Patents

Literature

41results about How to "Heating evenly and comprehensively" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

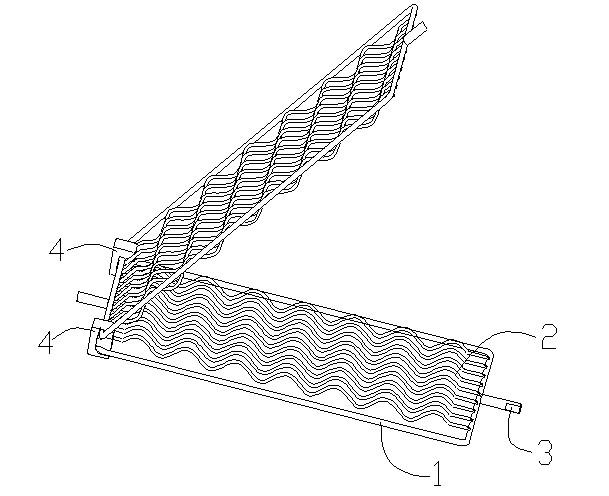

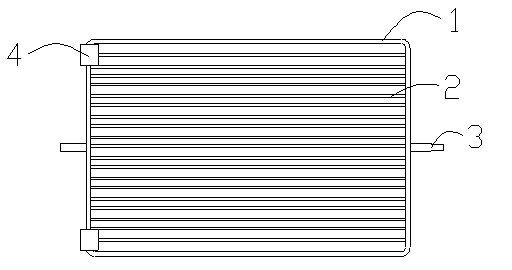

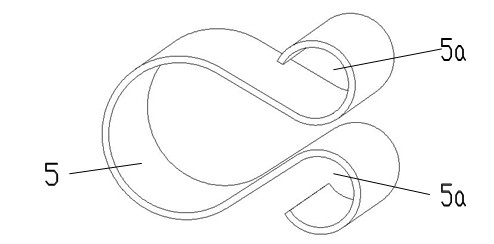

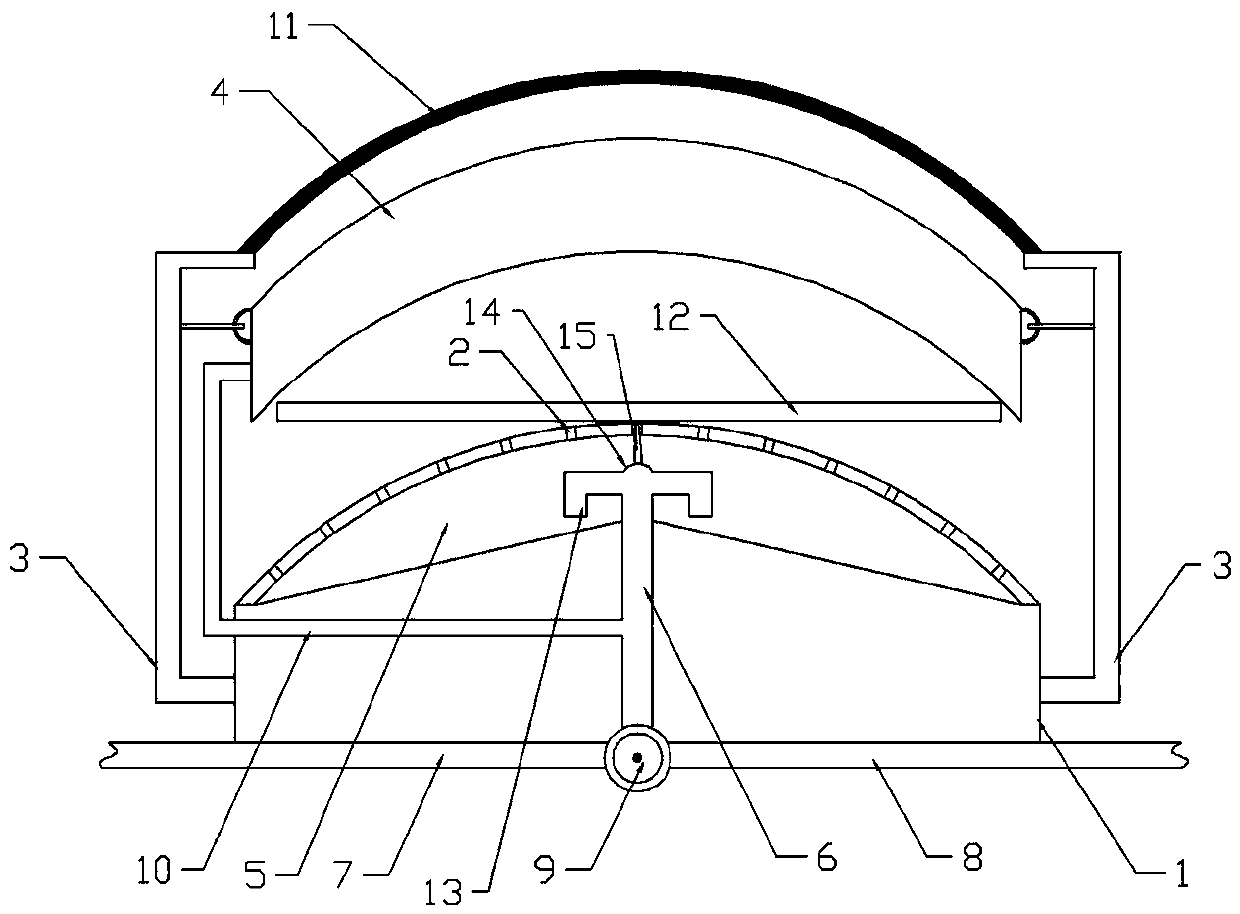

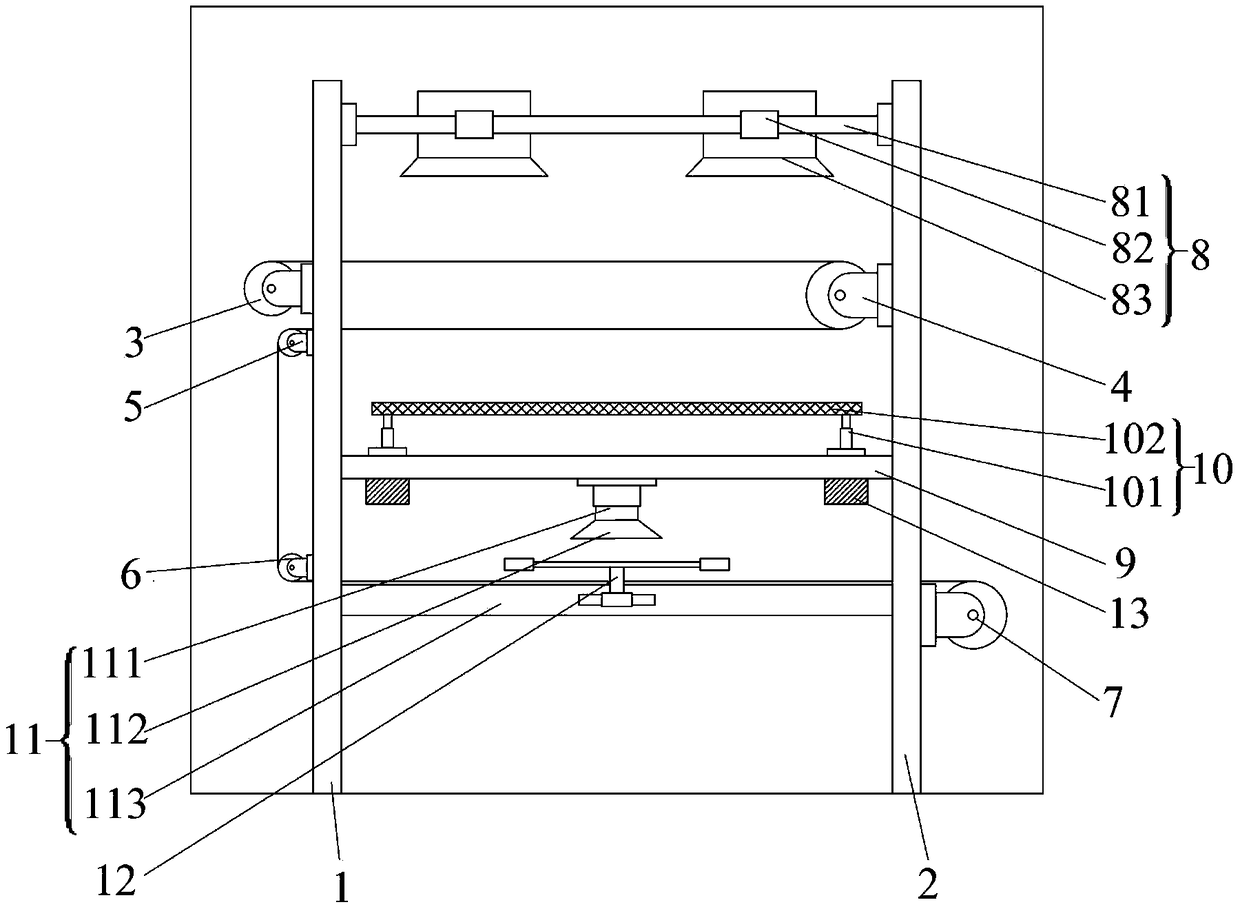

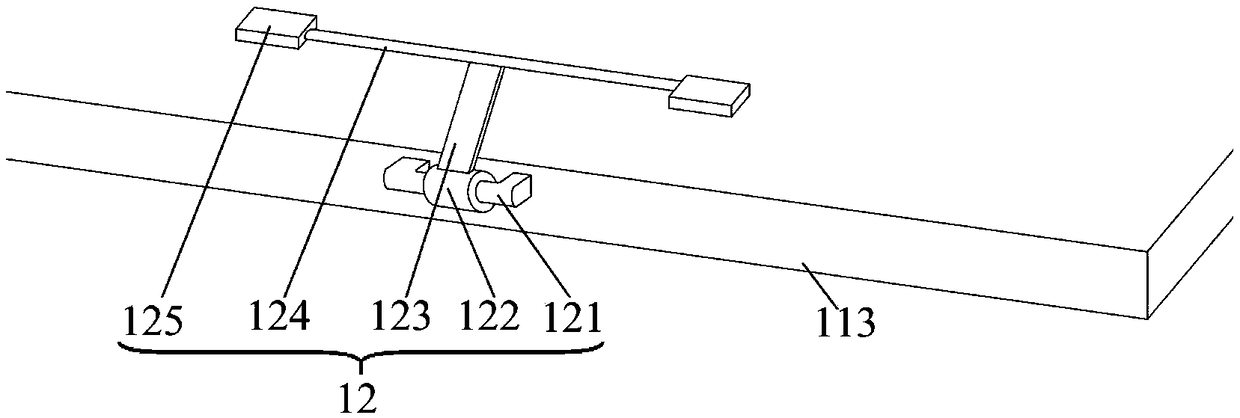

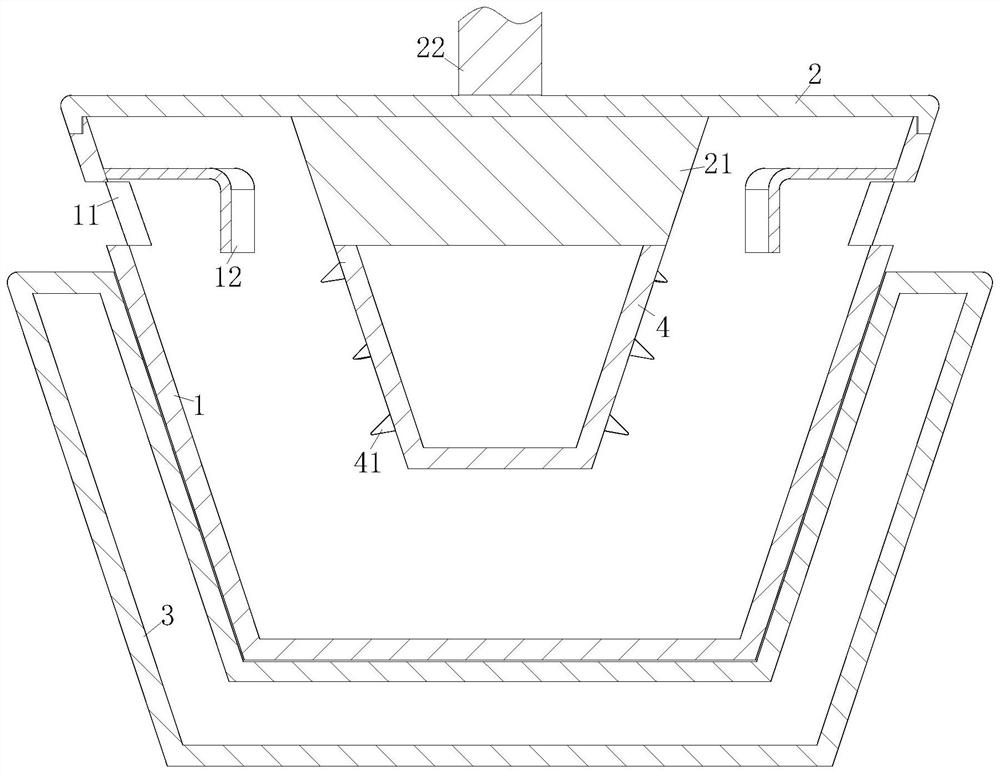

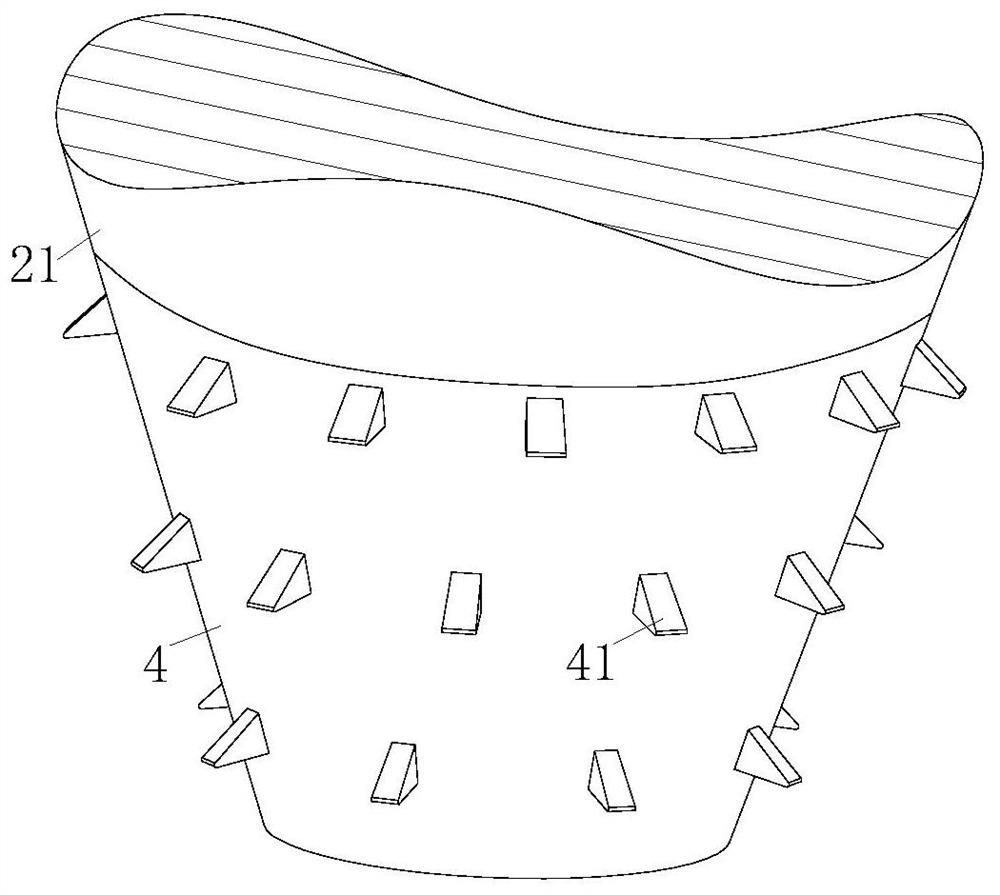

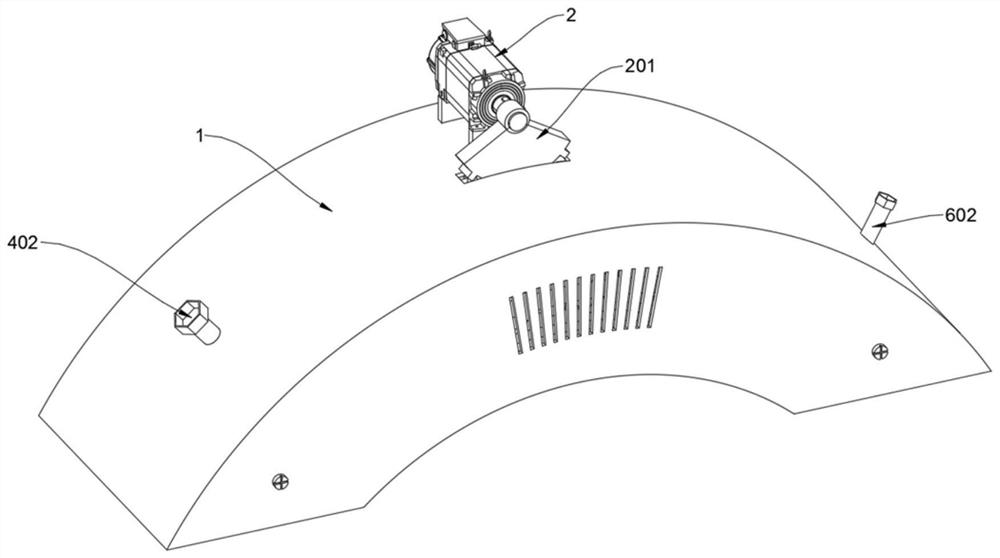

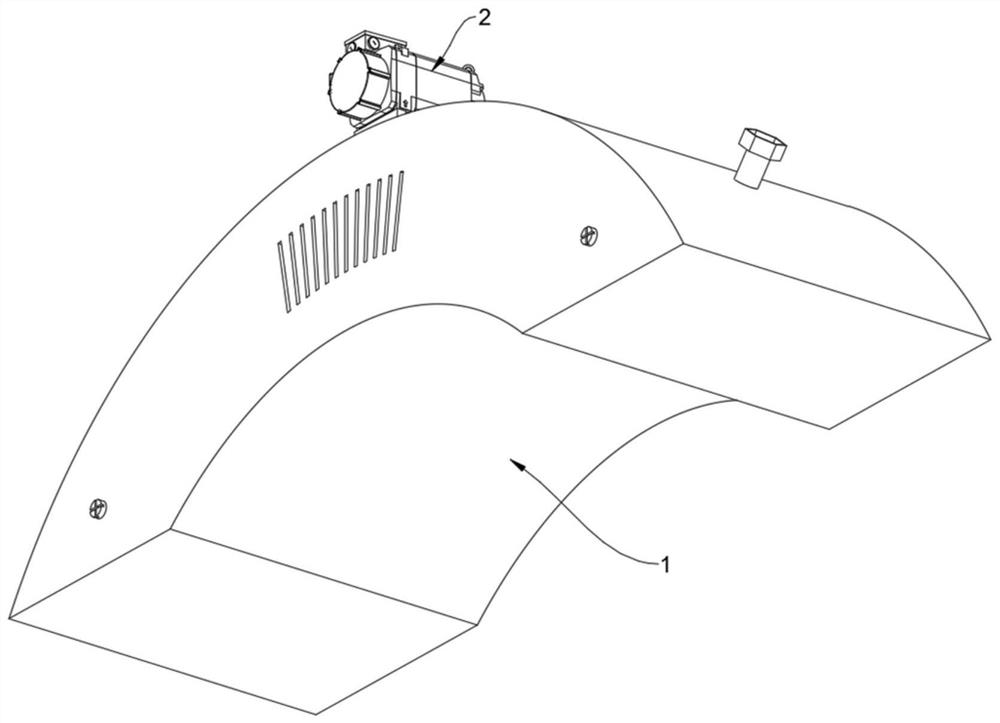

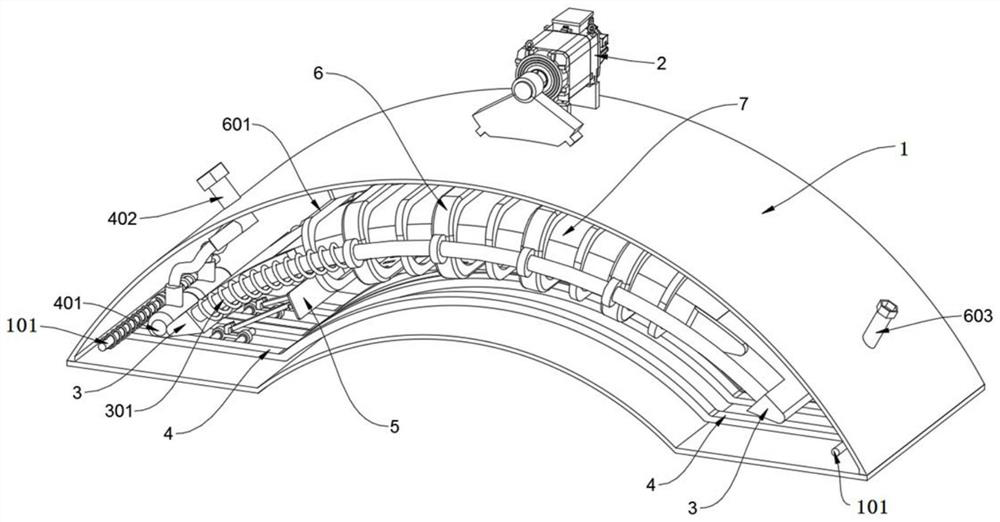

Rotatable roasting supporter

The invention discloses a rotatable roasting supporter. The roasting supporter comprises roasting boards formed by arranging a grill frame and multiple roasting anvil bars in the roasting frame, wherein the roasting boards are provided with an upper layer and a lower layer, and the two layers of roasting boards are movably connected with each other, so that the two layers of roasting boards can be unfolded and folded; and two opposite sides of the grill frame are provided with rotating shafts. When the roasting frame is used, food is fixed between the two layers of the roasting frame, the rotating shaft can be connected with a rotating motor, and the roasting frame is driven to rotate for roasting by the motor, so that the food can rotate at a constant speed on the roasting frame and be heated completely and uniformly at the angle of 360 degrees, the roasting function can be improved comprehensively, the roasting effect can be strengthened, and the operation can be simplified; simultaneously, the roasting frame can ensure that the relative position between the two layers of roasting boards is stable, is difficult to deform, is safely used, can be used independently, can be used in all types of roasting equipment, and has a wide application range.

