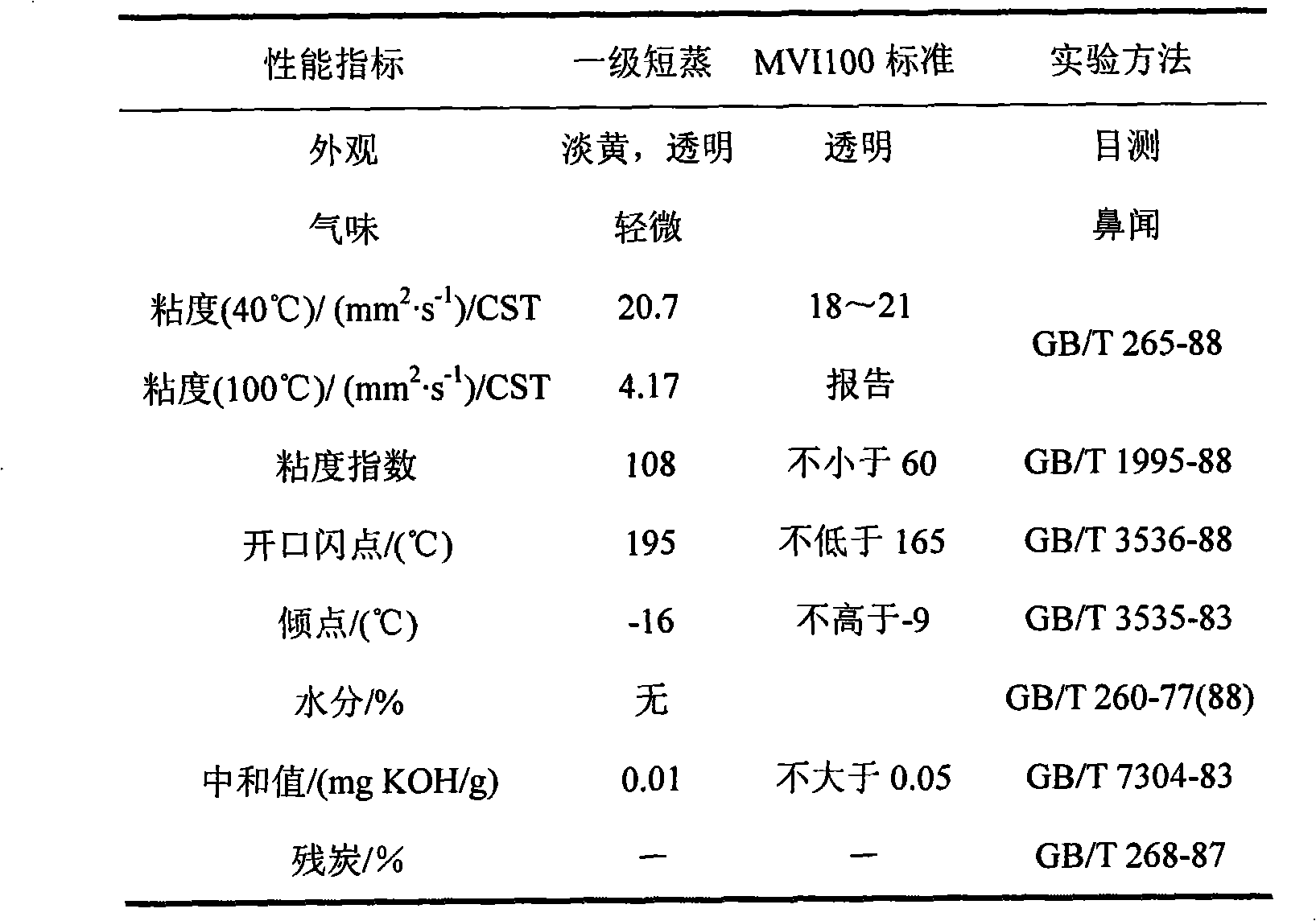

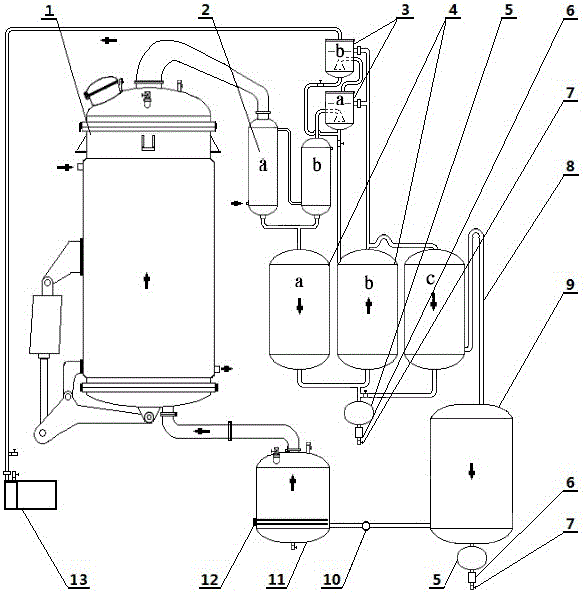

Application of distillation and multi-stage molecular distillation technique in regeneration process for waste lubricant oil

InactiveCN101319166ANot easy to stickShort stayHydrocarbon distillationLubricant compositionDistillationPre treatment

The invention discloses a novel process of regenerating base oil from waste lubricating oil. The process which applies an advanced molecular distillation technology to regenerate base oil from waste lubricating oil can not only regenerate better base oil, but also carry out effluent fraction through multilevel series connections. The waste lubricating oil is deprived of light diesel oil in a rectification tower through pretreatment and deprivation of light components, and then the waste lubricating oil is pumped into a first-level molecular still through a first-level feed pump to distill off a relatively lighter base oil component as a product. Heavier components which are left by the first-level distillation and serves as the raw material of a second-level molecular still are pumped into the second-level molecular still through a second-level feed pump to distill off a component heavier than the first-level molecular distillation product to serve as a product, and the distillation residuals are taken as the raw material of a third-level distillation. The process is repeated in the manner until a required n level is reached, wherein n is more than or equal to 2 and is less than or equal to 5, and the recommended optimal level number is 3 or 2. The process has the advantages that: the obtained product only contains the base oil component, while other impurities including additives are discharged in the form of residuals; the process also can produce a plurality of products with good quality and varied viscosities, thereby bringing about great convenience for the preparation of product lubricating oil.

Owner:尹英遂 +2

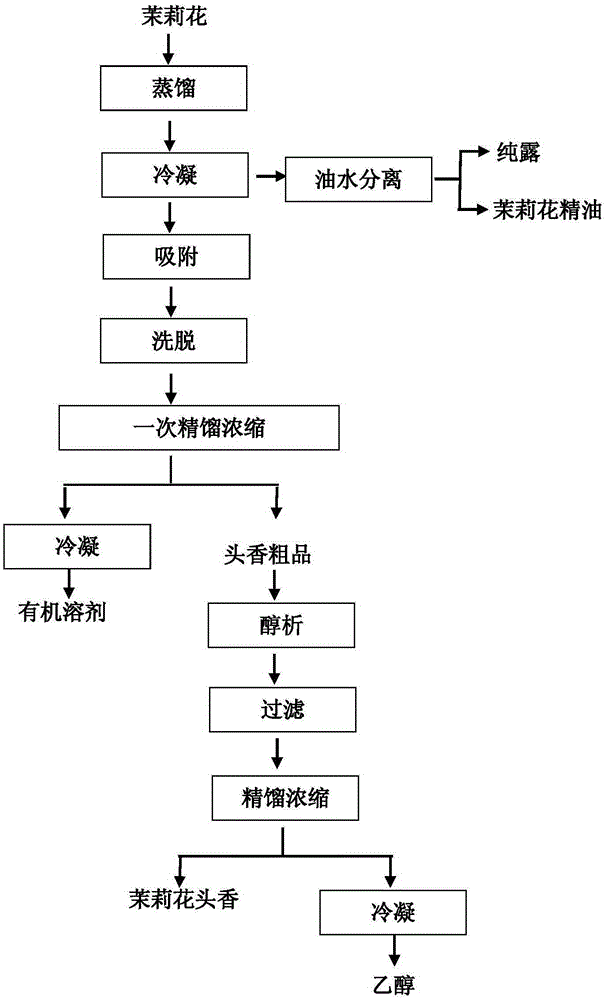

Method for extracting essential oil and headspace volatile of arabian jasmine flower

InactiveCN105296162AOvercome technical problemsLower distillation temperatureEssential-oils/perfumesOrganic chemistryHorticulture

The invention discloses a method for extracting essential oil and headspace volatile of arabian jasmine flowers. The method comprises the steps of distilling, condensing, oil water separating, adsorbing, primary rectifying concentrating, alcohol precipitating, secondary rectifying concentrating and the like. According to the method, in a vacuum state, vapor is adopted to distill the essential oil of the arabian jasmine flowers, distilling temperature is reduced, distilling time is shortened, the use rate of equipment is improved, the quality and yield of the essential oil of a product are improved, the production cost is reduced, and the technical problems of the existing traditional solvent method and supercritical carbon dioxide method are overcome. The headspace volatile of the arabian jasmine flowers is obtained by concentrating of a rectifying tower, and compared with the existing reduced pressure distillation, the method has the advantages that the loss of easy-to-volatile headspace volatile component is reduced, and the purity of the headspace volatile can be improved. By using the method in the invention to extract the essential oil and headspace volatile of the arabian jasmine flowers, the yields are respectively 0.23-0.28% and 5.5-6.0% and the yields of the respective components are obviously improved.

Owner:GUANGXI FORESTRY RES INST

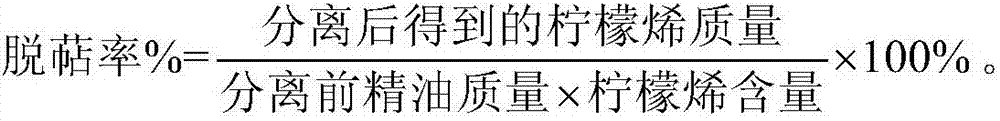

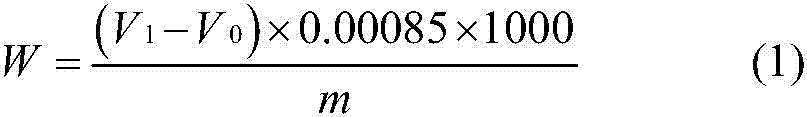

Extraction method of navel orange peel essential oil

InactiveCN106978257APromote dissolutionReduce extraction timeEssential-oils/perfumesPectinaseDistillation

The invention discloses an extraction method of navel orange peel essential oil. The extraction method comprises the following steps: (1) preparation of crude navel orange peel essential oil: crushing navel orange peels, mixing with water, carrying out enzymolysis by virtue of compound enzyme formed by pectinase and cellulase so as to obtain enzymolysis mixed liquid, carrying out enzyme deactivation on the enzymolysis mixed liquid, extracting essential oil by virtue of microwave-assisted supercritical CO2 fluid extracting instrument, injecting extracting liquid into a separator to separate CO2, and rectifying a separated product, so as to obtain the crude navel orange peel essential oil; and (2) terpene removal treatment of the crude navel orange peel essential oil: putting the crude navel orange peel essential oil obtained in the step (1) into a reaction kettle of a molecular distillation instrument, carrying out molecular distillation, and collecting a distillation residue, so as to obtain the navel orange peel essential oil. The extraction method of the navel orange peel essential oil has the advantages of rapidness, high efficiency, yield and essential oil content, stable quality and the like.

