Preparation method for basic lubricating oil

A lubricating oil and basic technology, applied in the field of lubricating oil, can solve the problem of reducing the smell of basic lubricating oil, achieve the effects of reducing coking, reducing odor, and preventing local high-temperature cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

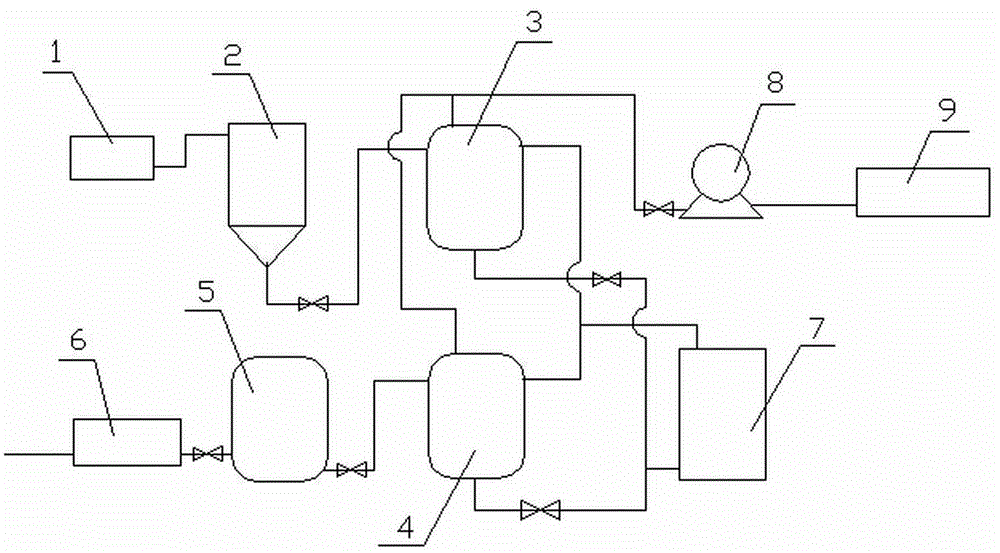

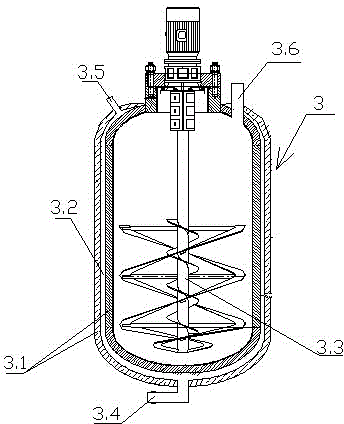

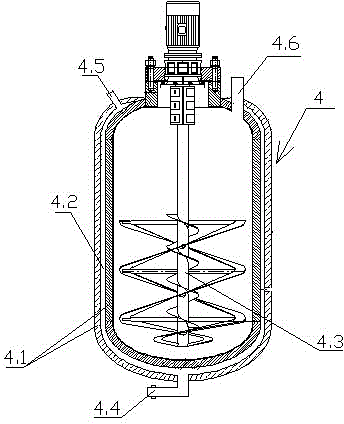

Method used

Image

Examples

Embodiment 1

[0028] Various lubricating oils that people need can be prepared by adding different preparations to the base lubricating oil.

[0029] A method for preparing a base lubricating oil, specifically using recovered waste engine oil to prepare the base lubricating oil, the specific steps of the method are as follows:

[0030] (1) Pretreatment: add a catalyst to the waste oil separated by settling and stir; put the collected waste engine oil into the premix tank, and first pretreat the waste engine oil in the premix tank, that is, oil-water separation and sludge Metal dust treatment, etc.; the treatment method is to take the catalyst of 3%-8% of the weight of waste engine oil and the water of 3%-10% of the weight of waste engine oil, put the catalyst into the water, mix it evenly with a stirrer, and then put the mixed solution Add to the premix tank and stir, let stand for 12-48 hours.

[0031] (2) Pre-distillation: input the above-mentioned pretreated waste engine oil into the pr...

Embodiment 2

[0037] A method for preparing a base lubricating oil, specifically using recovered waste engine oil to prepare the base lubricating oil, the specific steps of the method are as follows:

[0038] (1) Pretreatment: add a catalyst to the waste oil separated by settling and stir; put the collected waste engine oil into the premix tank, and first pretreat the waste engine oil in the premix tank, that is, oil-water separation and sludge Metal dust treatment, etc.; the treatment method is to take 3% of the catalyst by weight of waste engine oil and water of 10% by weight of waste engine oil, put the catalyst into water, mix evenly with a stirrer, and then add the mixed solution into the premixing tank and stir , let stand for 24 hours.

[0039] (2) Pre-distillation: input the above-mentioned pretreated waste engine oil into the pre-distillation tank, use a vacuum pump to extract the air above the pre-distillation tank, so that the vacuum degree in the pre-distillation tank is 100 Pa,...

Embodiment 3

[0044]Various lubricating oils that people need can be prepared by adding different preparations to the base lubricating oil.

[0045] A method for preparing a base lubricating oil, specifically using recovered waste engine oil to prepare the base lubricating oil, the specific steps of the method are as follows:

[0046] (1) Pretreatment: add a catalyst to the waste oil separated by settling and stir; put the collected waste engine oil into the premix tank, and first pretreat the waste engine oil in the premix tank, that is, oil-water separation and sludge Metal dust treatment, etc.; the treatment method is to take 8% of the catalyst by weight of waste engine oil and water of 10% by weight of waste engine oil, put the catalyst into water, mix evenly with a stirrer, and then add the mixed solution into the pre-mixing tank and stir , let stand for 36 hours.

[0047] (2) Pre-distillation: input the above-mentioned pretreated waste engine oil into the pre-distillation tank, use a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com