Owner:WHIRLPOOL CHINA

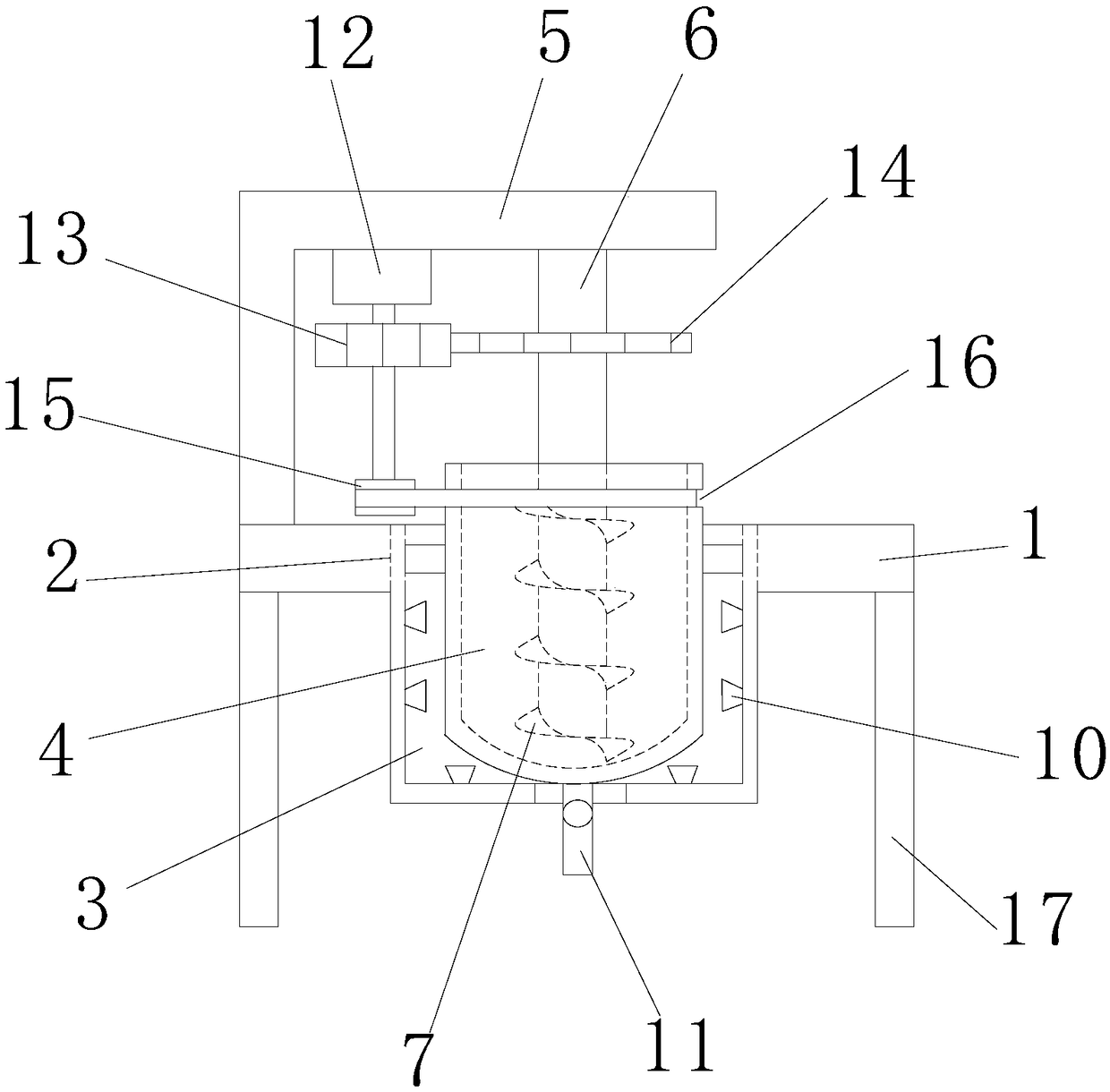

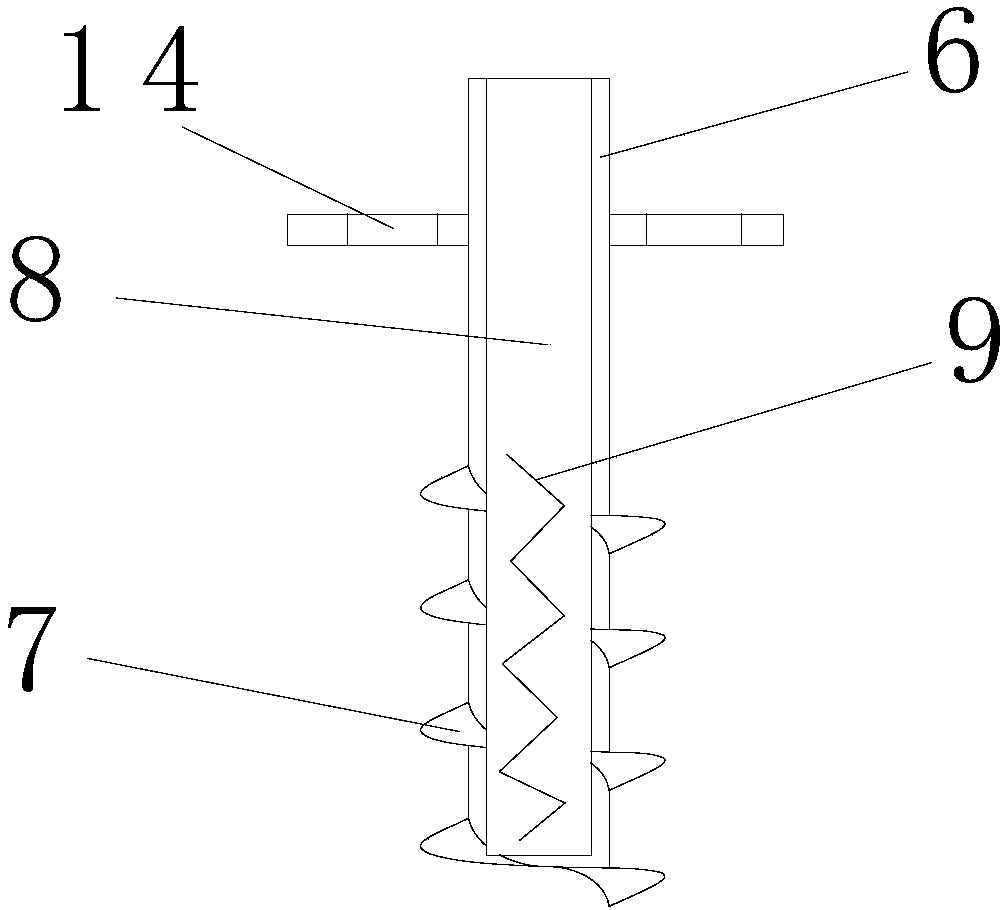

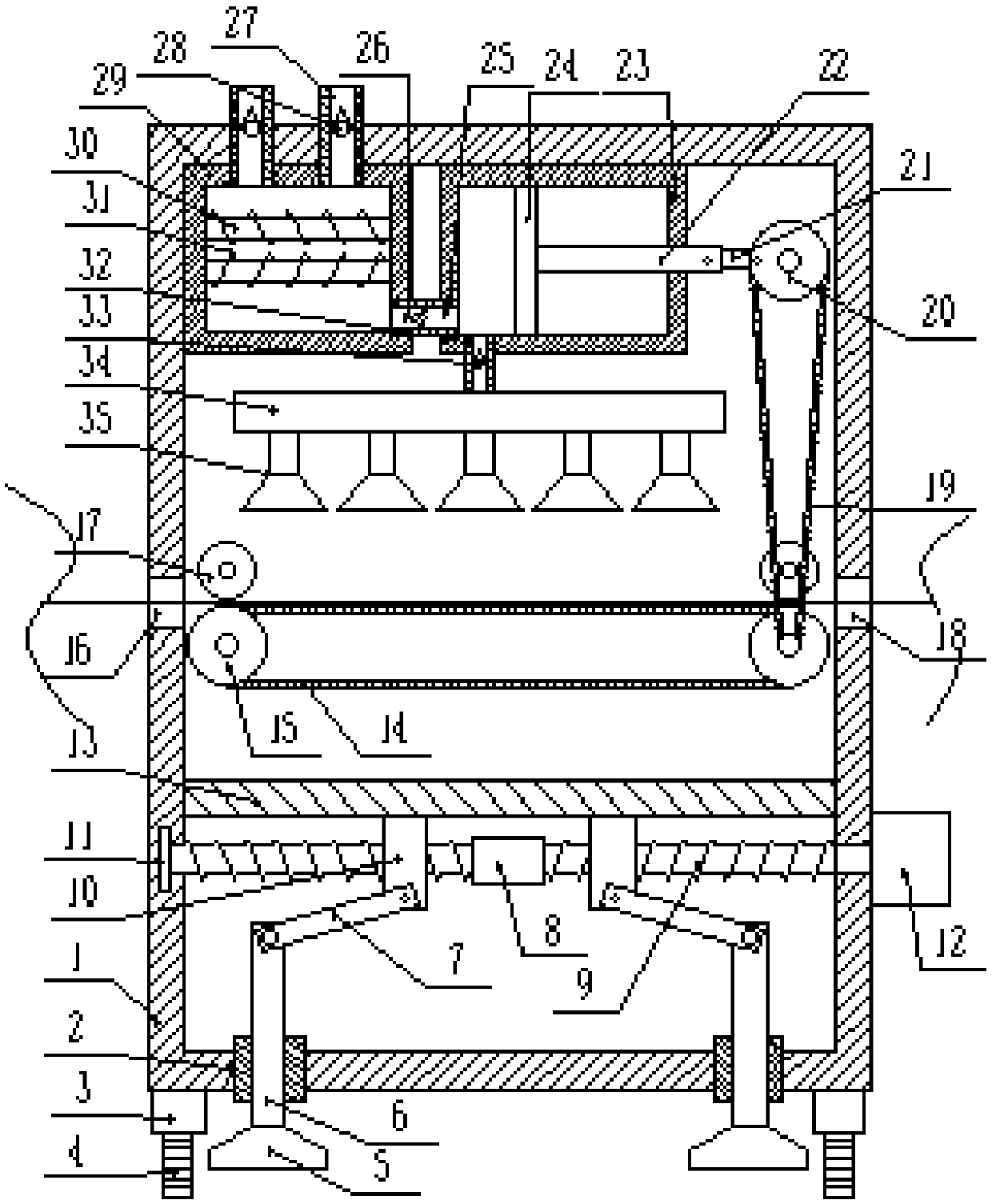

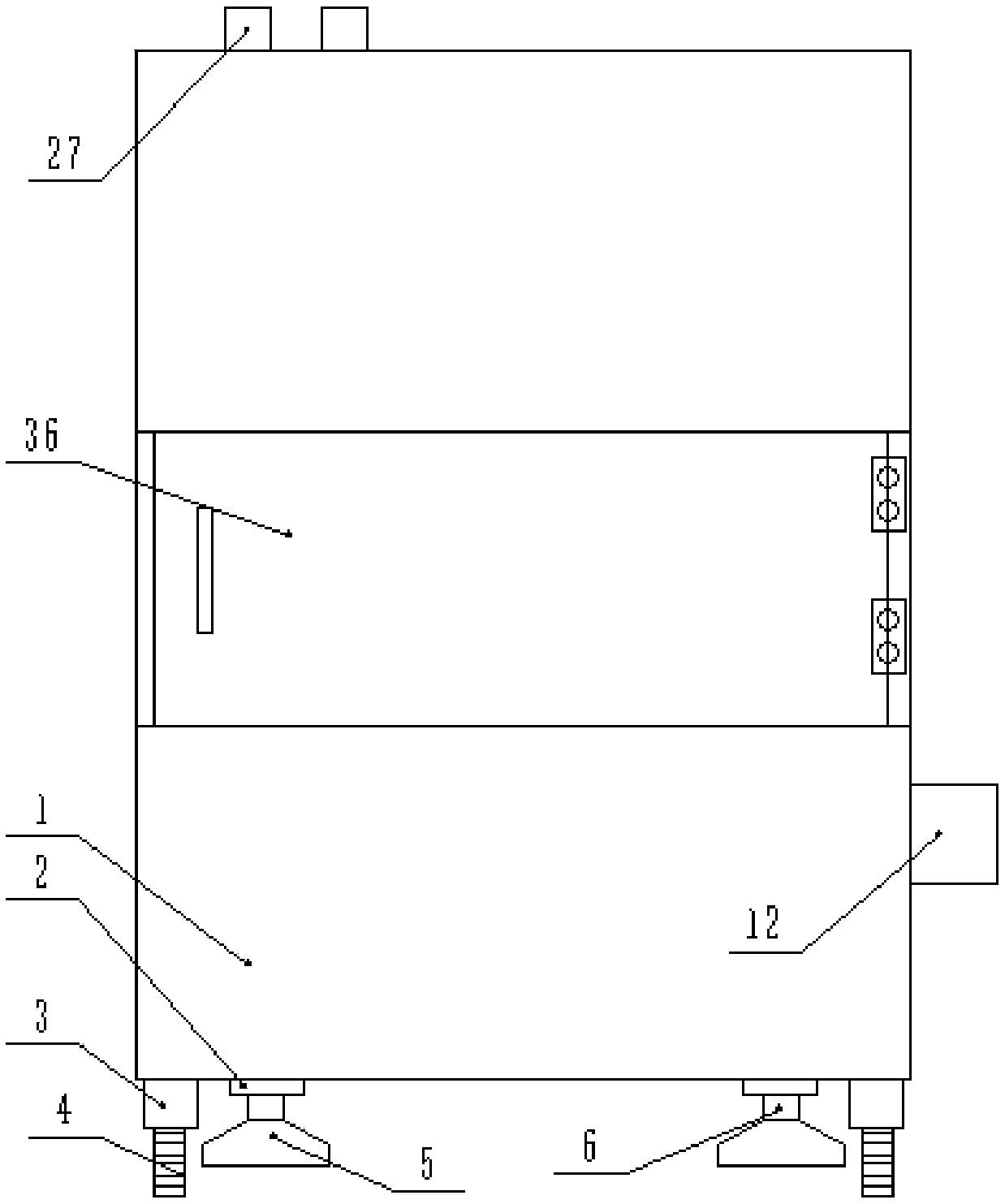

Device for injection molding of high polymer material

InactiveCN108673822AImprove melting qualityHeating evenly and comprehensivelyGrain treatmentsEngineeringInjection molding machine

The invention discloses a device for injection molding of a high polymer material. The device comprises a crushing box, a fusion box and a stirring heating frame. A cavity is formed in the fusion box.A heating layer is arranged at the position, around the cavity, of the fusion box. Resistance wires distributed in an array manner are arranged in the heating layer. The crushing box is arranged at the upper end of the fusion box. Three through pipes distributed at equal distances are arranged at the lower end of the crushing box. The stirring heating frame is inserted into the fusion box in a penetrating manner and provided with a rotating shaft. A first rotating shaft inner cavity and a second rotating shaft inner cavity are arranged in the rotating shaft. Stirring rods distributed in an array manner are arranged on the rotating shaft. A stirring rod outer cavity and a stirring rod inner cavity are arranged in each stirring rod. According to the device for injection molding of the highpolymer material, heating is uniform and comprehensive, the high polymer material is not prone to adhering to a boiler, the fusion material of the high polymer material is high, and injection moldingis facilitated.

Owner:肇庆益晟商贸有限公司

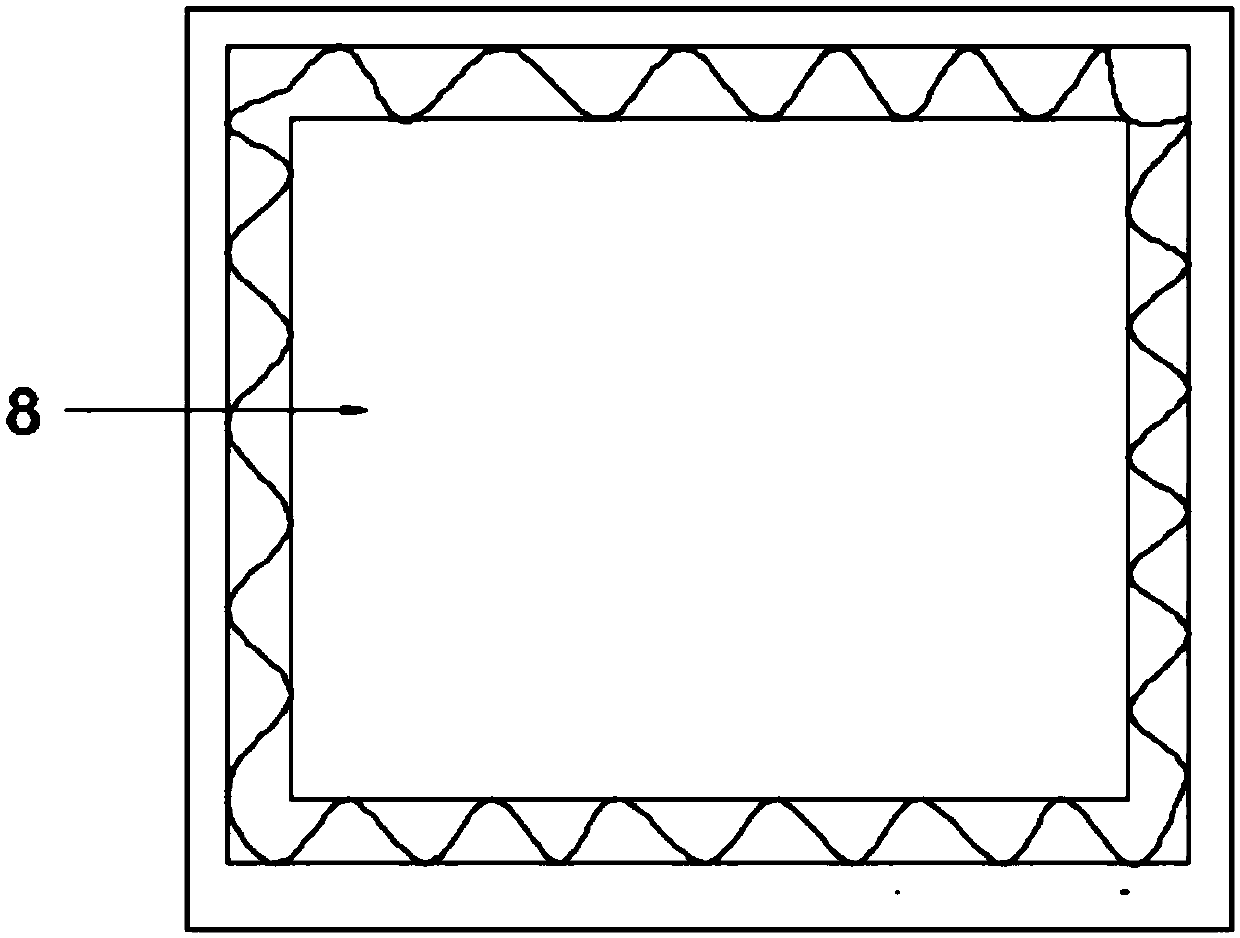

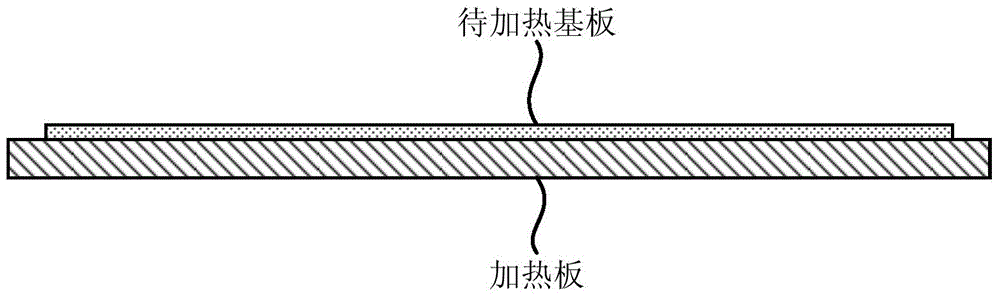

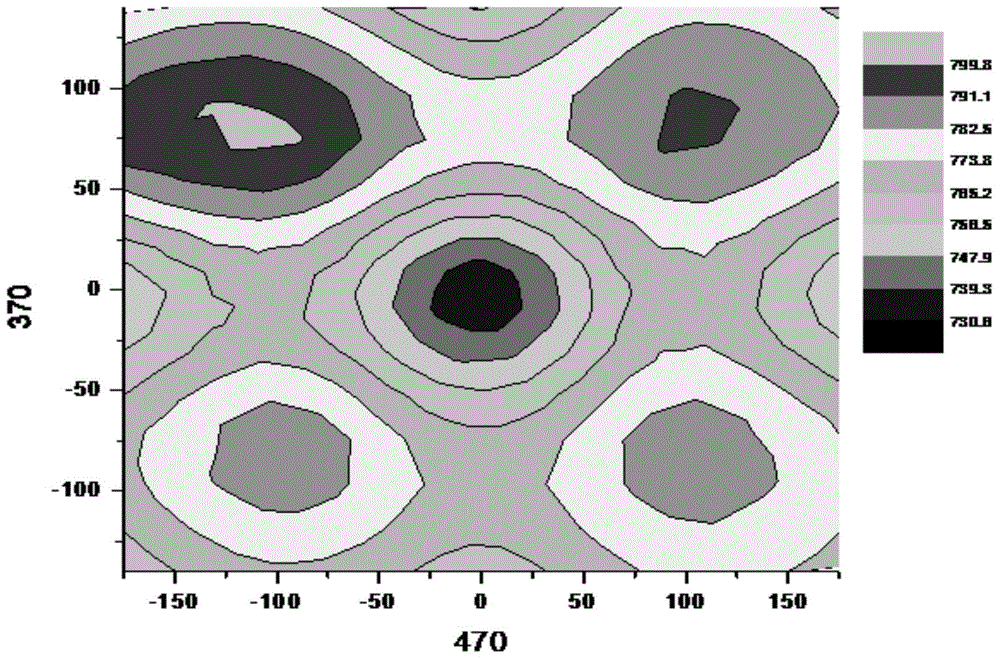

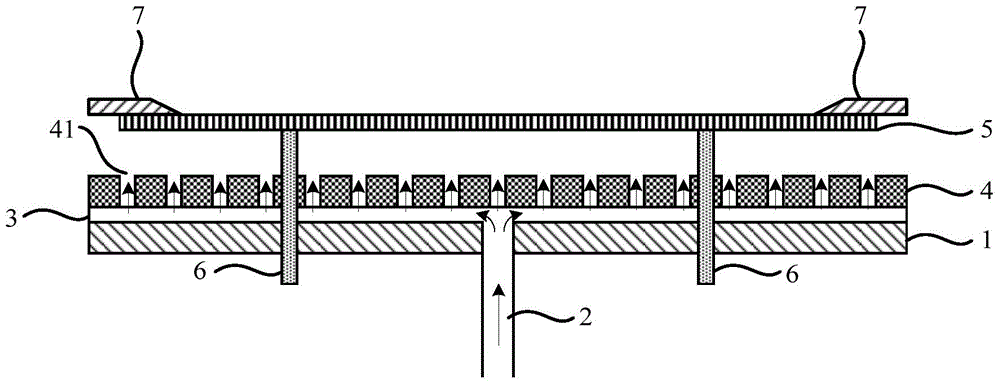

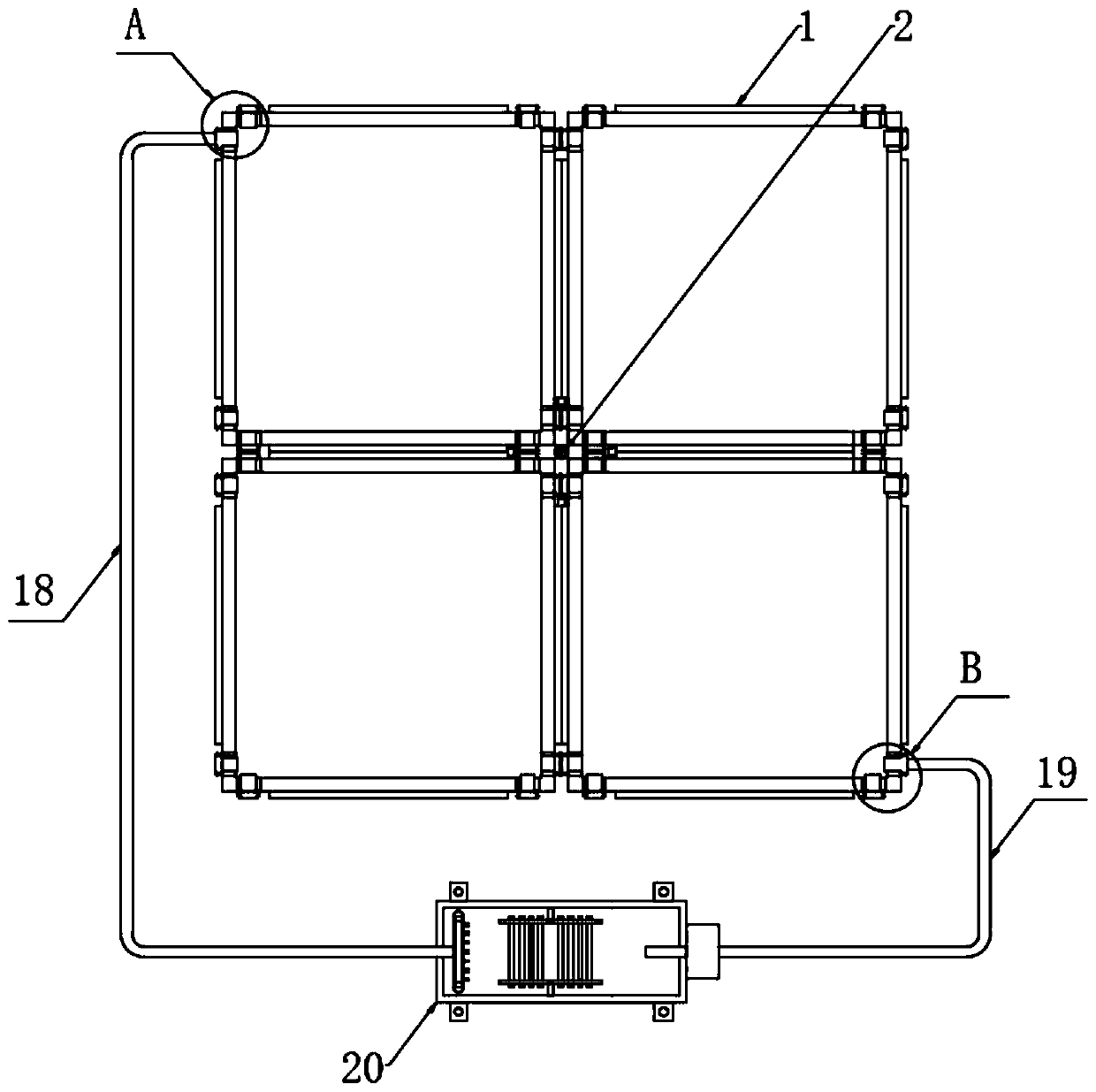

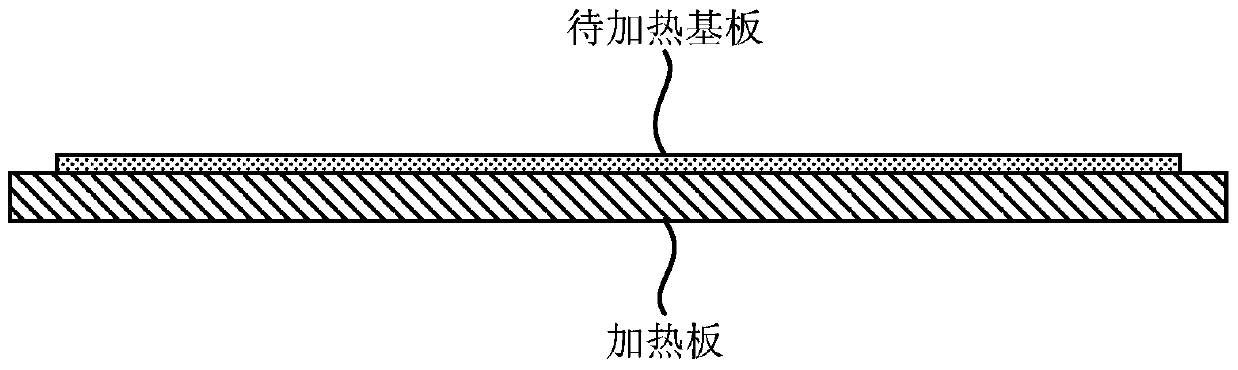

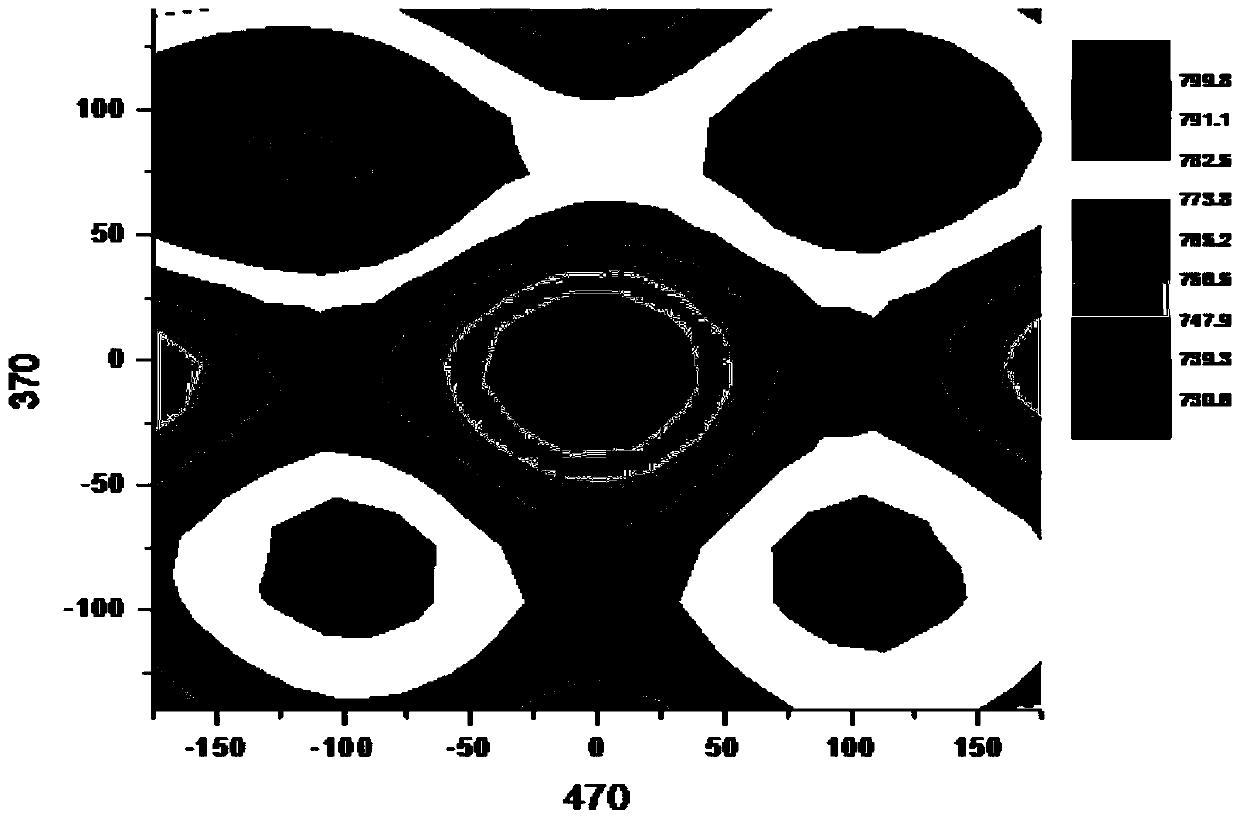

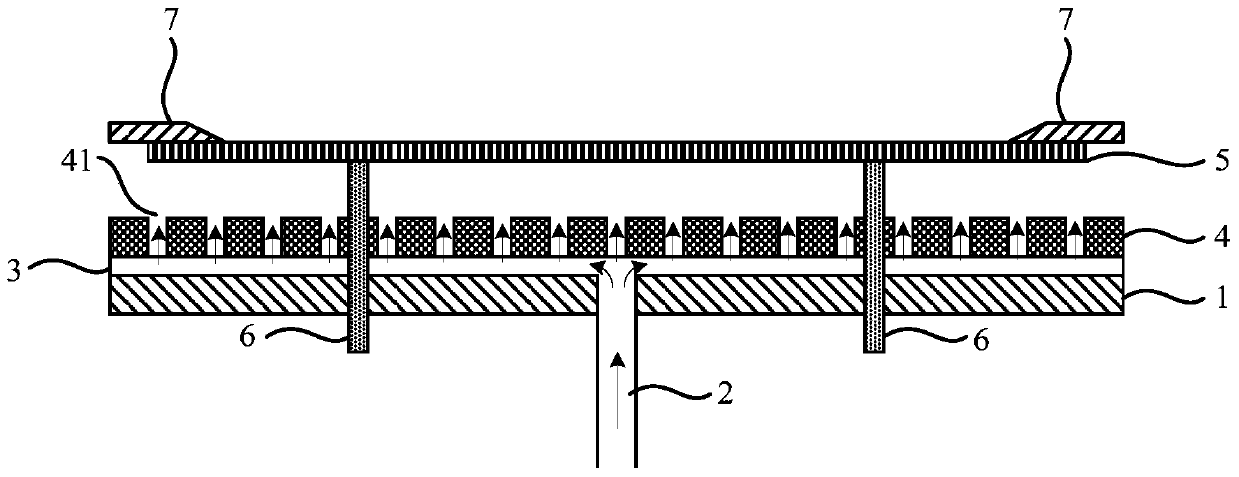

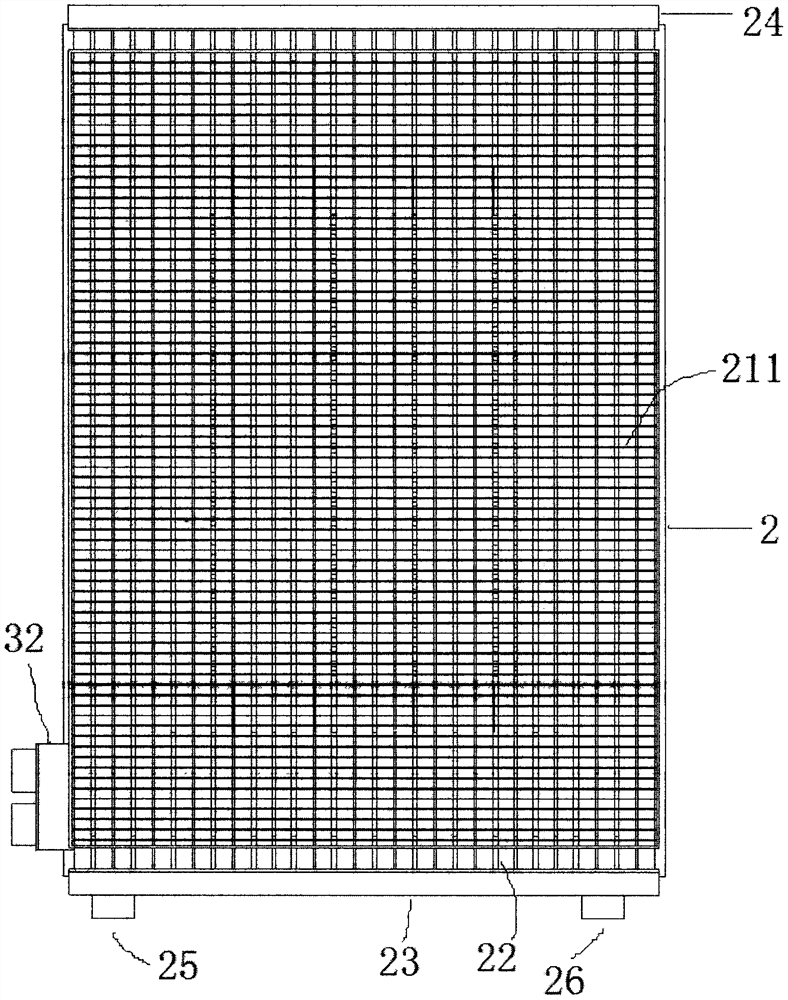

Substrate heating device and substrate heating method

ActiveCN104681402AUniform surface temperatureAvoid wastingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingDiffusion layerMaterials science

The invention relates to a substrate heating device and a substrate heating method. The device comprises a heating layer used for conducting heat, a transmission tube used for transmitting gas to a diffusion layer, the diffusion layer arranged on the heating layer and used for enabling the gas to be uniformly distributed between a lead-out layer and the heating layer, and the lead-out layer arranged on the diffusion layer and internally and uniformly provided with a plurality of through holes, wherein the through holes are used for leading out the gas in the diffusion layer to a lower side of a to-be-heated substrate, thereby enabling the to-be-heated substrate to be uniformly heated. Through the technical scheme of the invention, the to-be-heated substrate can be uniformly and comprehensively heated, so that the temperature of an upper surface of the to-be-heated substrate is more uniform and processes such as etching, depositing and / or sputtering performed on the to-be-heated substrate are enabled to achieve better effects.