Owner:HEZHOU UNIV

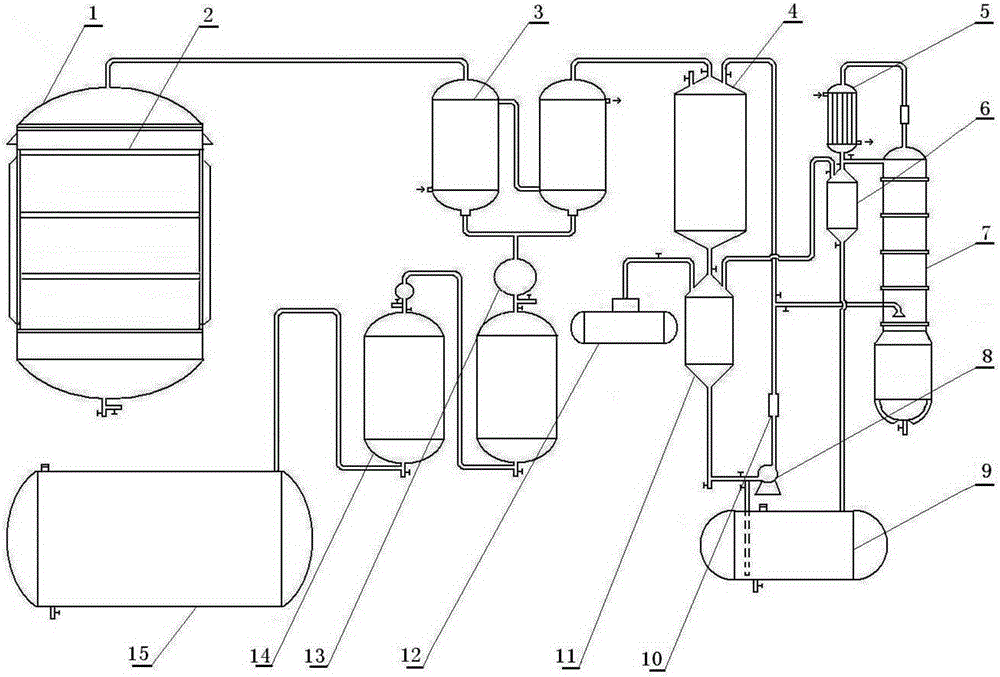

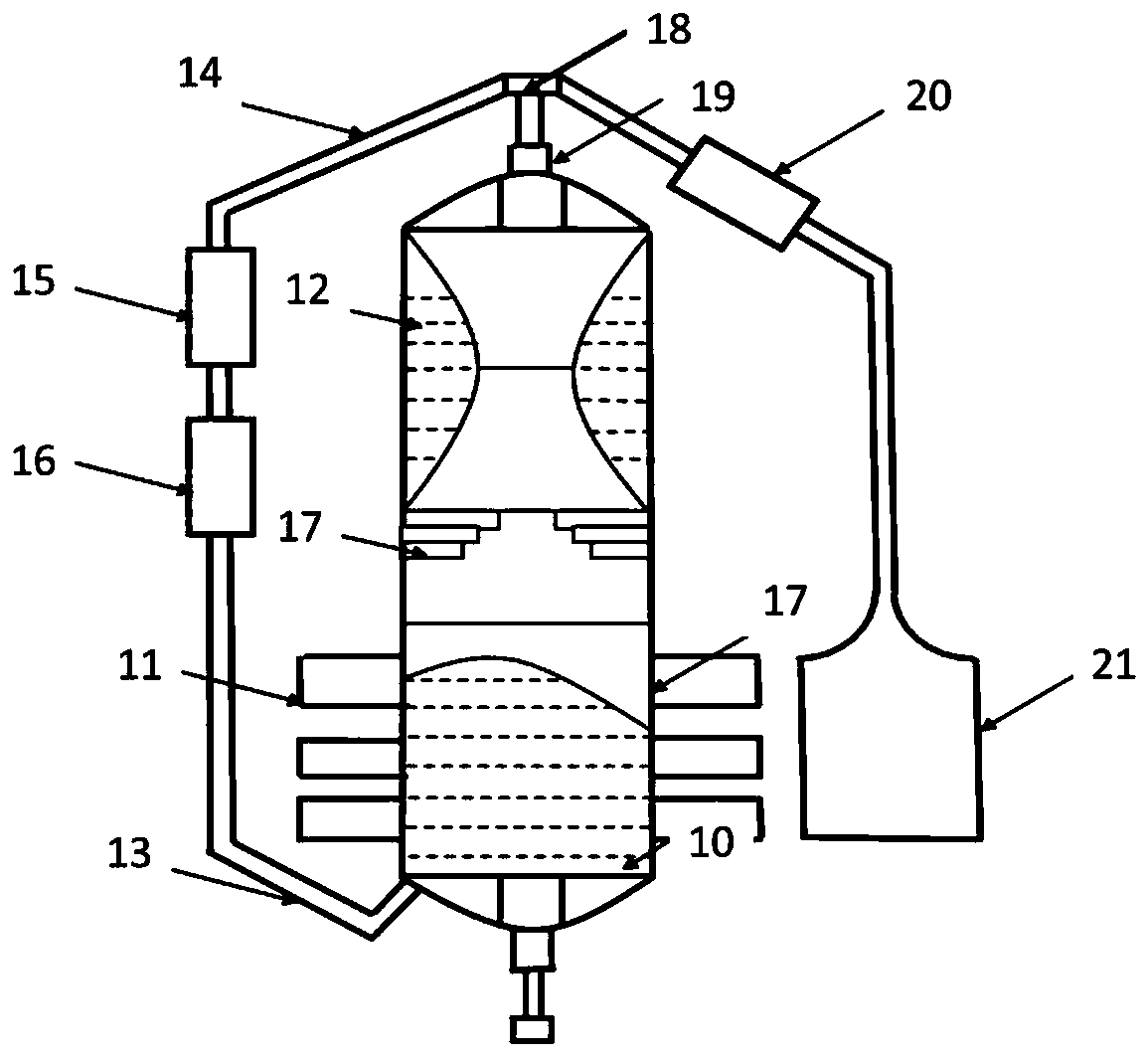

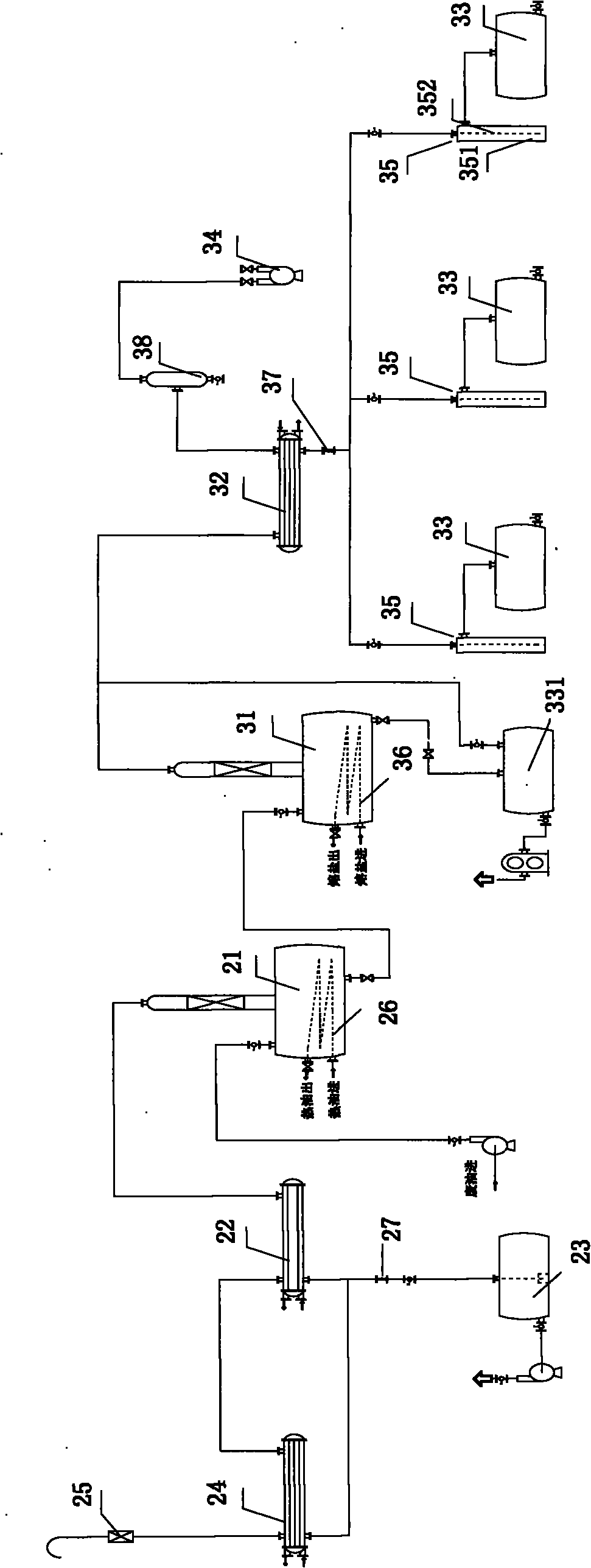

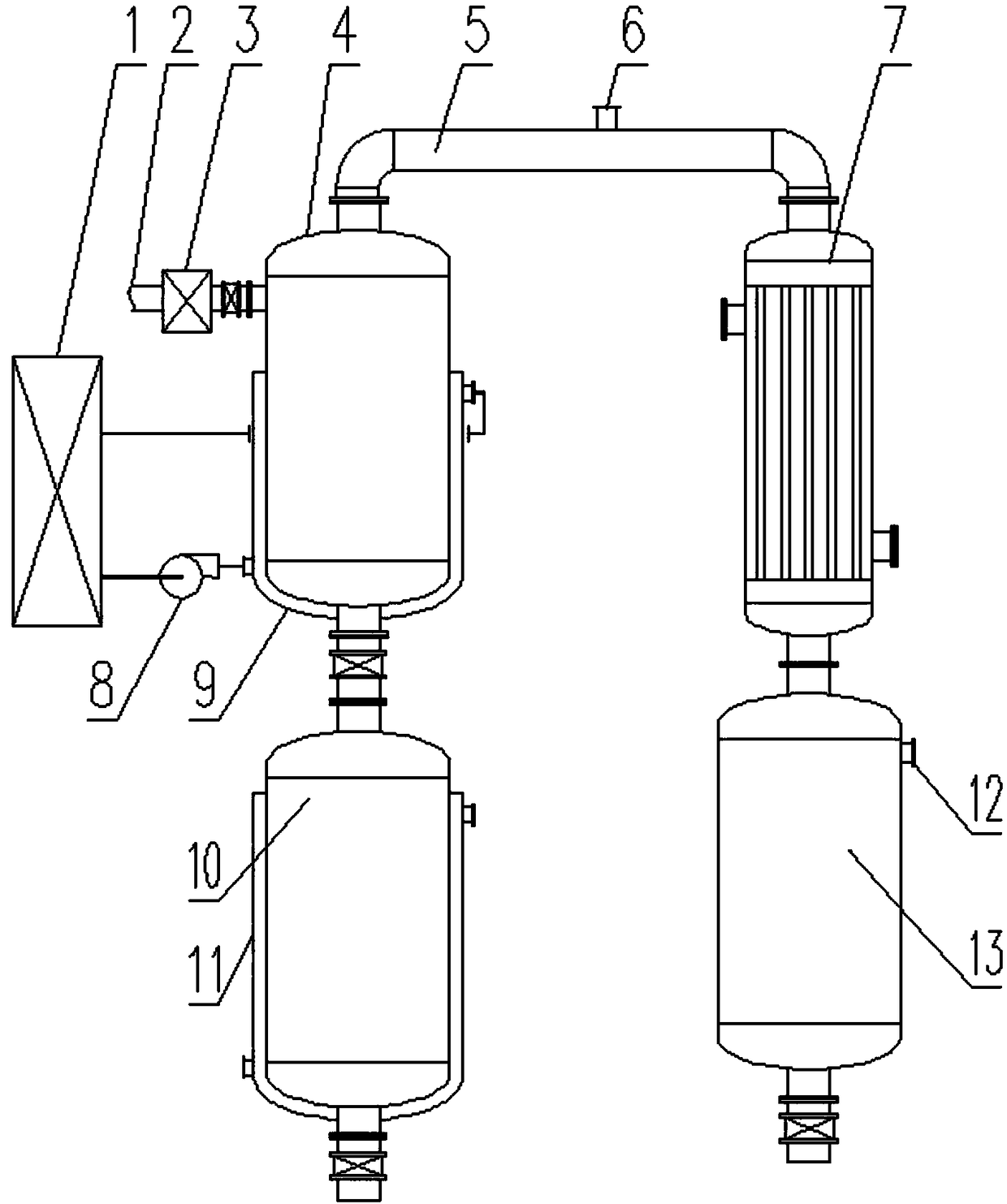

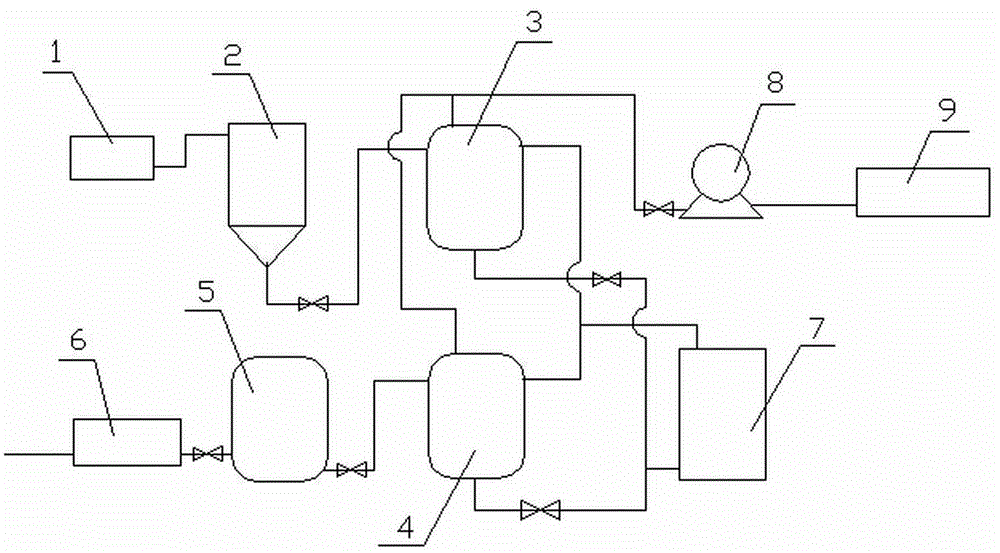

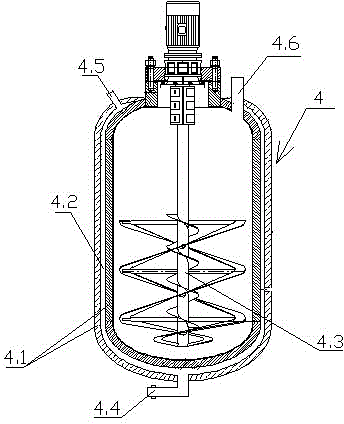

Extraction equipment for fragrant plant essential oil and headspace volatile

InactiveCN105296163AEasy to recycleTechnical Difficulties in Overcoming LossEssential-oils/perfumesAlembicOrganosolv

