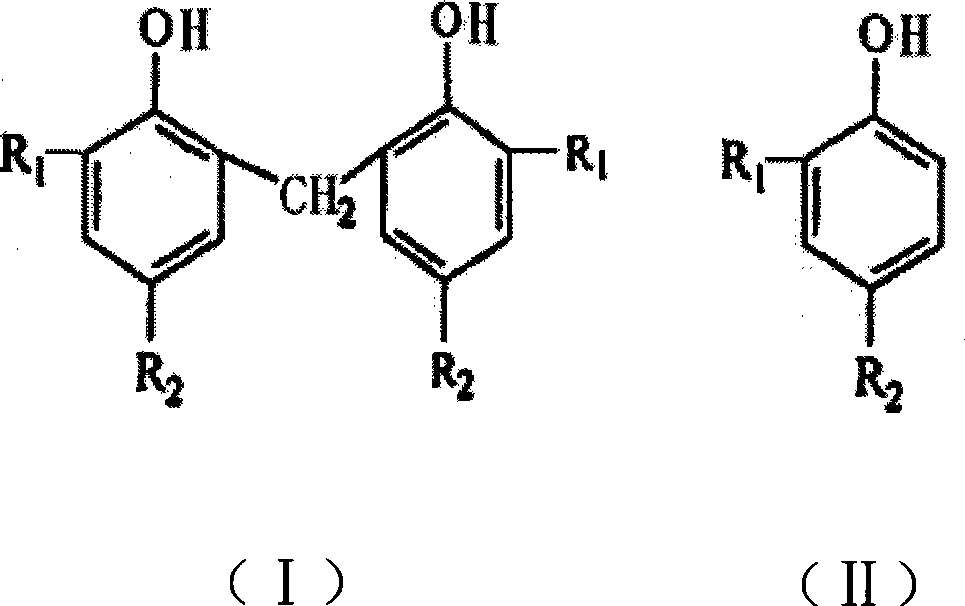

Preparation method for organic phosphate nucleating agent

A technology of organic phosphate and organic phosphate, applied in organic chemistry, phosphorus organic compounds, chemical instruments and methods, etc., can solve the problems of low nucleating agent yield, high solvent toxicity, poor solubility, etc., and achieve reaction efficiency High, easy solvent recovery, strong solvency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