Owner:BOE TECH GRP CO LTD

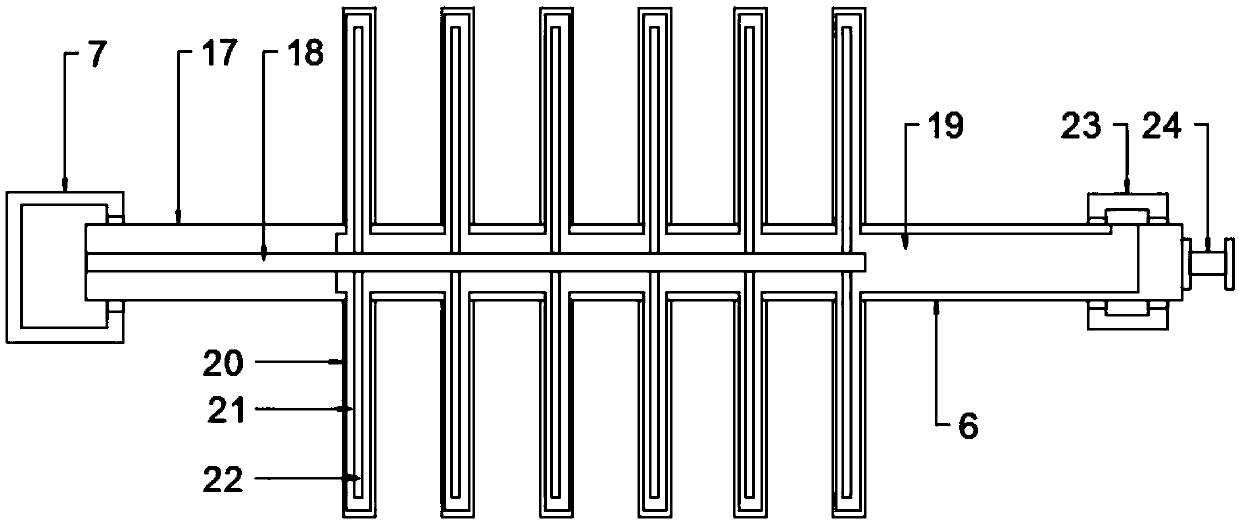

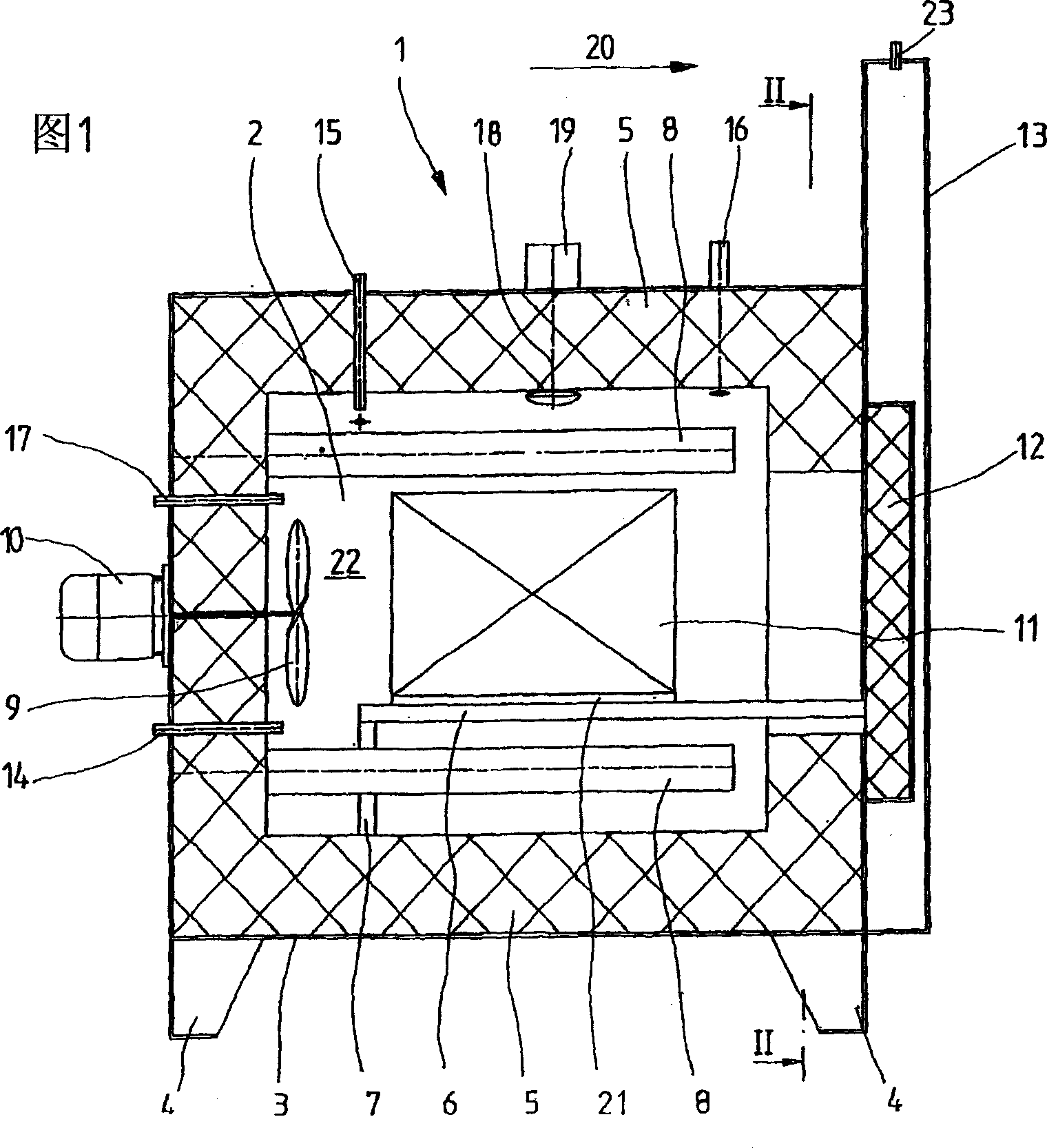

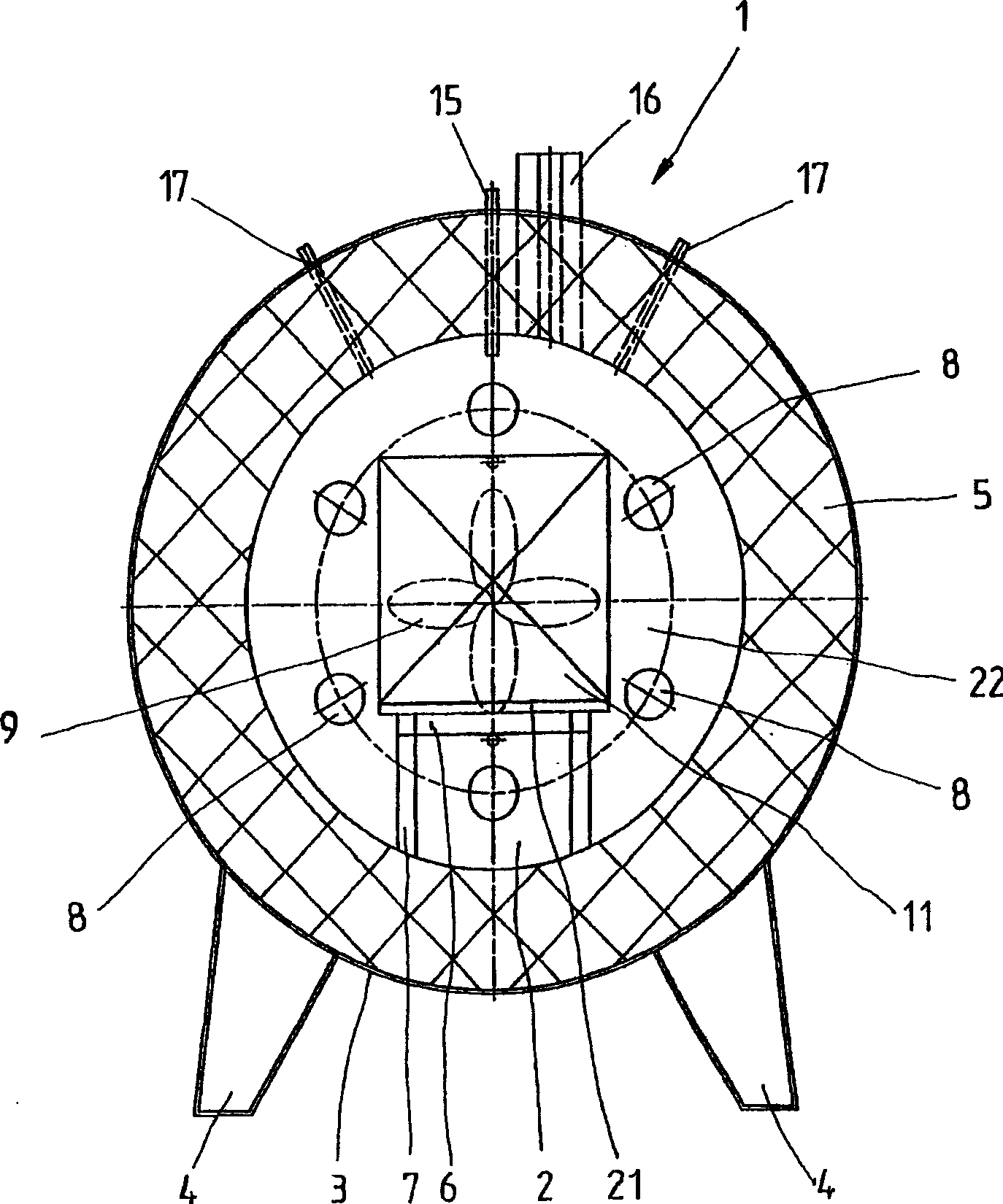

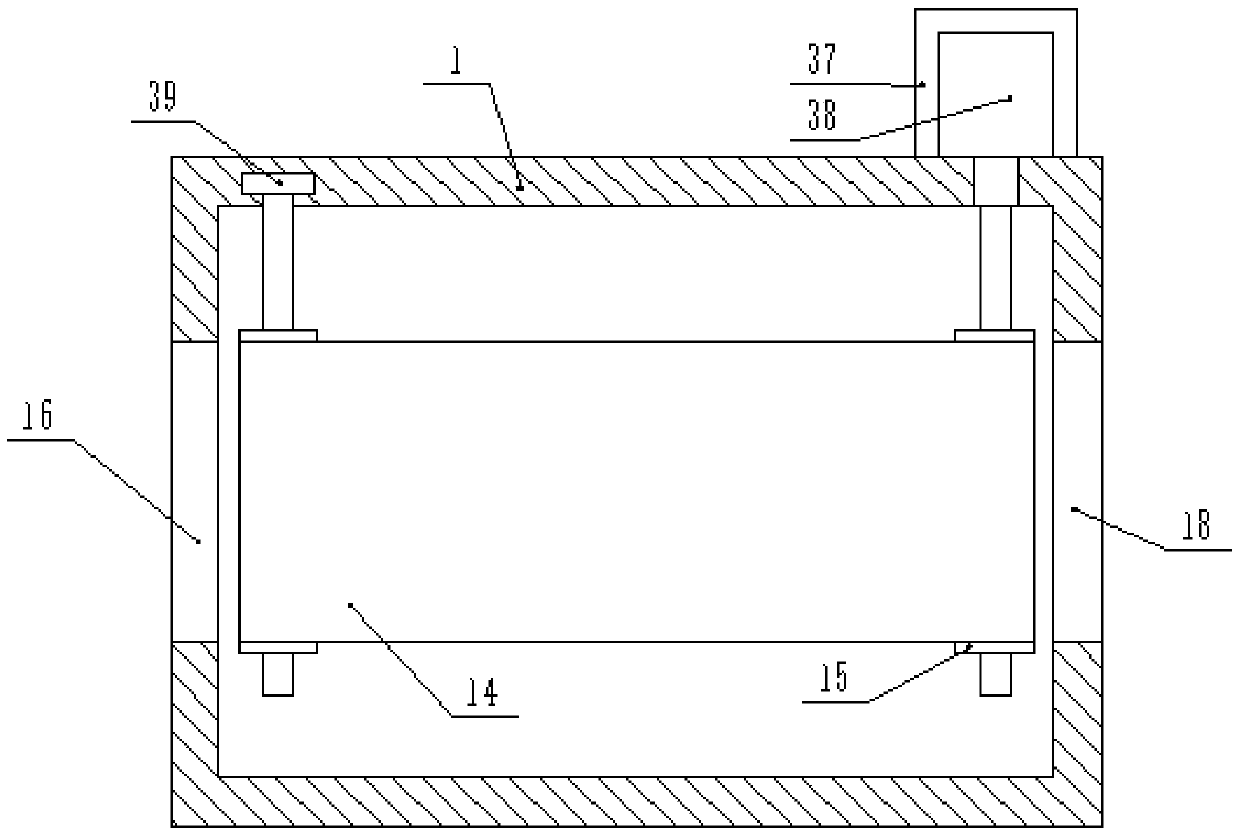

Apparatus and method for heat treatment of metallic work pieces

InactiveCN1878878AHeating evenly and comprehensivelyMaintainance of heating chambersCharge manipulationAir tightnessQuenching

The invention relates to a horizontal atmospheric furnace for heat treating, in particular, metallic workpieces at high temperatures. In order to create a furnace that, while having a simple design and being easy to operate at the same time, enables a transfer of heat-treated workpieces into a quenching device while concluding the atmosphere surrounding the furnace, the invention provides that a horizontal atmospheric furnace for heat treating, in particular, metallic work pieces (11) at high temperatures with a preferably cylindrical furnace chamber (2) and with a furnace door (12) that closes the furnace chamber (2) in a gas-tight manner. Said furnace door (12) is mounted in a manner that enables it to be displaced inside a door case (13), which forms a lock that can be closed in a gas-tight manner.

Owner:IPSEN INT INC

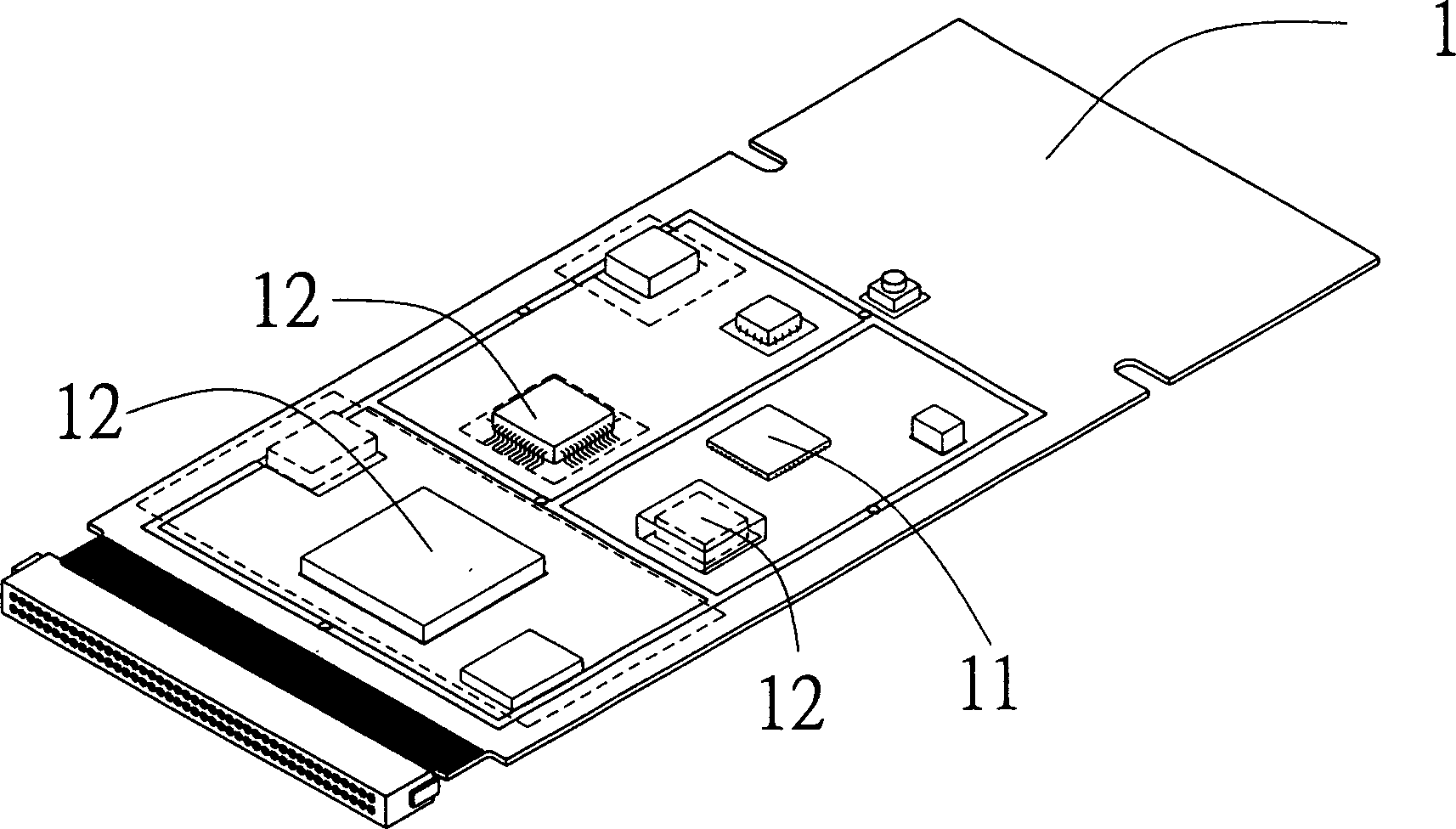

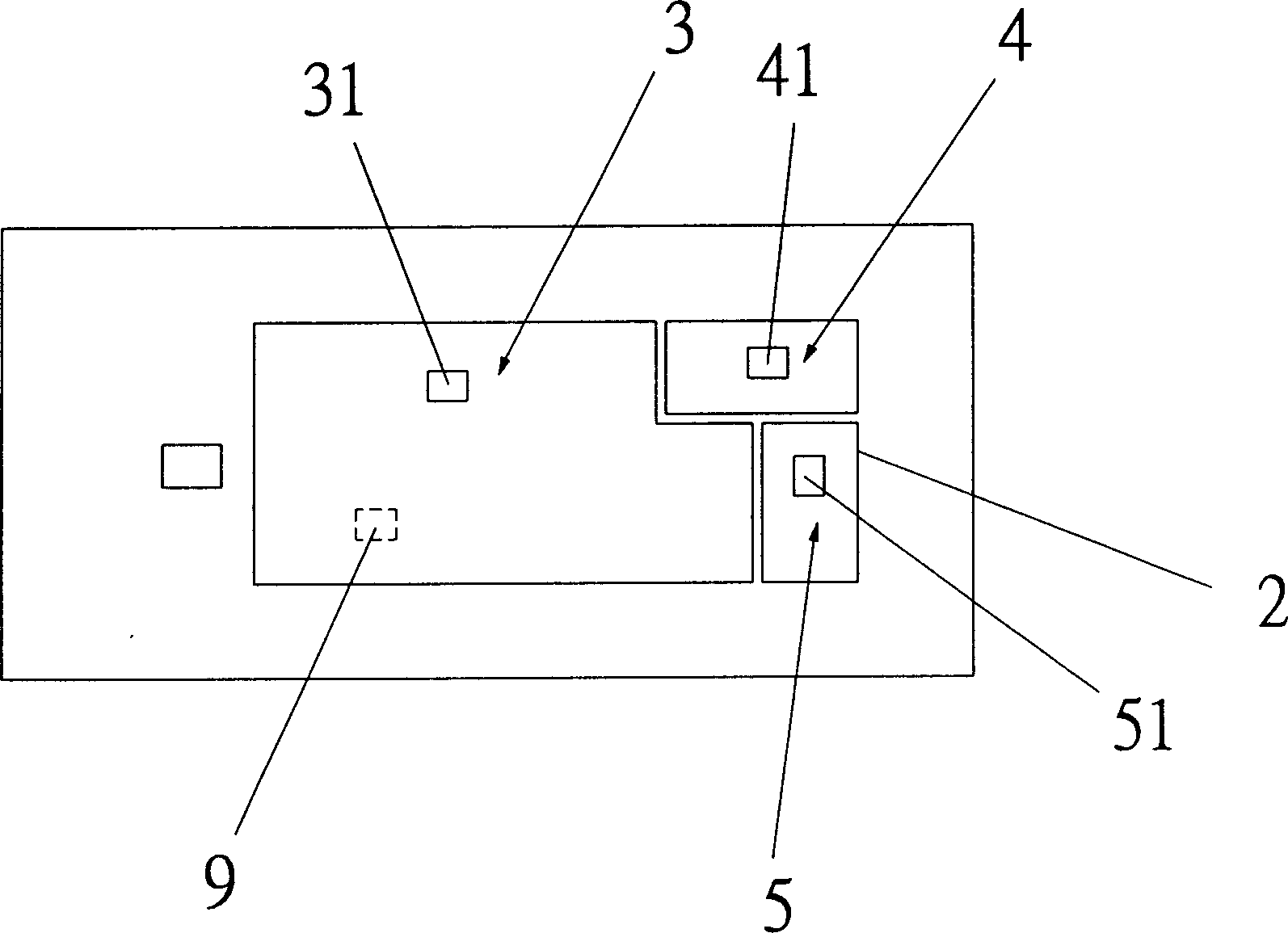

Improved structure of circuit anti-interference device

InactiveCN1414824AThe production process is simpleIncrease productivityMagnetic/electric field screeningPrinted circuit manufactureFit frequencyInterference resistance

A structural improvement for antidisturbance device of line uses a number of frame lines to form a number of frequency domain zone blocks according to the requirement by dividing in the design to seteach related circuit element belonging to oscillation source to the fitted frequency domain zone block as per the magnitude of the frequency so that the copper frame body independent to each other being formed on the circuit board by using frequency domain zone blocks divided in advance after the surface being processed with catching. The effective isolation of external impurity message and internal disturbance to each other can be realized by using the copper line frame body to lead the individual / message to the ground end so as to prevent the mixed wave disturbance to each other from oscillation source in different property frequency.

