Preparation method and applications of agilawood-type tobacco essence

A technology for tobacco flavor and agarwood essential oil, which is applied in the directions of essential oil/spice, fat production, etc., can solve the problems of loss of effective components, low product yield, poor aroma quality, etc., and achieves reduced damage, high product yield, and enhanced product quality. Elegant and comfortable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

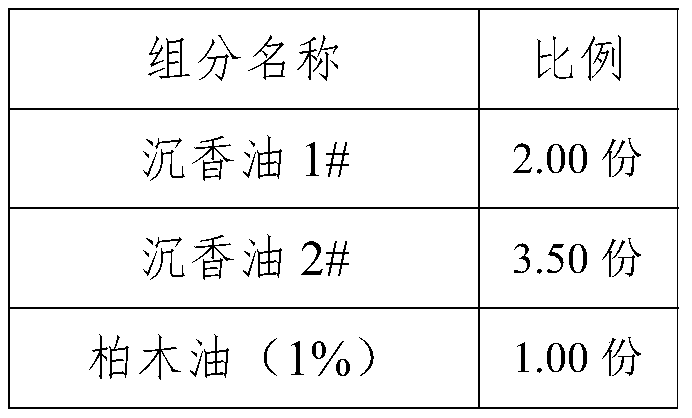

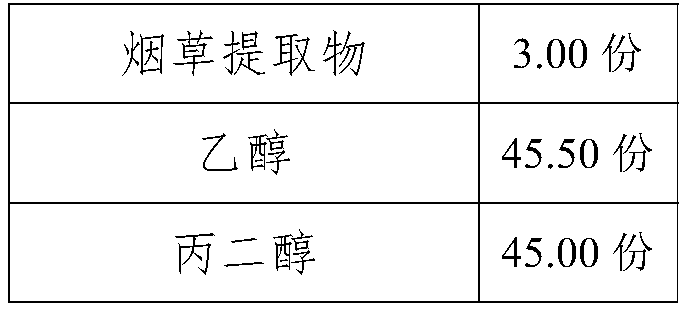

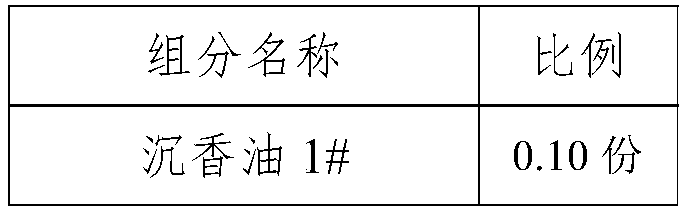

Embodiment 1

[0043] Agarwood is processed for impurity removal, drying (moisture content 12%) and crushing (60 meshes) for later use. Take by weighing 2 kg of crushed Agarwood, add 8 kg of ethanol with a mass fraction of 95% to carry out ultrasonic cell pulverization for 15 min (ultrasonic frequency 15 KHz, ultrasonic power 500 W, ultrasonic interval 5 s), and then drop into a volume of 30 L extraction tank. Add 95% ethanol to 20kg, reflux and extract twice, each time for 2 hours, the ratio of solid to liquid is 1:10, after the extraction is completed, release the extract and filter, combine the filtrate, centrifuge, concentrate under reduced pressure to remove the solvent to obtain the initial extract of agarwood (leaf extract) The paste yield was 40%). After heating the primary extract of agarwood to a fluid state, it is added to a molecular distillation feeder for three-stage molecular distillation. Yield of primary molecular distillation separation product: 26%, separation temperature...

Embodiment 2

[0048] Agarwood is processed for impurity removal, drying (moisture content 12%) and crushing (particle size 80 mesh) for subsequent use. Weigh 2 kg of pulverized Agarwood yunnanensis, add 10 kg of ethanol with a mass fraction of 90% to carry out ultrasonic cell pulverization for 20 min (ultrasonic frequency 15KHz, ultrasonic power 600W, ultrasonic interval 5s), and then put it into a 30L extraction tank. Add 90% ethanol to 24kg, reflux and extract twice, each time for 2 hours, the ratio of solid to liquid is 1:12, after the extraction is completed, release the extract, filter and combine the filtrate twice, centrifuge, concentrate under reduced pressure to remove the solvent to obtain the initial extraction of agarwood Cream (extract yield is 40.2%). After heating the primary extract of agarwood to a fluid state, it is added to a molecular distillation feeder for three-stage molecular distillation. Yield of primary molecular distillation separation product: 22%, separation t...

Embodiment 3

[0053] Agarwood is processed for impurity removal, drying (moisture content 12%) and crushing (60 meshes) for later use. Take by weighing 2kg of crushed Agarwood, add 12kg of ethanol with a mass fraction of 95% and carry out ultrasonic cell pulverization for 15min (ultrasonic frequency 15KHz, ultrasonic power 500W, ultrasonic interval 5s,) and put it into a 30L extraction tank with a volume of Add 95% ethanol to 20kg, reflux and extract twice, each time for 2 hours, the ratio of solid to liquid is 1:10, after the extraction is completed, release the extract and filter, combine the filtrate, centrifuge, concentrate under reduced pressure to remove the solvent to obtain the initial extract of agarwood (leaf extract) The paste yield was 42.2%). After heating the primary extract of agarwood to a fluid state, it is added to a molecular distillation feeder for three-stage molecular distillation. Yield of primary molecular distillation separation product: 23%, separation temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com