Application of distillation and multi-stage molecular distillation technique in regeneration process for waste lubricant oil

A technology of molecular distillation and waste lubricating oil, applied in hydrocarbon distillation, petroleum industry, lubricating composition, etc., to achieve the effects of stable operation, low distillation temperature and short material residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

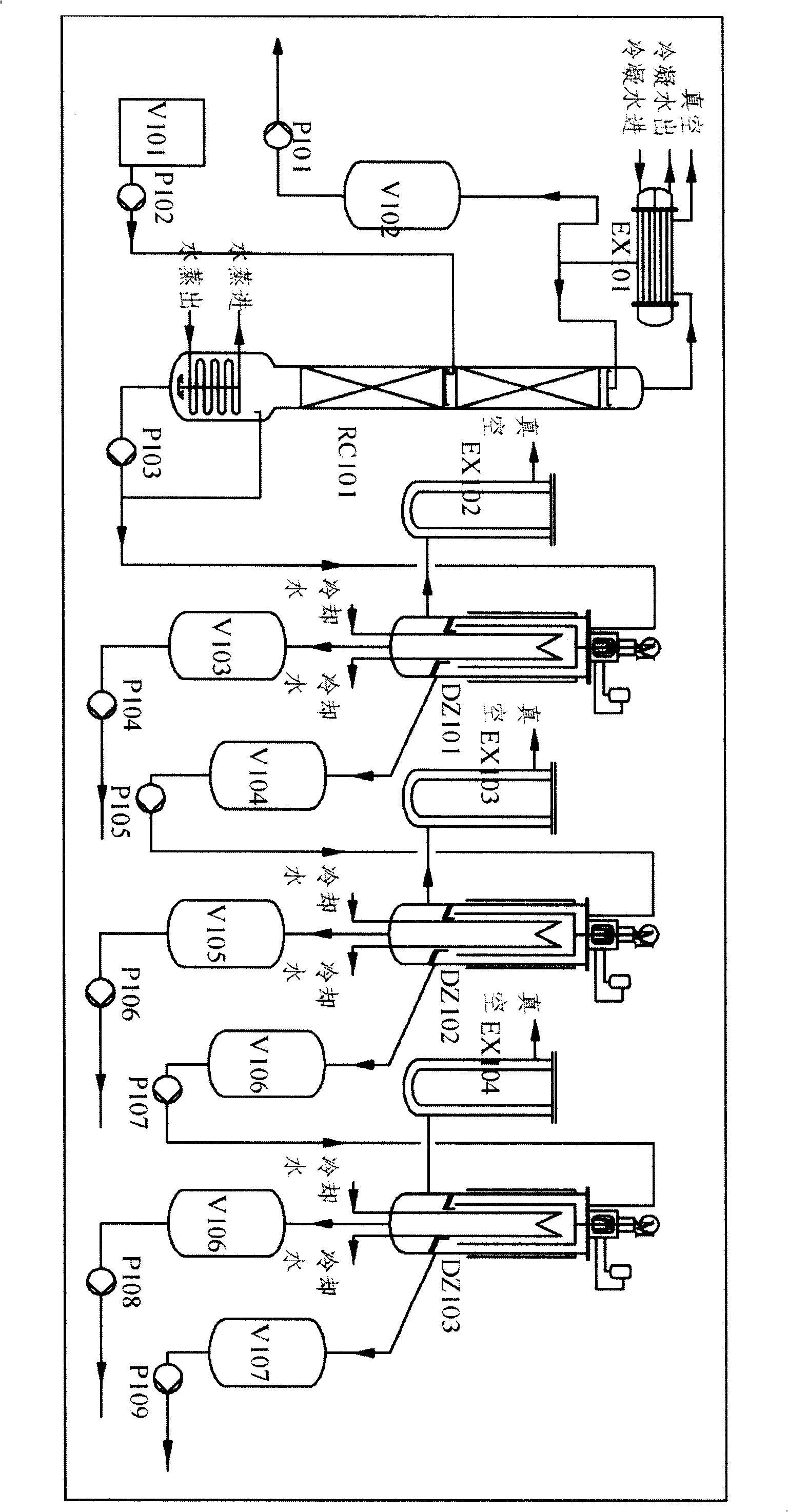

[0034] A three-stage molecular distillation process for regeneration of waste lubricating oil base oil, the main process of which is described as follows:

[0035] a. The waste lubricating oil stored in the waste lubricating oil storage tank V101 after pretreatment and degassing and drying is pumped into the RC101 through the primary feed pump P102 for rectification, and the light diesel oil component is separated.

[0036] b. The light diesel oil is condensed by the condenser EX101 and then enters the material temporary storage tank V102.

[0037] c. The heavy components after rectification are pumped into the first-stage wiped film molecular still DZ101 through the first-stage feed pump P103.