Owner:CAMEO COMM

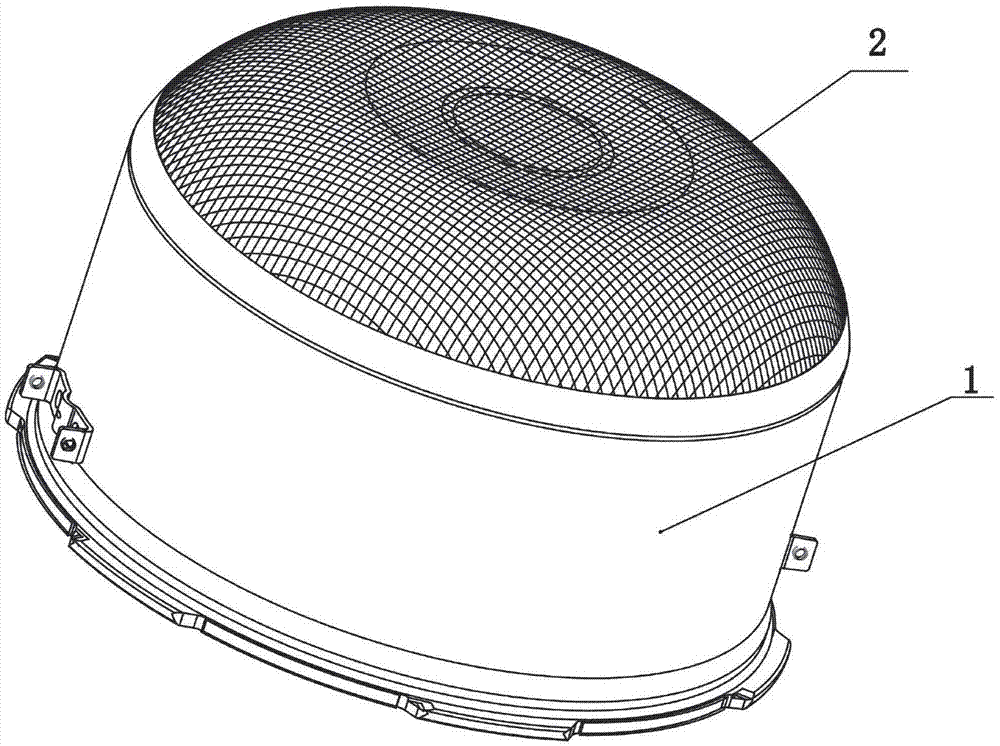

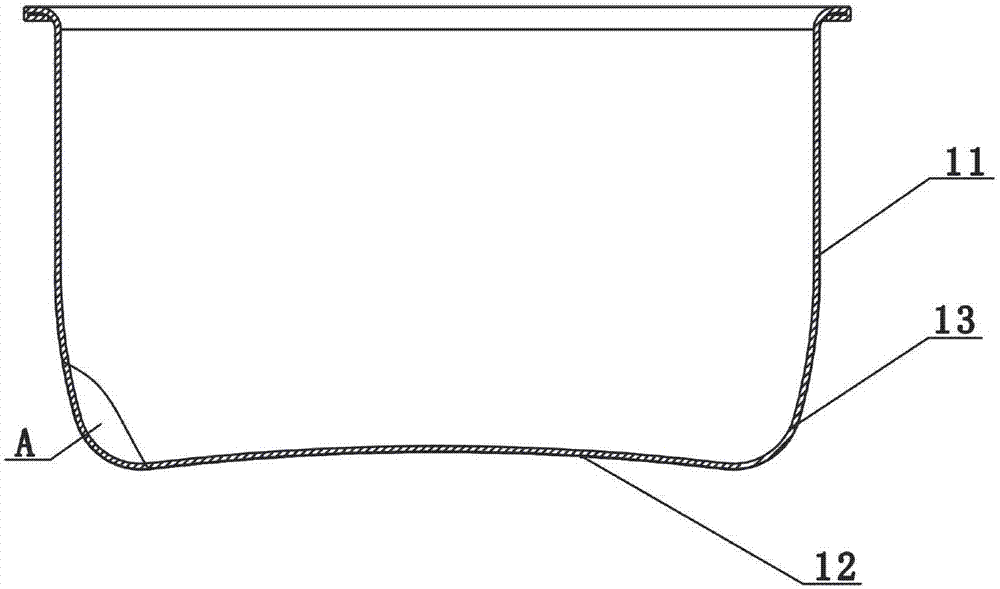

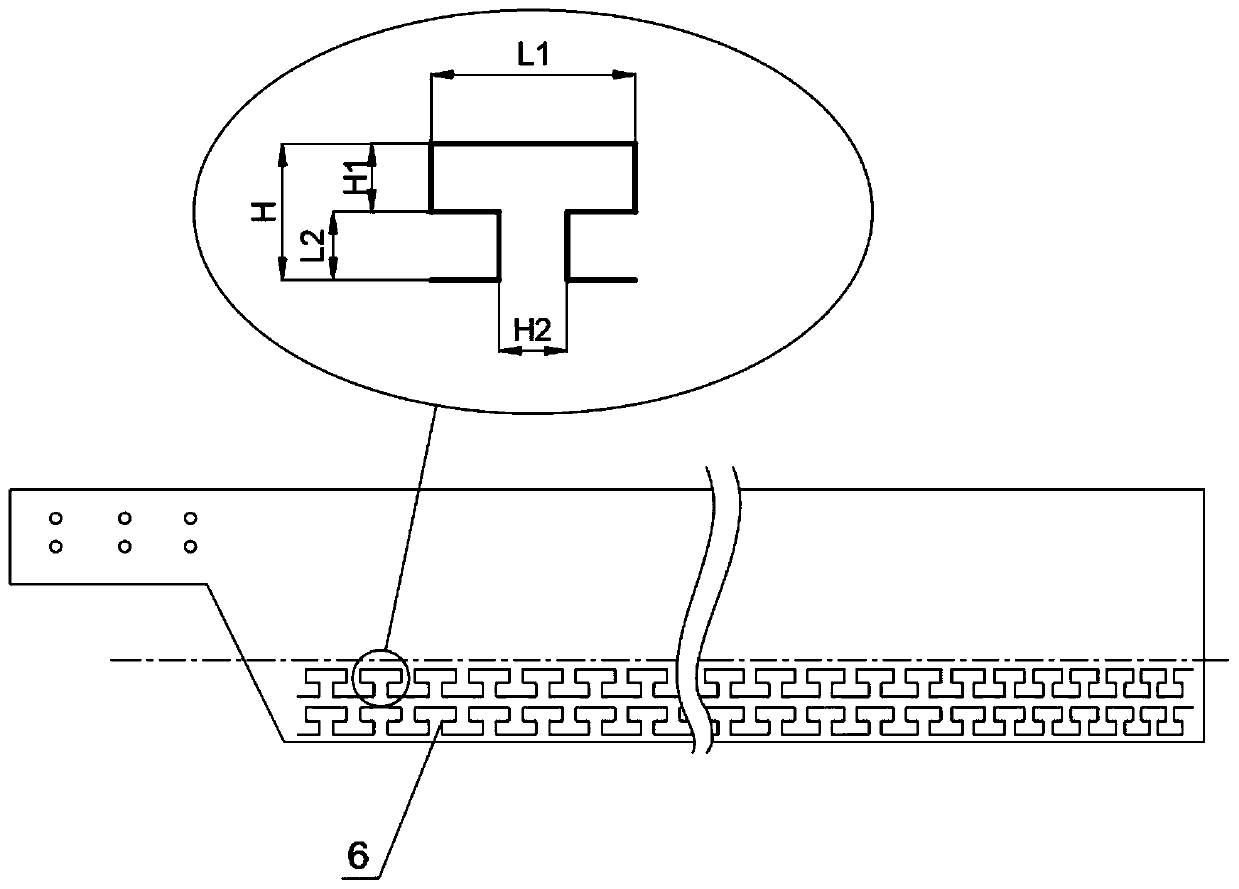

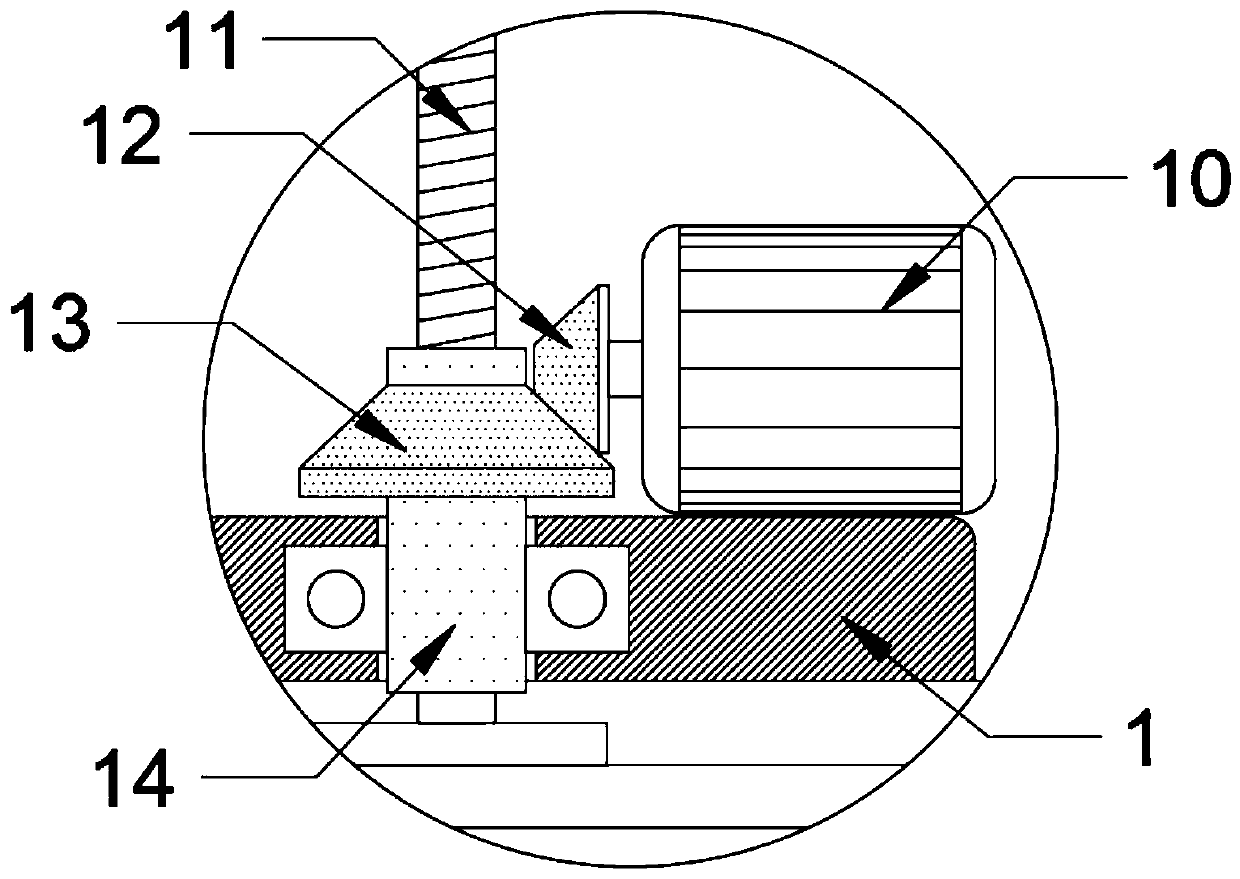

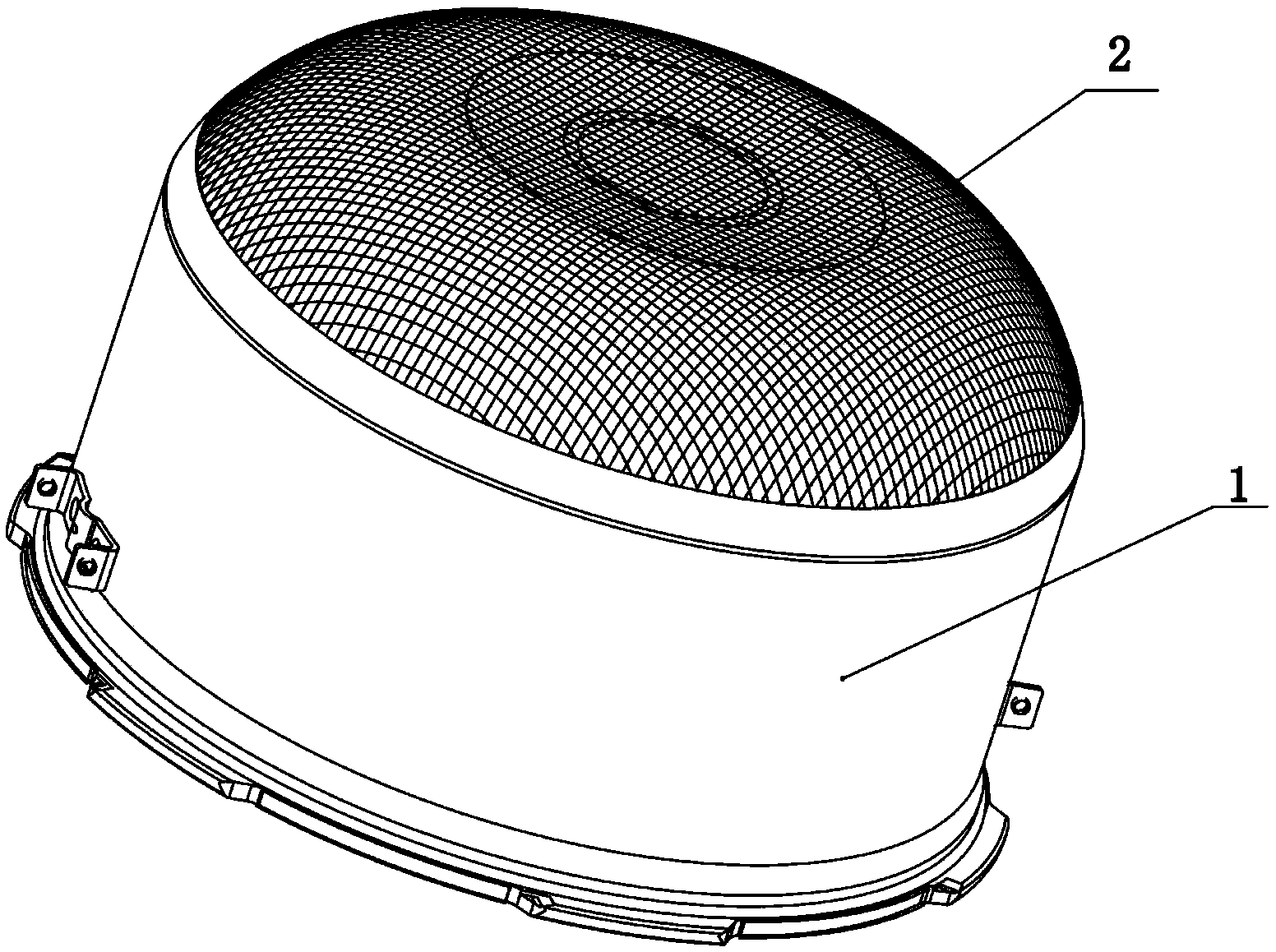

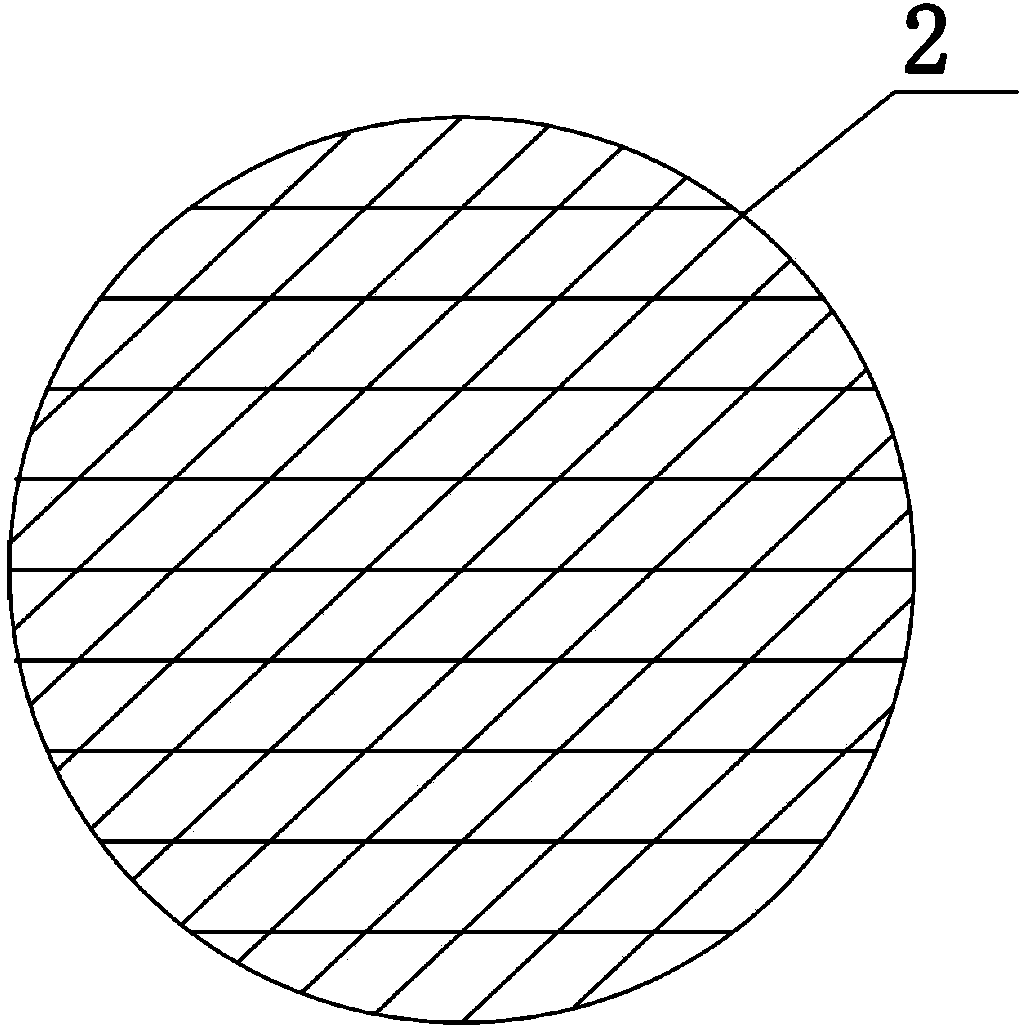

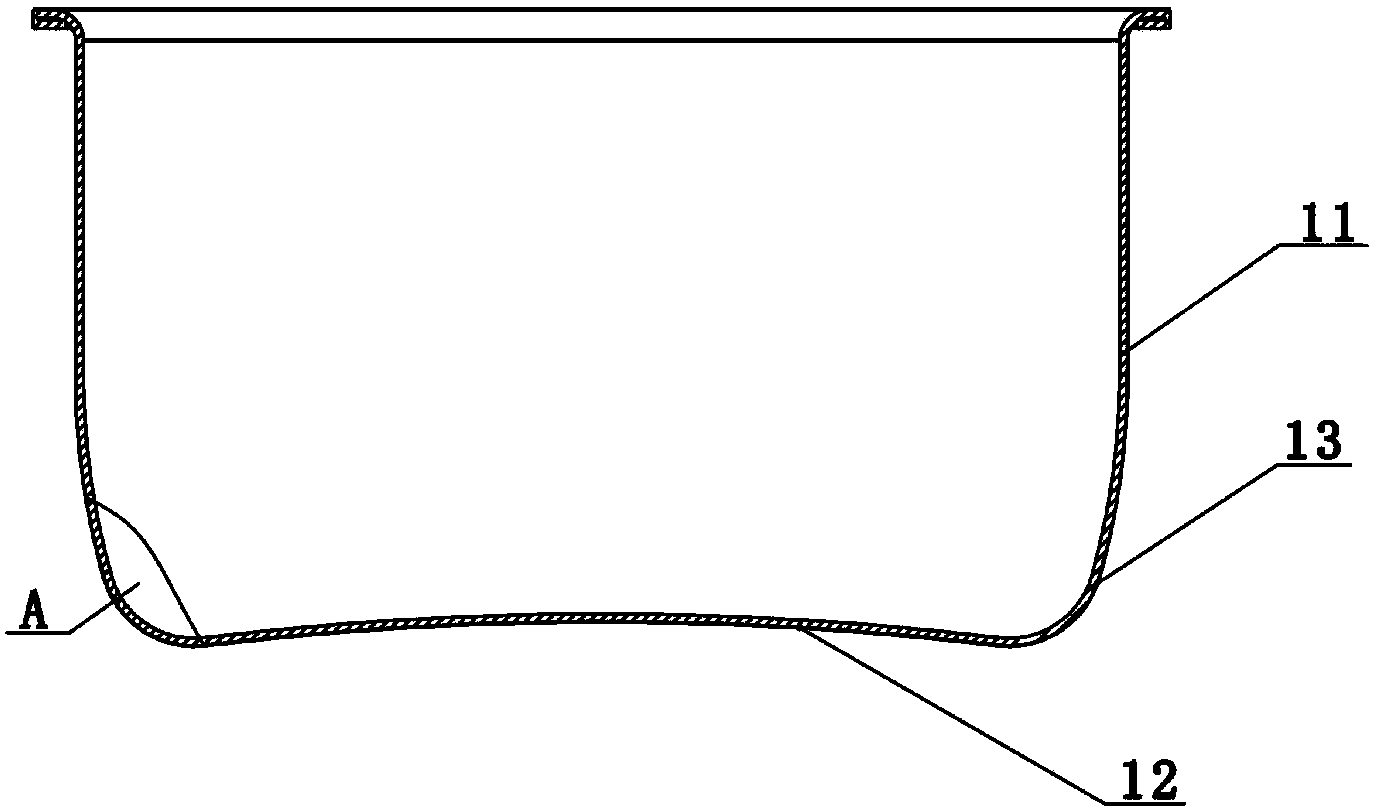

Electromagnetic heating cookware and three-dimensionally heated electromagnetic cooking appliance

ActiveCN102920310AFirmly connectedNo cracksCooking-vessel materialsPressure-cookersEngineeringElectromagnetic heating

The invention relates to an electromagnetic heating cookware and a three-dimensionally heated electromagnetic cooking appliance. The electromagnetic heating cookware is formed by stretching aluminum plates and is a cylindrical cookware with a bottom. The cookware comprises a pot body, a pot bottom, a transition part and a magnetic conduction heating element which is embedded into the outer side of the transition part, wherein the transition part is connected with the pot body and the pot base; the transition part is arc; the heat conduction heating element is a metal stretching net with a high extending property; the metal stretching net is compressed and connected to the corresponding part of the aluminum plate in advance and is stretched and formed into a cookware together with the aluminum plate. The three-dimensionally heated electromagnetic cooking appliance comprises a shell, the cookware and an electromagnetic wire coil for inducing the cookware to be heated three-dimensionally; the cookware is the cookware for electromagnetic heating; and the electromagnetic cooking appliance is an electric cooker, or an electric pressure cooker or an electric stewpan.

Owner:JOYOUNG CO LTD

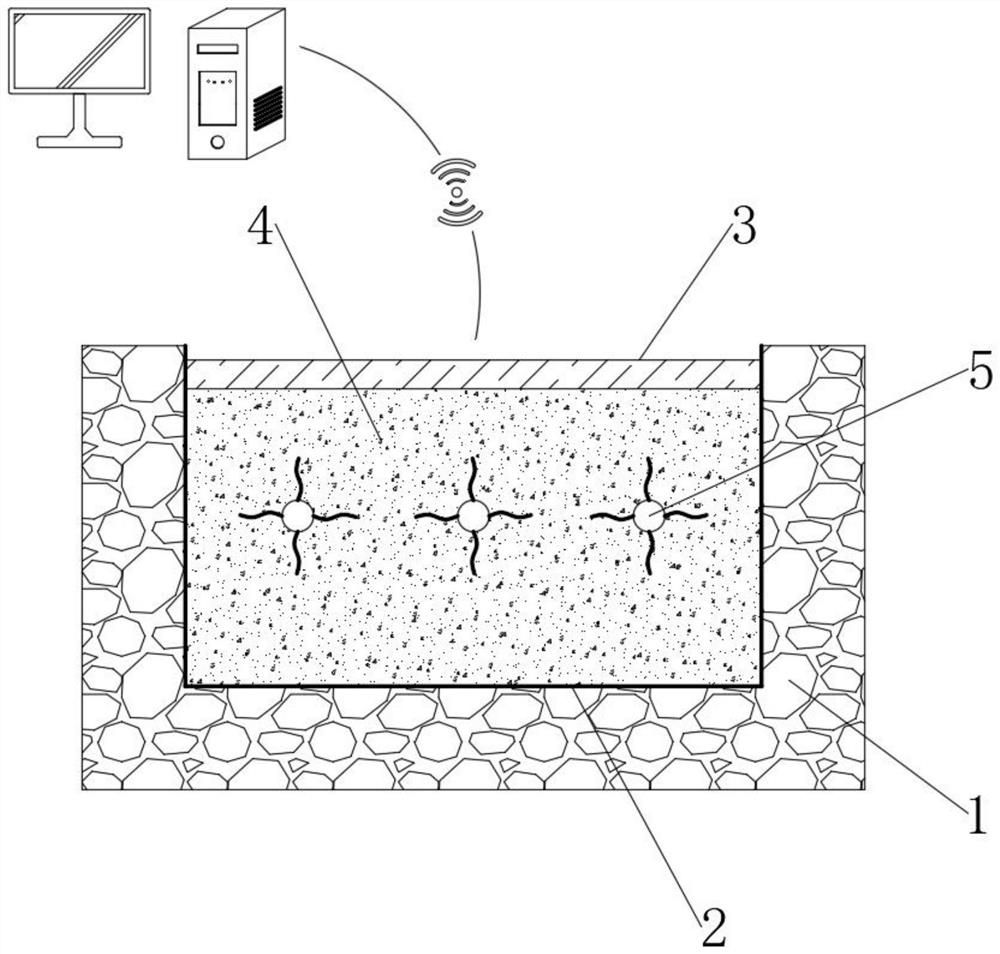

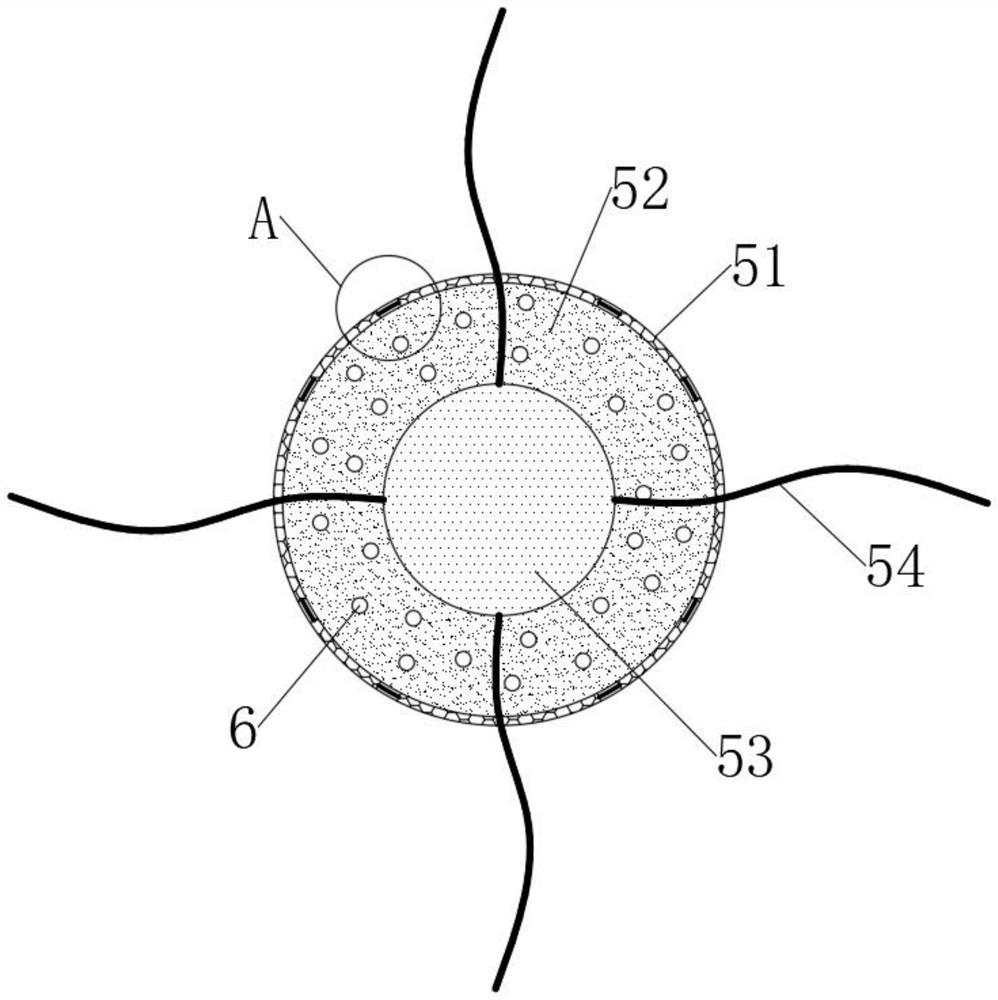

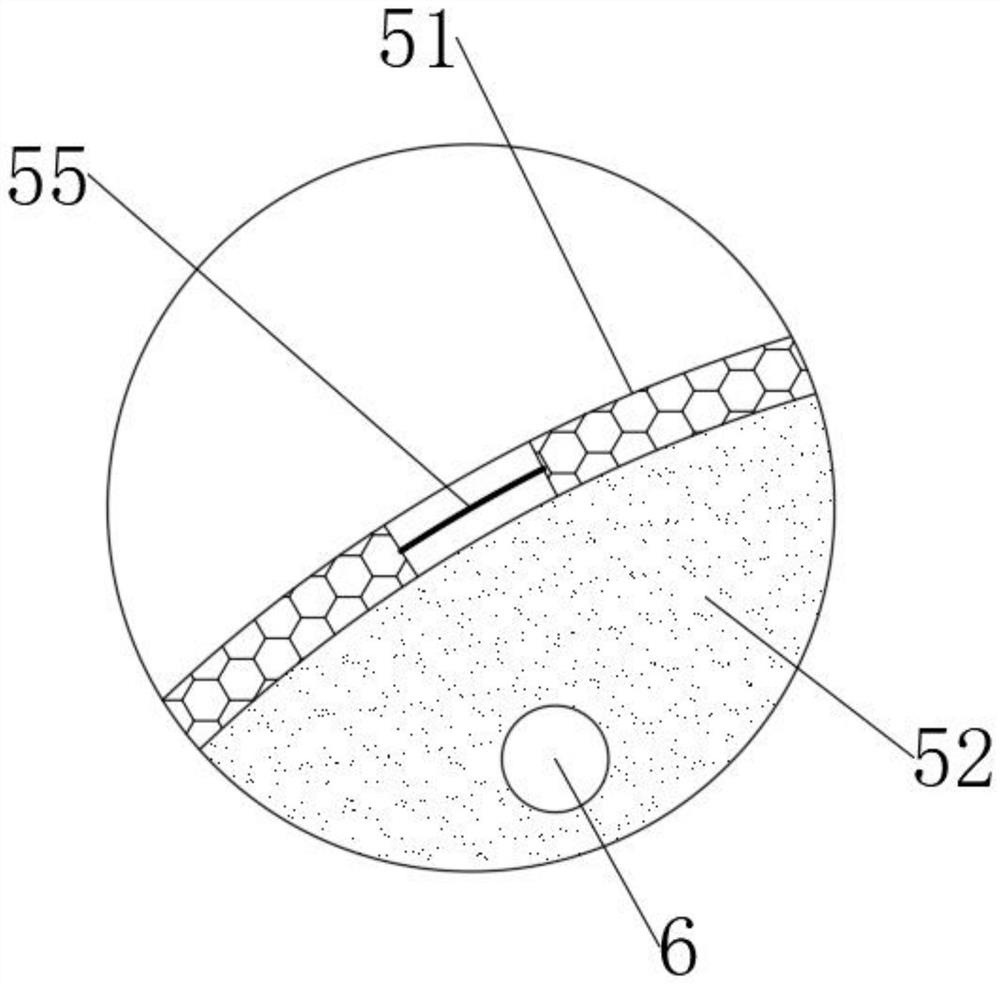

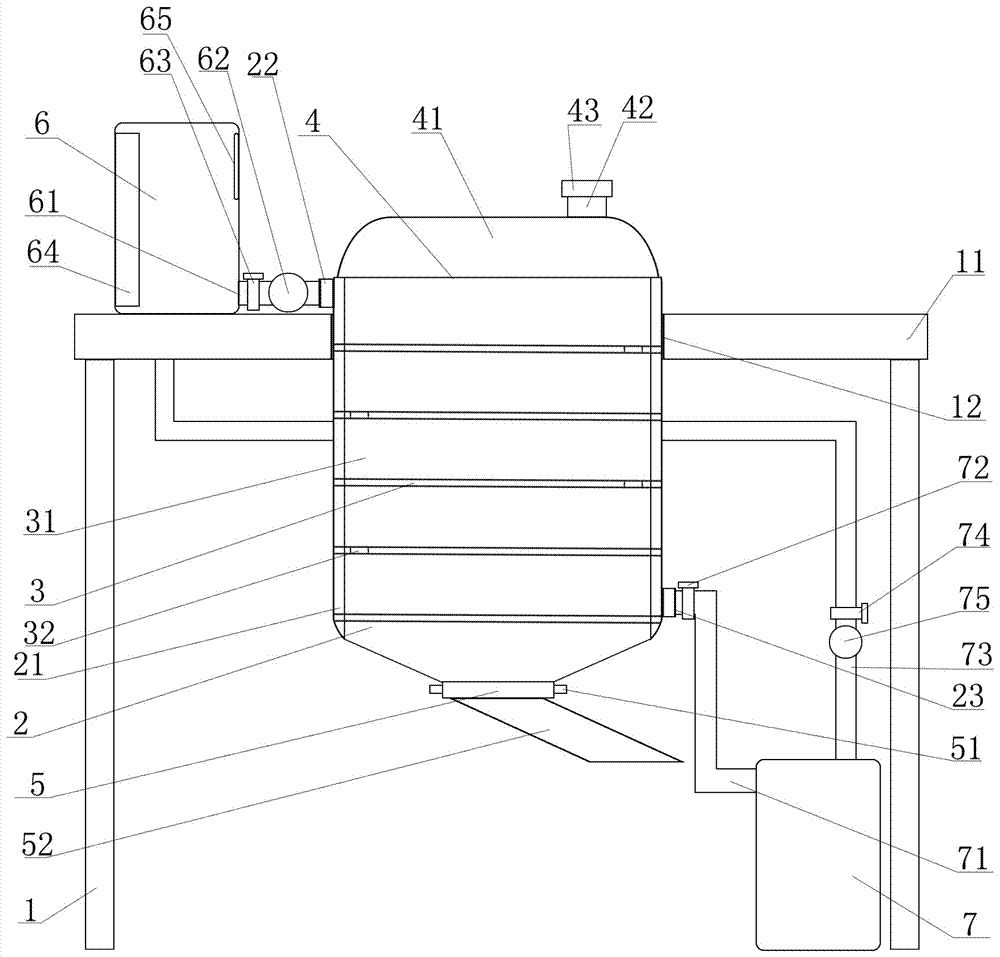

Soft soil thermal consolidation model test device and method

ActiveCN112945727AImprove thermal consolidation effectEasy dischargeEarth material testingMaterial strength using tensile/compressive forcesSoil scienceGraphite

The invention discloses a soft soil thermal consolidation model test device and a soft soil thermal consolidation model test method, and belongs to the technical field related to geotechnical engineering and foundations. A consolidation main ball is innovatively introduced, is pre-buried in to-be-tested soft soil, can autonomously absorb moisture and then triggers a gas generation reaction; the heat conduction graphite powder and the consolidation auxiliary balls enter the to-be-tested soft soil, the heat conduction graphite powder is diffused along pores of the to-be-tested soft soil so as to comprehensively and uniformly heat the to-be-tested soft soil, the consolidation auxiliary balls migrate to the geotechnical cloth under the action of a magnetic field, and in the migration process, the consolidation auxiliary balls not only can accelerate drainage of water, but also can release quicklime powder when uneven extrusion is carried out, the quicklime powder reacts with residual moisture of the to-be-tested soft soil to be consumed, heat is provided for assisting thermal consolidation, meanwhile, reaction products can reinforce the to-be-tested soft soil to improve the consolidation strength, and compared with the prior art, the method has the advantages that the thermal consolidation test precision is higher, the efficiency is higher, and meanwhile, the thermal consolidation effect of the soft soil to be tested is improved in an auxiliary manner.

Owner:ZHEJIANG UNIV

Plastic material melting equipment

The invention discloses plastic material melting equipment. The plastic material melting equipment comprises a worktable, a mounting port, a heating box, a material box, a frame, a stirring shaft, stirring blades, a mounting groove, an electric heating wire, a fire spraying gun, a discharge pipe, a motor, a driving gear, a driven gear, a belt wheel, a belt groove and support legs; the mounting port is formed in the worktable; the heating box is fixedly arranged in the mounting port; the material box is rotationally arranged in the heating box through a bearing; the frame is fixedly arranged atthe upper art of the worktable; the stirring shaft is vertically arranged in the material box; the upper end of the stirring shaft is rotationally connected with the frame through a bearing; the stirring blades are integrally arranged at the external of the part, positioned in the material box, of the stirring shaft; the mounting groove is axially formed in the top of the stirring shaft; and theelectric heating wire is arranged in the mounting groove. Compared with the prior art, the plastic material melting equipment can efficiently and quickly melt plastic materials, improves the melting efficiency and effect, and achieves more convenience for plastic processing.

