Multifunctional high-purity seven-in-one chemical and pharmaceutical equipment and manufacturing process thereof

A pharmaceutical equipment, high-purity technology, used in the chemical industry, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as affecting reactions, uneven heating, and uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

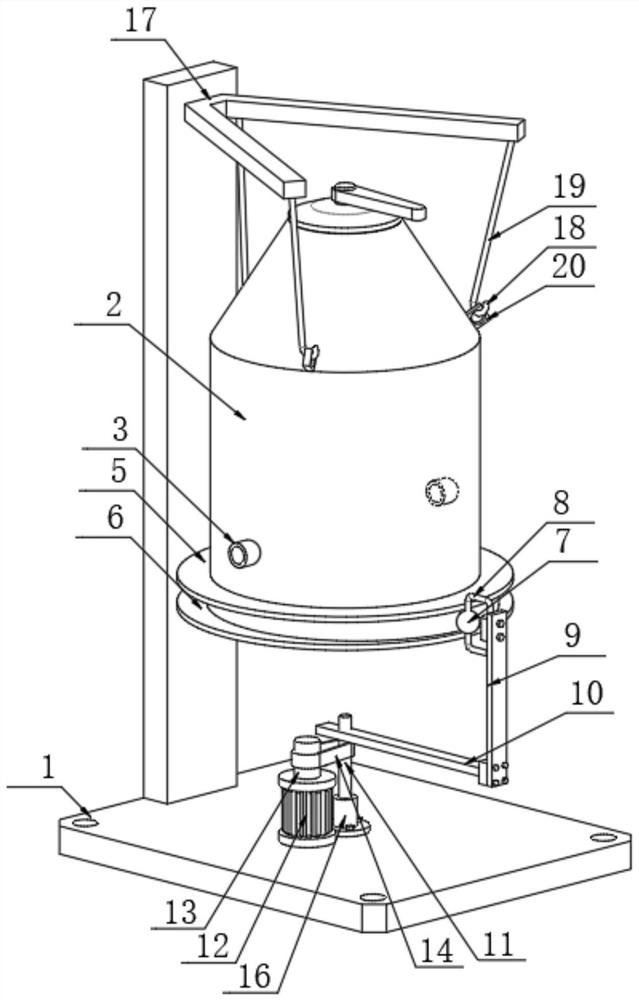

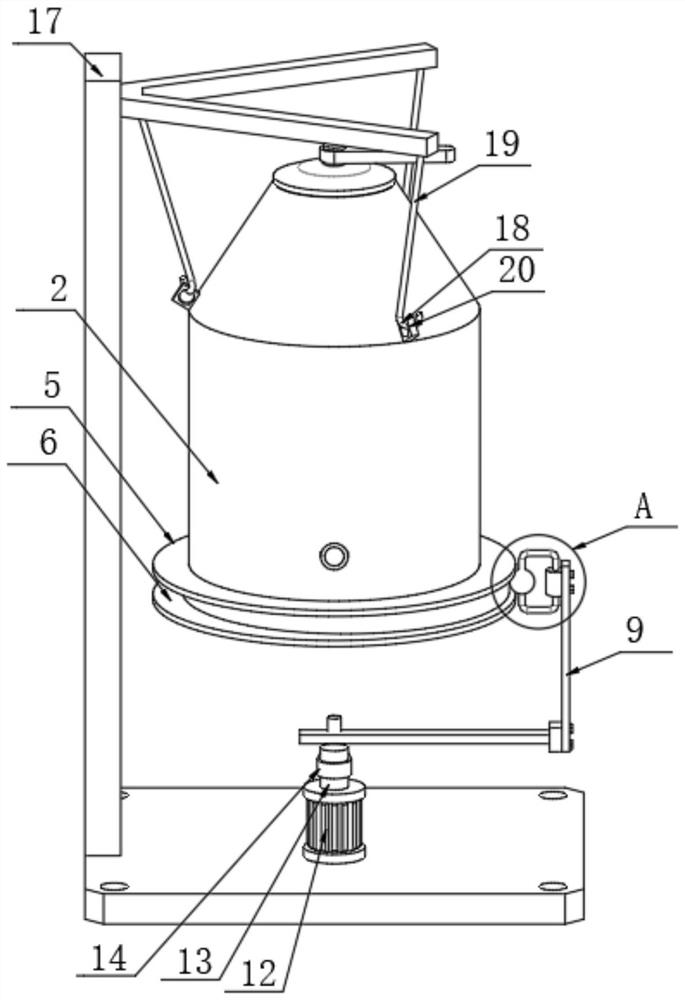

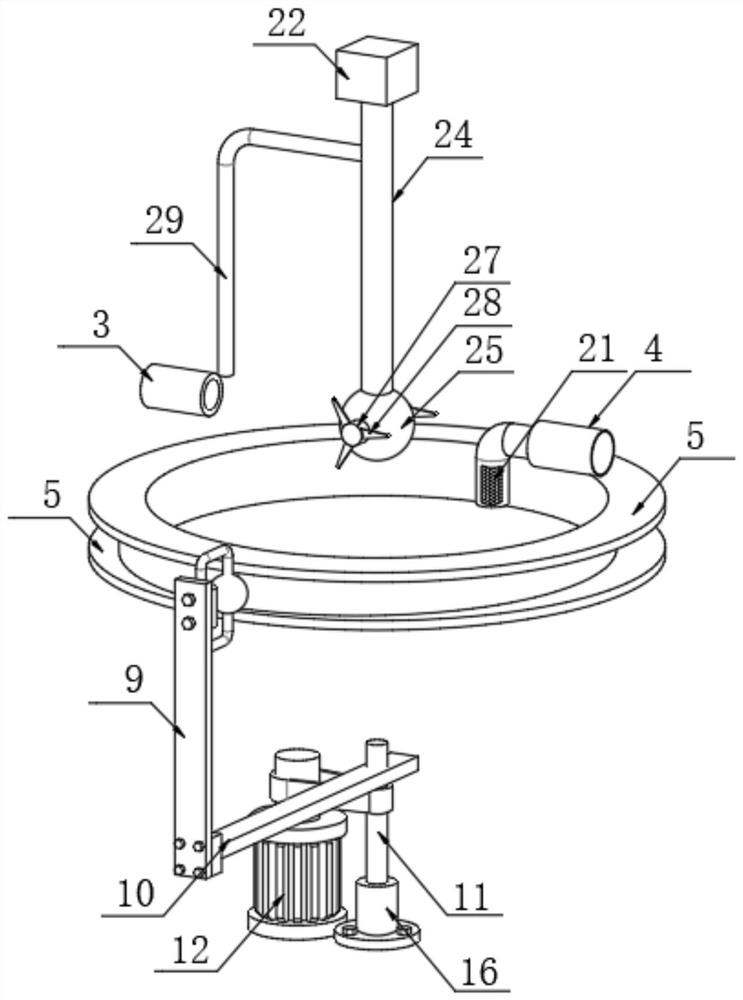

[0030] Embodiments of the present invention provide a multifunctional high-purity seven-in-one chemical and pharmaceutical equipment and its manufacturing process, such as Figure 1-6 As shown, the bottom plate 1 is included, the top of the bottom plate 1 is provided with a reaction furnace 2, one side of the reaction furnace 2 is provided with a water inlet pipe 3, the other side of the reaction furnace 2 is provided with a feed pipe 4, and the inner wall of the reaction furnace 2 is provided with a cavity. The water pipe 3 runs through the reaction furnace 2 and extends to the inside of the cavity. The feed pipe 4 runs through the reaction furnace 2 and extends to the inside of the reaction furnace 2. The cross-sectional shape of the feed pipe 4 is set to L-shape. Filter screen 21, filter screen 21 is conducive to filtering the liquid medicine after the reaction, the bottom end of the reaction furnace 2 is provided with an offset assembly, and the top end of the reaction furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com