The invention discloses extraction equipment for fragrant plant essential oil and headspace volatile. The extraction equipment comprises an alembic, a condenser I, an oil-water separator, an adsorber, a liquid pump and a rectifying tower, wherein a material steaming basket is arranged inside the alembic; the condenser I is connected with the alembic; the oil-water separator is connected with a liquid delivery pipe at the bottom of the condenser I; the adsorber is connected with the top of the condenser I; the bottom of the adsorber is connected with a headspace volatile elution gathering tank; the top of the headspace volatile elution gathering tank is connected with a vacuum system and the top of an organic solvent gathering tank; a feed port of the liquid pump is connected with a discharge port of the headspace volatile elution gathering tank through a valve; a discharge port of the liquid pump is connected with a feed port of the rectifying tower and the top of the adsorber by valves. The extraction equipment disclosed by the invention not only can well recycle the headspace volatile, but also has the advantages of high oil extraction rate, low energy dissipation, simple operation, low equipment cost and the like, the extraction equipment can easily realize industrialized production, has very good social and economical benefit.

Owner:GUANGXI FORESTRY RES INST

Processing method of high acid value greasy

InactiveCN100999695AQuality improvementLower distillation temperatureFatty-oils/fats refiningOil processingOil and grease

The present invention relates to high acid number oil processing method. Enzyme or acid chemical catalyst is added into the mixture of high acid number oil and lower alcohol, and through selective esterification reaction, the oil has the free fatty acid content lowered to below 1-5 wt%. Most of the residual free fatty acid is converted into soap for separating out to obtain soap-eliminating oil; and the soap-eliminating oil is further processed through drying, decolorizing and deodorizing to form refined oil. The present invention raises the product oil quality and value, and has high application value to refining bran oil, corn oil, cotton seed oil and other high acid number oil.

Owner:SOUTH CHINA UNIV OF TECH

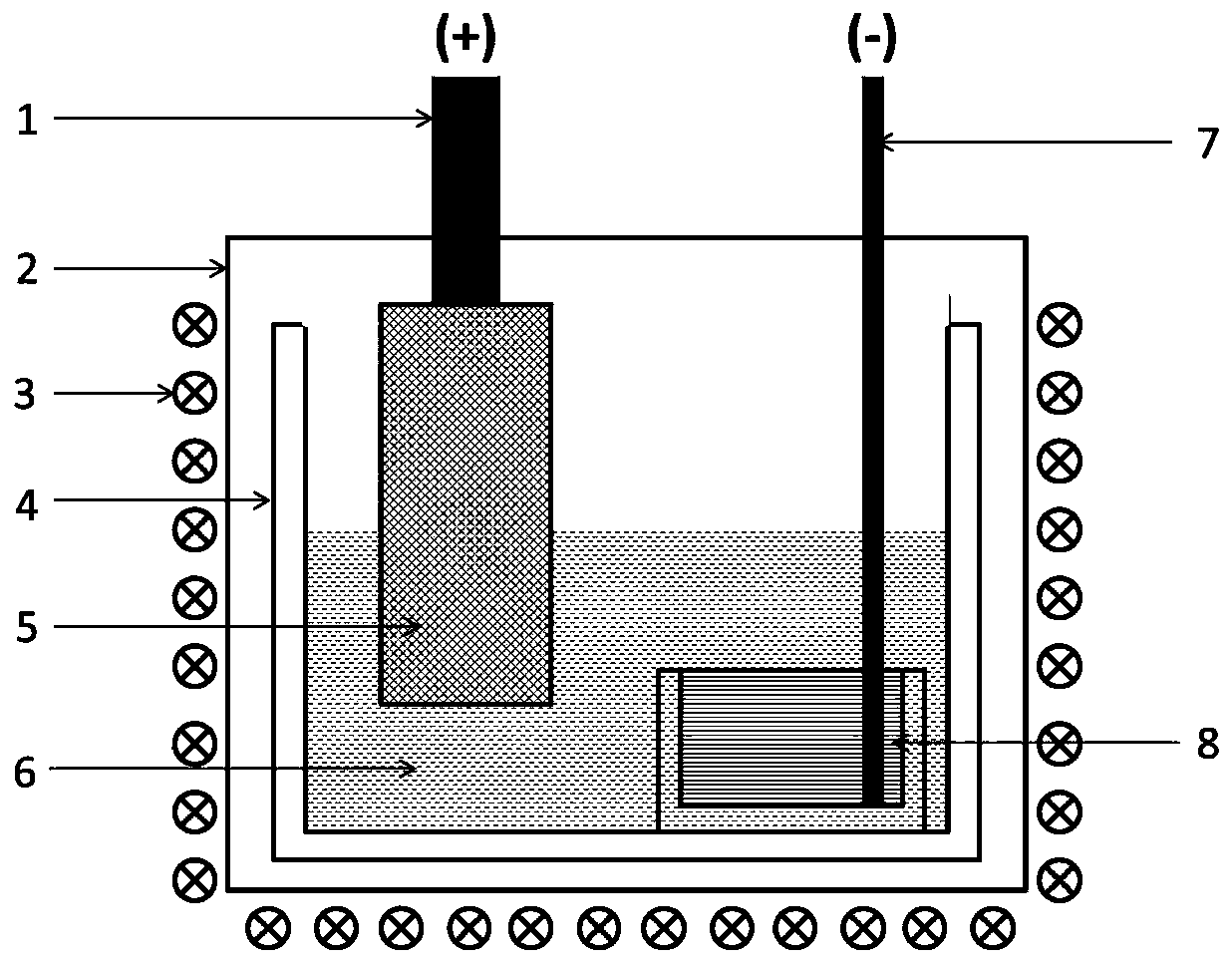

Device and method for preparing high-purity titanium metal through molten salt electrolysis-high-temperature distilling

InactiveCN109825854AReduce energy consumptionLower control costsProcess efficiency improvementElectrodesElectrolysisArgon atmosphere

The invention discloses a device and method for preparing high-purity titanium metal through molten salt electrolysis-high-temperature distilling, and belongs to the field of preparing high-purity titanium through an electrochemical method. The method comprises the following production steps that a titanium containing halide electrolyte is added in an electrolytic bath for premelting, and then, heat preservation is conducted under the argon atmosphere; liquid metal (bismuth, tin, lead and the like) serves as a cathode, titanium sponge or soluble titanium containing matter (titanium carbon oxygen solid solution and the like) serves as an anode, and electrolysis is conducted; and after electrolysis is finished, a cathode titanium alloy product is subjected to high-temperature distilling, andfinally, the high-purity titanium metal is obtained. The method has the characteristics that energy consumption is low, the equipment is simple, the production period is short, and the titanium yieldis high. Through the method, impurities in the anode can be effectively removed, the low-oxygen high-purity titanium metal is obtained, and the good application prospect is achieved.

Owner:UNIV OF SCI & TECH BEIJING +1

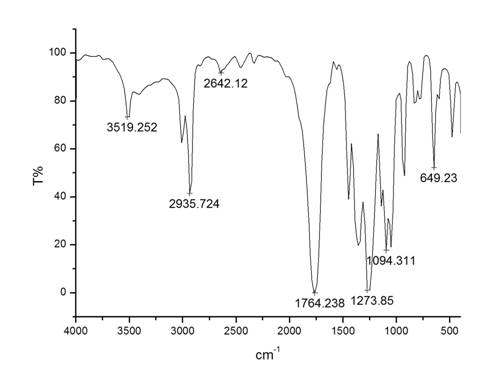

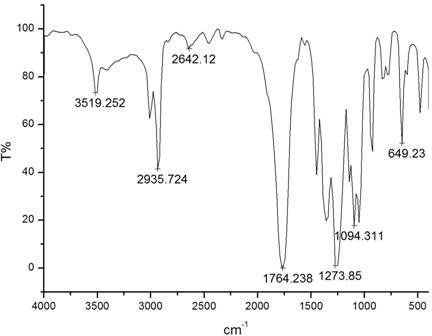

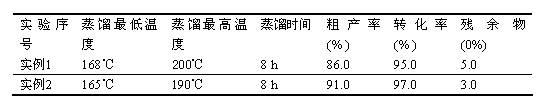

Method for preparing lactide by catalytic method under reduced pressure

InactiveCN102675277ALower distillation temperatureProduct yield is highOrganic chemistryDodecylsulfonic acidDistillation

The invention discloses a method for preparing lactide by a catalytic method under reduced pressure, which is characterized by comprising the following steps: firstly, removing free water in lactic acid at a temperature is 75-90 DEG C and at a vacuum degree of 0.080-0.090 MPa for 1-2 hours; secondly, adding a catalyst and a surfactant, wherein the catalyst consists of zinc oxide with a reactant mass percentage of 0.5-1 percent and stannous octoate with a reactant volume ratio of 0.5-1 percent, the surfactant is Tween 80 with a reactant volume ratio of 0.5-1 percent or sodium dodecyl sulfate with a reactant mass percentage of 0.5-1 percent ; thirdly, at a vacuum degree of 0.080-0.090 MPa and a temperature of 125-135 DEG C, removing combined water and reacting for 5 hours; and fourthly, agitating and raising the temperature to 165-200 DEG C, distilling and collecting the lactide with a crude production rate of 83-91 percent. The method has the beneficial effects that the distillation temperature of the lactide in the lactide preparation process can be reduced, the energy consumption is reduced, the by-product quantity generated at high temperature is reduced, the preparation production rate of the lactide is further improved, and the production cost is reduced.

Owner:NANYANG INST OF TECH

Method of extracting tea tree essential oil from tea trees

InactiveCN104830538AQuick extractionEfficient extractionEssential-oils/perfumesOrganic solventDistillation

The invention discloses a method of extracting tea tree essential oil from tea trees. The method includes: 1, washing tea leaves, crushing them to 20 meshes to 80 meshes in particle size, adding organic solvent, performing percolation extracting, and filtering extract; 2, concentrating filtrate under normal pressure, recycling solvent, and performing vacuum concentration to obtain tea tree concrete; 3, subjecting the tea tree concrete to molecular distillation, and removing the solvent and polymer materials successively to obtain the tea tree essential oil. The tea tree essential oil is purified and extracted by means of molecular distillation, organic solvent percolation and molecular distillation are made full use, and the tea tree essential oil is extracted quickly and efficiently.

Owner:JIANGSU NAIQUE BIOLOGICAL ENG

Navel orange peel essential oil extracting method

InactiveCN106867676APromote dissolutionAvoid influenceEssential-oils/perfumesSolid solvent extractionDistillationSolvent

The invention discloses a navel orange peel essential oil extracting method, which comprises the following steps: (1) crude navel orange peel essential oil preparation: smashing navel orange peel, putting into an extraction kettle of a microwave-ultrasonic wave synergistic extractor, adding an extracting solvent to perform microwave-ultrasonic wave synergistic extraction, filtering extract liquor and rectifying filtrate to obtain crude navel orange peel essential oil; (2) terpene removing treatment of the crude navel orange peel essential oil: putting the crude navel orange peel essential oil obtained in the step (1) into a reaction kettle of molecular distillation apparatus, performing molecular distillation and collecting distillation residues to obtain navel orange peel essential oil. The navel orange peel essential oil extracting method has the advantages of quickness, high efficiency, high yield, high essential oil content, stable quality and the like.

