Patents

Literature

47results about How to "No separability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

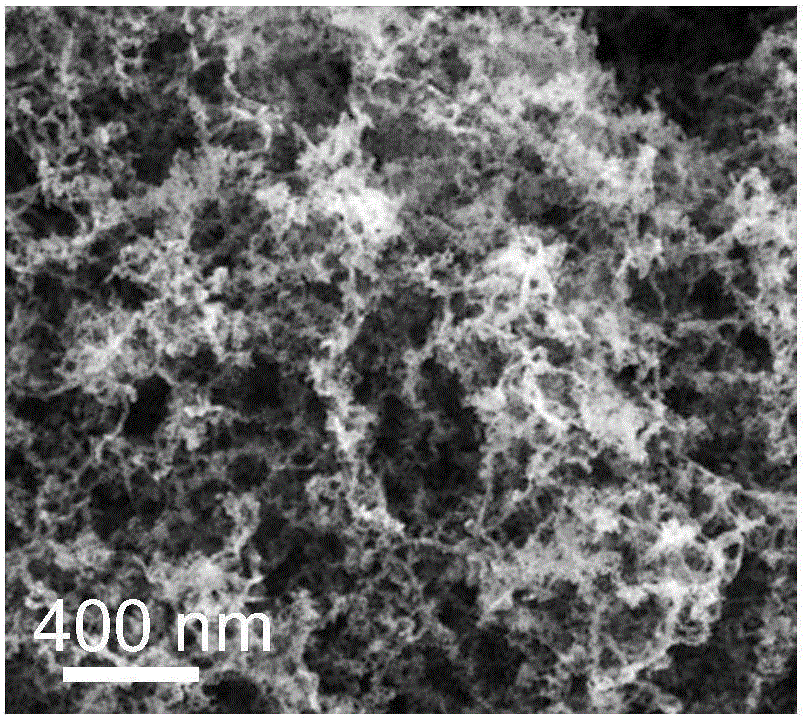

Phenolic resin/silicon dioxide composite aerogel materialand preparation method thereof

ActiveCN106189066ANo sheddingNo separabilityBulk chemical productionThermal insulationNanoscopic scale

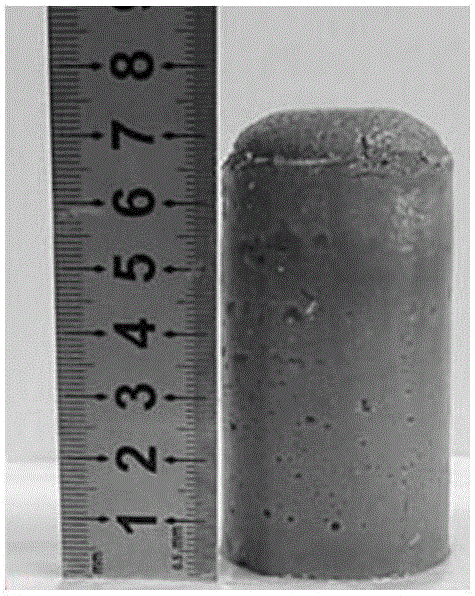

The invention provides a phenolic resin / silicon dioxide compositeaerogel material and a preparation method thereof. The phenolic resin / silicon dioxide composite aerogel material has a nano-grid structure in which a silicon dioxide phase and a resin phase are mutually tangled. The phenolic resin / silicon dioxide composite aerogel material is prepared from a material containing an organic silicon precursor, a phenolic compound, an aldehyde compound and chitosan by virtue of a sol-gel method and supercritical carbon dioxide. According to the composite aerogel material, an organic phase and an inorganic phase are respectively continuous nano-scale tangle structures and are integrated with the mechanical property of organic aerogel and the thermal insulation property and fire resistance of silicon dioxide aerogel; and after the composite gel material with a thickness of 1cm is impacted by the 1300-DEG C flame of a blast burner for over 30 minutes, the falling and the separation of the inorganic phase are not caused, and meanwhile, the temperature of a protected side does not exceed 300 DEG C. The preparation method has the beneficial effects that the operation is simple, the reaction is safe and reliable, and the thermal insulation property and the fire resistance of the material can be regulated and controlled by simply changing the material proportion.