Owner:浙江省新昌县华佳国财塑胶有限公司

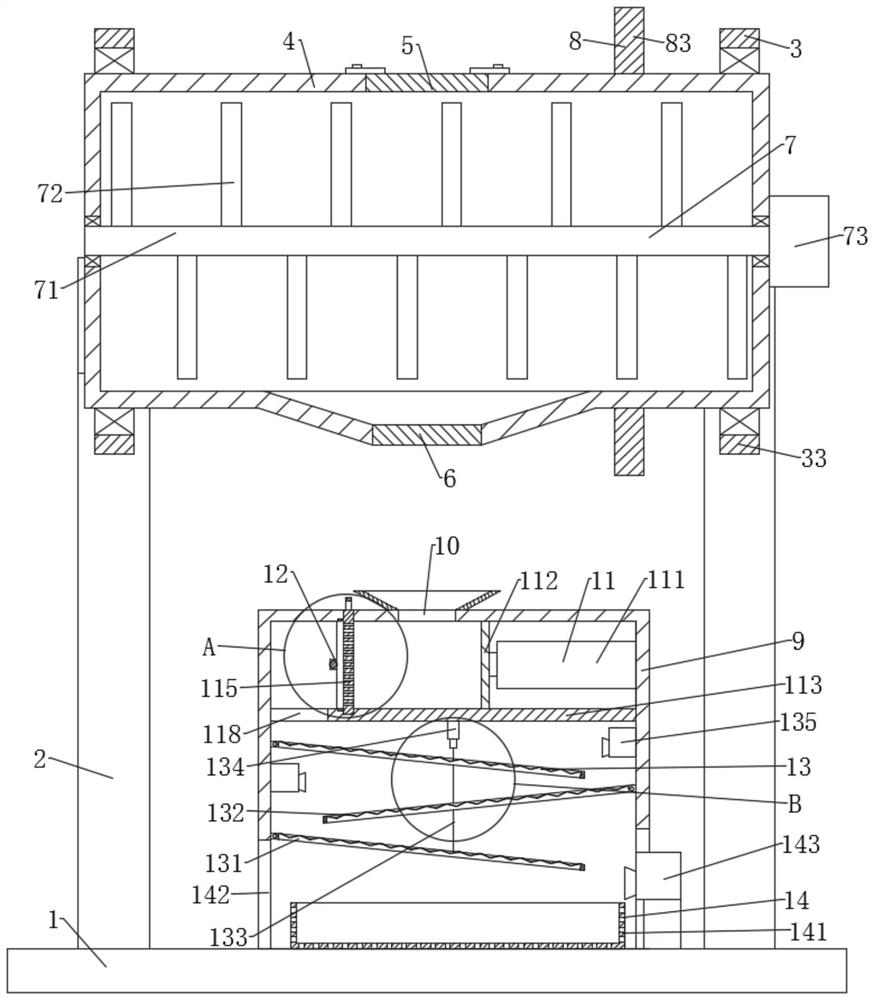

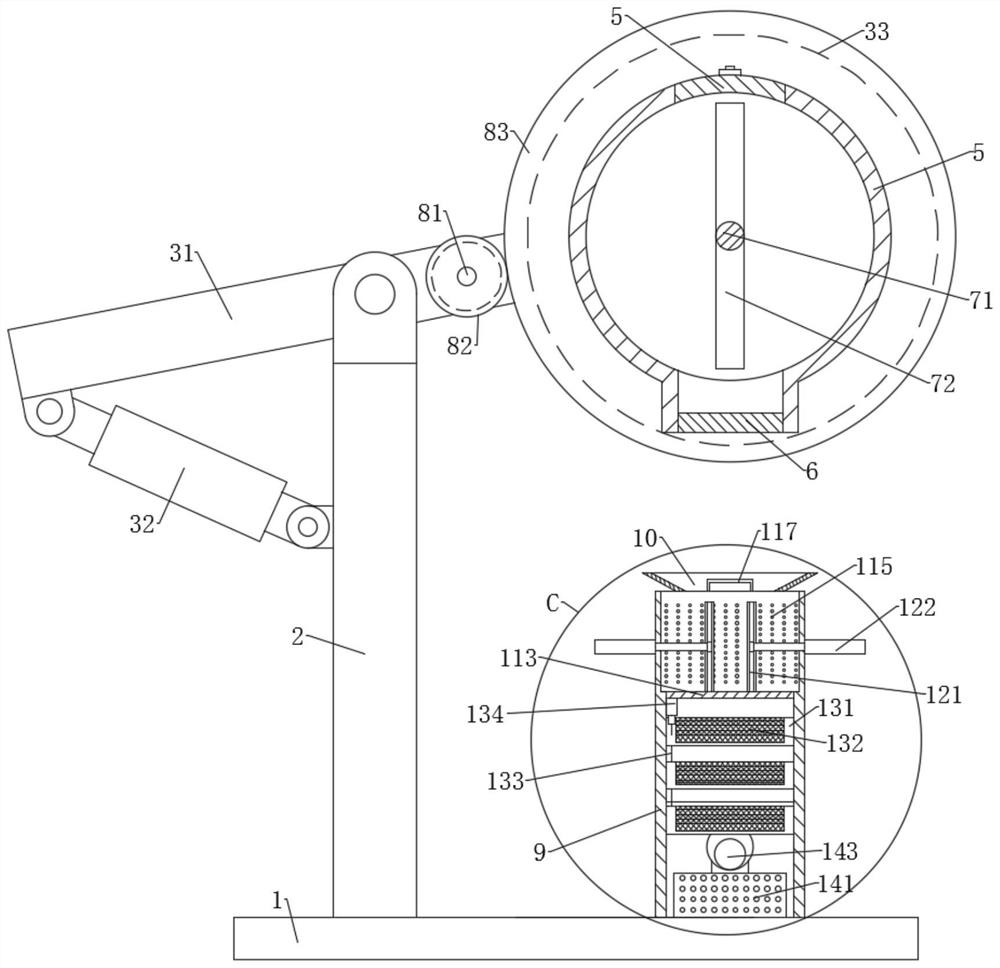

Aquatic product breeding feed manufacturing device and method

PendingCN114098117AImprove mix qualityRaw materials are mixed evenlyFeeding-stuffTransportation and packagingProcess engineeringInternal cavity

According to the aquatic product breeding feed manufacturing device and method, various raw materials are stirred through a stirring assembly, meanwhile, a stirring barrel is driven to swing up and down through a swinging assembly, the stirring barrel is driven to rotate through a driving assembly, the various raw materials in an inner cavity of the stirring barrel are fully mixed, and the mixing effect is good; the feed is extruded into long strips through the extrusion assembly, and the long-strip feed is sheared into granules through the shearing assembly; pellet feed is fully dried through the drying assembly, the drying effect is good, the pellet feed is dried, cooled and collected through the collecting assembly, feed spoilage caused by accumulation of hot feed is prevented, an insertion plate is convenient to disassemble, assemble and replace, and the device is suitable for manufacturing feed with different diameters.

Owner:含山县创兴水产品养殖专业合作社

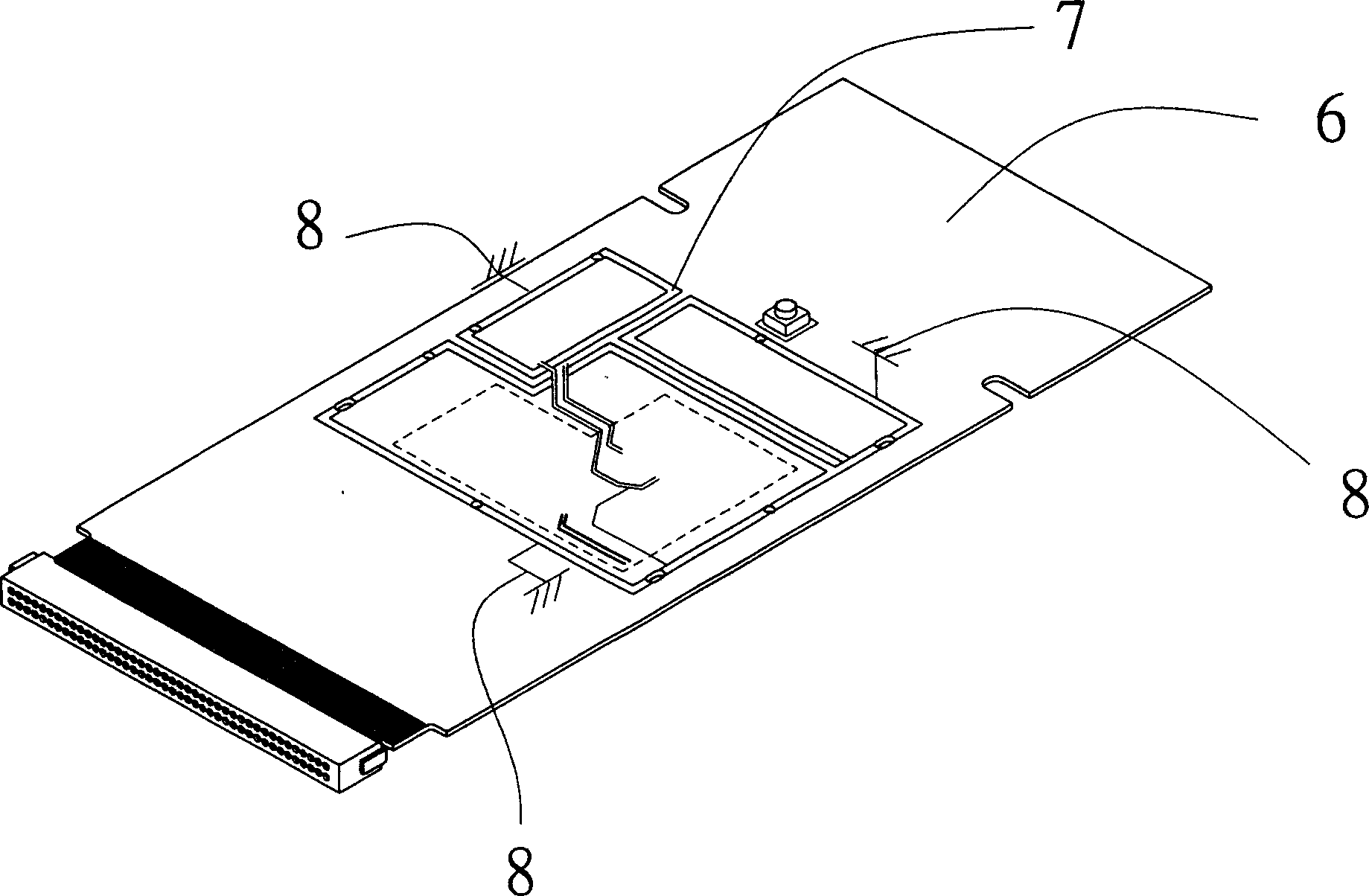

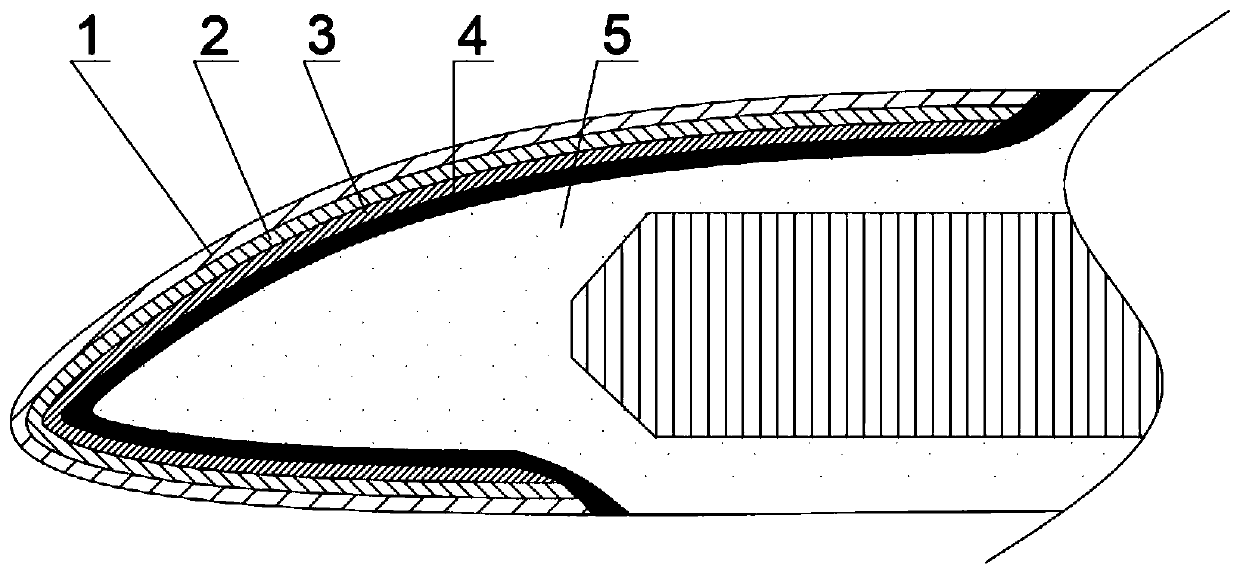

Graphene composite material helicopter rotor anti-icing and deicing device and manufacturing method

ActiveCN110481795AImprove heat transfer performanceEasy to passDe-icing equipmentsInsulation layerEngineering

The invention discloses a graphene composite material helicopter rotor anti-icing and deicing device and a manufacturing method; the graphene composite material helicopter rotor anti-icing and deicingdevice comprises a skin, an insulation heat transfer layer, a heating layer and an insulation heat insulation layer, and the skin, the insulation heat transfer layer, the heating layer and the insulation heat insulation layer are sequentially arranged from outside to inside along the chordwise direction; the skin, the insulation heat transfer layer, the heating layer and the insulation heat insulation layer are attached to form an outer edge body, the outer edge body is integrally heated and cured into a rotor front edge shape, and the outer edge body is installed on the rotor base body. Theheating layer comprises a plurality of bent linear heating components, and the bent linear heating components can cover the front edge of the heating rotor. By adopting the heating components and theheat transfer and insulation parts which are specially arranged, the heating efficiency of the rotor is improved, and the deicing efficiency of the rotor is favorably improved.

Owner:SHANDONG UNIV

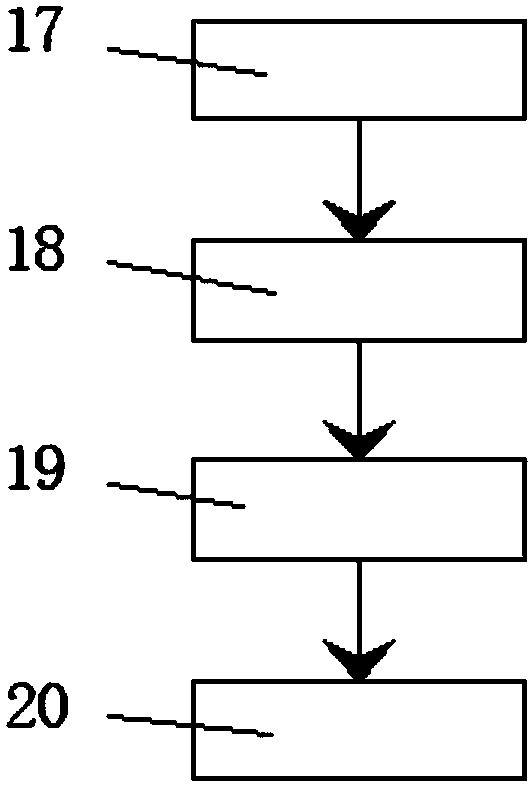

Method for bending forming of windshield

ActiveCN107673589AEasy to bendPromote softeningGlass reforming apparatusProcess efficiencyEngineering

The invention relates to a method for bending forming of a windshield and belongs to the technical field of reforming primary glass. The method comprises the following processing steps: step one, carrying out pretreatment processing on glass; step two, preparing glass bending forming equipment; step three: introducing hot gas for softening the glass; step four, continuously introducing the hot gas, using an air bag to act on the glass, and enabling the glass to be bent and laminated on a bending die; step five, introducing cold gas and carrying out cooling forming treatment on the glass. According to the technical scheme, the problem that the windshield is low in processing efficiency of bending forming in the prior art is effectively solved; the method has the advantages of good glass bending effect, convenience for glass forming, high practicality and high processing efficiency.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

Cloth drying device

PendingCN109162049ASimple structureCompact layoutLiquid/gas/vapor removal by gas jetsTextile shapingCombined usePulp and paper industry

The invention discloses a cloth drying device comprising a left frame, a right frame, a conveying roller, a guiding roller I, a guiding roller II, a guiding roller III, a winding roller, a fan mechanism, a fixation plate, a drying mechanism and an ironing mechanism. The fan mechanism is horizontally arranged between the left frame and the right frame and is arranged at the top of the upper cuttingsurface of the conveying roller. The fixation plate is horizontally arranged between the left frame and the right frame and is arranged between the upper cutting surface of the guiding roller II andthe lower cutting surface of the guiding roller III. The drying mechanism is arranged at the top of the fixation plate. The ironing mechanism is arranged at the bottom of the fixation plate. Accordingto the cloth drying device provided by the invention, on the basis of combination of the fan mechanism and the drying mechanism, rapid and comprehensive drying of the cloth is realized; and with theironing mechanism, the dried cloth is ironed to ensure the smoothness of the cloth without any wrinkles.

Owner:丁逸飞

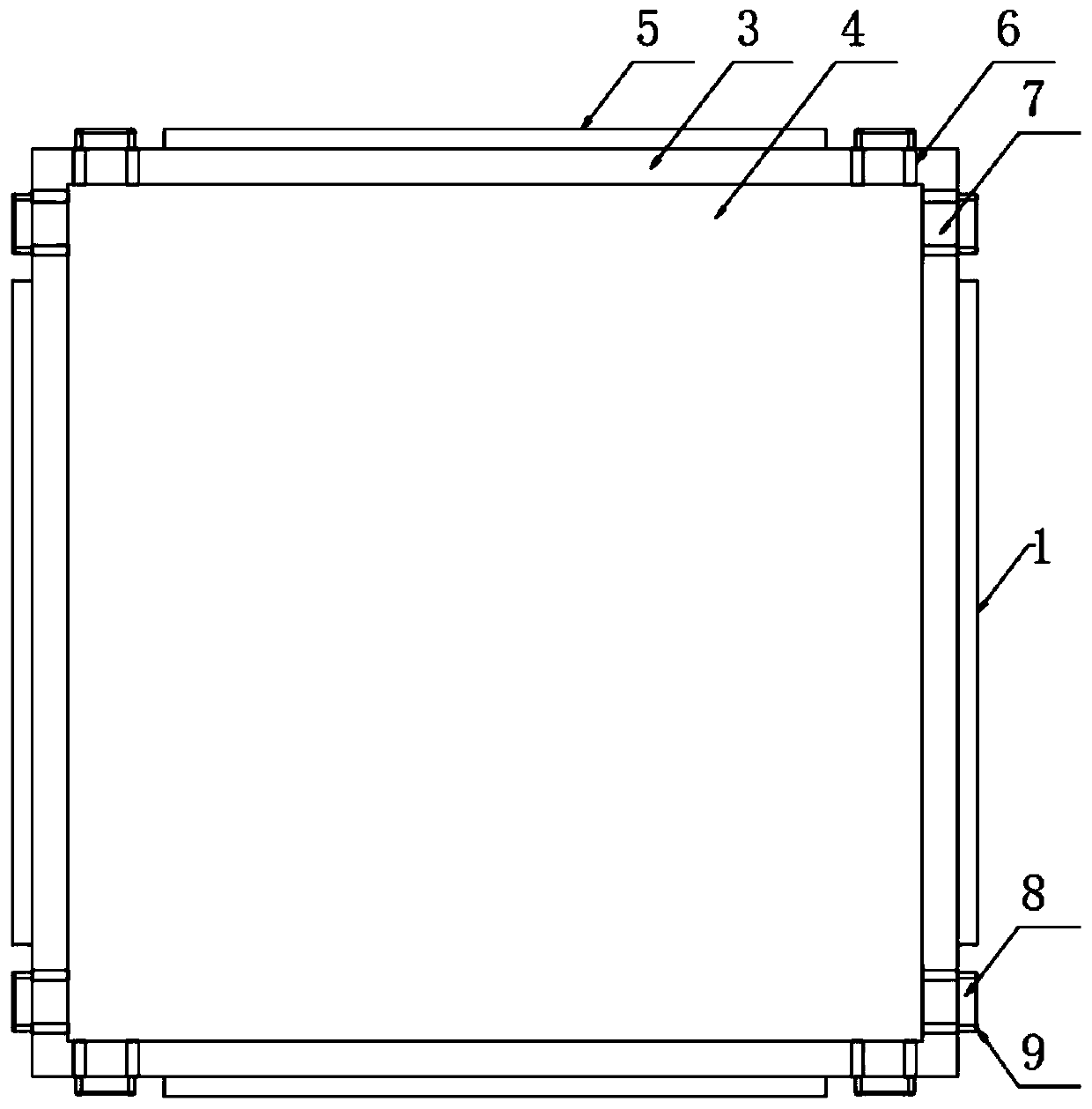

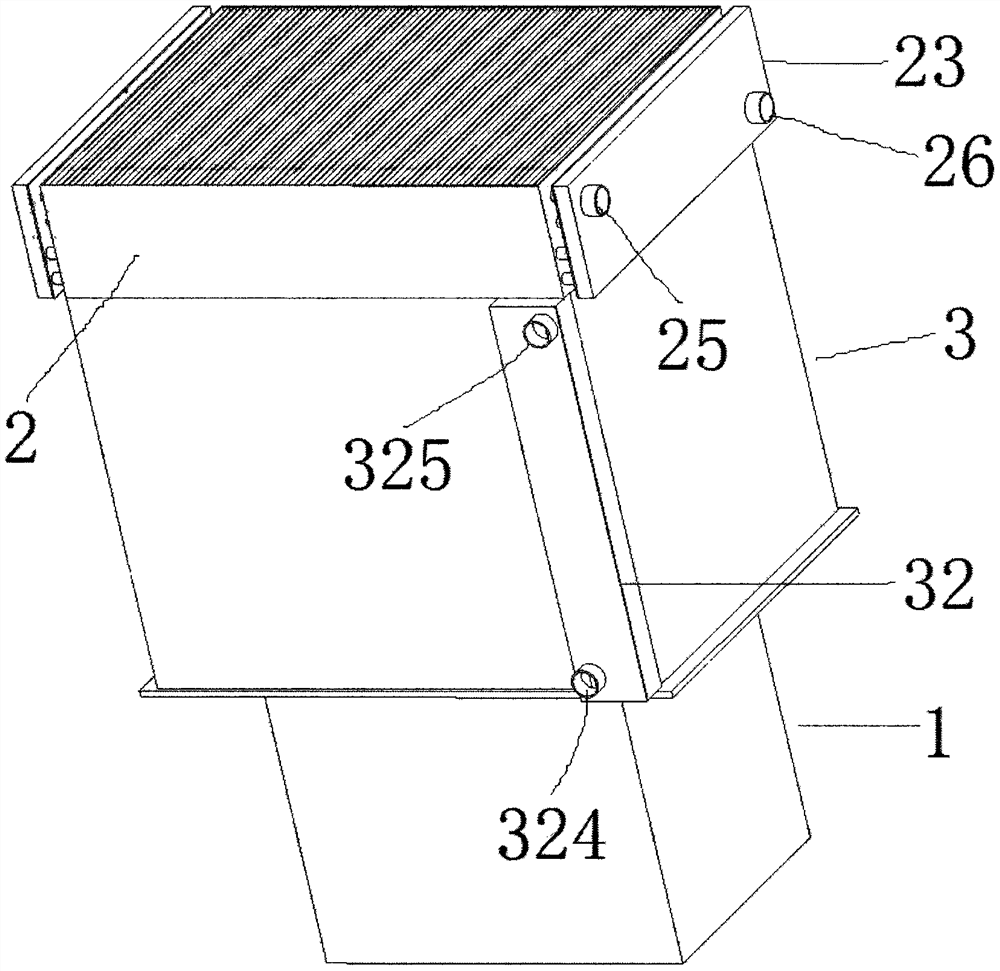

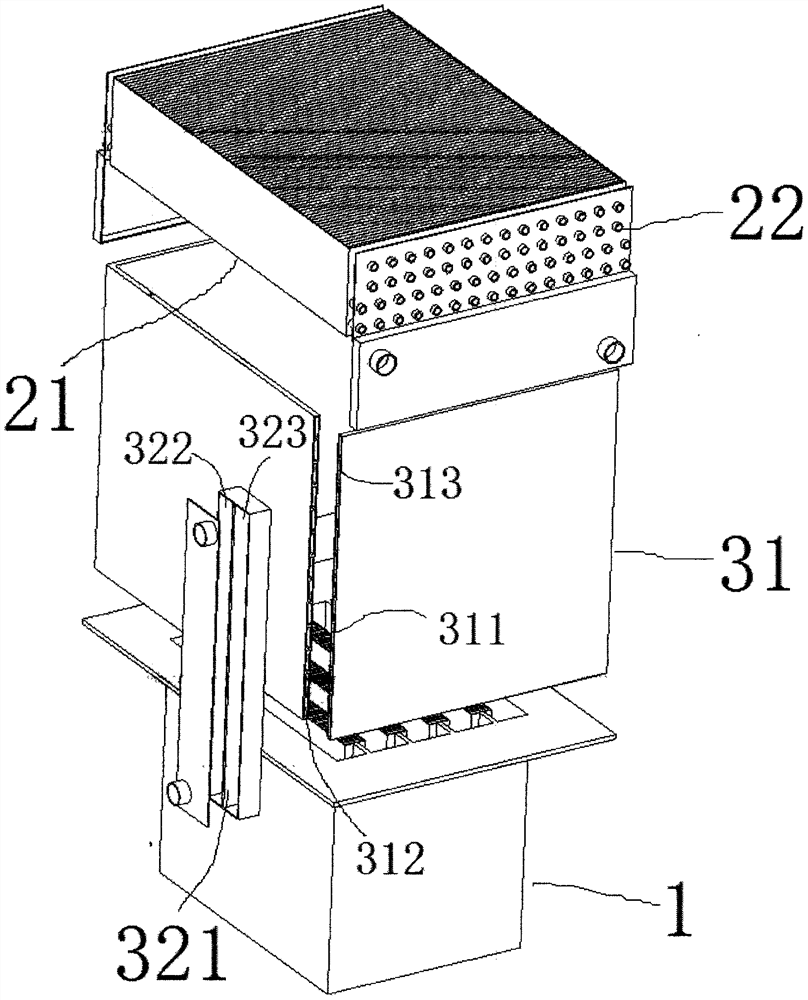

Building heat preservation and insulation mechanism

ActiveCN111197355AEasy to installSimplify the installation processLighting and heating apparatusElectric heating systemArchitectural engineeringStructural engineering

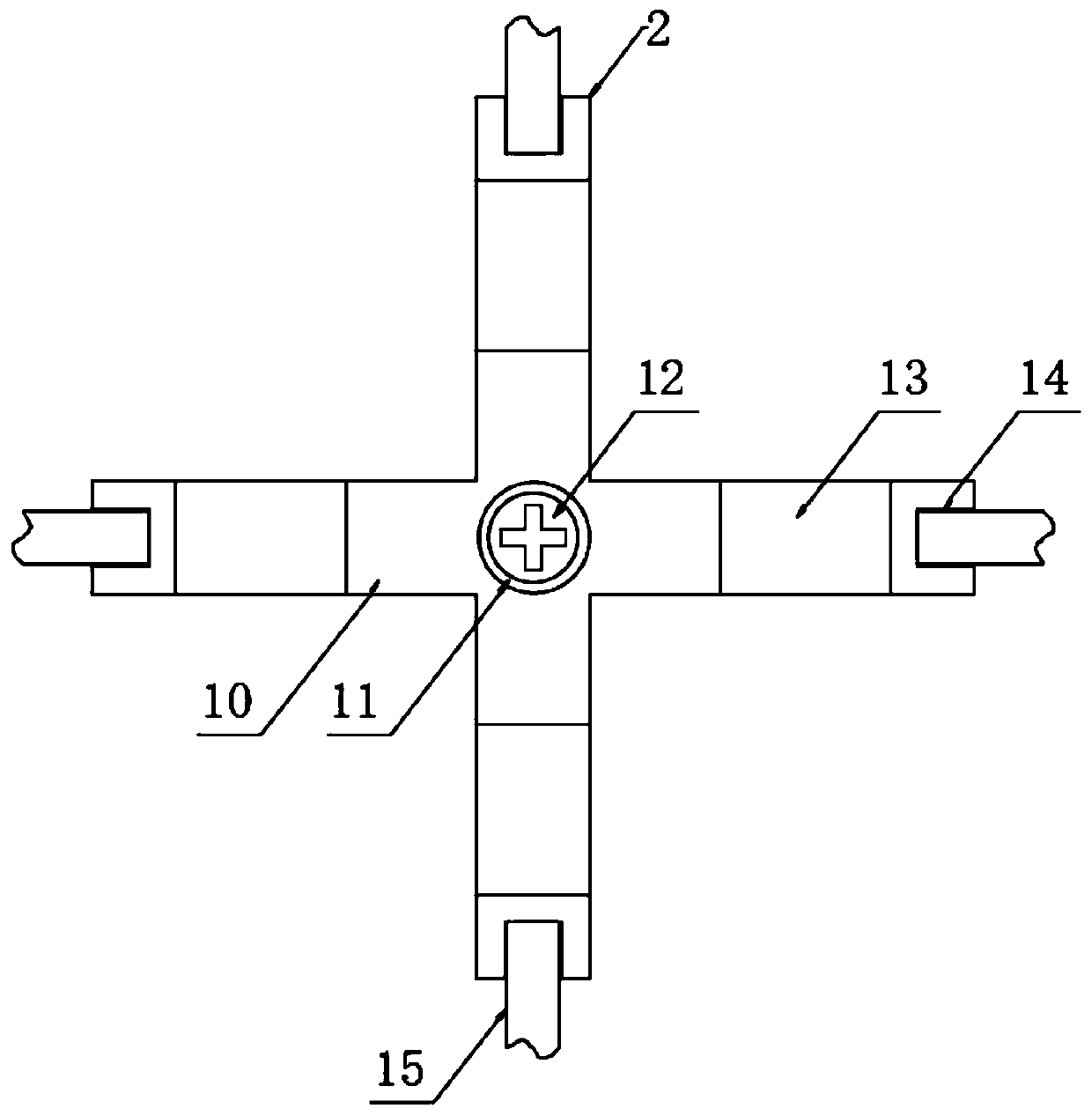

The invention discloses a building heat preservation and insulation mechanism, and belongs to the technical field of building heat insulation. According to the technical points, the building heat preservation and insulation mechanism includes a plurality of heat preservation and insulation components, and installation components are arranged between the heat preservation and insulation components;the heat preservation and insulation components include heat insulation boards, cavities are formed in the heat insulation boards, a plurality of limiting plates are evenly arranged on the outer sides of the heat insulation boards, and the plurality of limiting plates are all fixedly connected with the heat insulation boards; the installation components include cross-shaped installation frames, screw slots are formed in the centers of the front surfaces of the cross-shaped installation frames, screw holes are formed in the bottoms of the inner sides of the screw slots, and installation screwsare connected to the inner sides of the screw holes in a threaded mode; and four accommodation grooves are evenly formed in each of the cross-shaped installation frames. The building heat preservation and insulation mechanism effectively simplifies the installation process, reduces the installation difficulty, and improves the installation efficiency. In addition, since the heat preservation andinsulation components are arranged separately, compared with larger plates in the prior art, the building heat preservation and insulation mechanism is further more convenient to transport and install.

