Lifting-dismounting type fire-heating ceiling pot winemaking device

A technology of fire-fired pot and hanging type, which is applied in the field of hanging-type direct-fired pot wine making device, which can solve the problems of bad taste of finished wine, less flavor substances of wine, and far inferior taste, so as to achieve thorough distillation and pure finished wine , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

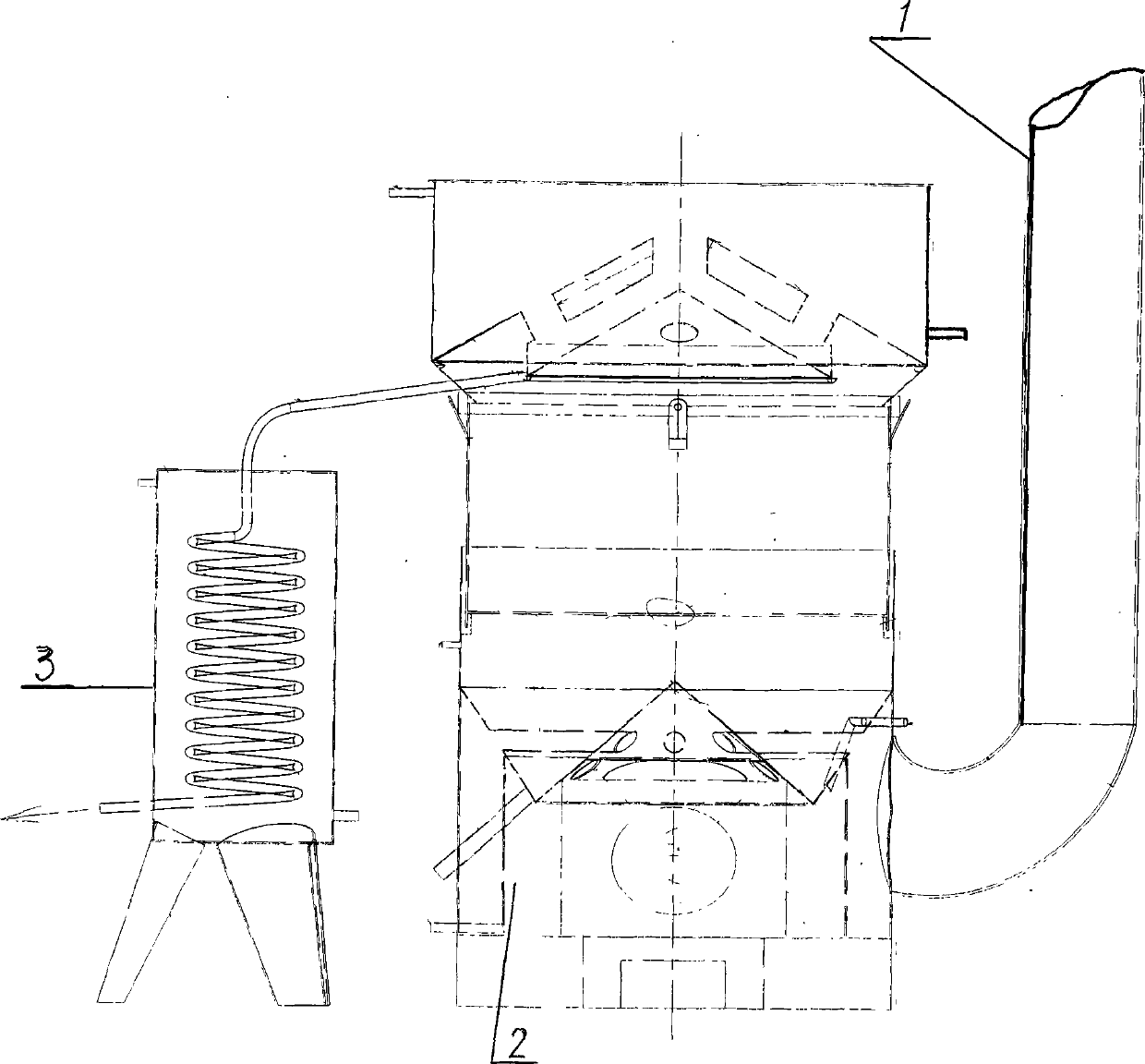

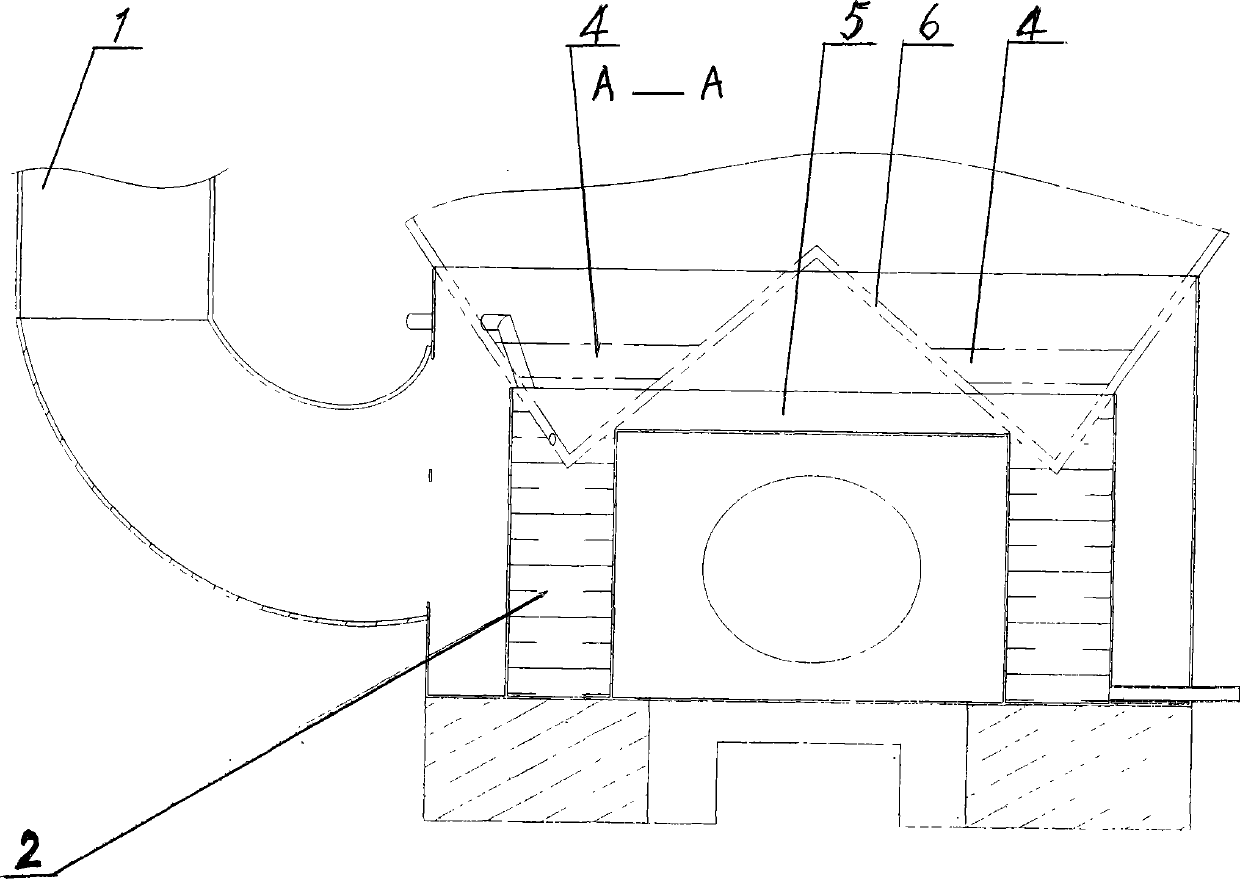

[0029] The present invention is described in further detail below in conjunction with accompanying drawing and embodiment thereof:

