Resin short path distiller and resin distillation process

A short-path distillation and rosin technology, applied in the field of rosin processing, can solve the problems of environmental impact and high energy consumption, and achieve the effects of small volume, no direct steam, and light rosin color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

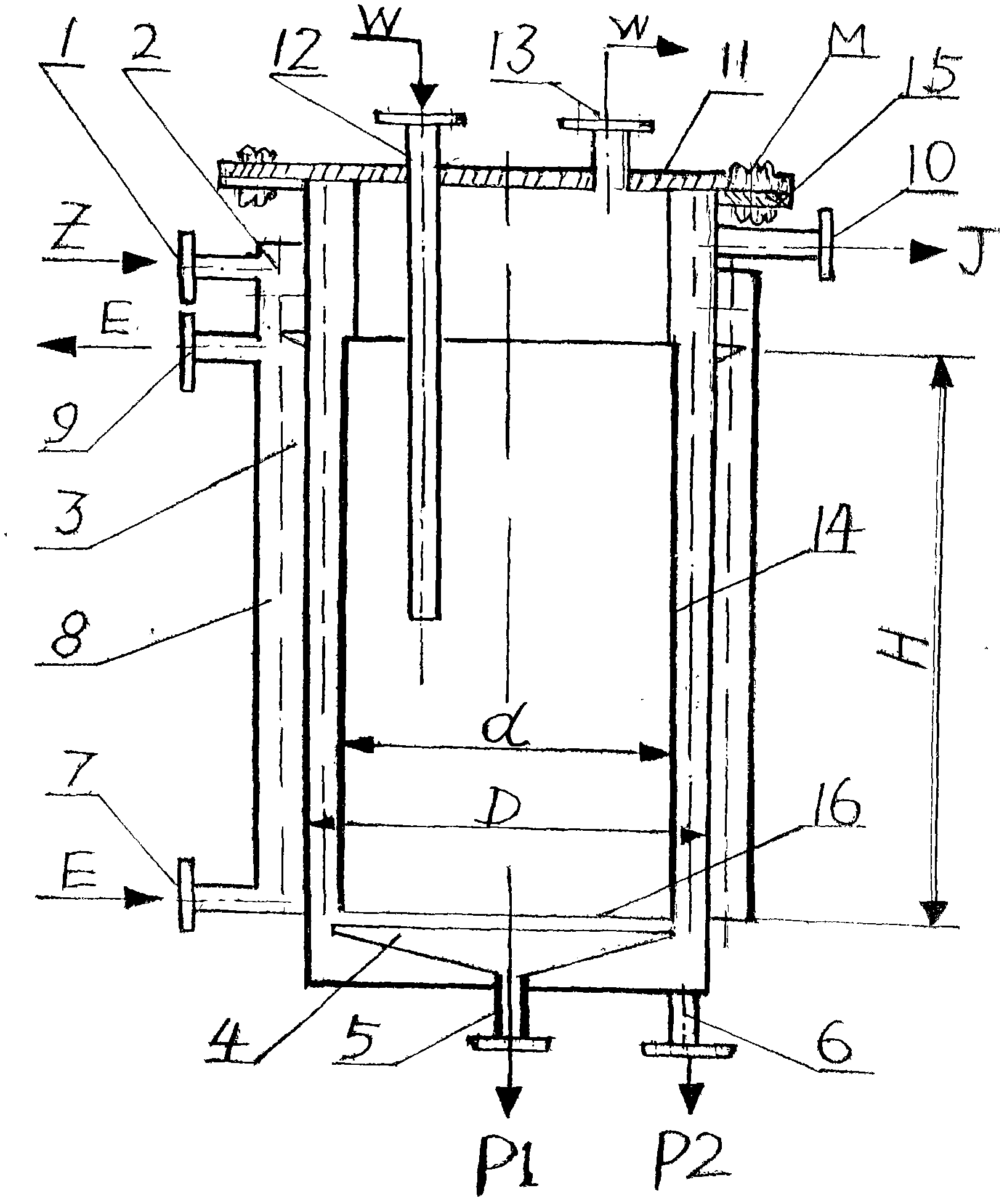

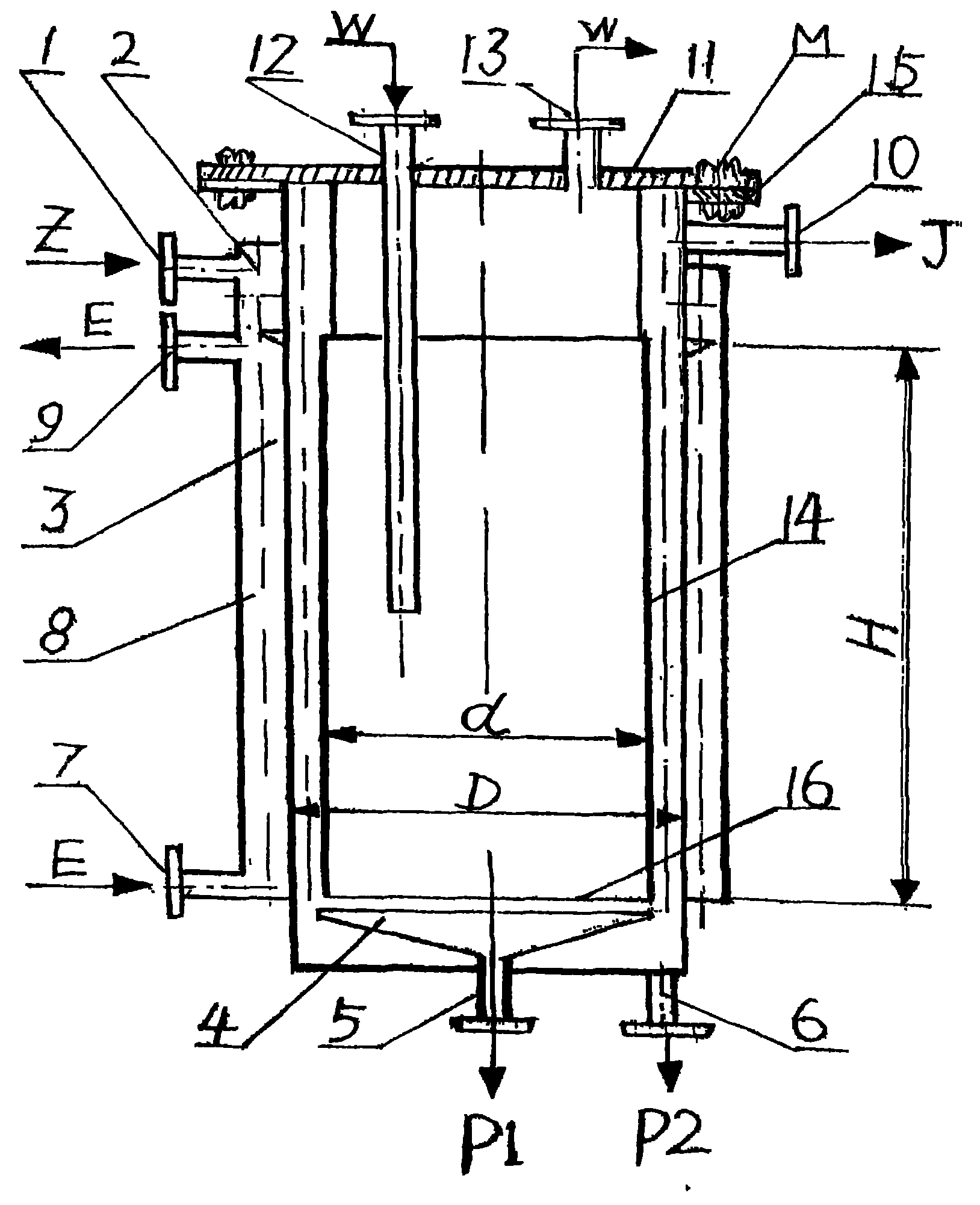

[0020] Producing 180 kilograms of pine rosin per hour below is an example to further illustrate the structure of the short-path rosin distiller of the present invention and the rosin distillation process thereof.

[0021] With reference to accompanying drawing, turpentine short-path distiller of the present invention is made up of molecular evaporation cylinder and molecular cooler made of metal, and described molecular evaporation cylinder is straight cylindrical shape, and the cylinder outer wall of molecular evaporation cylinder has heating jacket 8, in heating The lower part of the jacket 8 is provided with a heating source inlet 7, and the upper part is provided with a heat source outlet 9. There is a connecting flange 15 on the top of the molecular evaporation cylinder, and a vacuum pump interface 10, a rosin resin liquid inlet 1 and a turpentine resin liquid separator are arranged below the connecting flange 15. The ring 2 has a turpentine connection plate 4, a turpentin...

Embodiment 2

[0031] Rosin short-path still with an output of 500 kg of slash pine resin per hour and its resin distillation process

[0032] The boiling point of slash pine turpentine is slightly higher than that of southern Asian pine, and the data of the distiller are calculated as follows:

