Rosin production technology process

A production process and technology of rosin, which is applied in the field of rosin production, can solve the problems that the product quality of rosin ester or modified rosin ester cannot meet the requirements, cannot meet the requirements of industrialization, and the quality of rosin and turpentine is not high, so as to improve the melting effect, The effect of shortening the melting time and narrowing the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples. It should be noted that the examples do not constitute a limitation to the protection scope of the present invention.

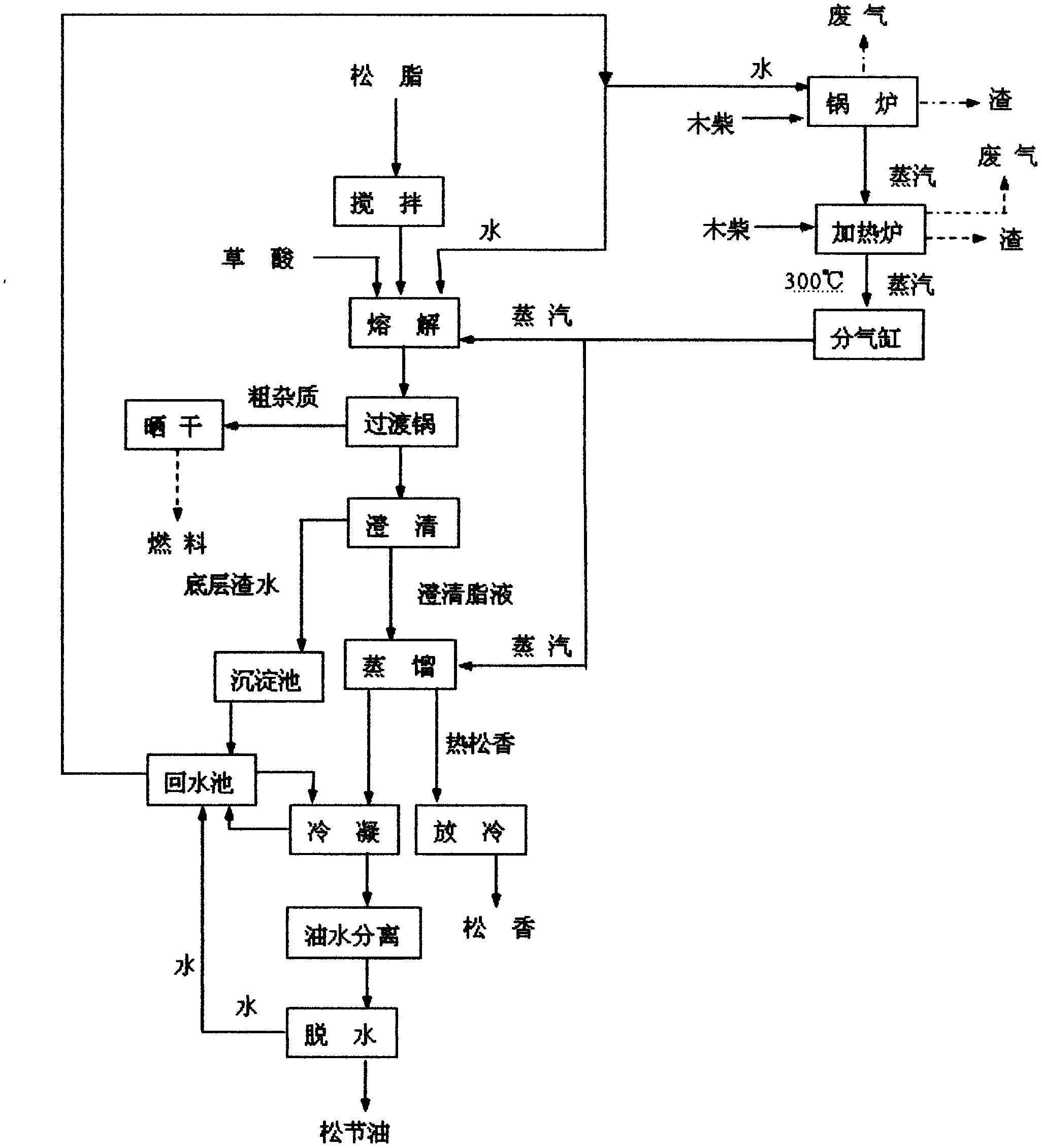

[0021] Rosin production process method, as shown in Figure 1, its step comprises:

[0022] (1) At first, the turpentine in the fat storage tank is transported to the melting pot through a screw conveyor, and the conveying process is also a stirring process, and part of the massive turpentine is pulverized, thereby improving the speed and efficiency of turpentine dissolution;

[0023] (2) inject water, turpentine and oxalic acid in described melting pot, wherein said turpentine: water: the weight ratio of turpentine is 3: 1.5: 1, and oxalic acid is thrown in according to the 2‰ ratio of turpentine weight.

[0024] (3) Heat the melting pot. When the temperature of the fat liquid reaches about 110°C, the rosin is basically fully melted.

[0025] (4) Use 1-2kg / cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com