Extraction equipment for fragrant plant essential oil and headspace volatile

A technology for aromatic plants and extraction equipment, which is applied in the directions of essential oils/spices, fat production, etc., can solve the problems of low oil yield and difficulty in recovering top fragrance, and achieves high oil yield, improved equipment utilization, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

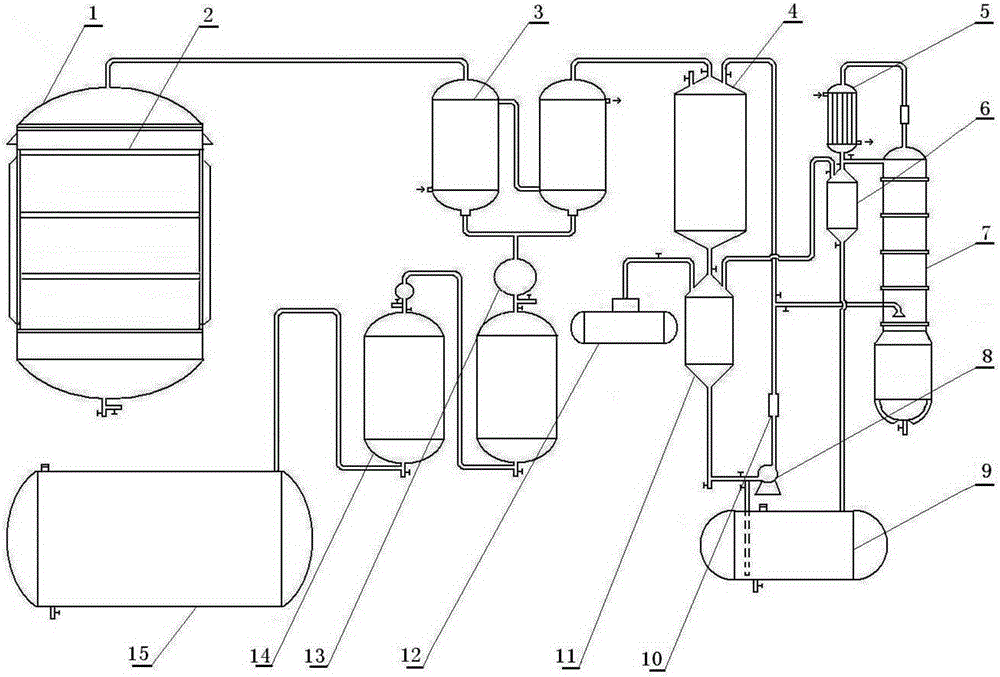

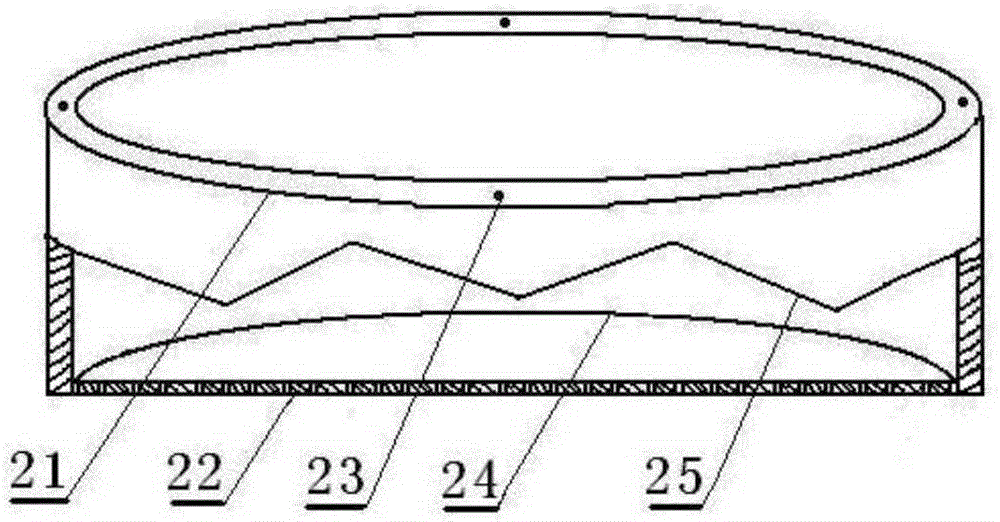

[0030] as attached figure 1 And attached figure 2 As shown, a kind of aromatic plant essential oil and head fragrance extraction equipment includes distillation tank 1, condenser I3, oil-water separator 14, adsorber 4, liquid pump 8 and rectification tower 7; described distillation tank 1 is equipped with The steaming basket 2, the steaming basket 2 includes a basket body 25, a suspension ring 21 and a flower plate I24. The top of the basket body 25 is provided with a suspension ring 21, and the bottom of the basket body 25 is provided with a flower plate I24. The flower plate I24 is evenly distributed with small holes 22, and the lifting ring 21 is evenly provided with two hoisting holes 23; the condenser I3 is connected to the steam outlet on the top of the distillation tank 1 through a steam guide tube, and the oil-water separator 14 is connected to the condenser The liquid guide pipe at the bottom of I3 is connected, and a spherical oil separator 13 is provided between t...

Embodiment 2

[0032] as attached figure 1 And attached figure 2As shown, a kind of aromatic plant essential oil and head fragrance extraction equipment, including distillation tank 1, secondary condenser I3, secondary oil-water separator 14, adsorber 4, liquid pump 8 and rectification tower 7; described distillation tank 1. There is a steaming basket 2 inside. The steaming basket 2 includes a basket body 25, a suspension ring 21 and a flower plate I24. The top of the basket body 25 is provided with a suspension ring 21, and the bottom of the basket body 25 is provided with a flower plate I24. The flower plate I24 mentioned above has small holes 22 evenly distributed, and the lifting ring 21 is evenly equipped with two hoisting holes 23; The primary oil-water separator 14 is connected to the liquid guide pipe at the bottom of the secondary condenser I3, and two spherical oil separators 13 are arranged between the secondary condenser I3 and the secondary oil-water separator 14, and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com