Integral disposal process of acid copper chloride etching waste liquid

A technology of etching waste liquid and copper chloride, which is applied in copper sulfate, photographic technology, chlorine/hydrogen chloride, etc., can solve the problems of poor economic benefits and high recycling costs, and achieve the goals of saving production costs, maximizing profits, and flexible operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

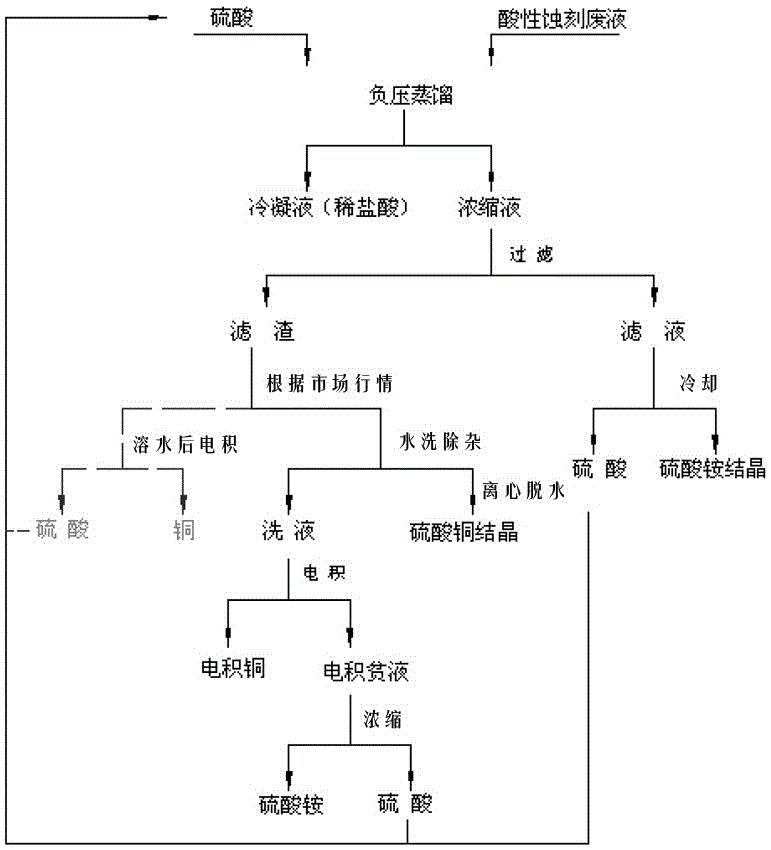

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0026] A comprehensive disposal process for acid copper chloride etching waste liquid, comprising the following steps in sequence:

[0027] (1) Recovery of hydrochloric acid

[0028] ① Add acidic etching waste liquid with copper content ≥ 9.5% into the enamel reaction kettle with insulation layer, then slowly add concentrated sulfuric acid, and stir at 50-60 rpm to form a mixed solution; the amount added is about 35% of the weight of the etching waste liquid. %, due to the addition of concentrated sulfuric acid, the exothermic temperature of the solution rises to 70-80°C;

[0029] Wherein, the concentration of the concentrated sulfuric acid is 99.8%; the addition of the concentrated sulfuric acid is 1.3 times of the theoretical value required for the complete reaction of the copper ion content and the sulfuric acid in the enamel reactor;

[0030] ② Tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com