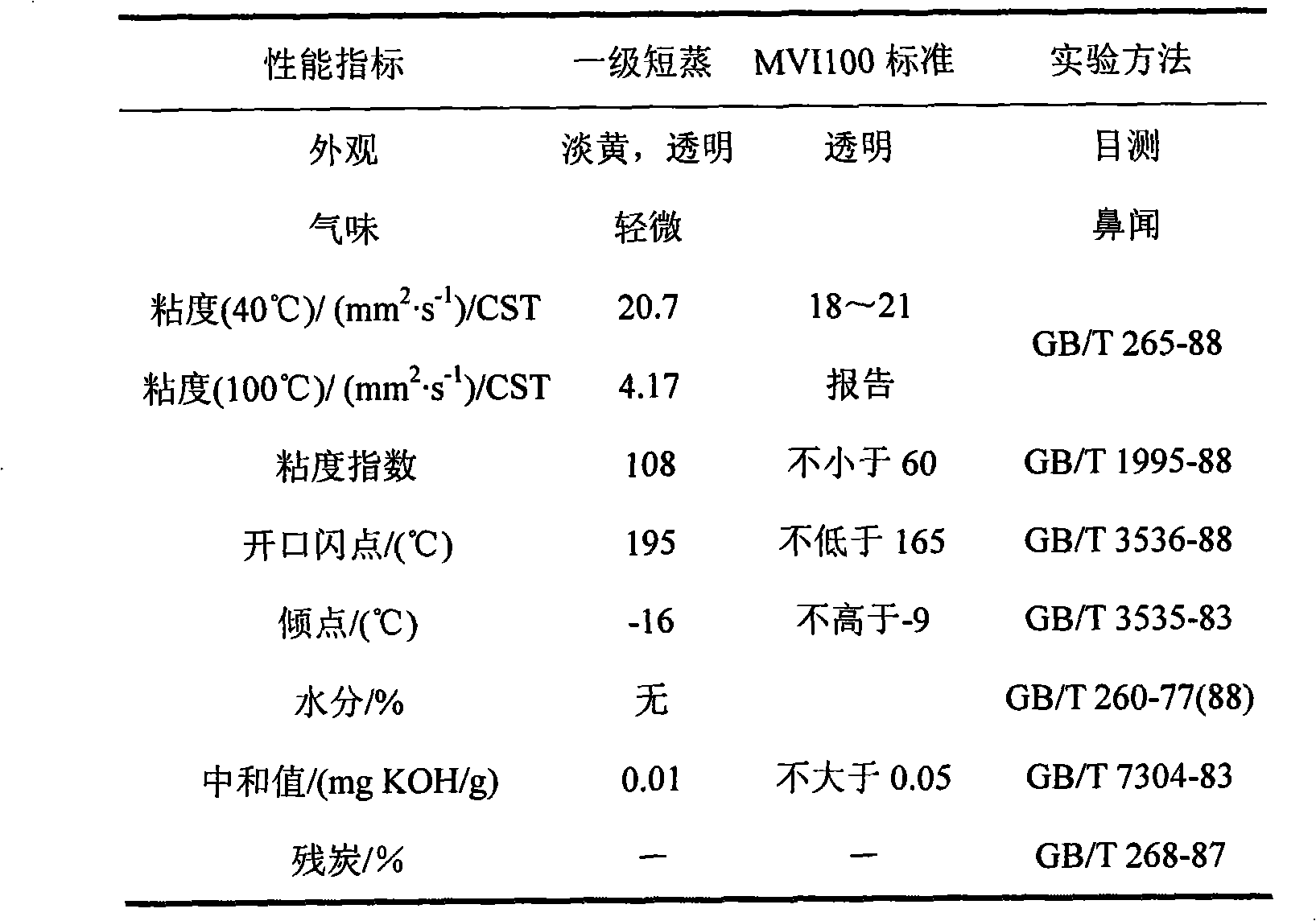

[0038] The first-stage molecular still has a distillation temperature of 200°C, a vacuum of 80Pa, a distillation distillation range of 370-450°C, and a discharge volume of 27%. The viscosity and flash point meet the technical specifications of MVI100 base oil.

[0039] d. The light l...

Embodiment 2

[0054] A secondary molecular distillation process for regeneration of waste lubricating oil base oil, the main process of which is described as follows:

[0055] a. The waste lubricating oil stored in the waste lubricating oil storage tank V101 after pretreatment and degassing and drying is pumped into the RC101 through the primary feed pump P102 for rectification, and the light diesel oil component is separated.

[0056] b. The light diesel oil is condensed by the condenser EX101 and then enters the material temporary storage tank V102.

[0057] c. The heavy components after rectification are pumped into the first-stage wiped film molecular still DZ101 through the first-stage feed pump P103.

[0058] The first-stage molecular still has a distillation temperature of 210°C, a vacuum of 80Pa, a distillation distillation range of 370-440°C, and a discharge volume of 51%. The viscosity and flash point meet the technical specifications of MVI200 base oil.

[0059] d. The light lub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com