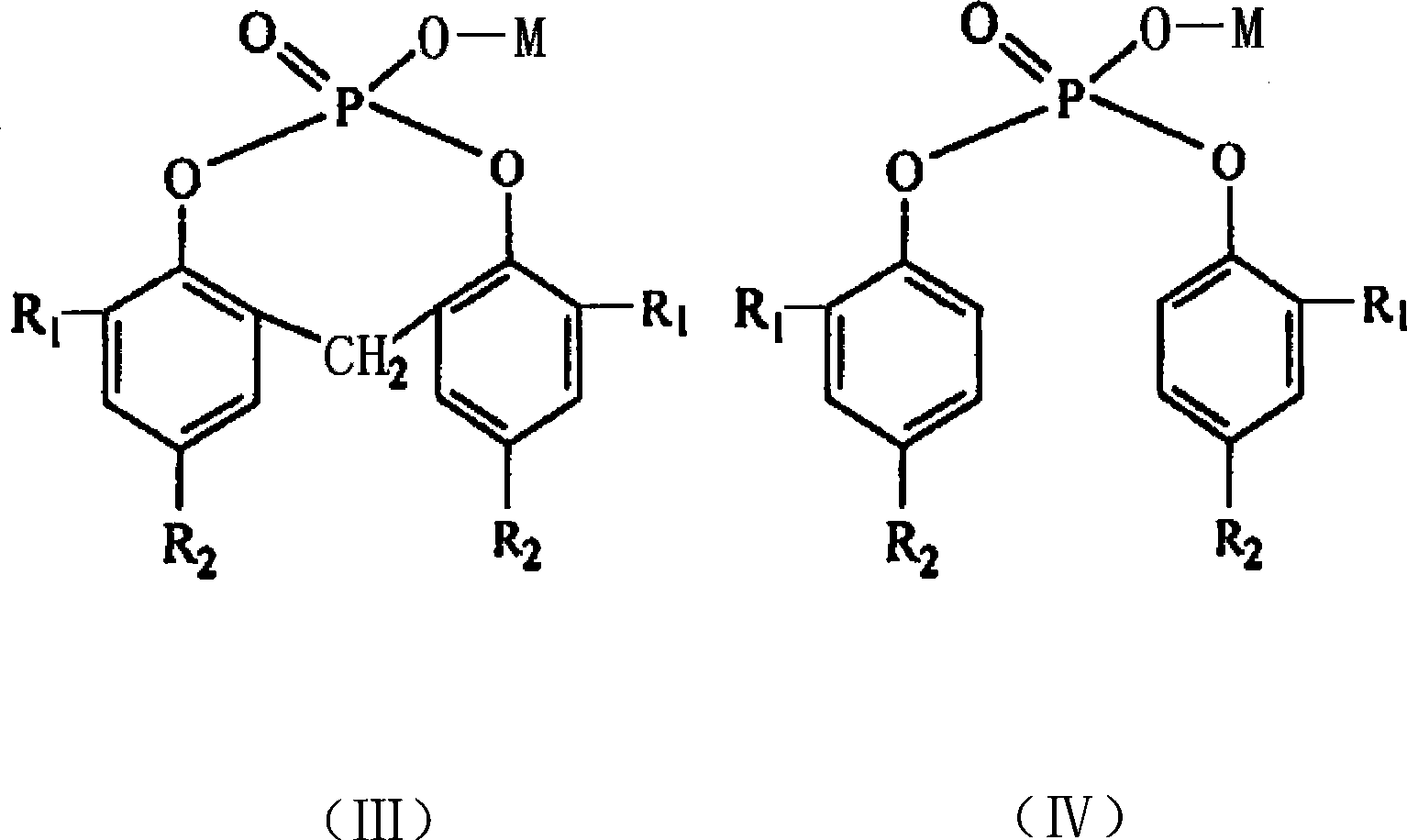

[0052] Add 2,2'-methylene-bis(4,6-di-tert-butylphenol) 42.4g, dichloromethane 160ml and triethylamine 50ml into the reaction flask, stir until the solid is fully dissolved, and slowly Slowly add 20ml of phosphorus oxychloride, and react at room temperature for 12 hours after the dropwise addition; then add 150ml of water and stir for 1.5hr, then evaporate the solvent, filter and wash with water to obtain a solid product, purify the solid product with ethanol, remove the liquid phase, and dry Afterwards, 48.6 g of a white solid was obtained, which was the intermediate product 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)phosphate, and the yield of the intermediate product was 99.8%.

[0053] Then dissolve the intermediate product in a mixture of acetone and water, add aqueous sodium hydroxide solution to form a salt and neutralize it, and distill off the acetone to obtain a white solid product. After filtering, wash with deionized water until the pH value is neutral. After heati...

Embodiment 2

[0055] Add 42.4g of 2,2'-methylene-bis(4,6-di-tert-butylphenol), 150ml of dibromomethane and 45ml of triethylamine into the reaction flask, stir until the solid is fully dissolved, and slowly Add 20ml of phosphorus oxychloride, react at room temperature for 12 hours after the dropwise addition; then add 150ml of water and stir for 1.5hr, then evaporate the solvent, filter and wash with water to obtain a solid product, purify the solid product with ethanol, remove the liquid phase, and dry 48.3 g of white solid was obtained, which was the intermediate product 2,2'-methylene-bis(4,6-di-tert-butylphenoxy)phosphate, and the yield of the intermediate product was 99.4%.

[0056] Then dissolve the intermediate product in a mixture of acetone and water, add aqueous sodium hydroxide solution to form a salt and neutralize it, and distill off the acetone to obtain a white solid product. After filtering, wash with deionized water until the pH value is neutral. After heating and drying, 46...

Embodiment 3

[0058] Add 42.4g of 2,2'-methylene-bis(4-methyl-6-tert-butylphenol), 170ml of chloroform and 52ml of triethylamine into the reaction flask, stir until the solid is fully dissolved, and Slowly add 22ml of phosphorus oxychloride, and react at room temperature for 12 hours after the dropwise addition; then add 150ml of water and stir for 1.5hr, then evaporate the solvent, filter and wash with water to obtain a solid product, purify the solid product with ethanol, and remove the liquid phase , to obtain 49.6g of white solid after drying, which is the intermediate product 2,2'-methylene-bis(4-methyl-6-di-tert-butylphenoxy) phosphate, and the yield of the intermediate product is 99% %.

[0059] Then dissolve the intermediate product in a mixture of acetone and water, add aqueous sodium hydroxide solution to form a salt and neutralize it, and distill off the acetone to obtain a white solid product. After filtering, wash with deionized water until the pH value is neutral. After heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com