Plastic material melting equipment

A technology for melting equipment and plastics, which is applied in the field of plastic material melting equipment, and can solve problems such as complex structure, unsatisfactory effect, and uneven heating of plastic materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

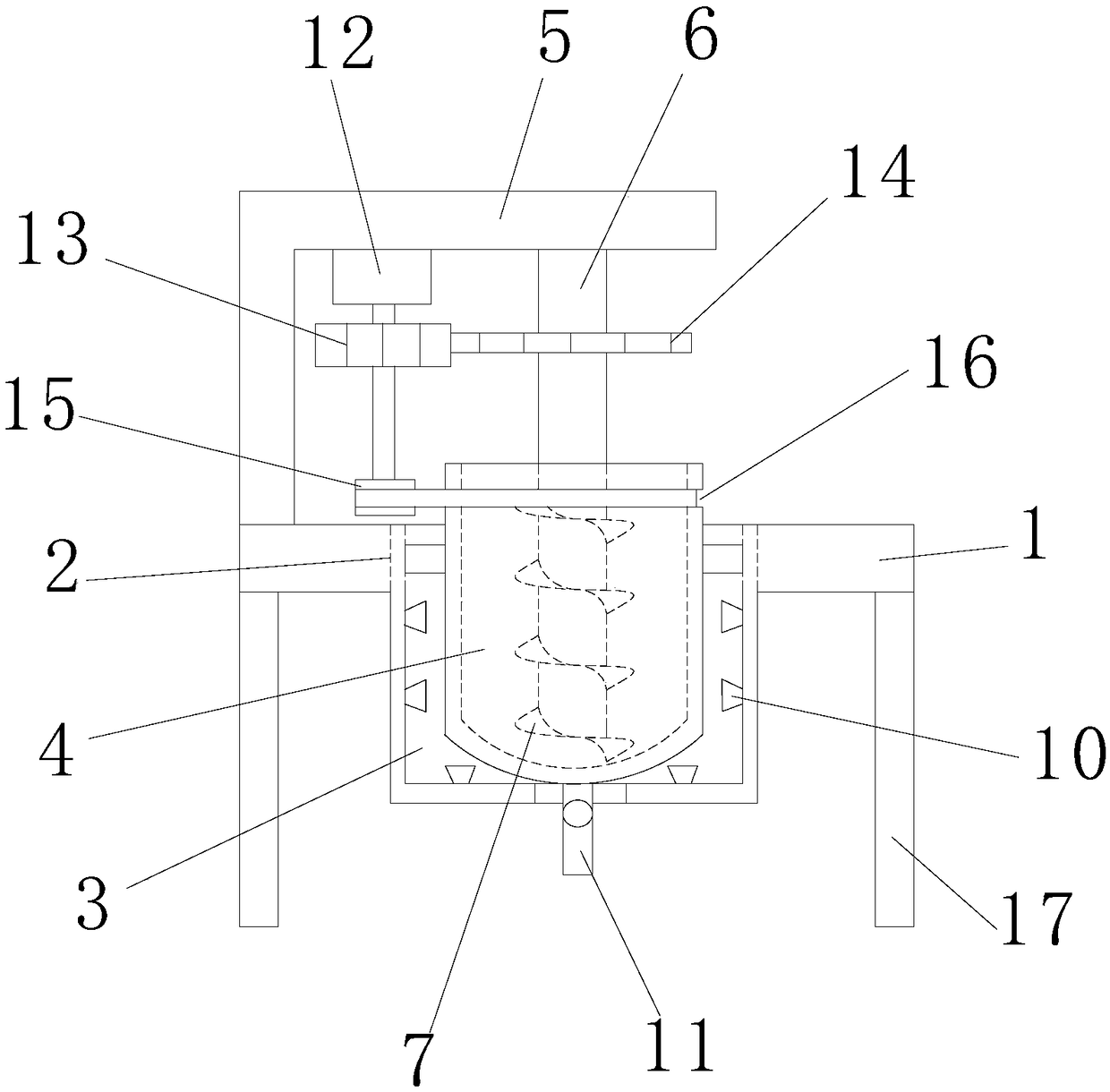

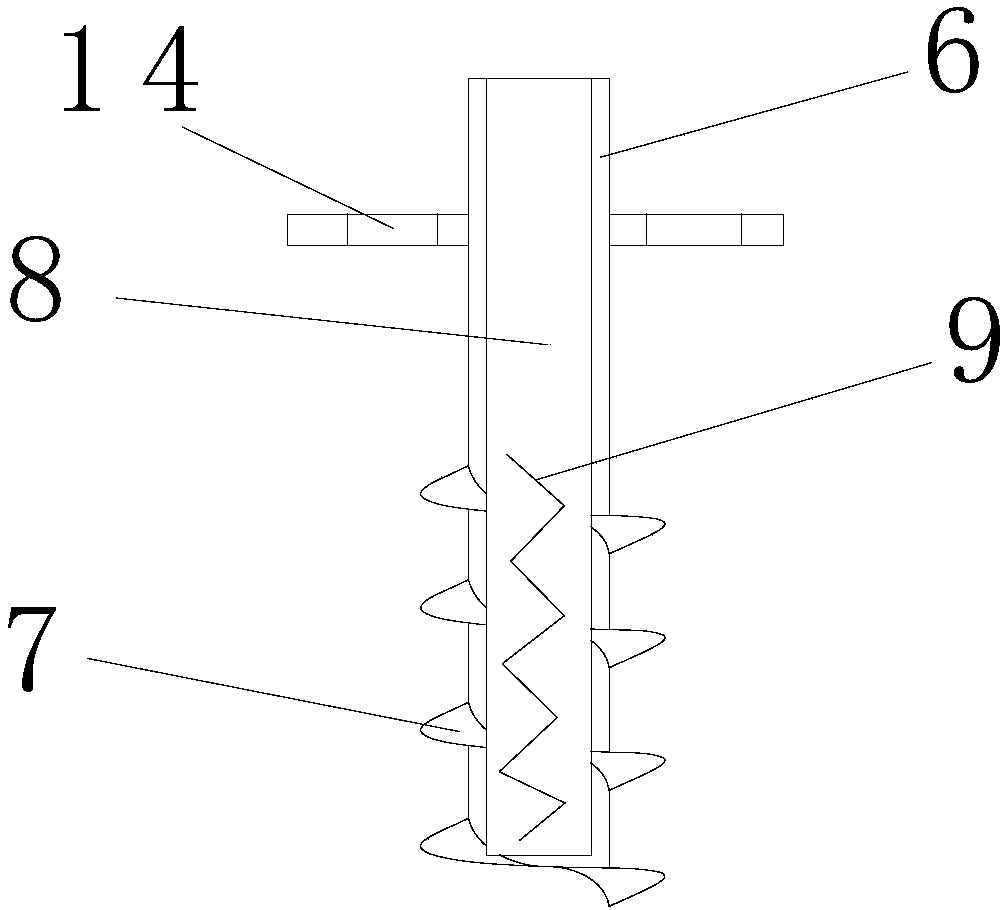

[0016] refer to figure 1 , 2 , a plastic material melting equipment of the present invention, comprising a workbench 1, an installation port 2, a heating box 3, a material box 4, a frame 5, a stirring shaft 6, a stirring blade 7, an installation groove 8, a heating wire 9, and a torch 10 , discharge pipe 11, motor 12, driving gear 13, driven gear 14, belt pulley 15, belt groove 16 and support leg 17, said workbench 1 is provided with installation port 2, and said installation port 2 is fixedly provided with A heating box 3, in which a material box 4 is rotatably provided by a bearing, a frame 5 is fixedly arranged on the top of the workbench 1, and a vertical stirring shaft 6 is arranged in the material box 4, The upper end of the stirring shaft 6 is rotatably connected with the frame 5 through a bearing, and the external portion of the stirring shaft 6 positioned at the inside of the material box 4 is integrally provided with a stirring blade 7, and the top of the stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com