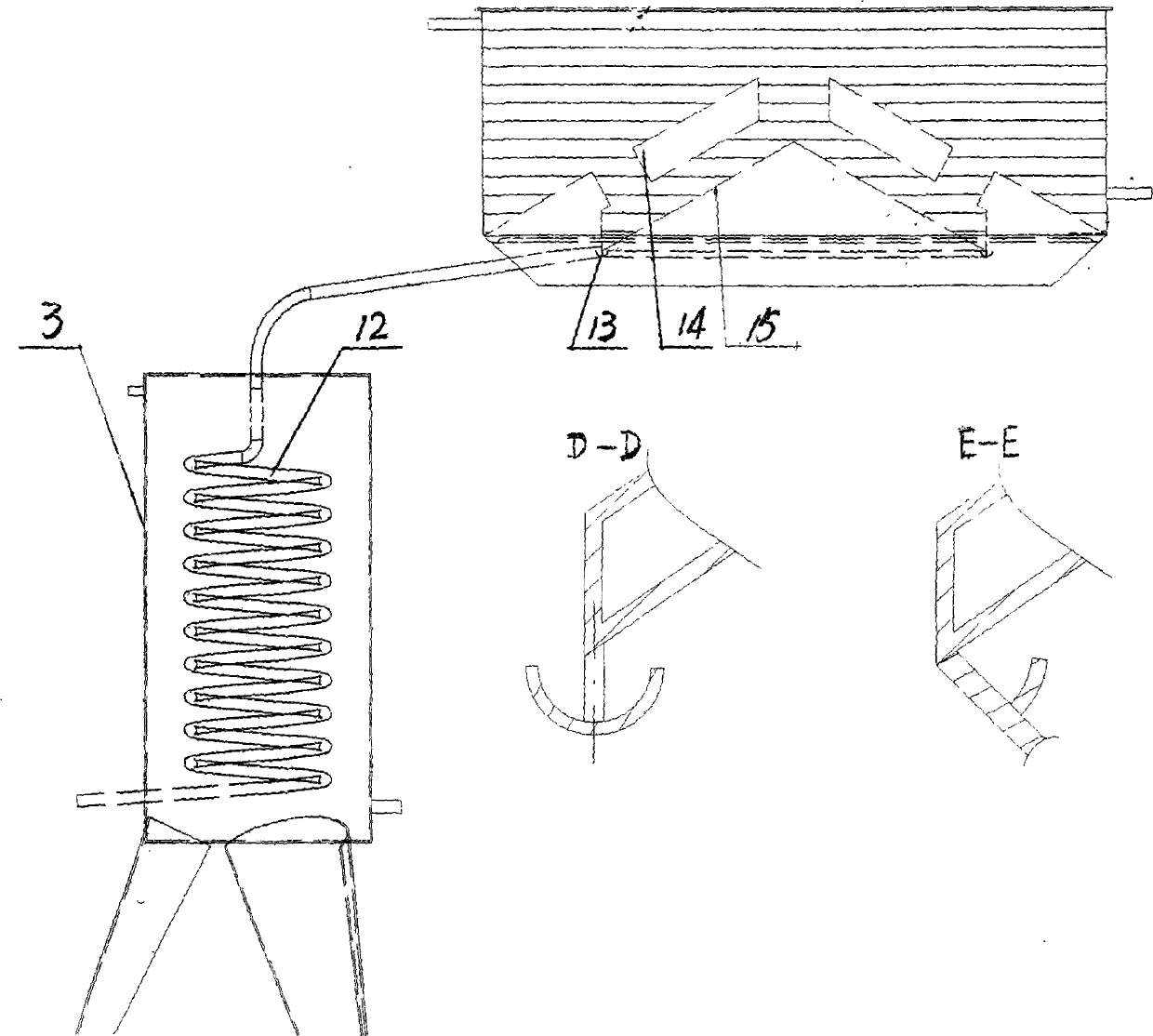

[0030] (1) The structure of the high-efficiency and energy-saving cooker is: five parallel heating tubes 5 at the upper end of the furnace 7 communicate with the "W" shaped pot bottom 6, and communicate with the water in the pot, that is, five heating tubes 5 parallel to each other full of water. Above the five heating pipes 5 parallel to each other, there are eight fire exhaust pipes 4 arranged on the top of the furnace 7, and communicate with the return air cavity 8 of the cooker through the "W" shaped pot bottom 6, that is, the return air furnace, the furnace The fire is discharged into the return air cavity through eight fire discharge pipes 4, and is discharged into the atmosphere through the chimney 1. In the middle of the air return cavity and the furnace 7, a water circle 2 is arranged below the "W" shaped pot bottom 6.

[0031] (2) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com