Owner:UNIV OF SCI & TECH OF CHINA

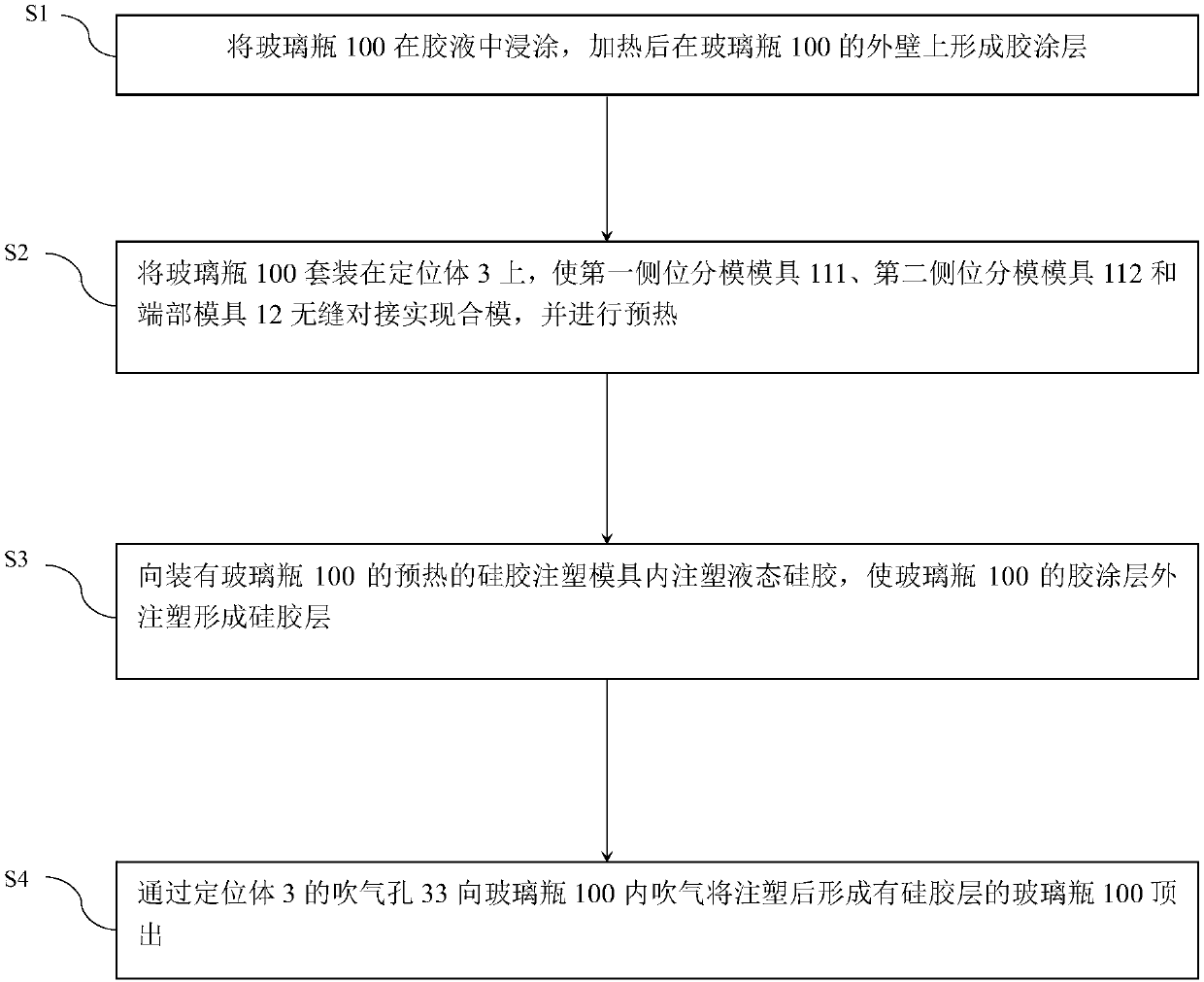

Technological method for forming silica gel layers on surfaces of glass bottles by means of injection molding