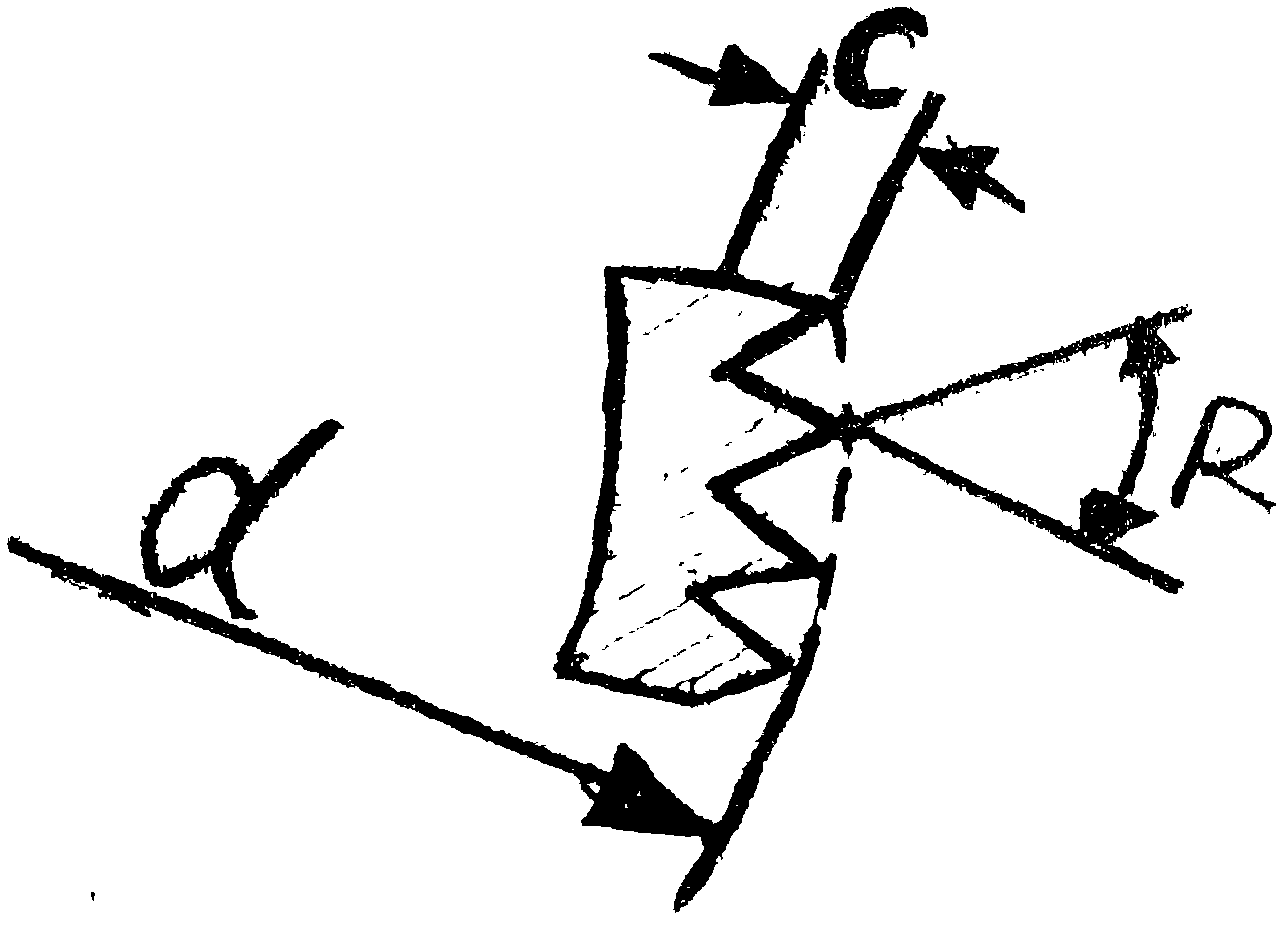

[0033] Molecular evaporation surface area is 3.47m 2 Therefore, the diameter D of the molecular evaporation surface is set as 550 mm, the vertical length H of the evaporation surface is set as 2000 mm, the diameter d of the addendum circle is set as 520 mm, the side length C of the tooth shape is set as 5 mm, and the tooth angle R is set as 60 °, the distance between the molecular cooling surface 14 and the molecular distillation surface 3 is 15 millimeters, with the data of above-mentioned setting, make the turpentine short-path distiller by the structure of embodiment one.

[0034] The preheating temperature of the rosin liquid is set at 135°C, the speed of the turpentine liquid supply system Z t...

Embodiment 3

[0037] Rosin short-path still with an output of 1000 kg of masson pine rosin per hour and its rosin distillation process

[0038] Masson pine turpentine has the highest boiling point, and the various data of the turpentine short-path distiller are calculated as follows:

[0039] Molecular evaporation surface area is 6.95m 2 Therefore, the diameter D of the molecular evaporation surface is set as 890 mm, the vertical length H of the molecular evaporation surface is set as 2500 mm, the diameter of the addendum circle d is set as 850 mm, the side length C of the tooth shape is set as 6 mm, and the tooth angle R is set as 60 °, the distance between the molecular cooling surface 14 and the molecular evaporation surface 3 is 20 millimeters, according to the data of above-mentioned setting, make the turpentine short-path distiller by the structure of embodiment one.

[0040] The preheating temperature of the turpentine resin liquid is set as 140°C, the speed of the turpentine liquid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com