Owner:HEZHOU UNIV

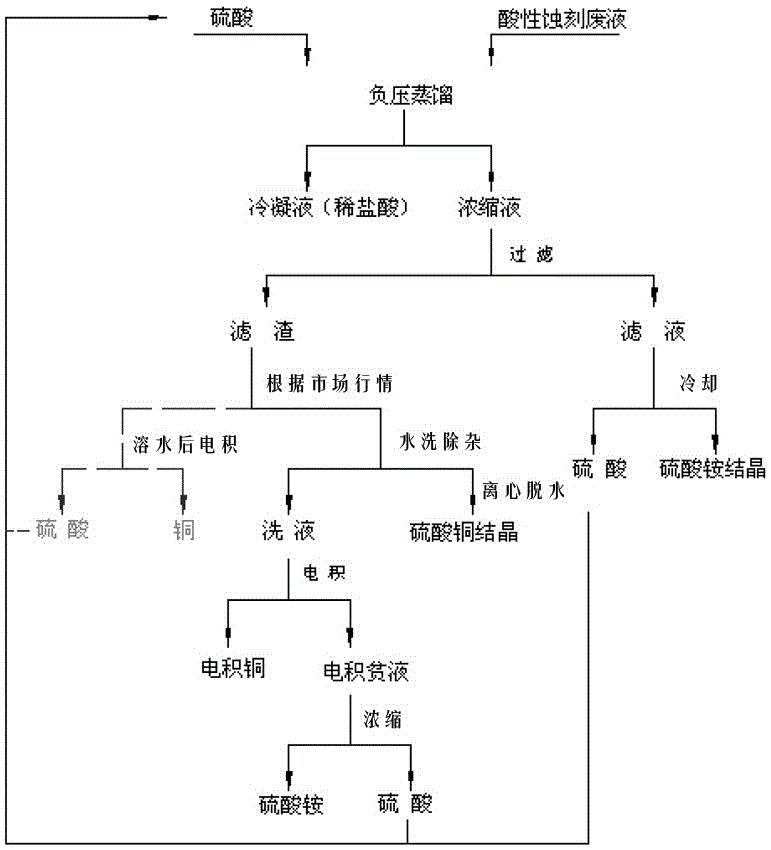

Integral disposal process of acid copper chloride etching waste liquid

InactiveCN106185810AReduce dosageReduce manufacturing costChlorine/hydrogen-chloride purificationPhotography auxillary processesAcid etchingDistillation

The invention relates to an integral disposal process of acid copper chloride etching waste liquid. The integral disposal process comprises the process steps of (1) recovering hydrochloric acid; adding acid etching waste liquid into concentrated sulfuric acid; performing distillation recovery at the pressure of -0.05MPa and the temperature of 80 to 90 DEG C; (2) recovering ammonium sulphate; filtering a concentration solution; cooling filtering liquid to separate out ammonium sulphate crystals; (3) recovering electro deposited copper or copper sulphate; concentrating filter residue after the solution is filtered; selecting the final product according to the market conditions of the electro deposited copper and the copper sulphate in the market; (4) then, recovering ammonium sulphate. The process provided by the invention has the advantages that the operation is flexible; the consumption of alkali is greatly reduced; the production cost is reduced.

Owner:方亚飞 +1

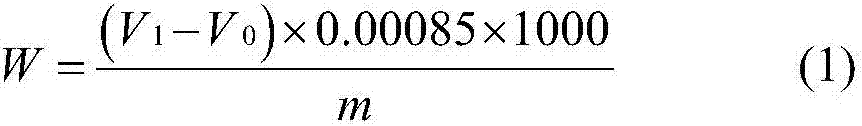

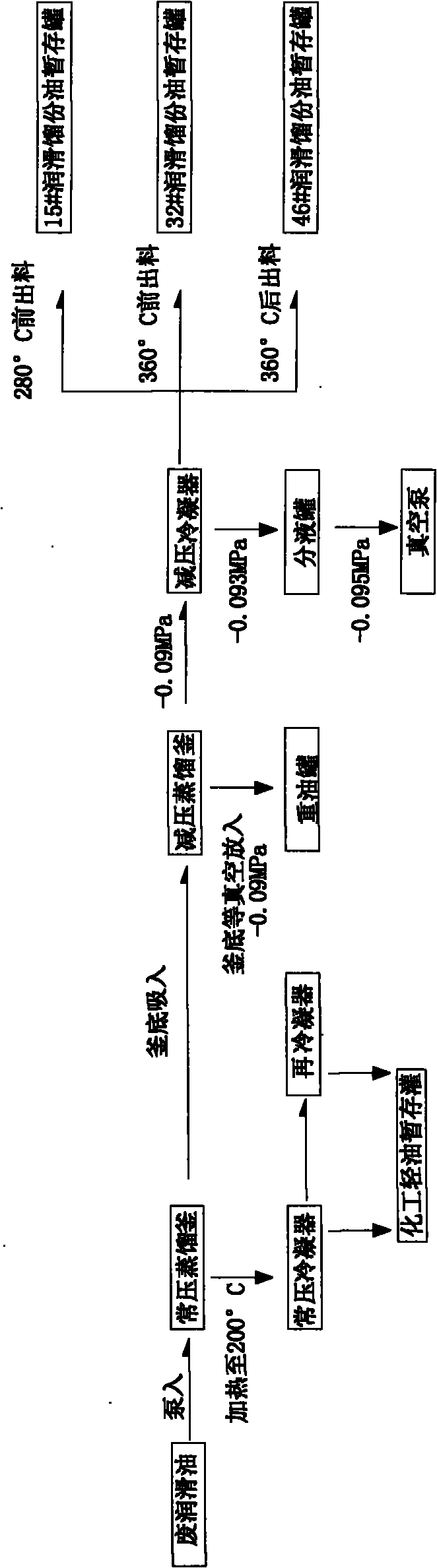

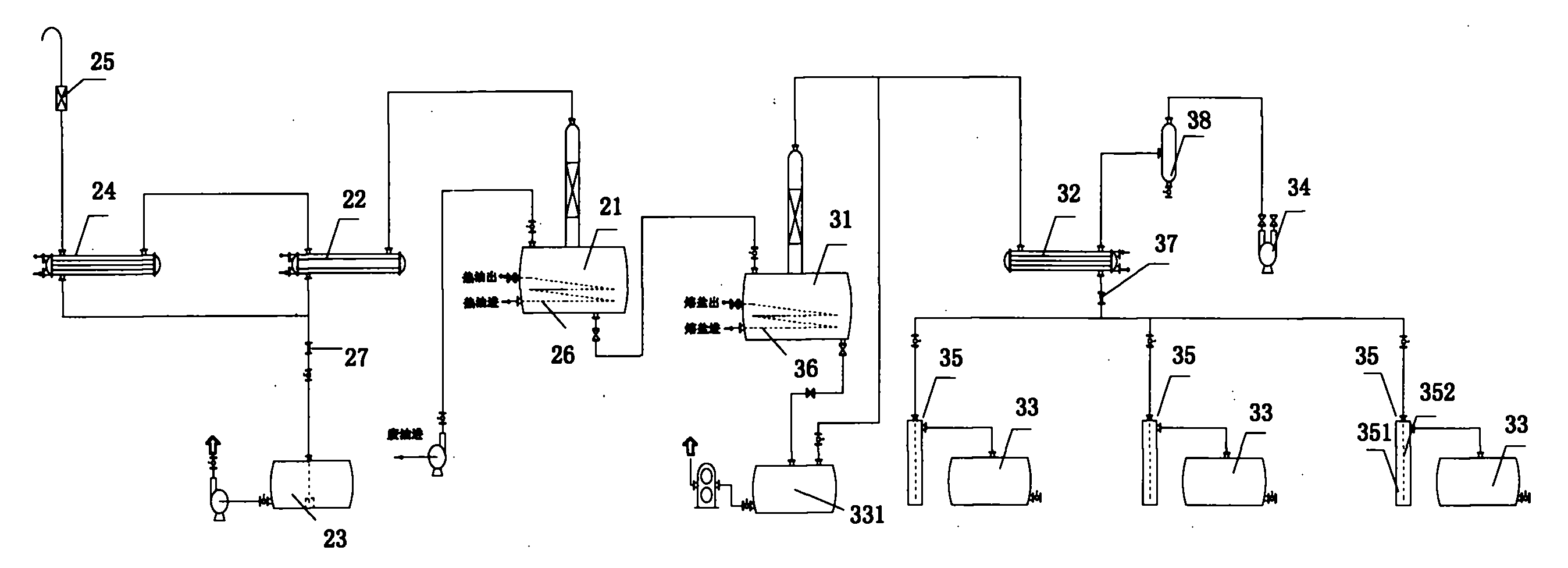

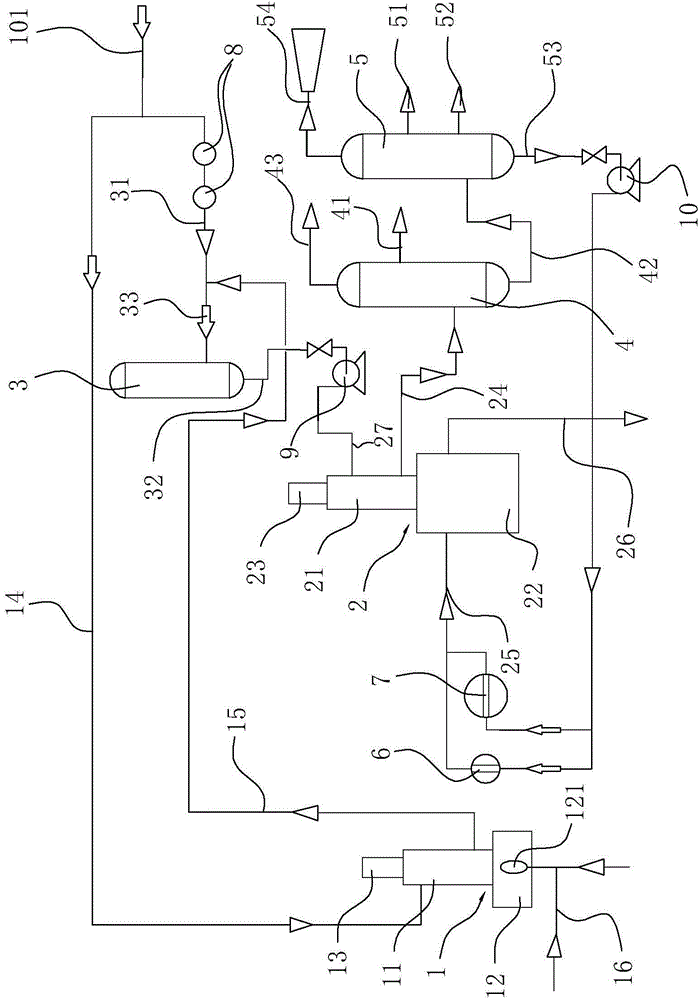

Recovery system for reclaimed lubricating distillate oil and recovery processing method

InactiveCN101818096AEasy to divideCleavage does not occurDistillation separationLubricant compositionDistillationBoiling point

The invention relates to a recovery system for reclaimed lubricating distillate oil. The recovery system comprises a primarily processing system, an atmospheric distillation system and a reduced pressure distillation system, wherein the primarily processing system comprises a stirring kettle and filter pressing equipment; the atmospheric distillation system comprises an atmospheric distillation still, an atmospheric condenser and a low-boiling point distillate oil temporary storage tank; the reduced pressure distillation system comprises a reduced pressure distillation still, a molten salt furnace pipe, a reduced pressure condenser, a vacuum pump, a liquid seal device and a distillate oil temporary storage tank; the reduced pressure distillation still is communicated with the atmospheric distillation still through a pipeline; the molten salt furnace pipe is arranged in the reduced pressure distillation still; the reduced pressure condenser is arranged above the reduced pressure distillation still; the vacuum pump is connected with the reduced pressure condenser; the liquid seal device is arranged below the reduced pressure condenser; and the distillate oil temporary storage tank is arranged below the liquid seal device. The invention also relates to a recovery processing method for the reclaimed lubricating distillate oil. Due to the adoption of the recovery system and the recovery processing method, the reclaimed lubricating distillate oil has good color, high purity, high recovery utilization ratio and safe and convenient operation and can replace basic lubricating oil.

Owner:上海通凌新能源科技发展有限公司

Melaleuca alternifolia cheel essential oil extracting method

InactiveCN106929156AHigh purityReduce moisture contentEssential-oils/perfumesOrganic solventDistillation

The invention discloses a Melaleuca alternifolia cheel essential oil extracting method and relates to the field of tea tree essential oil producing and processing. The method comprises the following steps that raw materials are collected; impunity removal and drying are conducted; smashing is conducted; an organic solvent is added after ultrasonic treatment; distillation is conducted; cooling is conducted; oil water separation is conducted to obtain the tea tree essential oil. The tea tree essential oil has the advantages of being high in purity, free of residual toxic and harmful solvents, simple in technology, and suitable for mass production and utilization.

Owner:四川艾朗特生物科技有限公司

Energy-efficient methanol gasoline additive

InactiveCN105199792AAvoid corrosionAvoid volumeLiquid carbonaceous fuelsFuel additivesAlcoholOil additive

The invention discloses an energy-efficient methanol gasoline additive, which is formed by 30-50 percent of hymatomelanic acid, 1-5 percent of inositol hexaphosphoric acid, 1-5 percent of solubilizer, 3-10 percent of antifreezing dispersing agent, 10-30 percent of stabilizer, 1-5 percent of anti-corrosion anti-swelling agent, 10-30 percent of consumption reduction agent and 0-2 percent of synergist. The energy-efficient methanol gasoline additive is prepared by mixing at normal temperatures and pressures, is 4-6 percent of the weight of methyl alcohol and can be used for preparing M70-M100 methanol gasoline. The energy-efficient methanol gasoline additive has the aims that the comprehensive technical function of the additive is improved, the methanol gasoline prepared by the additive is excellent in usability, the oil consumption is reduced, the methanol gasoline can be directly filled to use without making any change on automobiles, stability and safety in storage and transportation are realized, and exhaust gas emission reaches the standard. The energy-efficient methanol gasoline additive is simple to prepare, excellent in performance, and convenient to be popularized and used in market.

