Atmospheric and vacuum catalytic flue gas-oil slurry heat combined device

A technology for catalyzing flue gas and a combined device, which is applied in the petroleum industry, processing hydrocarbon oil, etc., can solve the problems of reducing economic benefits, reducing the power of the hood, increasing the back pressure of the hood, and solving the problems of low heat utilization rate and structural Reasonable design and the effect of improving economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

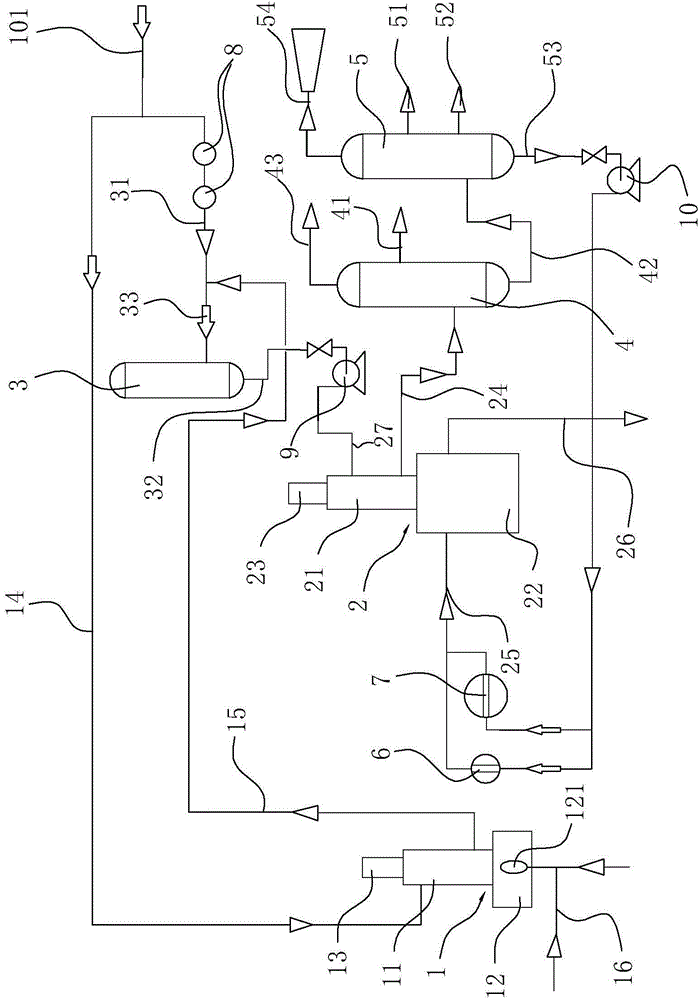

[0039] Such as figure 1 As shown, the atmospheric and vacuum device of the present embodiment, which replaces heating furnace fuel with catalytic flue gas and oil slurry waste heat, includes a first heating furnace 1, a second heating furnace 2, a flash tower 3, an aviation coal atmospheric tower 4, Diesel decompression tower 5, No. 2 heat exchanger 6 and oil slurry heat exchanger 7, wherein the first heating furnace 1 is a flue gas heating furnace, which is a pure convection tube heating furnace without a radiation chamber. The first heating furnace 1 is divided into the first convection chamber 11 and the upper and lower parts of the combustion chamber 12. The bottom of the first heating furnace 1 is provided with the flue gas pipeline 16 of the combustion chamber 12 for the catalytic flue gas to enter, and the combustion chamber 12 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com