Owner:新疆智友建设工程有限公司

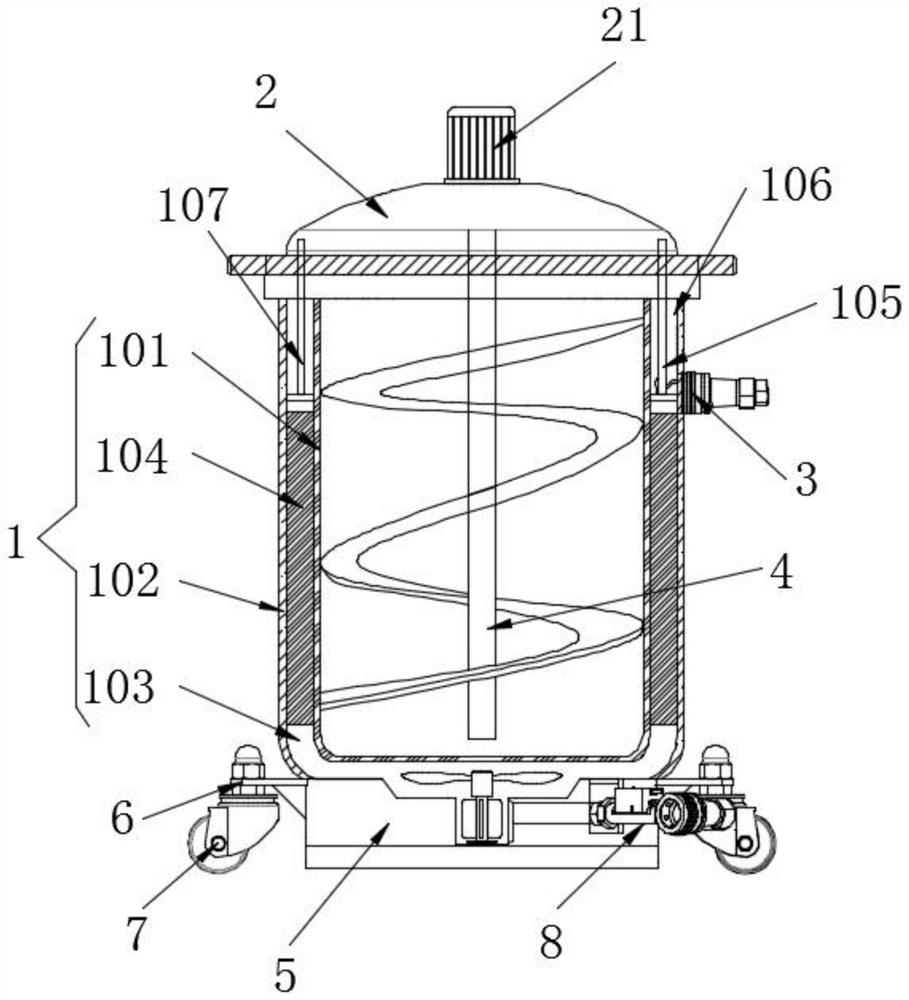

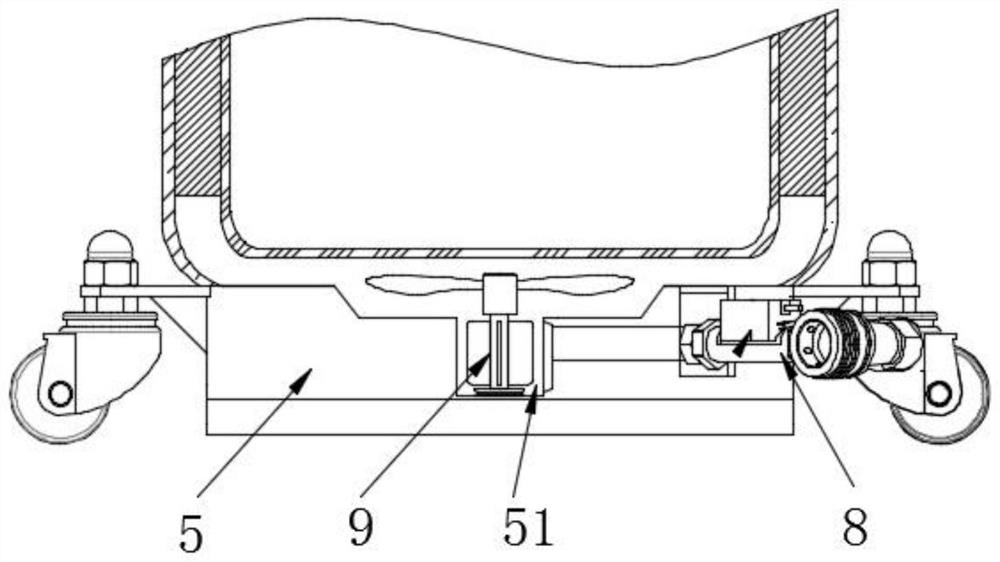

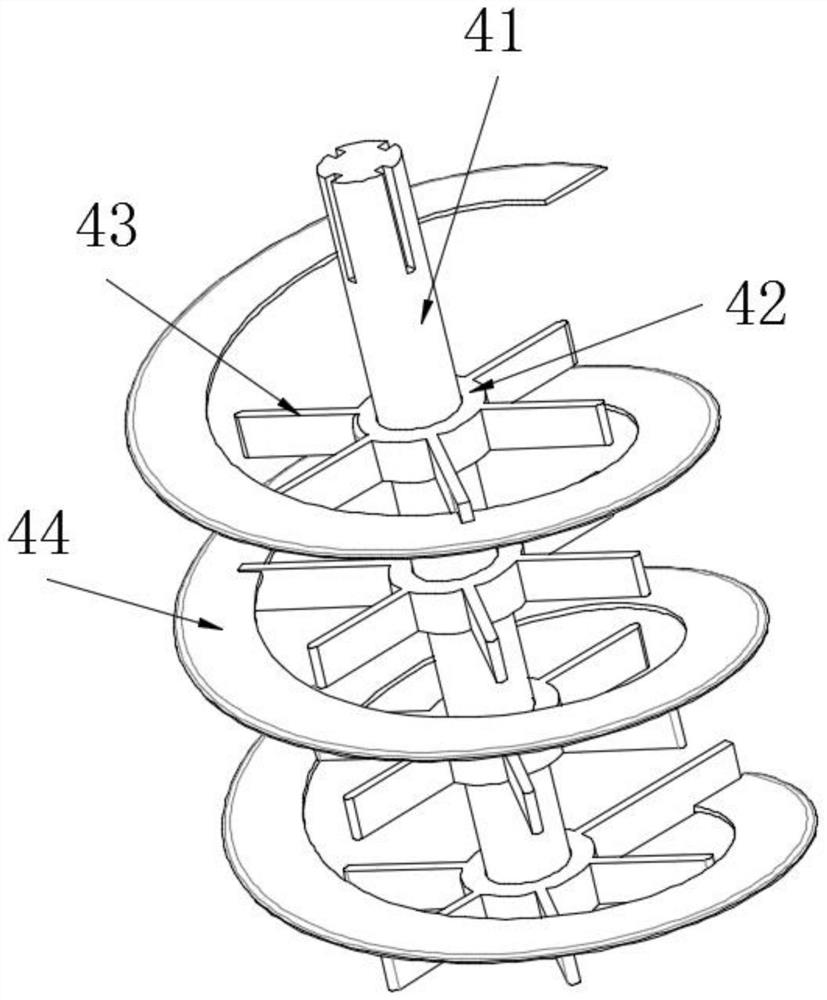

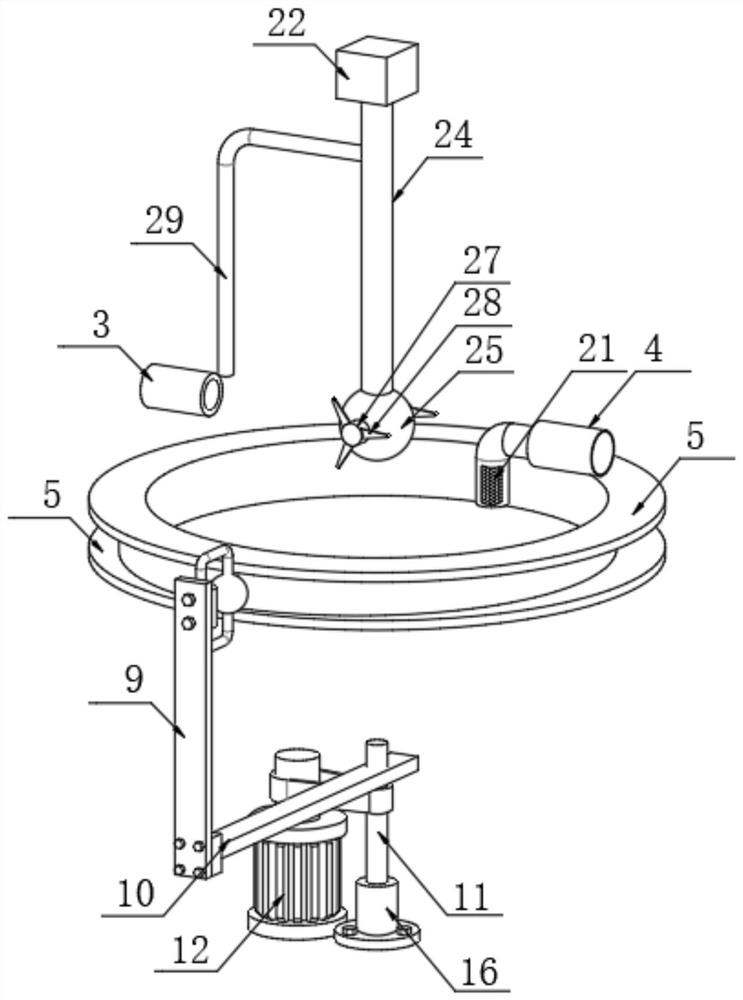

Starch gelatinization system

The invention discloses a starch gelatinization system. The starch gelatinization system comprises a gelatinization heating cylinder, a stirring assembly and a shunting mechanism, the bottom of the gelatinization heating cylinder is connected with a heating base, the heating base is further connected with an air supply mechanism, and an end cover is detachably arranged at the top of the gelatinization heating cylinder; and a stirring assembly is rotationally arranged in the gelatinization heating cylinder and used for stirring starch in the gelatinization heating cylinder and scraping and separating starch attached to the inner wall of the gelatinization heating cylinder. According to the gelatinization heating cylinder, an annular partition plate is arranged in a heating cavity formed between a heating inner container and a heating cylinder body, the annular partition plate can be adjusted to ascend and descend through an adjusting screw rod, the heating area of the gelatinization heating cylinder is changed according to the gelatinization starch amount, and the effects of saving energy and reducing the processing cost are achieved.

Owner:邵阳桂花香食品有限公司

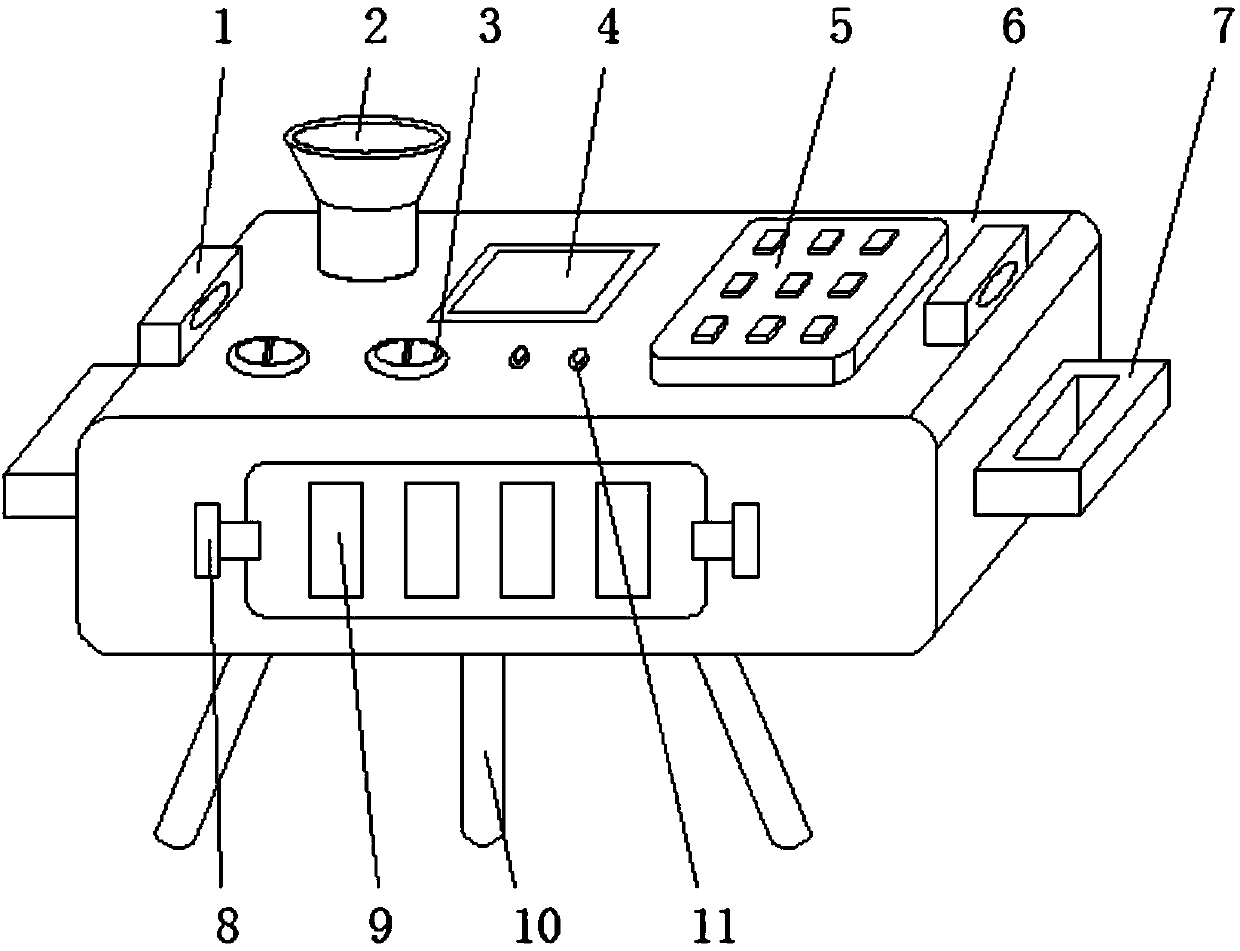

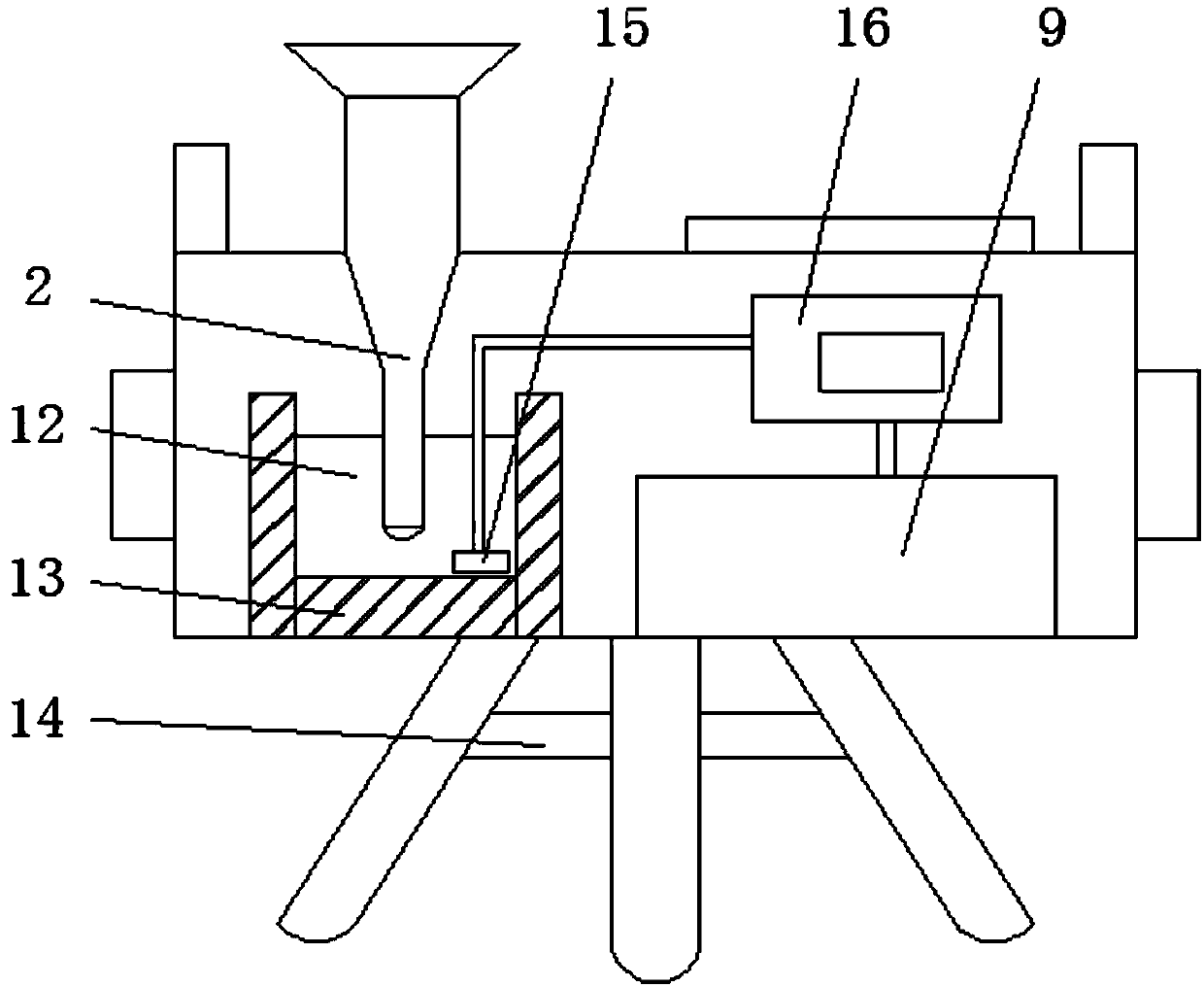

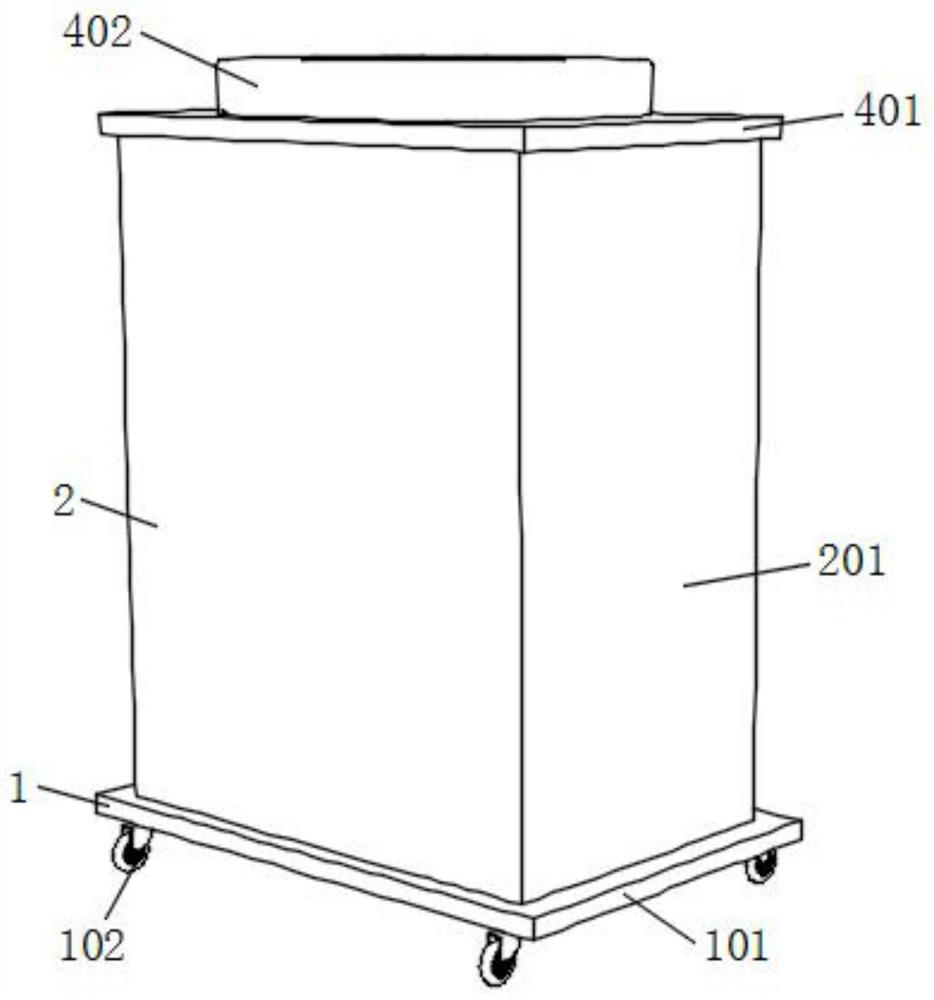

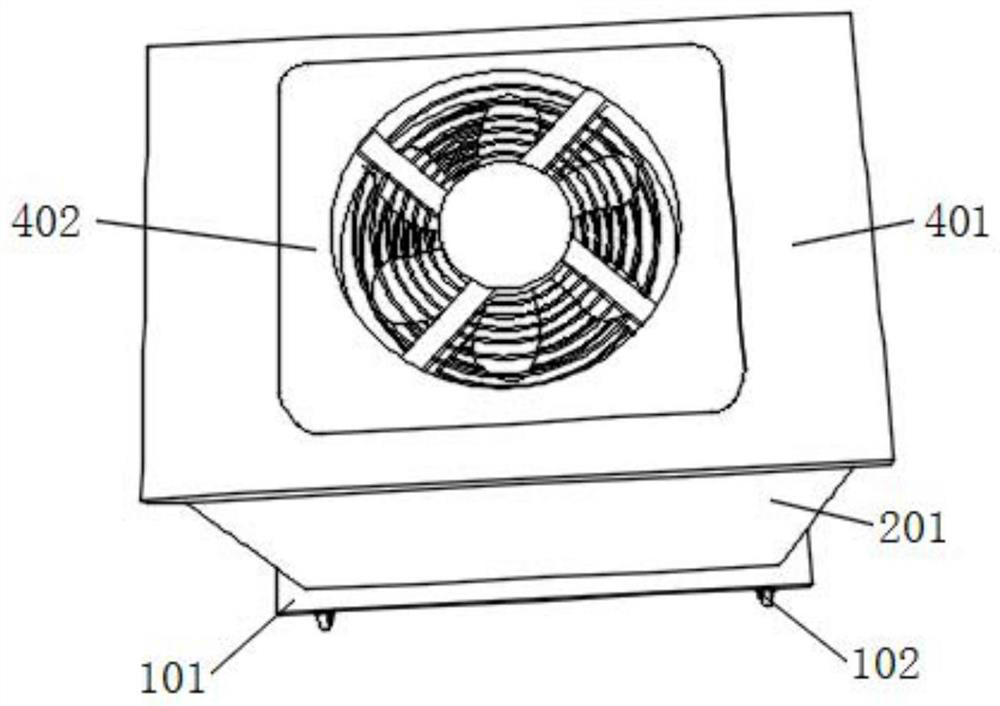

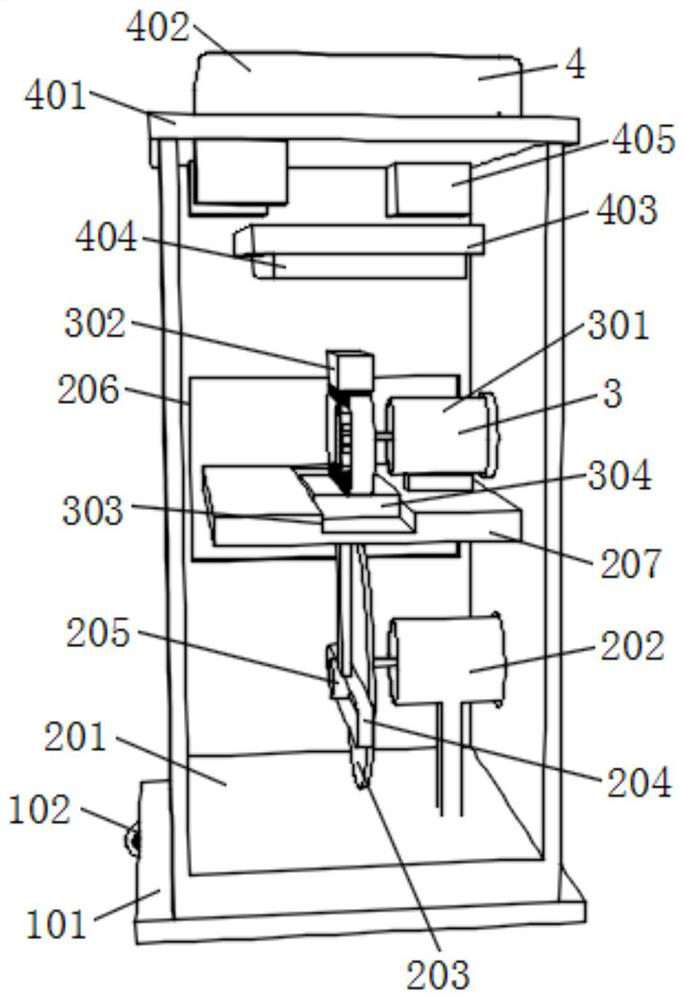

Medical assay instrument convenient to carry and move

InactiveCN109900883AEasy to carryImprove operational flexibilityBiological testingLocking plateInstrumentation

The invention discloses a medical assay instrument convenient to carry and move. The portable mobile medical assay instrument comprises chemical analysis equipment; the two sides of the outer surfaceof the chemical analysis equipment are welded with connecting interfaces; the outer surface of the chemical analysis equipment is sleeved with a waste feeding joint; an adjustable switch is arranged below the waste feeding joint; power supply storage devices and locking plates matched with the power supply storage devices are arranged on the front surface wall of the chemical analysis equipment; the outer surface wall of a water basin for cold and hot rise of an object is provided with a gasket for the cold and hot rise of the object; the output end of a filtering circuit is electrically connected with the input end of an amplifying circuit; and the output end of the amplifying circuit is electrically connected with the input end of an output circuit. The medical assay instrument disclosedby the invention is very simple in structural design, convenient to carry and move, simple to use and energy-saving, and has high practicability.

Owner:刘健

Substrate heating device and substrate heating method

ActiveCN104681402BUniform surface temperatureAvoid wastingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEtchingDiffusion layer

The present invention relates to a substrate heating device and a substrate heating method. The device comprises: a heating layer for conducting heat; a transmission tube for transmitting gas to the diffusion layer; a diffusion layer arranged on the heating layer for The gas is evenly distributed between the lead-out layer and the heating layer; the lead-out layer is arranged on the diffusion layer, and a plurality of through holes are uniformly arranged in it, and the plurality of through holes are used to lead the gas in the diffusion layer to the substrate to be heated below, so that the substrate to be heated is evenly heated. Through the technical scheme of the present invention, the substrate to be heated can be heated evenly and comprehensively, so that the temperature of the upper surface of the substrate to be heated is more uniform, so that the etching, deposition and / or sputtering processes of the substrate to be heated can obtain better effects .

Owner:BOE TECH GRP CO LTD

Dehumidifying device for textile fabric processing

ActiveCN109520255AHeating evenly and comprehensivelyImprove dehumidification effectDrying gas arrangementsDrying machines with progressive movementsEngineeringIdler-wheel

The invention discloses a dehumidifying device for textile fabric processing. The dehumidifying device comprises a first box, wherein the interior of the first box is fixedly connected to a horizontalplate; a threaded rod is arranged in the first box body below the horizontal plate; the middle part of the threaded rod is fixedly connected to a fixing block; and threads on the threaded rods of thetwo sides of the fixing block are opposite in direction. When the dehumidifying device is used, a second motor operates to enable a first belt to play a certain role of conveying and supporting a fabric, and then a plurality of air outlet housings are used for blowing hot air so as to dehumidify the fabric, so that the fabric is heated evenly and comprehensively, and further the dehumidificationeffect is relatively good; and when the device needs to be moved at work, a first motor can be opened to operate, so that the threaded rod rotates, two thread blocks are close to each other, and simultaneously a first sliding rod is driven to move in a landing manner toward liftoff idler wheels of a sliding supporting seat in a first box, so that the working force of personnel is reduced, the working time is also saved, and the working efficiency of the fabric dehumidification is improved.