Owner:徐邦舜

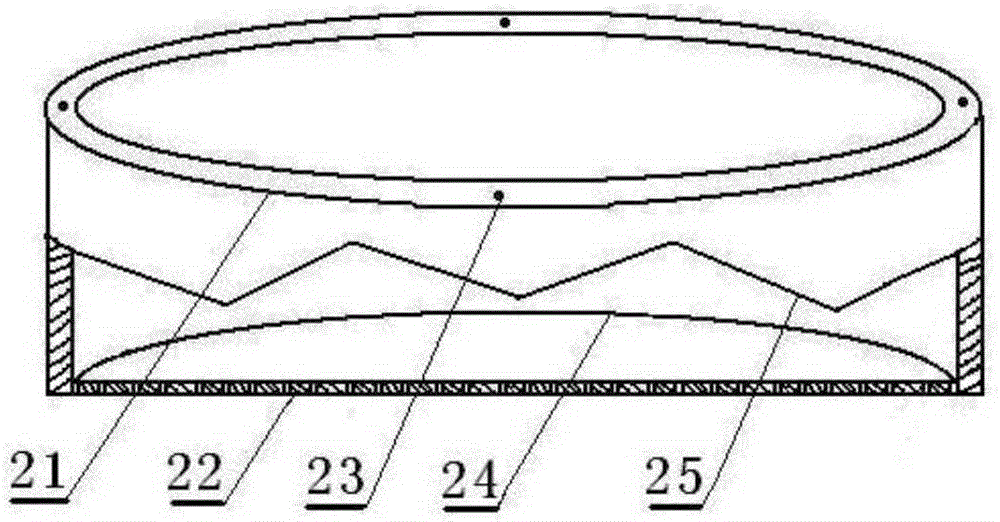

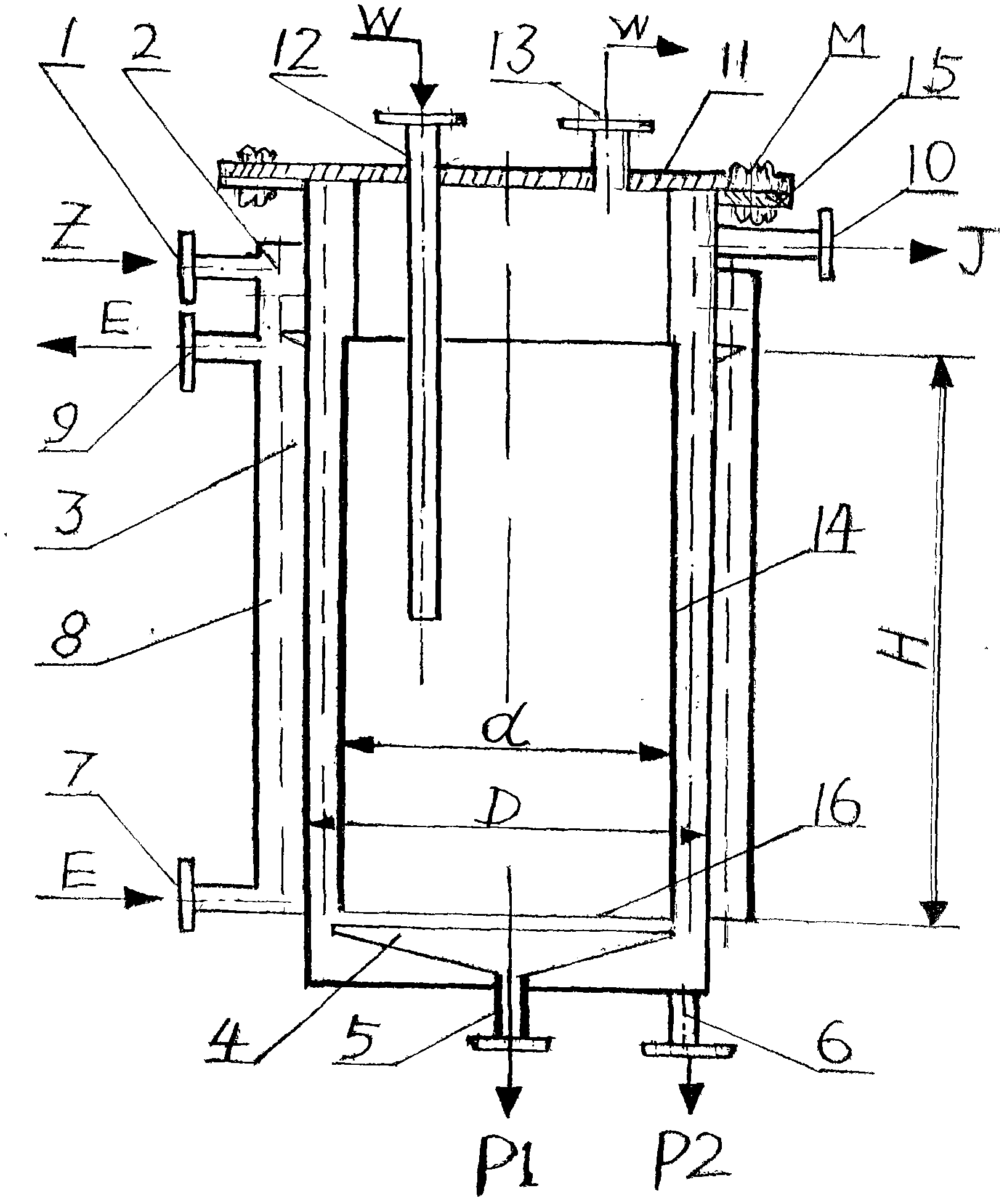

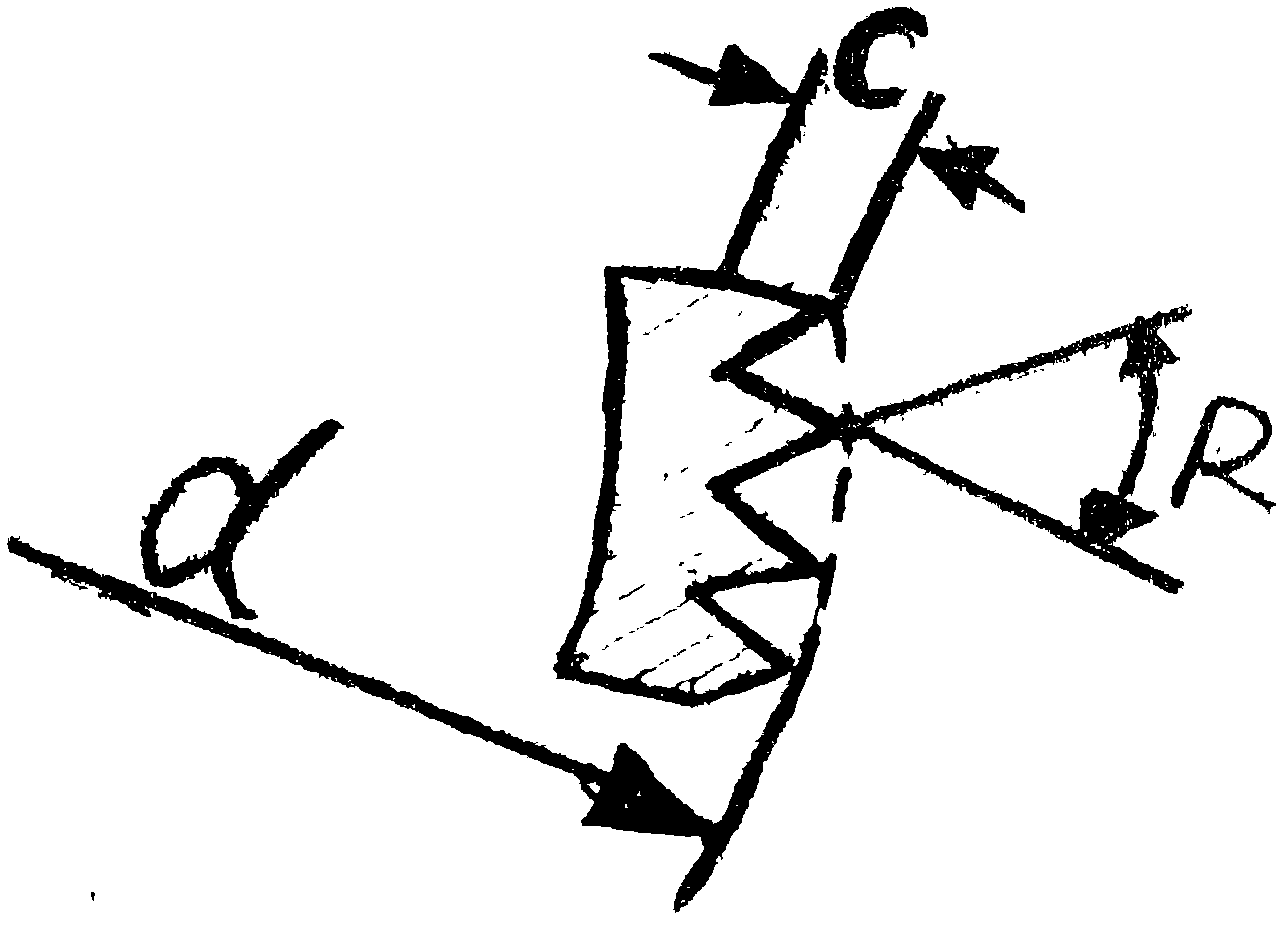

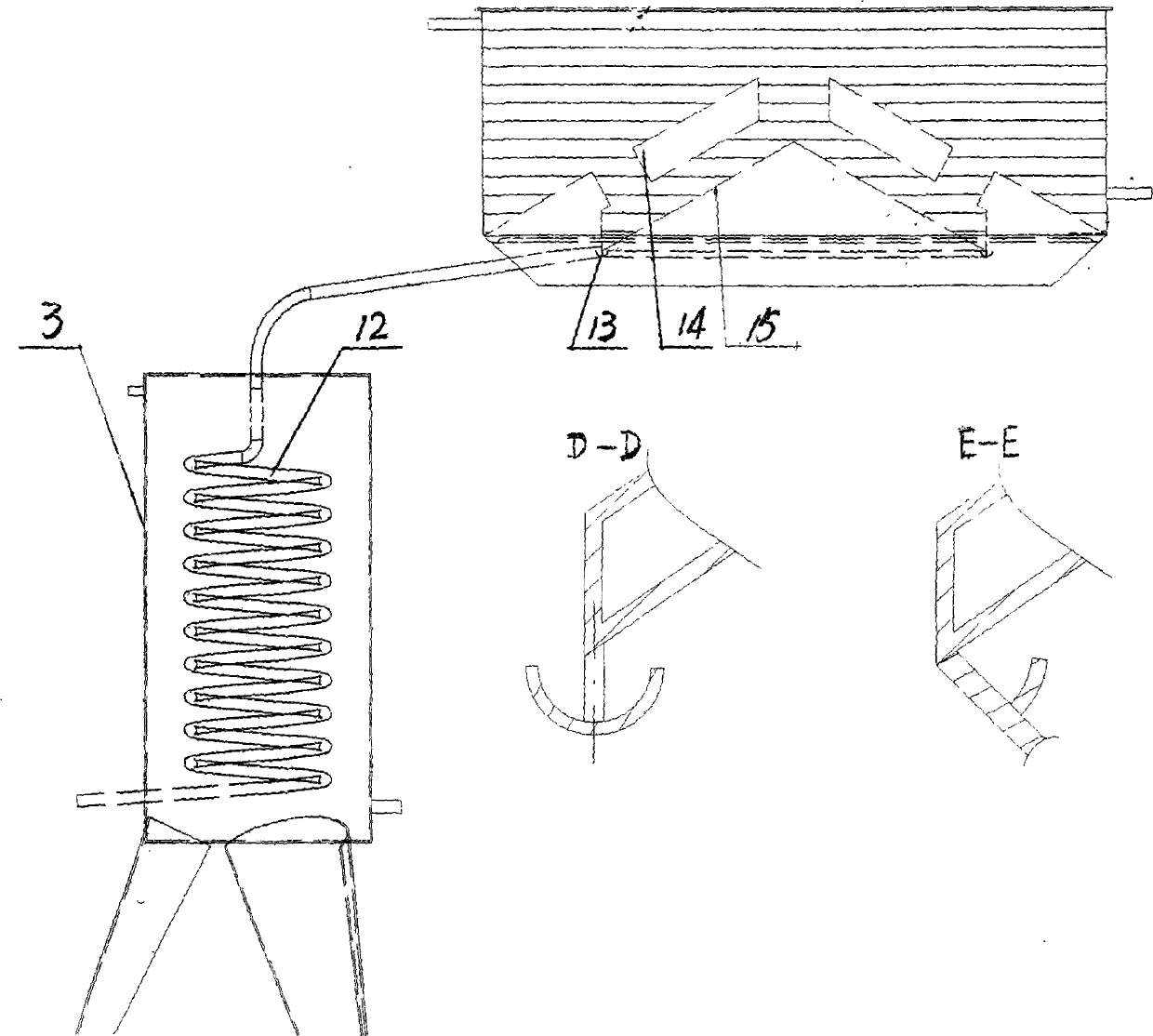

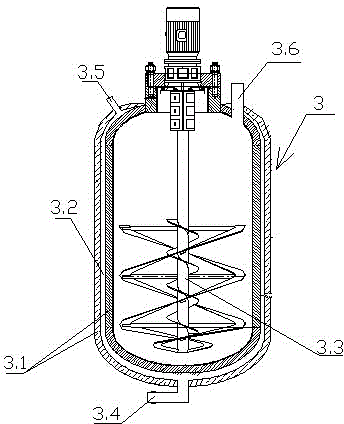

Resin short path distiller and resin distillation process

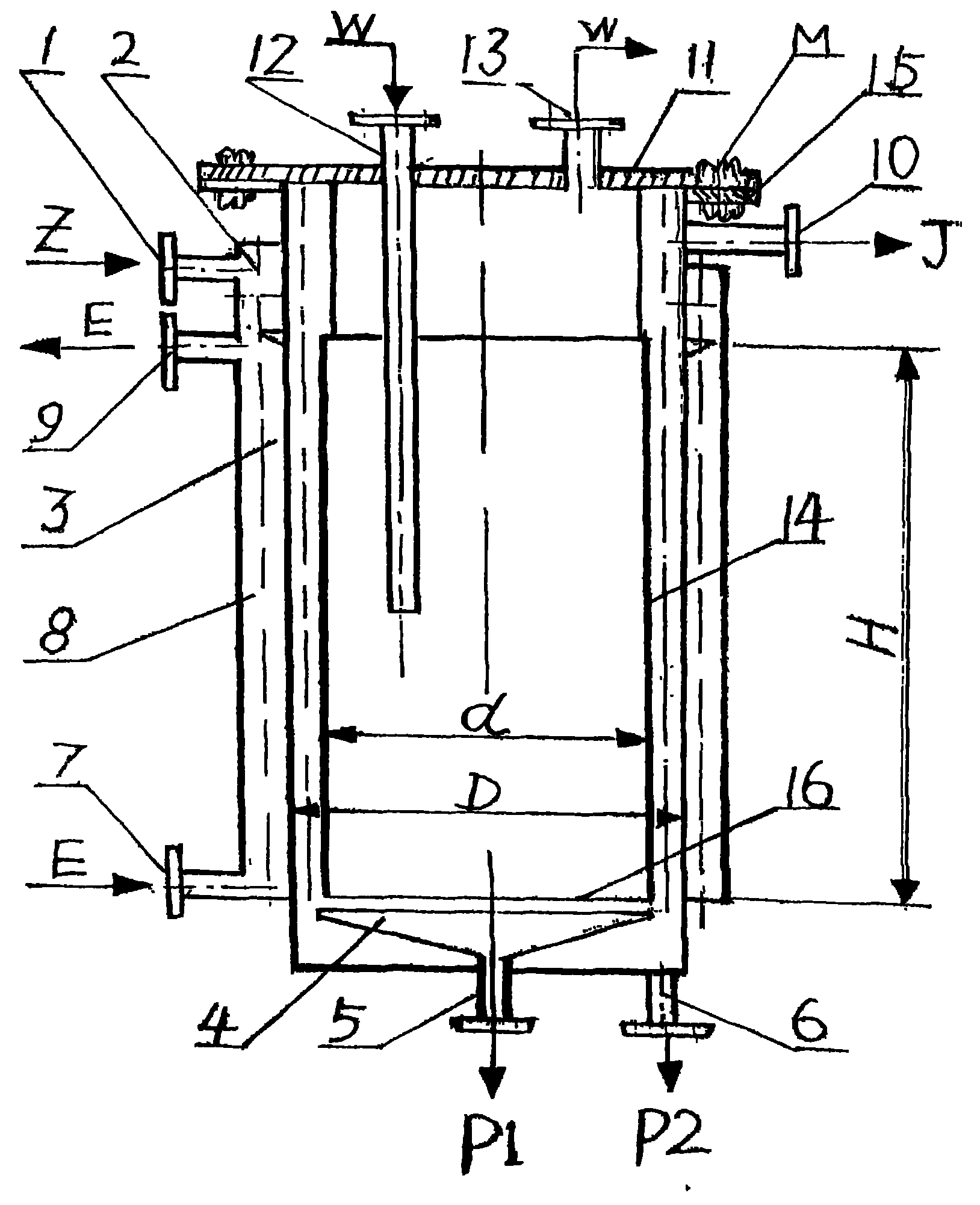

ActiveCN102321436ALower distillation temperatureReduce volumeTurpentine spiritsNatural resin purificationThermal energyDistillation

The invention relates to a resin short path distiller and a resin distillation process. The distiller comprises a feed opening 1, a resin liquid distribution ring 2, a molecule evaporation surface 3, a turpentine tray 4 and an outlet 5, a rosin outlet 6, a heating jacket 8, a molecule evaporation tube consisting of a vacuum interface 10 and a flange 11, and a molecule cooler consisting of a waterinlet 12, a water outlet 13, a tooth-shaped corrugated molecule cooling surface 14, a flange 15 and a seal bottom. The evaporation surface is preheated to 130DEG C to 140DEG C, and vacuumized to 50Pato 100Pa; after cooling liquid is injected into the cooler, the pre-heated resin liquid is put into the resin liquid distribution ring; the resin liquid is distributed into a liquid membrane which flows downwards along the molecule evaporation surface and is heated by the evaporation surface, so that molecule distillation is carried out; turpentine molecules escape from the liquid surface and arecooled by the molecule cooling surface into turpentine which flows down to the tray and flows into a storage tank P1 from the outlet 5; and the rest rosin of the liquid membrane flows into a storage tank P2 from the outlet, and the distillation process lasts for 10s to 15s. The resin distillation process provided by the invention is simple and easy to operate, saves above 70 percents of heat compared with a distillation process, so that the color of the rosin is lighter.

Owner:陆让先

Pine resin processing method with pine resin processing yield increased

The invention relates to the field of pine resin processing and discloses a pine resin processing method with pine resin processing yield increased. The method includes the steps of pre-treatment, dissolution, water washing, clarification, residue recovery, distillation, and finish product collection. In the method, a raw material is pre-treated and is water-washed under supersonic wave; and during the dissolution, an internal heating coil is employed for heating the raw material, zeolite added to break the raw material; and meanwhile, through the residue recovery, vacuum distillation and the like, efficiency of pine resin processing is improved and yield of pine resin is increased. The method is free of big modification on devices and can achieve stable control, thereby achieving stable production and yield increasing.

Owner:广西兴业县新贵松脂厂

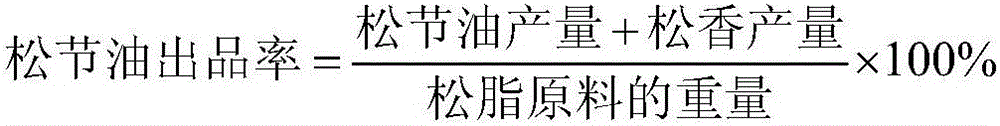

Negative-pressure ammonia distillation tower and ammonia distillation method

ActiveCN104355345ALow boiling pointLower distillation temperatureWater/sewage treatment by heatingWater/sewage treatment by degassingReboilerBoiling point

The invention relates to a negative-pressure ammonia distillation tower and an ammonia distillation method. The negative-pressure ammonia distillation tower comprises a tower main body, a skirt, a tar outlet, a manhole, an ammonia distillation wastewater outlet, a conduction oil inlet, a conduction oil outlet, a reboiler, a full-flow baffle plate, a communicating pipe, a tray, an alkali liquor inlet, a raw material ammonia water inlet, an ammonia dephlegmator, a cooling water inlet, a cooling water outlet and an ammonia vapor outlet. The negative-pressure ammonia distillation tower is characterized in that the reboiler is arranged in the tower main body, the ammonia dephlegmator is arranged at the upper part of the tower main body, the raw material ammonia water inlet is located at the upper part of the tower main body, the alkali liquor inlet is located at the middle part of the tower main body, ammonia distillation wastewater in the downcommer of the bottommost tray is guided into the bottom layer of the tower by use of the communicating pipe, and the full-flow baffle plate is arranged at the bottom layer of the tower main body. The negative-pressure ammonia distillation tower has the advantages that the ammonia distillation tower works under negative pressure so that the solution boiling point is low and the distillation temperature can be reduced, and therefore, the energy consumption is reduced, besides, the anticorrosion process is optimized, the medium corrosion problem is solved and the material cost is saved, and furthermore, the reboiler is integrated in the ammonia distillation tower so that the ammonia distillation process can be simplified and the loss in the process can be reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Vacuum distillation device for precision part cleaning liquid

