Device of using negative-pressure circulating water to extract star anise oil

A technology of star anise oil and circulating water, which is applied in the directions of fat oil/fat production and fat generation, can solve problems such as extraction or chemical reaction that are difficult to industrialize, and achieve the effects of lowering distillation temperature, increasing yield and high product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

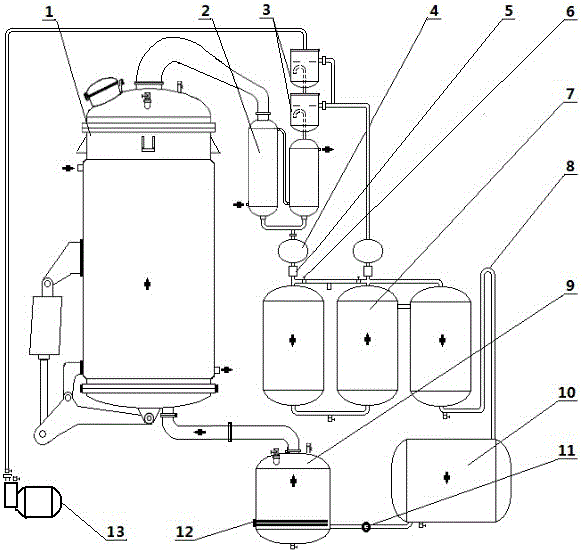

[0029] A device for extracting star anise oil with negative pressure circulating water is provided with a distillation tank 1, a condenser 2, an exhaust tank 3, an oil collector 4, an oil-water separator 7, a liquid collection tank 10, a steam boiler 9, and a vacuum device 13, The distillation tank 1, the condenser 2, the tail gas tank 3, the oil collector 4, the oil-water separator 7, the liquid collection tank 10, the steam pot 9, and the distillation tank 1 are sequentially connected in circulation; the described distillation tank 1 is a vertical A sandwich distillation tank, the lower end of the distillation tank 1 is provided with a slag unloading head, the slag unloading head is provided with a flower plate and a slag unloading mechanism, the described flower plate is arranged in the slag unloading head, and the slag unloading mechanism A hydraulic device and a lever mechanism are provided. One end of the hydraulic device is movably connected through a fixed ear fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com