Owner:江苏晟宏生态纺织科技有限公司

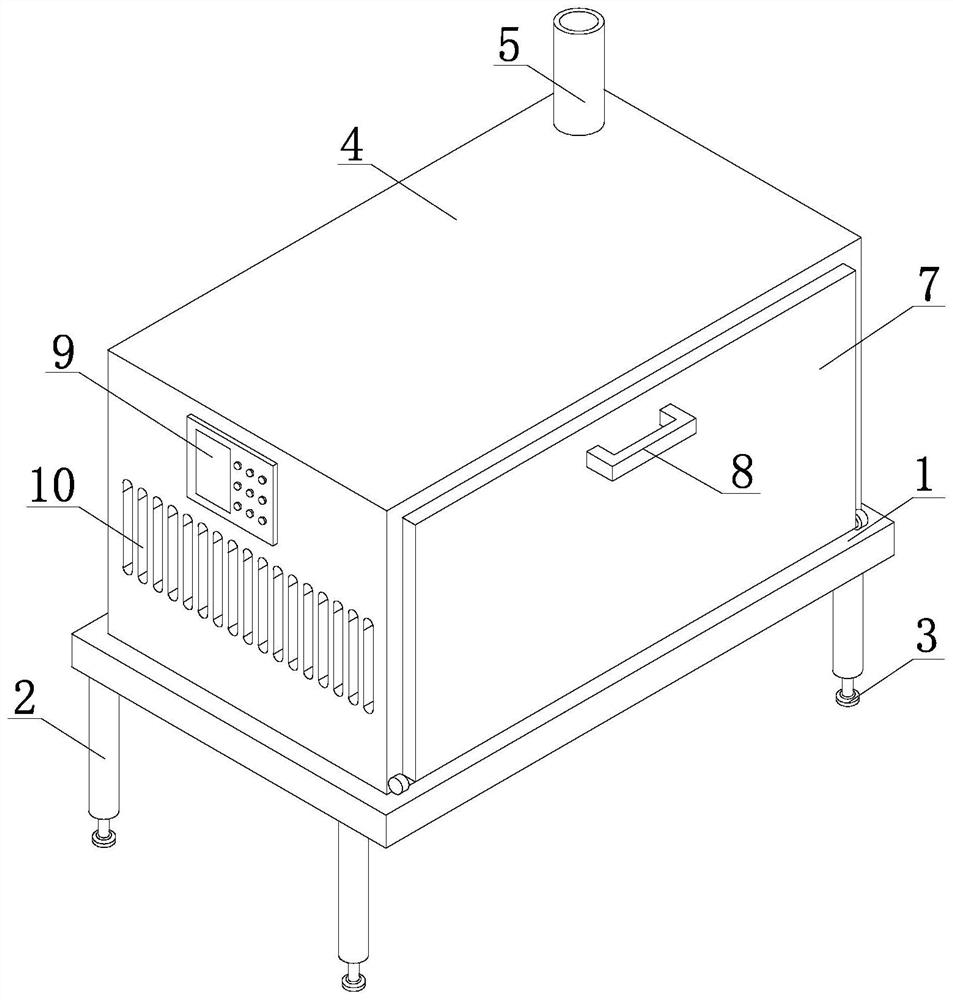

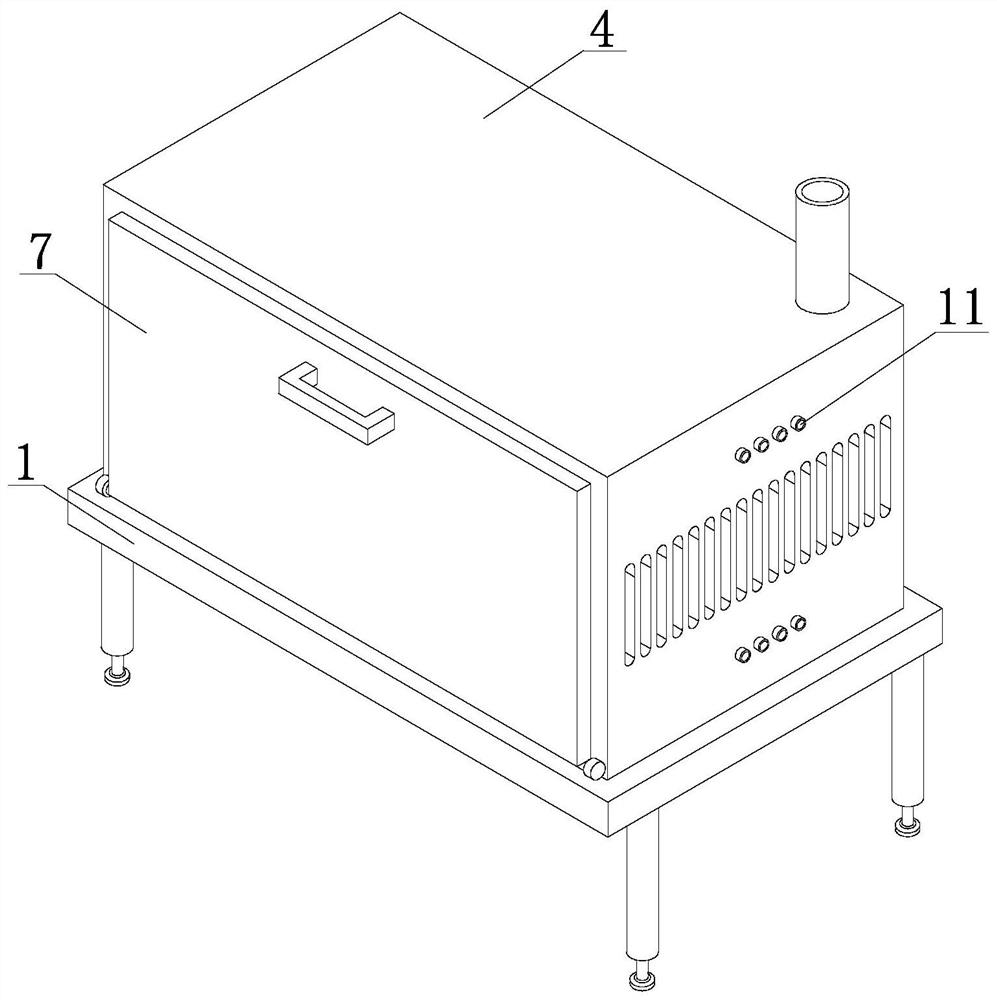

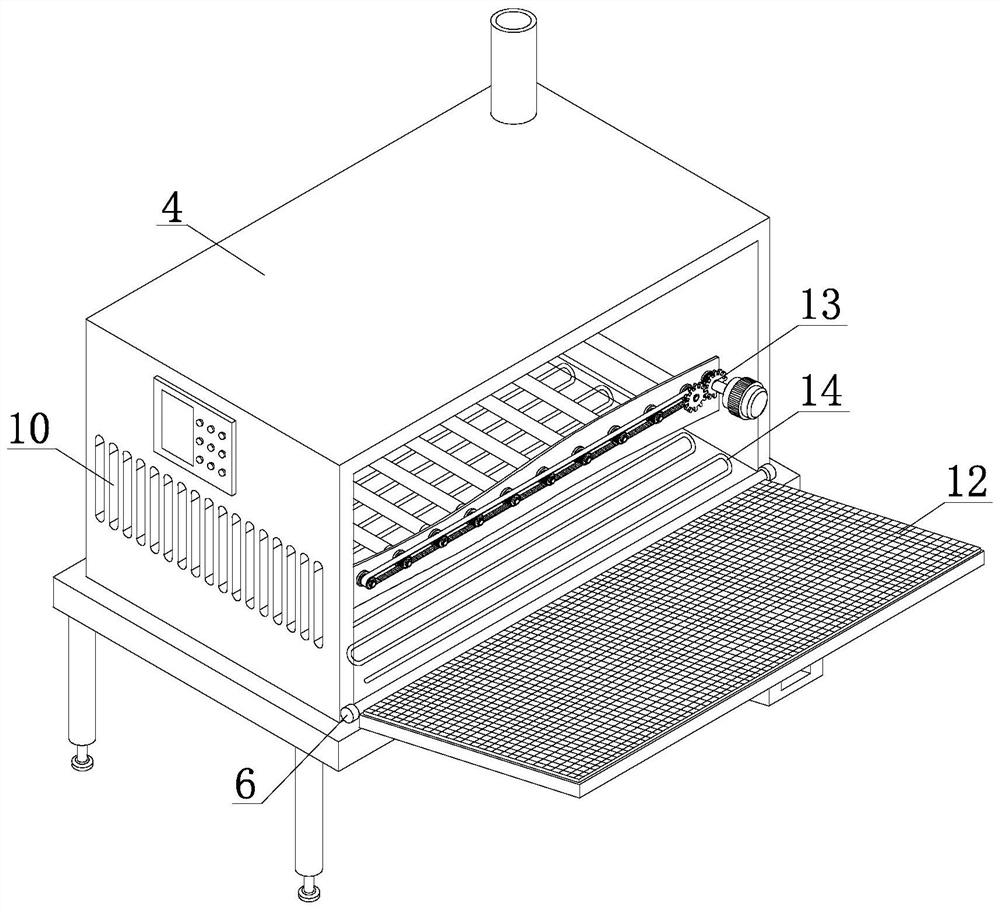

Plastic uptake heating forming device

Owner:苏州市美华包装材料有限公司

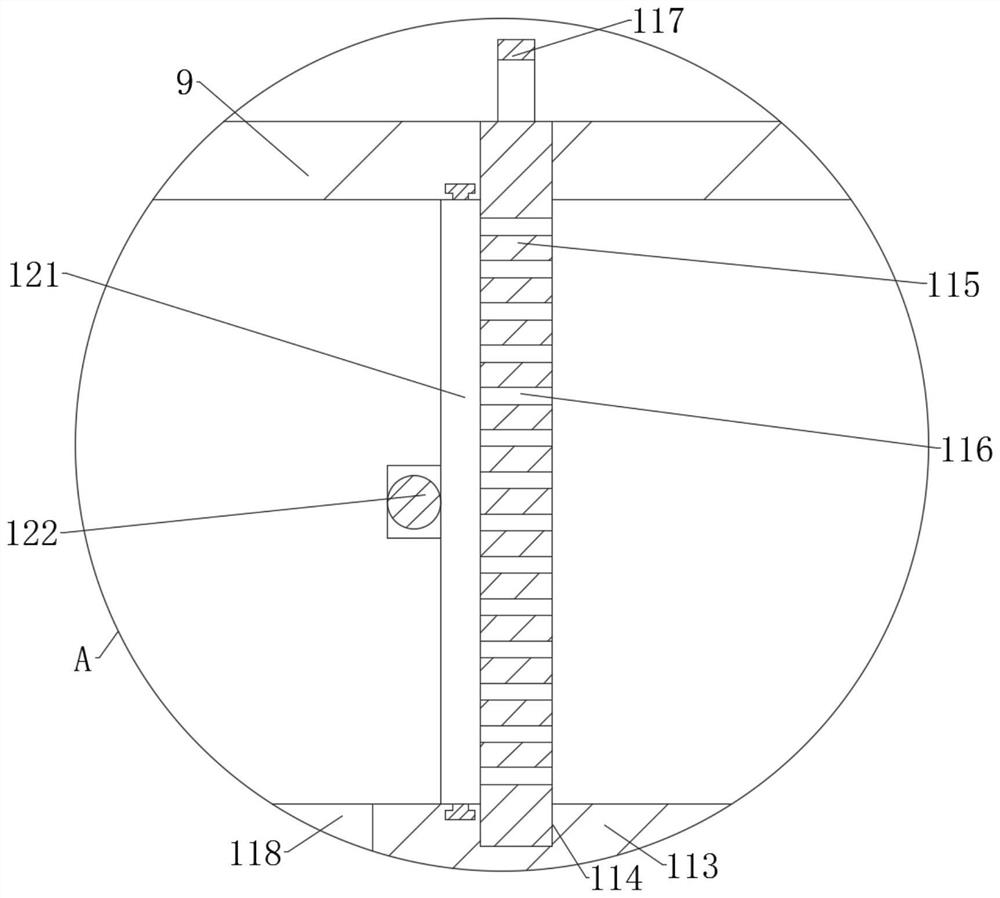

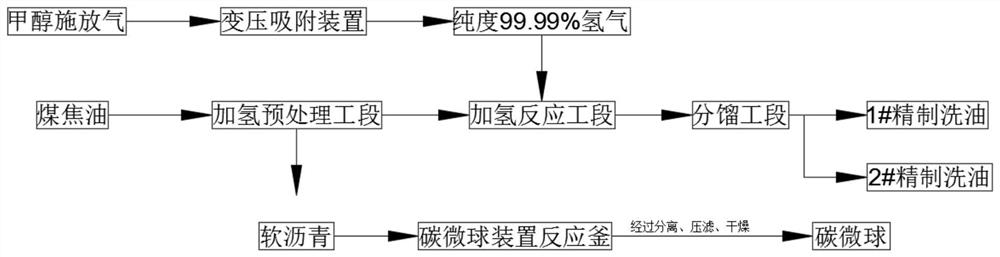

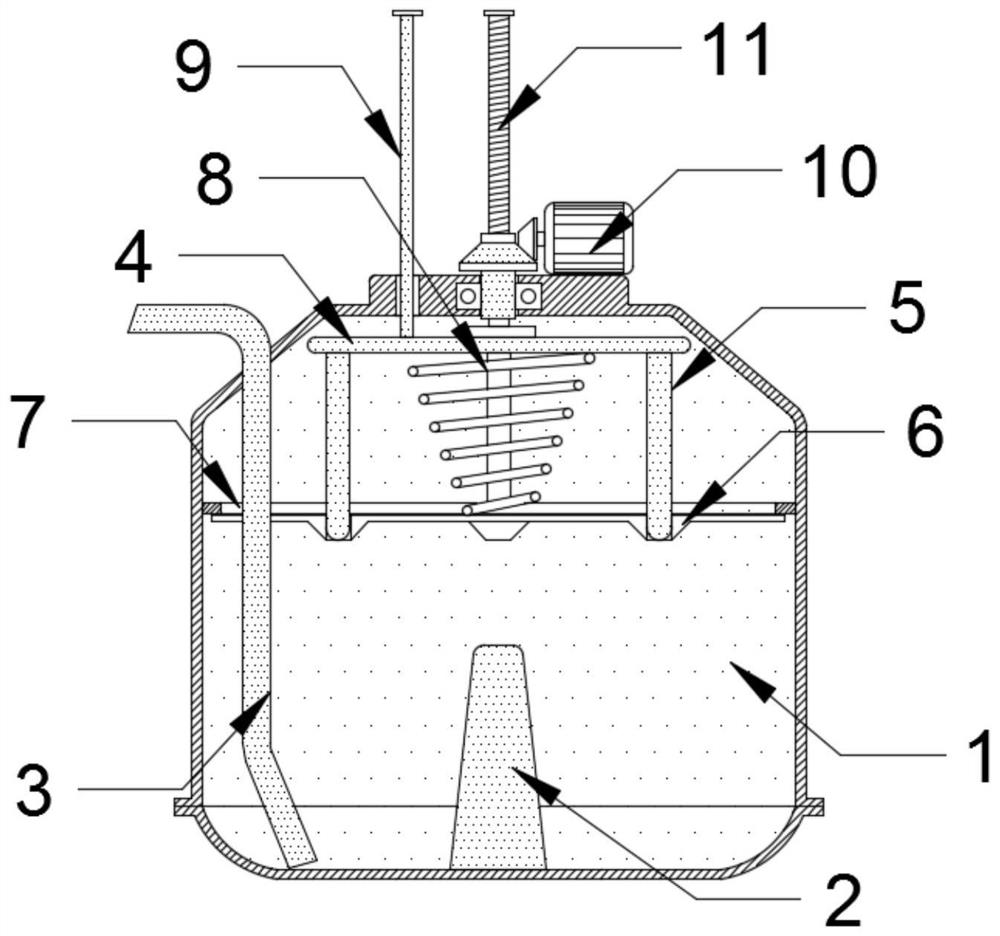

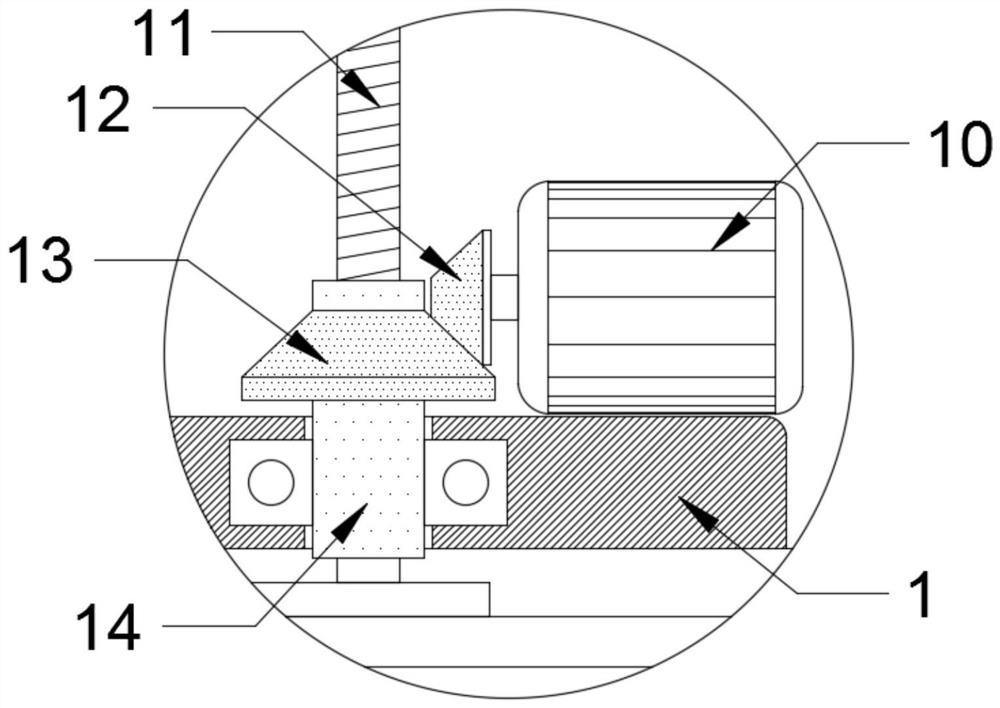

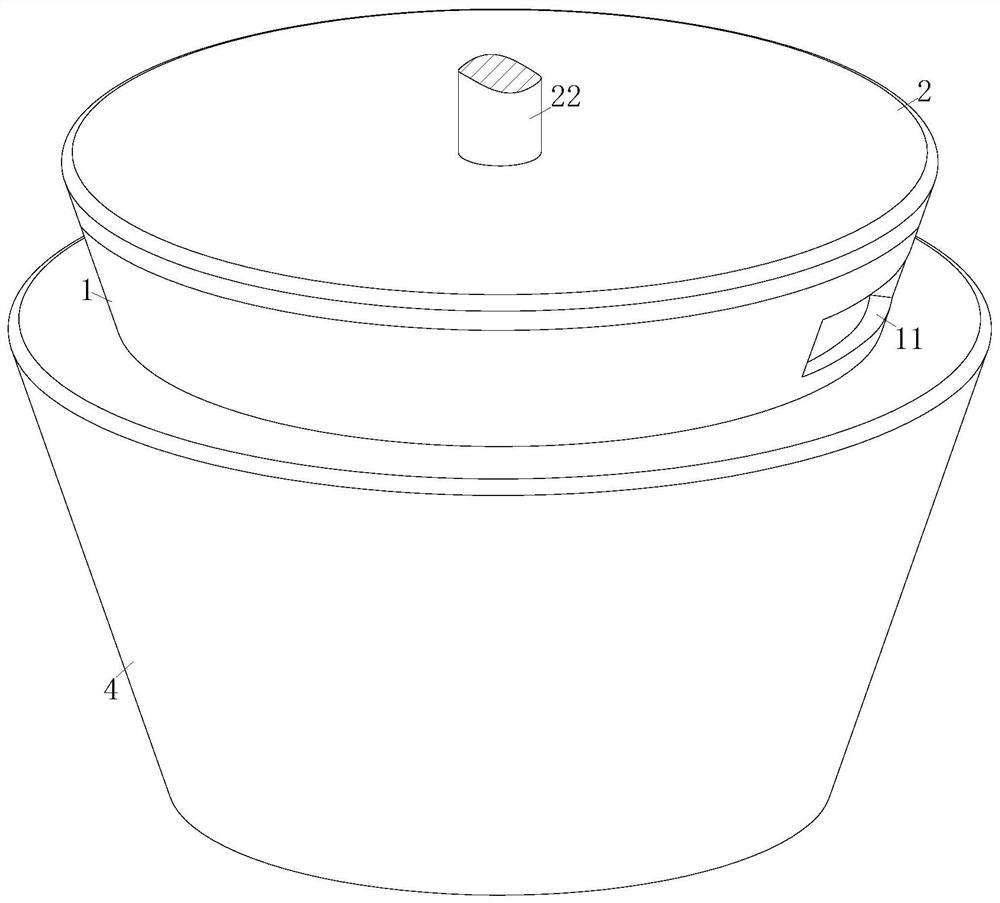

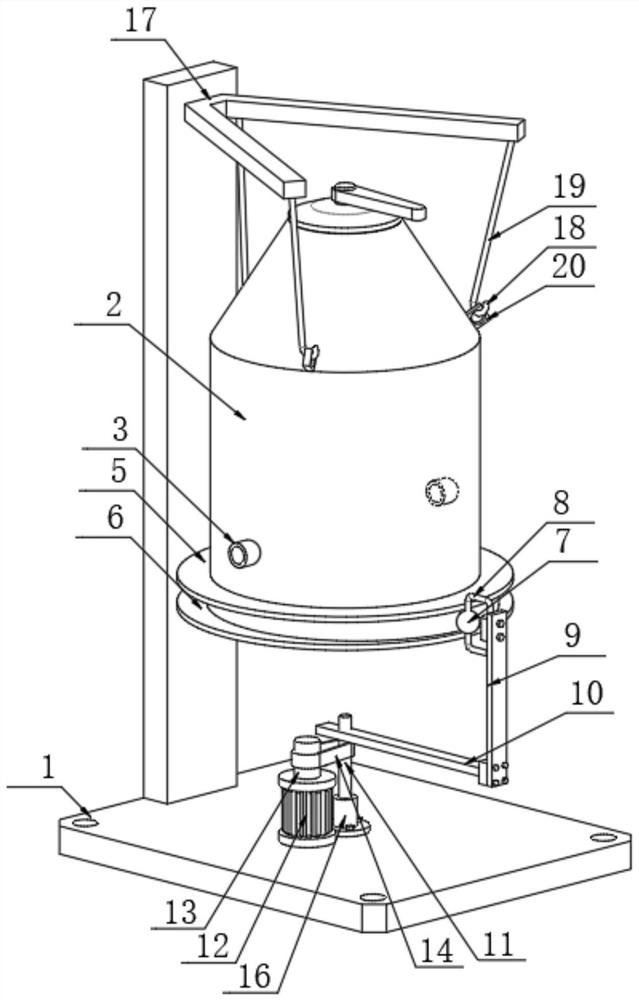

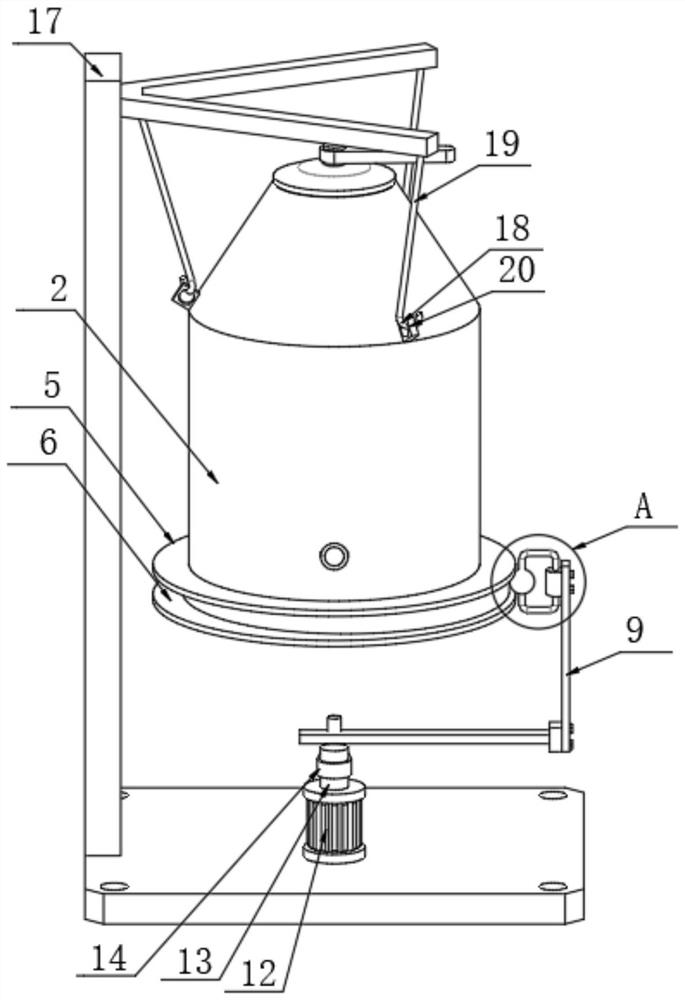

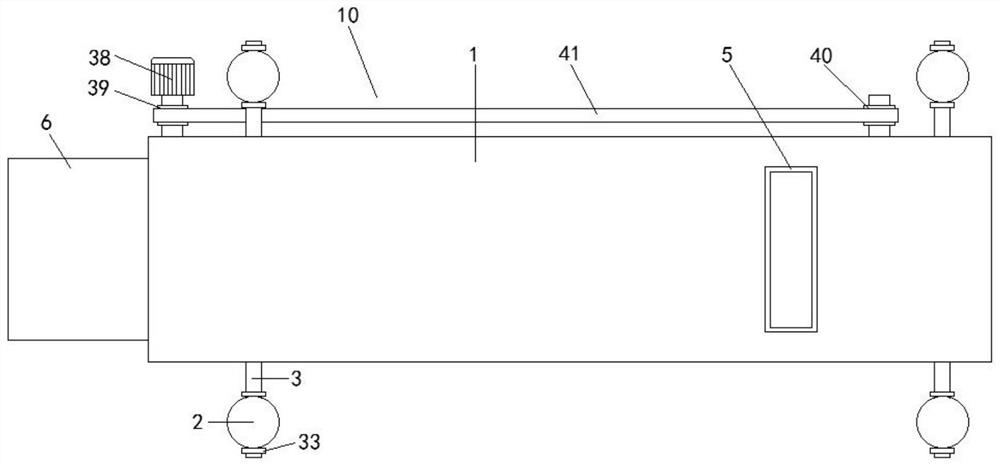

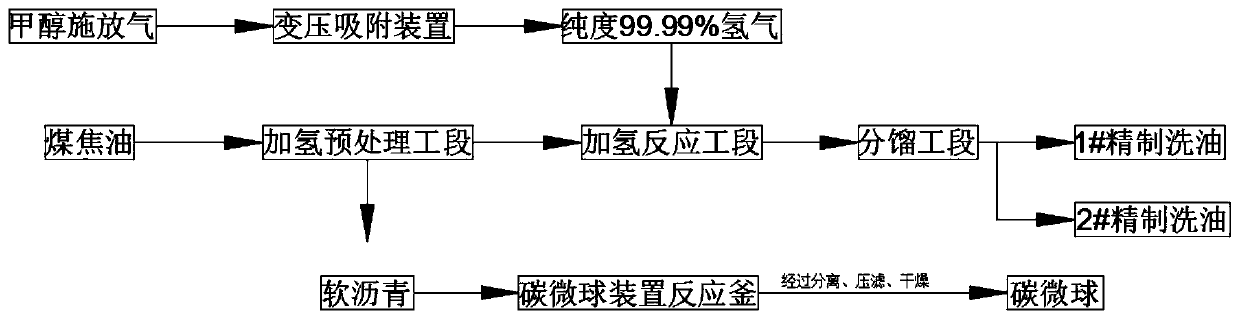

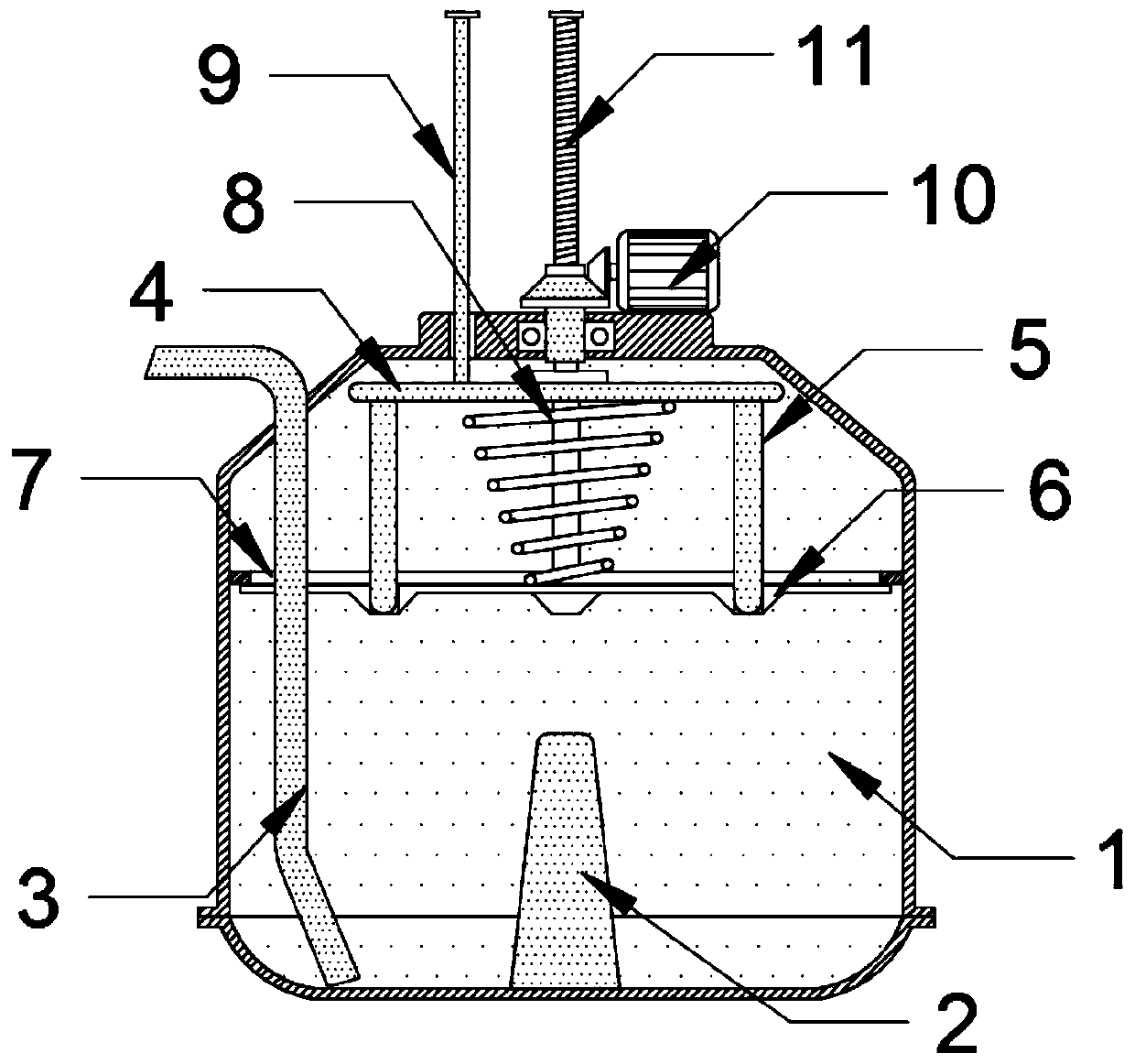

A high-temperature coal tar hydrogenation co-production equipment for mesophase carbon microspheres

ActiveCN110343536BHeating evenly and comprehensivelyImprove heating efficiencyChemical industryCarbon preparation/purificationMicrosphereElectric machine

The invention discloses a device for high-temperature coal tar hydrogenation and co-production of mesophase carbon microspheres, which includes a furnace body, a main heater, a material guide pipe, a substrate, a heating pipe, a scraper, a retaining ring, a return spring, a motor, and a screw thread. Rod, driving bevel gear, driven bevel gear and threaded sleeve, a material guide pipe is inserted on the top side of the furnace body, a main heater is installed at the center of the bottom surface of the furnace body, a base plate is arranged inside the furnace body, In addition, four heating pipes are symmetrically installed on the bottom surface of the substrate, and a threaded sleeve is installed on the top of the furnace body. This high-temperature coal tar hydrogenation co-production mesophase carbon microsphere equipment is jointly heated by the main heater and the heating pipe to improve The heating efficiency and heating uniformity of materials facilitate the production of mesophase carbon microspheres and effectively assist follow-up work. The production of this process increases the economic benefits of the enterprise, prolongs the company's industrial chain, and makes the energy represented by coal tar The industry has undergone a perfect transformation to the high-quality lithium-ion anode material industry.