InactiveCN108854131ALow boiling pointImprove securityDistillation regulation/controlVacuum distillation separationEconomic benefitsLiquid storage tank

The invention discloses a vacuum distillation device for precision part cleaning liquid. A heating jacket is fixed at the outer side of the lower part of a distillation retort; an entrance of the heating jacket is connected with an exit of a heat conduction oil circulation pump by means of a pipeline; an entrance of the heat conduction oil circulation pump is connected with an exit of a heat conduction oil heater by means of a pipeline; an entrance of the heat conduction oil heater is connected with an exit of the heating jacket by means of a pipeline; a gas outlet of the distillation retort is connected with an entrance of a condenser by means of a communicating pipe; a bottom liquid outlet of the condenser is connected with a cleaning liquid storage tank; a vacuum pipe is installed on the side wall of the upper part of the cleaning liquid storage tank; a liquid inlet of the distillation retort is connected with an outlet of a filter by means of a pipeline; an inlet of the filter is connected with a cleaning liquid inlet pipe; a bottom residue outlet pipe of the distillation retort is connected with an entrance of a residue tank. The vacuum distillation device for the precision part cleaning liquid has the advantages of being clean, environmentally friendly and good in safety, and can effectively improve the economic benefit of an enterprise.

Owner:安徽宜安精密机械零部件有限公司

Synthesis method of isoeugenol

InactiveCN103848728AEasy to separateIncrease relative volatilityEther separation/purificationEther preparation by isomerisationUltrasound - actionDistillation

The invention provides a synthesis method of isoeugenol. The method comprises the following steps: adding ground cloves powder to a potassium hydroxide solution which is 1mol / L in concentration and ethanol, and keeping under an ultrasonic condition at 100-130 DEG C for 1-2 hours to obtain a decomposition solution; stirring and mixing the decomposition solution with methylbenzene, heating and distilling under a vacuum state, controlling distilling and heating temperature at 50-90 DEG C, controlling temperature of a distillation gas volatilization outlet at 35-45 DEG C, and condensing and collecting distillation gas through a condenser to obtain low boiling point impurities; continuing to distill rest filtrate after removing the low boiling point impurities, controlling distilling and heating temperature at 100-120 DEG C, controlling temperature of the distillation gas volatilization outlet at 90-105 DEG C, and condensing and collecting the distillation gas through the condenser to obtain the isoeugenol. The synthesis method disclosed by the invention is light in environmental pollution, more simple to operate and quite low in production cost; moreover, content of trans-isoeugenol can achieve more than 95% in the isoeugenol.

Owner:ZIBO VOCATIONAL INST

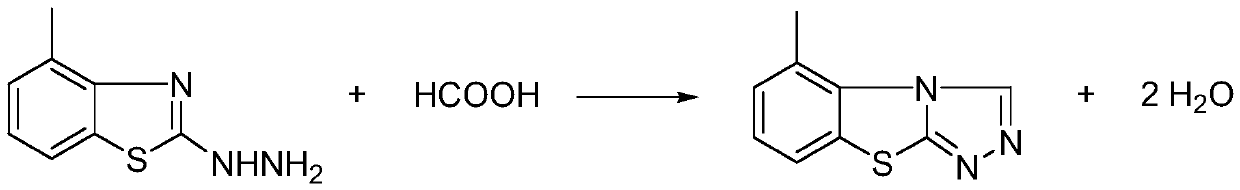

Production process of tricyclazole

The invention provides a production process of tricyclazole, and belongs to the field of pesticide production. The method solves the problems that the utilization rate of formic acid is low in the prior art; the production process of tricyclazole comprises the following steps of S01, putting 30-35% of reaction formic acid into 4-methyl-2-hydrazino benzothiazole, heating to 105-110 DEG C and performing reflux reaction for 2-5h; and S02, after reflux reaction is ended, carrying out reduced pressure distillation, evaporating out and recovering formic acid, wherein the temperature of reduced pressure distillation is 130-160 DEG C; dropwise adding water into the reduced pressure distillation residue, wherein the dropwise adding speed is 30 drops / min to 60 drops / min; carrying out cooling and crystallizing after dropping, wherein the temperature of the cooling crystallization is minus 10 DEG C to 40 DEG C; performing filtering, and then drying on filter cake obtained by filtering at 50-100 DEG C to obtain a tricyrazole crude product; and carrying out refining on the tricyrazole crude product obtained in the step S02 by an ethyl acetate-ethyl alcohol mixed solvent to obtain refined tricyclazole. The method disclosed by the invention is high in yield of the tricyclazole.