Owner:七台河宝泰隆新能源有限公司

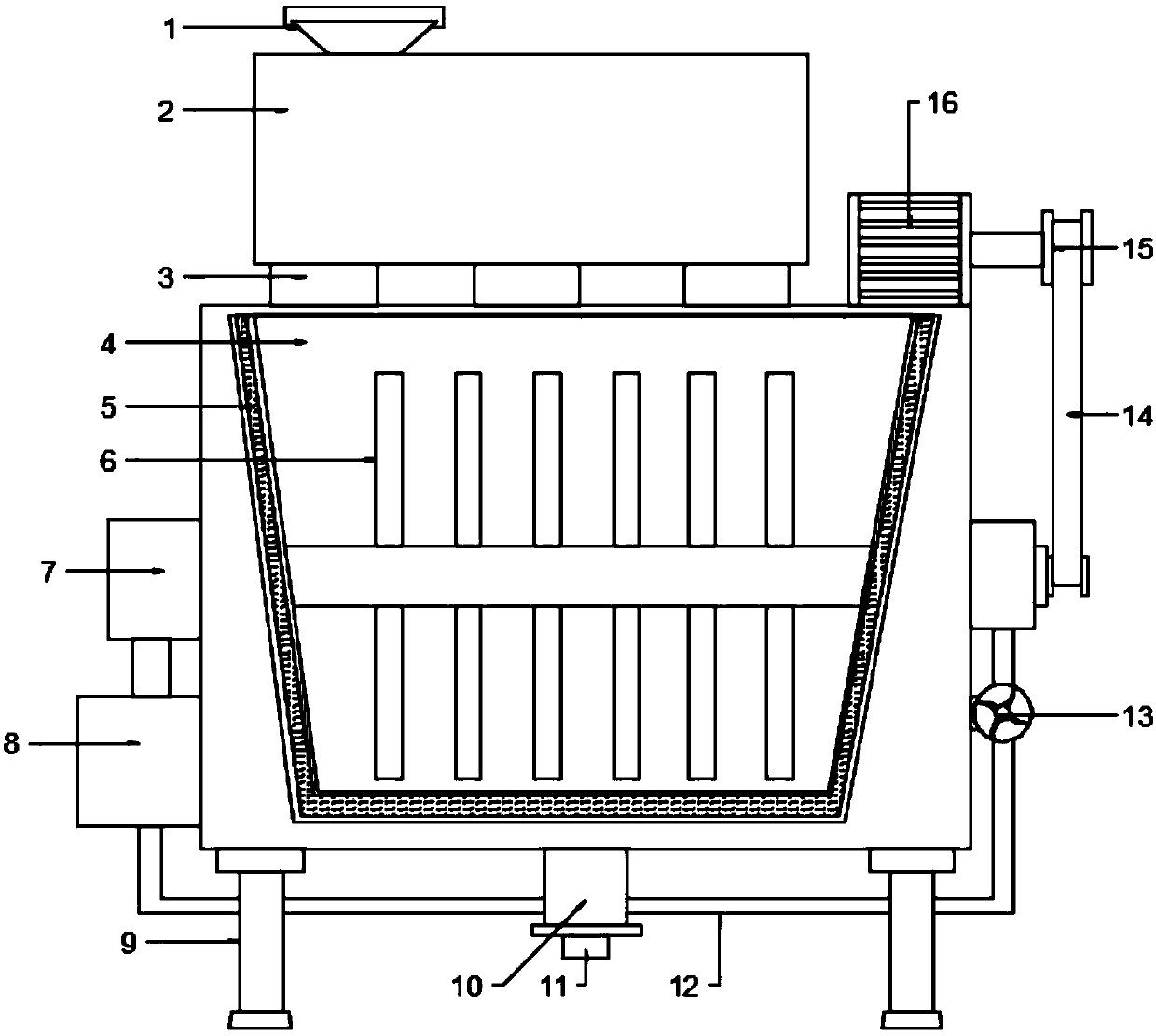

Aluminum profile smelting furnace

PendingCN113758249AHeating evenly and comprehensivelyImprove work efficiencyCrucible furnacesElectric machineryEngineering

The invention belongs to the technical field of smelting equipment, and particularly relates to an aluminum profile smelting furnace. The aluminum profile smelting furnace comprises a furnace body, a furnace cover, a first heating chamber and a second heating chamber; the side wall of the furnace body is obliquely arranged, and feeding ports are evenly distributed in the position, close to the top end, of the side wall of the furnace body; and the furnace cover is arranged at the top end of the furnace body. By arranging the first heating chamber, the second heating chamber, the feeding ports and material guiding plates, materials in the furnace body are evenly and comprehensively heated inside and outside, the problems that when a traditional smelting furnace works, because the accumulation thickness of the materials in the middle is too large, the materials are not heated in time and are always melted later are solved, and the working efficiency is improved; and by arranging a motor rotating shaft and convex blocks, the motor rotating shaft drives the furnace cover to rotate to finally drive the second heating chamber to rotate while the materials are added into the furnace body from the outside, so that the outer surface of the side wall of the second heating chamber and the convex blocks scatter the clamped materials in the rotating process, the materials can smoothly roll to the upper surface of the bottom end of the furnace body, and the working efficiency of the aluminum profile smelting furnace is further improved.

Owner:张国林

Novel water heater heating device

The invention discloses a novel water heater heating device. The device comprises a fire grate, a first heating layer and a second heating layer, the second heating layer is arranged at the upper portion of the fire grate, the first heating layer is arranged at the upper portion of the second heating layer, and the second heating layer comprises a two-layer channel and a two-layer inlet and outletbox. A two-layer spacer is arranged in the two-layer water inlet and outlet box, a plurality of flow dividing pieces are transversely arranged in the two-layer channel, a second water inlet and a second water outlet communicate with a water inlet groove and a water outlet groove correspondingly, a first water inlet and a first water outlet are formed in the outer surface of a one-layer water inlet and outlet box, and a one-layer spacer is arranged in the one-layer water inlet and outlet box; and a plurality of heating pieces are vertically arranged in a shell, and pipelines are arranged in the shell in parallel, penetrate through the heating pieces and extend out of the shell. According to the water heater heating device, through secondary heating and reduction of heat loss, the heating speed and effect are greatly improved, and meanwhile energy consumption is reduced.

Owner:汪华

Multifunctional high-purity seven-in-one chemical and pharmaceutical equipment and manufacturing process thereof

ActiveCN112206736AHeating evenly and comprehensivelyPrevent extractionChemical industrySolution crystallizationPharmacyMetallurgy

The invention provides multifunctional high-purity seven-in-one chemical and pharmaceutical equipment and a manufacturing process thereof, and relates to the technical field of pharmacy. The multifunctional high-purity seven-in-one chemical and pharmaceutical equipment comprises a bottom plate, a reaction furnace is arranged at the top of the bottom plate, a water inlet pipe is arranged on one side of the reaction furnace, a feeding pipe is arranged on the other side of the reaction furnace, an offset assembly is arranged at the bottom end of the reaction furnace, a hoisting assembly is arranged at the top end of the reaction furnace, and the offset assembly comprises an annular plate; the annular plate is fixedly connected to the bottom end of the reaction furnace, and an annular groove is formed in the outer side of the annular plate. According to the multifunctional high-purity seven-in-one chemical and pharmaceutical equipment and the manufacturing process thereof, the vertical pipe and the storage chamber at the bottom end of the vertical pipe are in full contact with reaction liquid, the interior of the reaction liquid can be heated, and the heating medium in the cavity can heat the exterior of the reaction liquid, so that the reaction liquid can be comprehensively and uniformly heated, and the reaction can be promoted.

Owner:阜新峰成化工科技发展有限公司

Circulation type reaction feed liquid heating device

The invention discloses a circulating type reaction feed liquid heating device, which comprises a support, a connecting plate is horizontally arranged on the top of the support, and is characterized in that: a groove is formed on the connecting plate, and a cylindrical groove is arranged in the groove. The outer side of the tank body is provided with a heat capacity layer, the upper part of one side of the heat capacity layer is provided with an oil inlet, the lower part of one side of the heat capacity layer is provided with an oil outlet, and a plurality of baffles are arranged horizontally in the heat capacity layer. The separator divides the heat capacity layer into a plurality of heat capacity chambers. The odd-numbered layers of the separator are provided with through holes at the right end of the tank body, and the even-numbered layers of the separator are provided with through holes at the left end of the tank body. The oil outlet is communicated with the left side of the heat capacity cavity at the top, the oil outlet is communicated with the right side of the heat capacity chamber at the bottom, and the heat capacity layer is connected with a heat oil conduction mechanism. The present invention has the advantages of reasonable design, comprehensive and uniform heating, energy saving, convenient for the thorough pouring of the reaction material and liquid, convenient cleaning and the like.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

Heat treatment processing device for high-quality carbon steel

PendingCN112981078AAchieve efficiencyAvoid burnsFurnace typesHeat treatment furnacesHot workEngineering

The invention discloses a heat treatment processing device for high-quality carbon steel. The heat treatment processing device comprises a workbench, fixed legs are welded to the four corners of the bottom of the workbench, rubber pads are installed at the bottoms of the fixed legs, a groove is downwards formed in the upper end of the workbench, a working box is clamped in the groove, a demisting cylinder is fixed to one corner of the top of the working box, and the front end face of the working box is provided with an opening; and a pin shaft is installed at the bottom of the front end face of the working box. According to the heat treatment processing device for the high-quality carbon steel, the demisting cylinder can timely volatilize water mist in the working box to the outside, so that the interior of the working box is always kept in a dry state, a sealing gasket can seal the opening of the working box, the sealing performance of the device is improved, workers are prevented from being scalded by heat in the working box, and the safety of the workers is ensured; and a rolling device can turn over a pipe body of a steel pipe, so that the pipe body of the steel pipe is comprehensively and uniformly heated, the hot working efficiency of the steel pipe is improved, intelligent operation can be achieved through automatic turning, and the safety is improved.

Owner:河北敬业中厚板有限公司

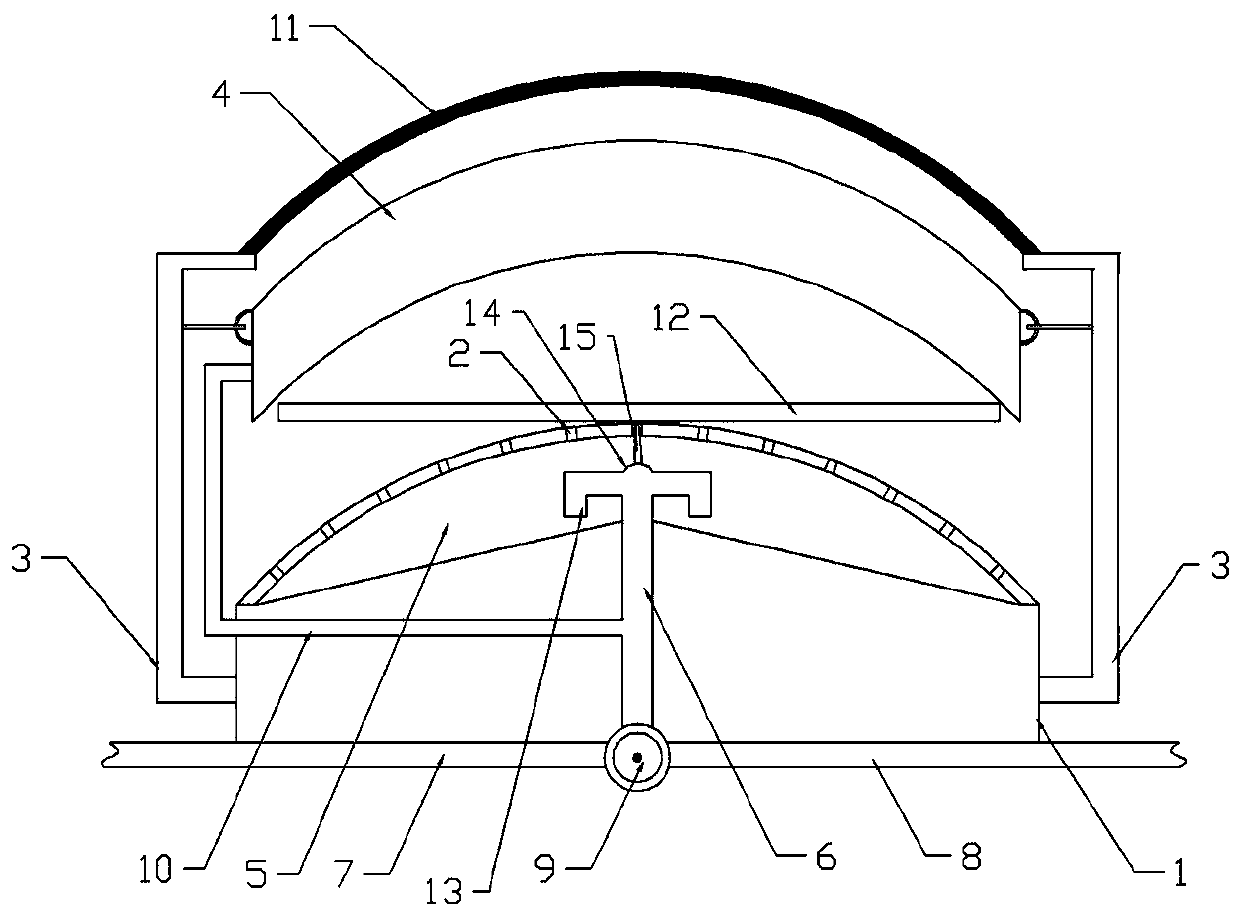

Magnet temperature control device of nuclear magnetic resonance equipment

InactiveCN111983535AIncrease the lengthImprove the heating effectMeasurements using magnetic resonanceTemperature controlNMR - Nuclear magnetic resonance

The invention discloses a magnet temperature control device for nuclear magnetic resonance equipment, relates to the technical field of the nuclear magnetic resonance equipment, and solves the problems that an existing temperature control device adopts hot air blowing heating, the hot air is mostly directional incoming air, only single-side blowing heating can be performed on the magnet, and blowing dead angles exist. The magnet temperature control device of the nuclear magnetic resonance equipment comprises a motor, an arc-shaped clamping plate, adsorption strip plates and a stress push plate, the motor comprises a sector gear, the middle of the top end of an arc-shaped shell is provided with the motor in a supporting mode, and a rotating shaft of the motor is sleeved with a sector gear;the arc-shaped shell comprises a transverse support positioning shaft; and two transverse support positioning shafts are symmetrically supported and welded at the root positions of the left side and the right side of the inner space of the arc-shaped shell. The front and rear groups of adsorption strip plates can intermittently slide back and forth oppositely in a reciprocating manner to adsorb and clean deposited dust swept from the inner wall of the bottom of the arc-shaped shell, so that the trouble of manual cleaning is saved.

Owner:李宁菘

A method of bending and forming a windshield

The invention relates to a method for bending forming of a windshield and belongs to the technical field of reforming primary glass. The method comprises the following processing steps: step one, carrying out pretreatment processing on glass; step two, preparing glass bending forming equipment; step three: introducing hot gas for softening the glass; step four, continuously introducing the hot gas, using an air bag to act on the glass, and enabling the glass to be bent and laminated on a bending die; step five, introducing cold gas and carrying out cooling forming treatment on the glass. According to the technical scheme, the problem that the windshield is low in processing efficiency of bending forming in the prior art is effectively solved; the method has the advantages of good glass bending effect, convenience for glass forming, high practicality and high processing efficiency.

Owner:CHONGQING SHUNHUA SAFETY GLASS CO LTD

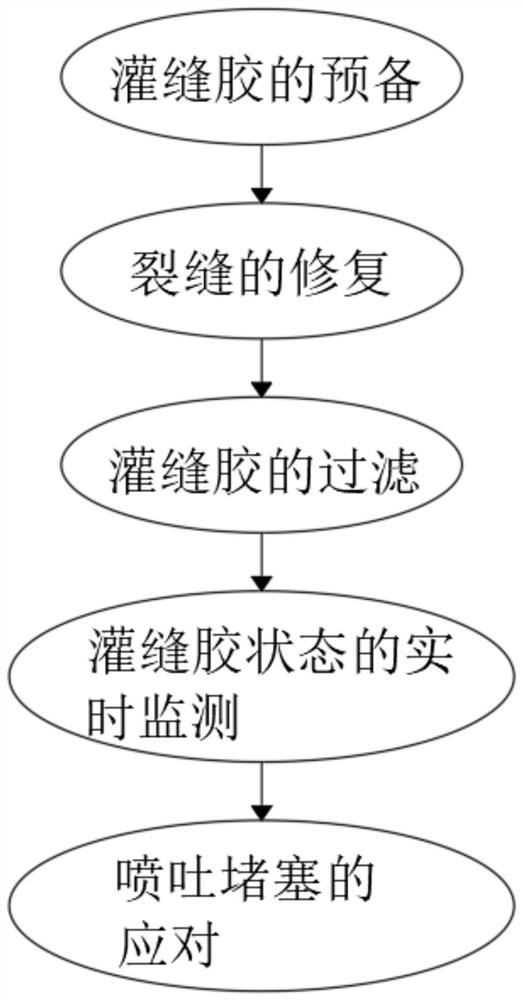

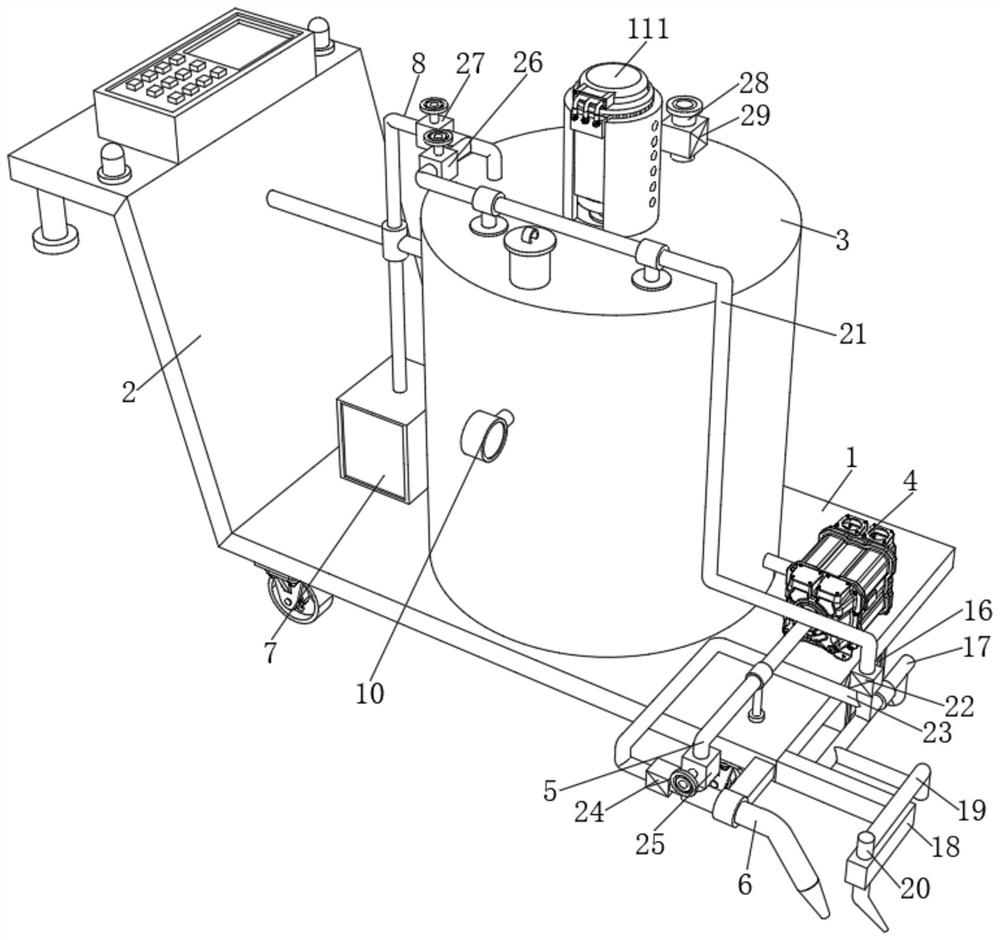

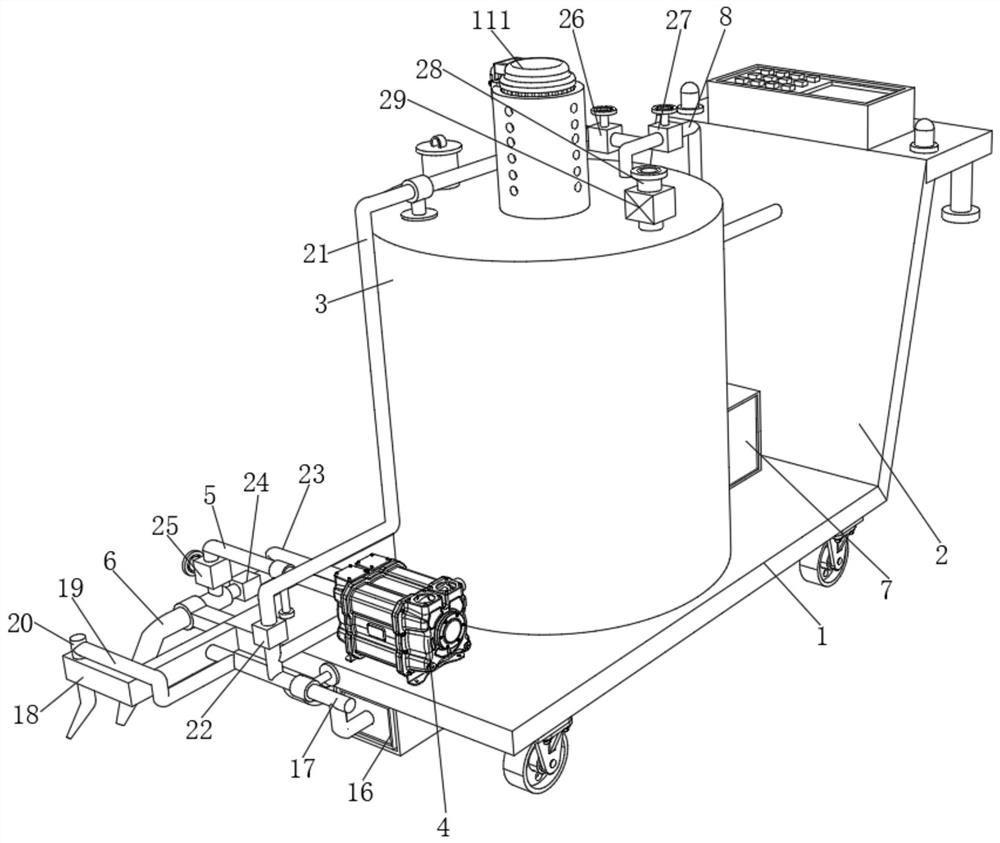

Road maintenance crack pouring construction process

PendingCN114775394AAvoid localized heatIncrease contact timeShaking/oscillating/vibrating mixersTransportation and packagingHighway maintenanceGear pump

The invention discloses a road maintenance crack pouring construction process which is characterized by comprising the following steps: S1, preparation of crack pouring glue: a constructor adds molten crack pouring glue into a placing tank (3) of a crack pouring device, then a heater (7) is started, the heater (7) continuously heats the bottom of the placing tank (3), and the bottom of the placing tank (3) is heated continuously; the contact time of the crack pouring glue at the bottom of the placing tank (3) and heat is prolonged, so that the crack pouring glue in the placing tank (3) is comprehensively and uniformly heated; step S2, crack repairing: after heating is completed, a constructor pushes a crack pouring device to the crack, then an air pump (16) and a gear pump (4) are started, compressed air is provided by the air pump (16), the compressed air is sprayed into the crack through an air spraying head (20) so as to remove impurities in the crack, then crack pouring glue in a placing tank (3) is conveyed into a spraying head (6) through the gear pump (4), and the crack pouring glue is sprayed into the spraying head (6) through the spraying head (6); the crack pouring glue is sprayed to the crack, and the crack is repaired.

Owner:马换玲

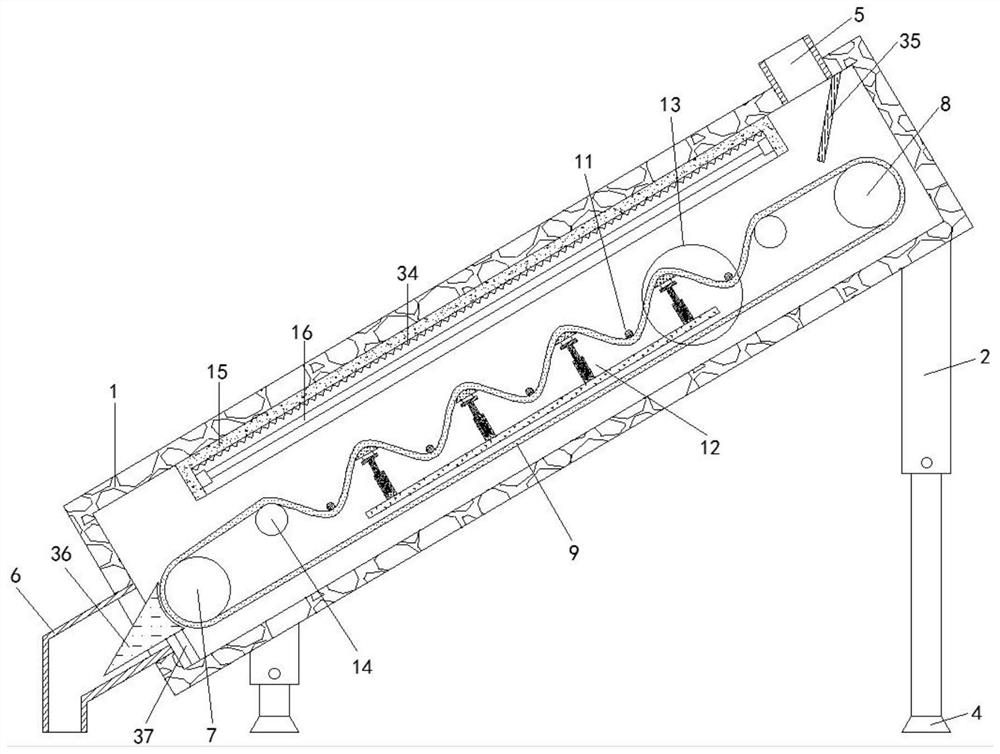

Raw material preheating device for capacitor plastic shell processing

The invention discloses a raw material preheating device for capacitor plastic shell processing, and relates to the technical field of capacitor plastic shell processing. The device comprises a preheating box, wherein the preheating box is obliquely arranged, the top of the upper end of the preheating box communicates with a feeding channel, the lower end of the preheating box communicates with a discharging channel, a driving roller, a driven roller and a conveying belt connecting the driving roller and the driven roller are arranged in the preheating box, and the driving roller and the driven roller are driven by a driving mechanism to rotate; a plurality of downward pressing mechanisms and jacking structures are arranged between the driving roller and the driven roller, the downward pressing mechanisms and the jacking structures are arranged in a staggered mode, the conveying belt penetrates through the downward pressing mechanisms and the jacking structures to form a continuous wavy structure, and guide rollers used for guiding the conveying belt are symmetrically arranged at two ends of the wavy structure; a heat insulation cover is fixedly connected to the inner top wall of the preheating box, and an infrared heating lamp tube is fixedly connected into the heat insulation cover. Defects in the prior art are overcome, plastic raw materials are evenly preheated, and the machining efficiency is improved.

Owner:TONGLING CHANGMAN PLASTIC CO LTD

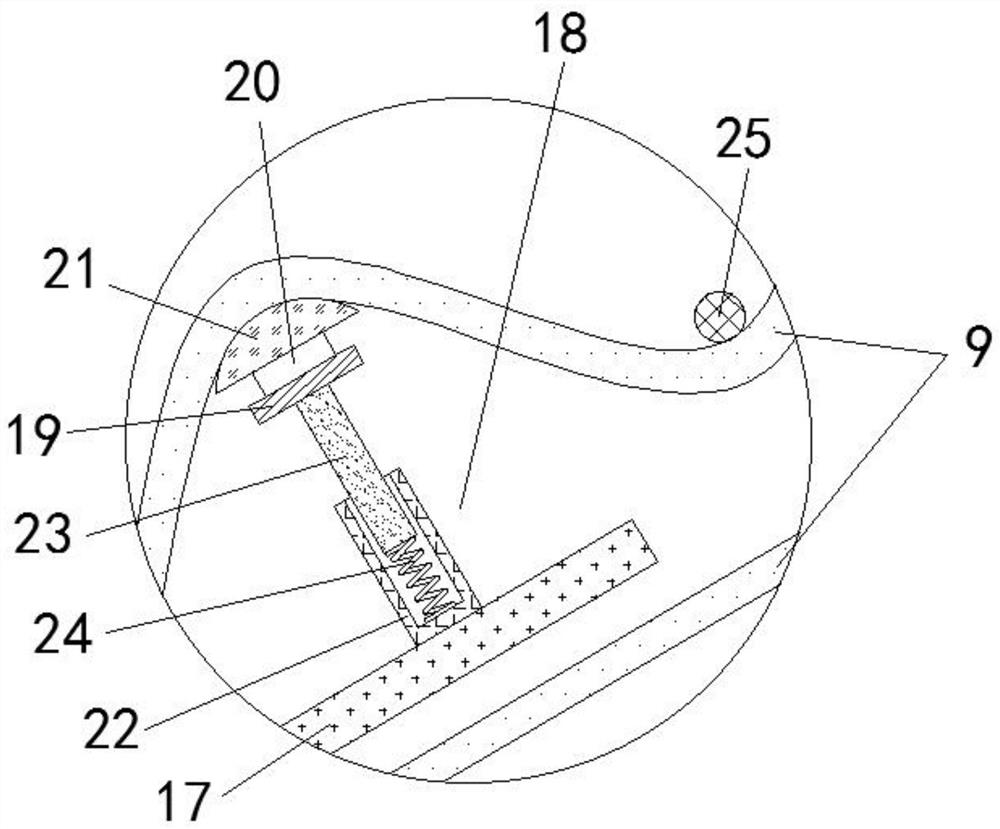

Equipment for coproduction of interphase charcoal microspheres through hydrogenation of high-temperature coal tar

ActiveCN110343536AHeating evenly and comprehensivelyImprove heating efficiencyChemical industryCarbon preparation/purificationLithiumMicrosphere

The invention discloses equipment for coproduction of interphase charcoal microspheres through hydrogenation of high-temperature coal tar. The equipment comprises a furnace body, a primary heater, a material guide pipe, a base plate, four heating pipes, a scraper, a retaining ring, a restoring spring, a motor, a threaded rod, a driving bevel gear, a driven bevel gear and a threaded sleeve, whereinthe material guide pipe is inserted to one side of the top of the furnace body, the primary heater is mounted at a central position of the bottom surface of the furnace body, the base plate is arranged inside the furnace body, the four heating pipes are symmetrically mounted on the bottom surface of the base plate, and the threaded sleeve is rotatably mounted at the top of the furnace body. According to the equipment for coproduction of the interphase charcoal microspheres through hydrogenation of the high-temperature coal tar, through joint heating of the primary heater and the heating pipes, the efficiency and uniformity of heating of materials are increased, the generation of the interphase charcoal microspheres is facilitated, and proceeding of follow-up work is effectively assisted;and due to production by the process, economic benefits of enterprises are increased, industry chains of companies are prolonged, and perfect transformation of energy industries represented by coal tar into a high-quality lithium-ion negative-pole material industry is performed.

Owner:七台河宝泰隆新能源有限公司

Electromagnetic heating cookware and three-dimensionally heated electromagnetic cooking appliance

ActiveCN102920310BFirmly connectedBeautiful appearanceCooking-vessel materialsPressure-cookersEngineeringElectromagnetic heating

The invention relates to an electromagnetic heating cookware and a three-dimensionally heated electromagnetic cooking appliance. The electromagnetic heating cookware is formed by stretching aluminum plates and is a cylindrical cookware with a bottom. The cookware comprises a pot body, a pot bottom, a transition part and a magnetic conduction heating element which is embedded into the outer side of the transition part, wherein the transition part is connected with the pot body and the pot base; the transition part is arc; the heat conduction heating element is a metal stretching net with a high extending property; the metal stretching net is compressed and connected to the corresponding part of the aluminum plate in advance and is stretched and formed into a cookware together with the aluminum plate. The three-dimensionally heated electromagnetic cooking appliance comprises a shell, the cookware and an electromagnetic wire coil for inducing the cookware to be heated three-dimensionally; the cookware is the cookware for electromagnetic heating; and the electromagnetic cooking appliance is an electric cooker, or an electric pressure cooker or an electric stewpan.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com