Owner:SHANGYU JINTENG MEDICAL CHEM IND

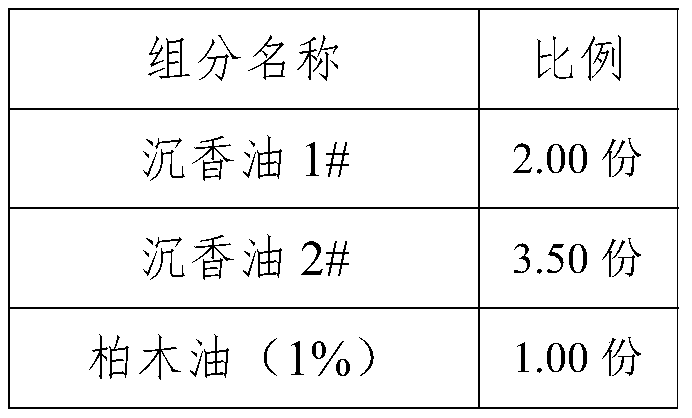

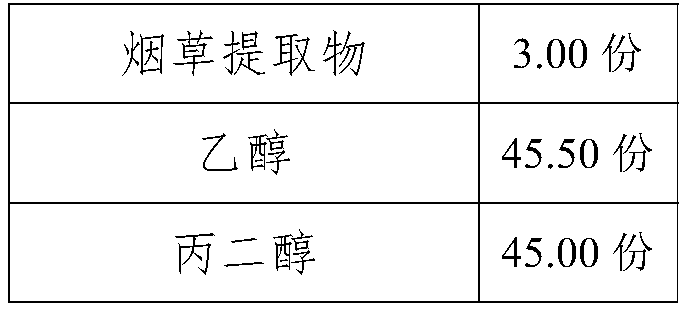

Preparation method and applications of agilawood-type tobacco essence

ActiveCN109897729AAvoid damageLower distillation temperatureEssential-oils/perfumesDistillationFractionation

The invention relates to a preparation method and applications of an agilawood-type tobacco essence. The preparation method comprises following steps: agilawood is crushed, and is subjected to ethanoldissolving, ultrasonic cell crushing, heat backflow extraction, filtering, reduced pressure concentration, and molecular distillation; wherein in the step of molecular distillation, three stage fractionation is adopted to prepare two kinds of agilawood essence oil including a second stage separated product agilawood essence oil and a third stage separated product agilawood essence oil. The agilawood-type tobacco essence comprises 0.1 to 3 parts of the second stage separated product agilawood essence oil, 2 to 7 parts of the third stage separated product agilawood essence oil, 0.05 to 3 partsof cedar oil, 1 to 10 parts of tobacco extract, 35 to 60 parts of ethanol, and 35 to 45 parts of propylene glycol. The cigarette product containing the agilawood-type tobacco essence possesses elegantagilawood fragrance, is mellow and thick in flavor, sweet aroma is enhanced, and throat comfortableness is improved.

Owner:CHINA TOBACCO SHANDONG IND

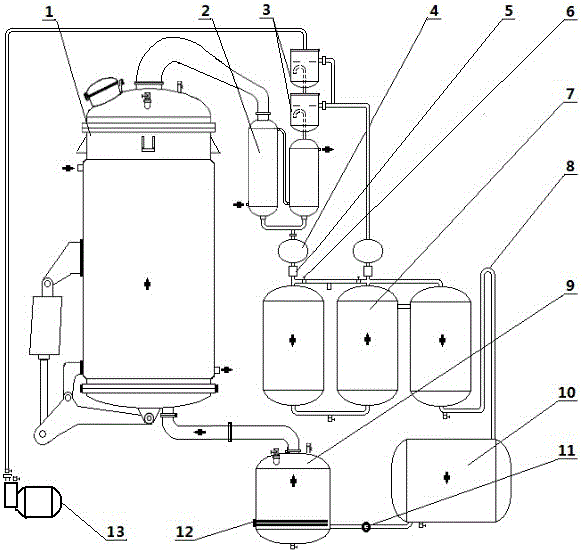

Device of using negative-pressure circulating water to extract star anise oil

The invention discloses a device of using negative-pressure circulating water to extract star anise oil. A distillation tank, two condensers, two tail gas tanks, an oil collector, two clocks, three oil-water separators, a liquid collection tank, a steam pot, a vacuum device and an automatic control valve are arranged, and the distillation tank is a vertical quick-to-open distillation tank with a deslagging end socket. The device is low in investment and reasonable in structure, and hot condensed water after being heated is enabled to flow into a heating tank from the deslagging end socket through a patterned plate to heat anise to form medium continuous circulating flow, so that extracted materials are ensured to be uniformly heated, continuous circulation and negative-pressure distillation are realized, distillation temperature can be lowered, extraction efficiency and product yield are greatly improved, and product quality is guaranteed; each of a deslagging mechanism, a charging port and a steam pipe is of a quick-mounting structure, so that convenience is brought to charging, deslagging, connecting and maintaining, process operation is easy, extraction effect is good, distillation time is short, energy resources are saved, safety and reliability are realized, and the device has remarkable economic benefit and social benefit.

Owner:都安瑶族自治县计量检定测试所

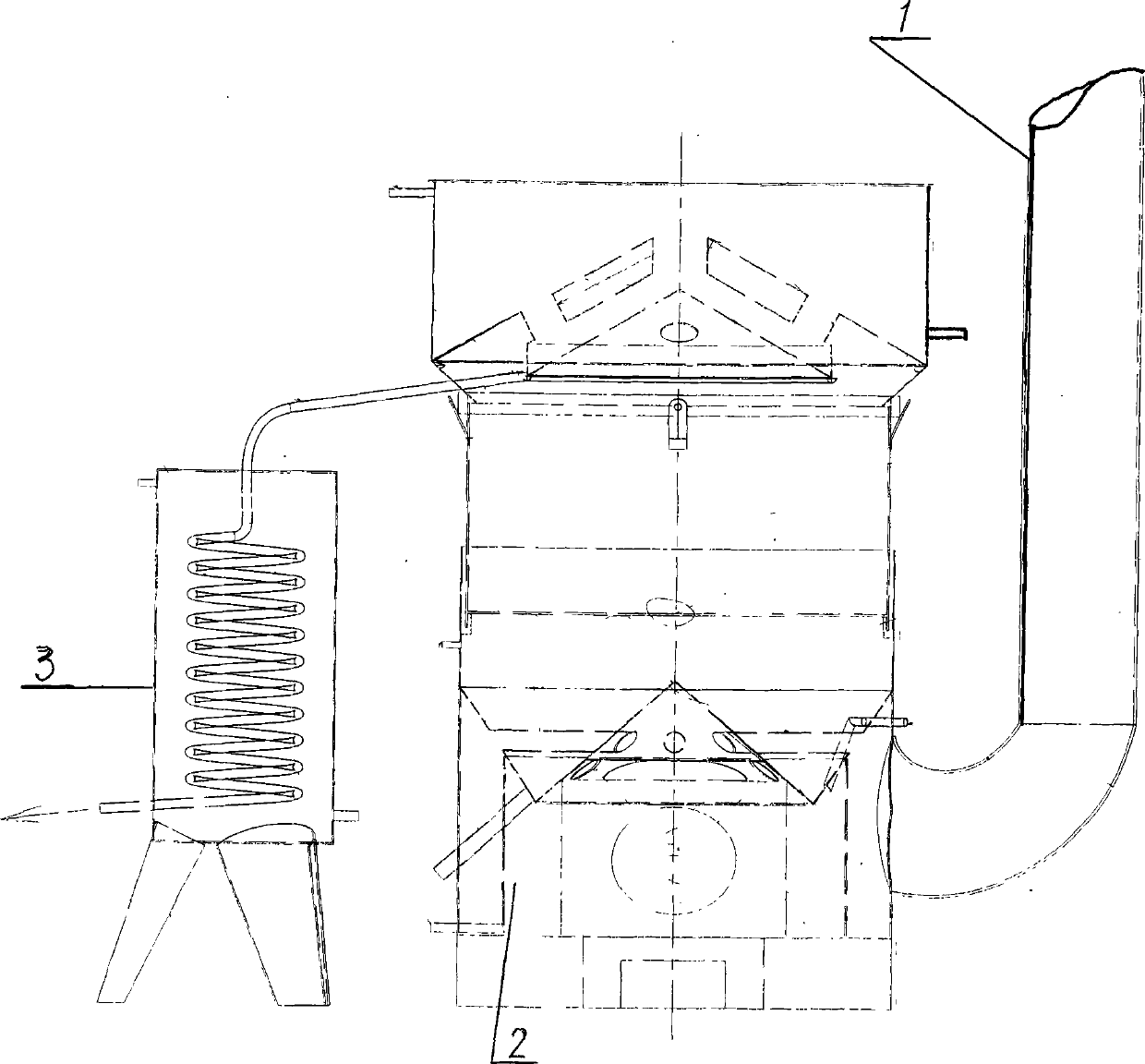

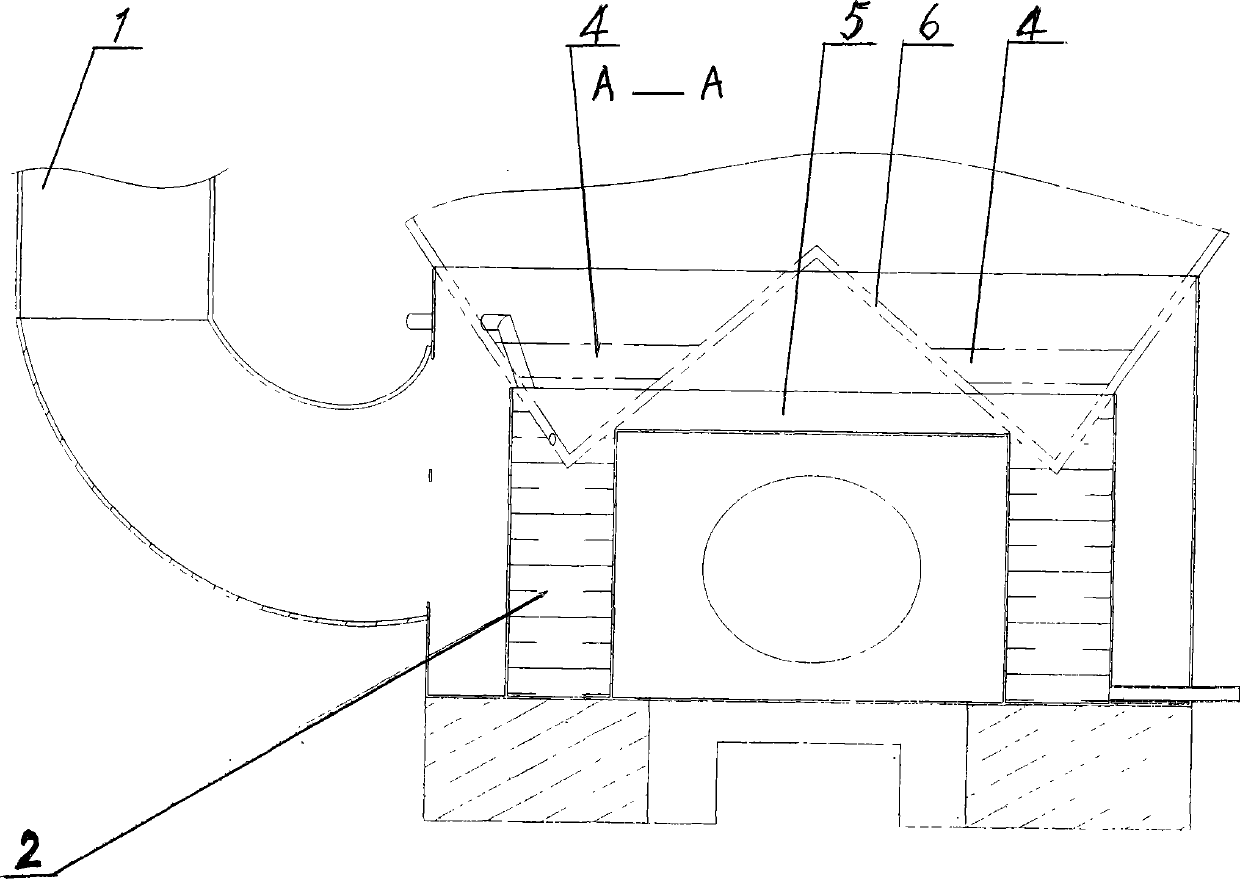

Lifting-dismounting type fire-heating ceiling pot winemaking device

InactiveCN104232452AShort labor intensityReduce labor intensityAlcoholic beverage preparationFlavorDistillation

The invention discloses a lifting-dismounting type fire-heating ceiling pot winemaking device which is used for solving the defects, namely great energy consumption, easiness for stream escaping, a small condensing area of the ceiling pot, insufficient cooling, much wine volatilization due to a high wine temperature, high cost, low yield, great labor strength and easiness for burning, in the background technology. The lifting-dismounting type fire-heating ceiling pot winemaking device is characterized in that five heating tubes, which are parallel to one another, at the upper end of a furnace hearth 7 are communicated with a W-shaped pot bottom; eight fire exhausting tubes 4 are arranged at the topmost end of the furnace hearth 7 above the five heating tubes 5 which are parallel to one another; cavities are internally formed in an upper ceiling pot body 15 and a lower ceiling pot body 14, and are filled with circulating cooling water; the two ends of each of five water tubes 11 are communicated with the upper ceiling pot body 15 and the lower ceiling pot body 14 respectively; a coiler secondary condenser is composed of a spiral coiled tube 12 and a condensing barrel 3. The lifting-dismounting type fire-heating ceiling pot winemaking device has the advantages of being energy-saving and environment-friendly, great in heating area, short in distillation time, great in cooling area, time-saving and labor-saving, complete in distillation, low in cost, high in yield, safe and reliable in pressure-free operation, less in possibility of pot burning, low in distillation temperature, low in wine temperature, high in flavor substance content of a finished product wine, good in quality and good in mouthfeel. The lifting-dismounting type fire-heating ceiling pot winemaking device is used for making wine.

Owner:周取闻

A kind of production method of triglycidyl isocyanurate

InactiveCN101367796BReduce consumptionHigh yieldOrganic chemistryPowdery paintsSynthetic materialsEpichlorohydrin

Owner:CHANGZHOU NIUTANG CHEM PLANT CO LTD

Atmospheric and vacuum catalytic flue gas-oil slurry heat combined device

ActiveCN104927905ALower distillation temperatureImprove heat transfer effectHydrocarbon oils treatmentSlurryFuel oil

An atmospheric and vacuum device adopting catalytic flue gas and oil slurry waste heat to replace a heating furnace fuel comprises a first heating furnace, a second heating furnace, a flash evaporation tower, a jet fuel atmospheric tower and a diesel fuel vacuum tower, wherein the first heating furnace adopts a flue gas heating furnace, and a first crude oil inlet pipeline and a first crude oil outlet pipeline are arranged on the flue gas heating furnace; a second crude oil inlet main pipeline is arranged on the flash evaporation tower, and crude oil after heating by the first heating furnace and second-way crude oil enter the pipeline to be mixed; a pipeline connected with a crude oil outlet pipeline on the flash evaporation tower and a crude oil output second heating furnace pipeline are arranged on the second heating furnace; a connection port connected with the crude oil output second heating furnace pipeline is formed in the jet fuel atmospheric tower; a connection port connected with a jet fuel atmospheric tower crude oil extraction pipeline is formed in the diesel fuel vacuum tower; a heavy oil extraction pipeline is arranged at the bottom of the diesel fuel vacuum tower, and an adjusting circulating oil heat exchanger and an oil slurry heat exchanger are arranged between the heavy oil extraction pipeline and the second heating furnace. The atmospheric and vacuum device is reasonable in design, efficient and energy-saving, three waste heats including the catalytic flue gas, the oil slurry and adjusting circulating oil are sufficiently used, and the economic benefits are enhanced.

Owner:雷泽永

Preparation method for basic lubricating oil

InactiveCN104818106AReduce dwell timeIncrease the proportion of componentsBase-materialsDistillationMolten salt

The invention discloses a preparation method for basic lubricating oil. The preparation method comprises the following concrete steps: (1) pretreatment: a step of adding a catalyst into waste engine oil having undergone settling separation; (2) pre-distillation: a step of inputting the pretreated waste engine oil into a pre-distillation tank, pumping out air in the upper part of the pre-distillation tank and heating the pre-distillation tank by using molten salt; (3) rectification: a step of inputting the pre-distilled waste engine oil into a rectification tank, pumping out air in the upper part of the rectification tank, heating the rectification tank by using molten salt and carrying out stirring, wherein heating temperature is 300 to 400 DEG C; and (4) refining and filtering: a step of adding white earth and successively carrying out stirring and filtering so as to obtain the basic lubricating oil. According to the invention, the component ratio of the basic lubricating oil is increased; local pyrolysis is prevented and coking caused by local overheating is alleviated; and the obtained basic lubricating oil has reduced smell, and energy is saved.

Owner:德阳市富可斯润滑油有限公司

Glycollic acid purification method, glycollic acid crystal and application thereof

PendingCN112645814AReduce chromaHigh recovery rateCosmetic preparationsToilet preparationsOrganic synthesisAqueous solution

The invention relates to the technical field of glycolic acid purification, and discloses a glycolic acid purification method, a glycolic acid crystal and application thereof. The method comprises the following steps of: (1) concentrating a glycollic acid aqueous solution of which the concentration is lower than 70wt% into a 70-90wt% glycollic acid aqueous solution by molecular distillation; and (2) crystallizing the 70-90wt% glycollic acid aqueous solution obtained in the step (1), and carrying out solid-liquid separation to obtain a glycollic acid crystal and a glycollic acid mother solution. The purity of the glycollic acid crystal obtained by the method provided by the invention is as high as 99.9 wt%, and the polymer content is less than 0.1 wt%. The glycollic acid crystal obtained by the method is applied to the fields of organic synthesis, medicines and cosmetics.

Owner:CHINA PETROLEUM & CHEM CORP +1

Apparatus for cyclic water extraction of cassia oil under reduced pressure

ActiveCN106433963AHigh purityHigh quality and high purityFatty-oils/fats refiningVacuum distillation separationSocial benefitsDistillation

The invention relates to an apparatus for cyclic water extraction of cassia oil under reduced pressure, comprising a distilling tank, two condensers, two tail gas tanks, three oil-water separators, an oil collector, a liquid collection tank, a heating pot, and a vacuum device; the distilling tank is a vertical sandwiched distilling tank, upper and lower heads are quick-opening heads, and two view clocks are provided. The apparatus is low in investment and reasonable in structure; hot condensate can be heated, steam flows through a perforated plate into a heating tank from a residue discharge head so as to heat cassia bark, a medium flows from bottom to top continuously and cyclically, it is guaranteed that all extracted materials can be evenly heated, continuous cyclic distillation under reduced pressure is achieved, extraction efficiency and production yield can be greatly increased, and product quality is guaranteed; a residue discharge mechanism, a feeding port and a steam pipe are each of quick-fitting structure, feeding, residue discharging, connecting and maintenance are facilitated; the process is easy to perform, extraction is effective, short time is taken, energy is saved, and the apparatus is good in safety and reliability and has significant economic and social benefits.

Owner:都安瑶族自治县计量检定测试所

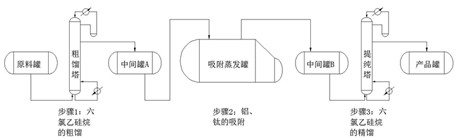

Process for preparing high-purity hexachlorodisilane

ActiveCN111643916AAvoid heat deteriorationStir wellFractional distillationHalogenated silanesMetallurgyDistillation

The invention relates to the field of preparation of high-purity hexachlorodisilane, in particular to a process for preparing high-purity hexachlorodisilane. According to the method, sorbitol is adopted to replace chelate resin to adsorb metal impurities, nitrogen is added in the purification process for accompanying as inert gas for protection and rectification, the introduced nitrogen mainly hasthe effects of reducing the distillation temperature and enhancing stirring of liquid in the tower kettle to prevent local overheating of the liquid in the kettle, therefore hexachlorodisilane is prevented from being heated to deteriorate. The process is high in rectification efficiency and low in process cost.

Owner:HUBEI JINGXING SCI & TECH INC CO LTD

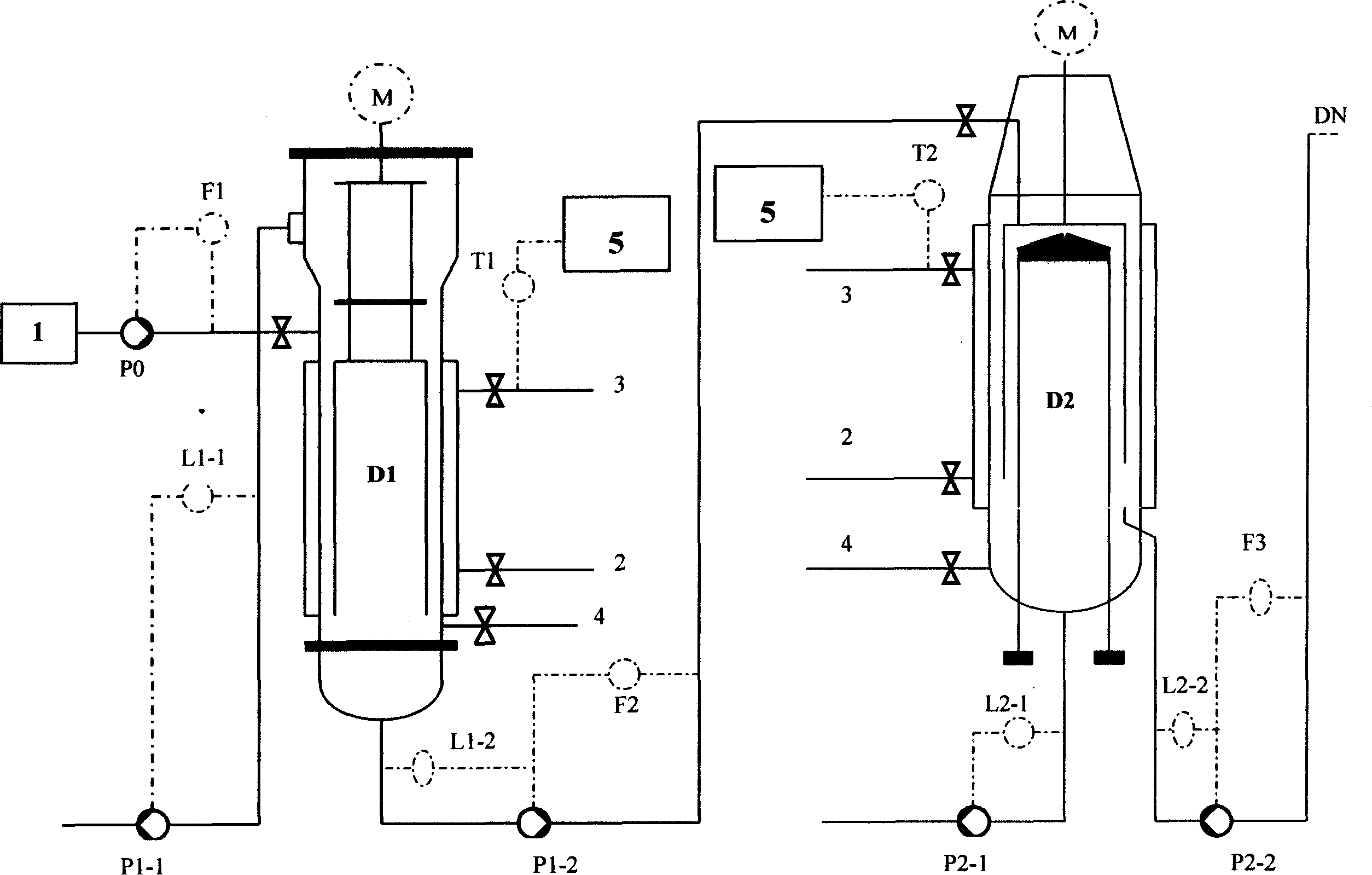

Biodiesel oil multiple-grade molecular distillation process and its device

InactiveCN1884442AShort stayLower distillation temperatureHydrocarbon distillationBiodiesel feedstockBiodiesel

The invention discloses biological diesel fuel polymolecular distillation process, comprising the following steps: putting the biological diesel fuel into first grade molecular distillation device, evaporating water and air, putting the distillate into container, then putting the materials without being distilled into second grade distillation device; the putting the materials into container; putting the material without being distilled into gathering tank, or putting them into next grade distillation device; after n grades distilling, putting the valid combination into container, and putting the refuse into gathering tank. The distillation number of steps is between 2 and 6.

Owner:杜小星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com