The invention relates to a technological method for forming silica gel layers on the surfaces of glass bottles by means of injection molding. The technological method includes carrying out dip-coatingon the glass bottles in glue solution, heating the glass bottles and forming glue coatings on the outer walls of the glass bottles; carrying out injection molding on liquid silica gel in preheated silica gel injection molds with the glass bottles and forming the silica gel layers outside the glue coatings of the glass bottles by means of injection molding. The technological method has the advantages that the glass bottles are adhered in liquid silica gel injection modes, the surfaces of the glass bottles do not need to be sprayed, only dip-coating needs to be carried out on the surfaces of the glass bottles in the glue solution, accordingly, silica gel can be effectively adhered, and the glass bottles are explosion-proof and drop-resistant; broken glass can be prevented from being scattered around even after the glass bottles are smashed, and accordingly excellent safety protection effects can be realized; bodies of the glass bottles are formed at one step by means of silica gel injection molding, accordingly, products are high in yield, and firm silica gel and glass adhesion effects can be realized; the surfaces of the products feel soft, good service effects can be realized, andthe products are excellent in user experience.

Owner:深圳市酷萌宝贝母婴用品有限公司

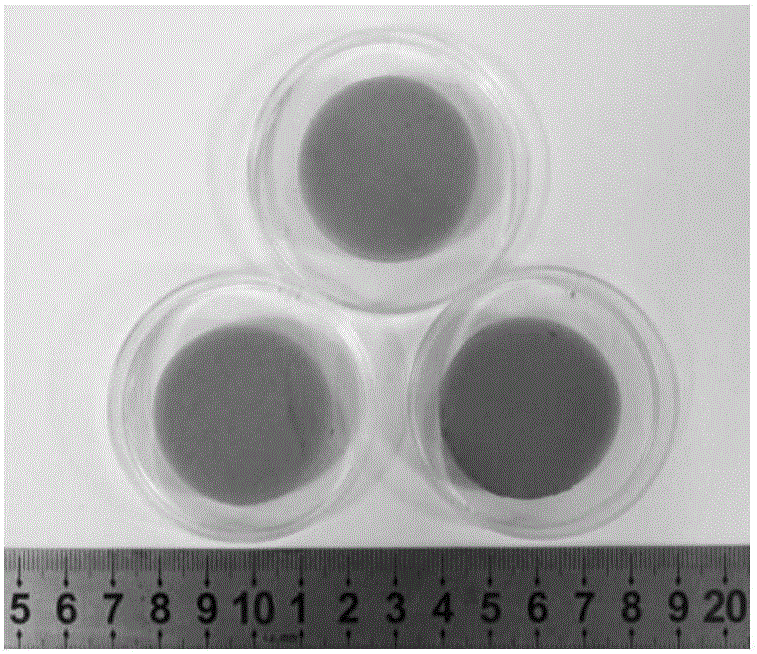

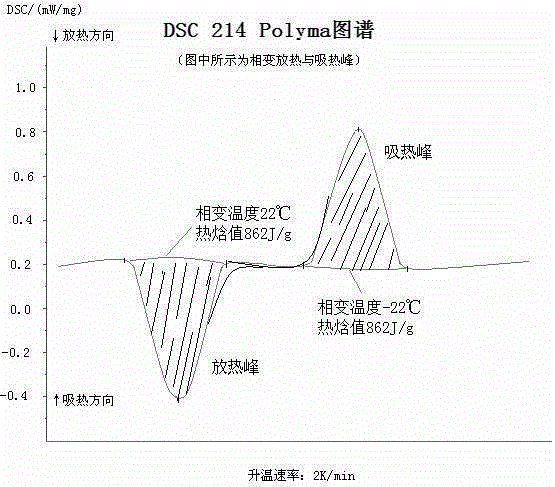

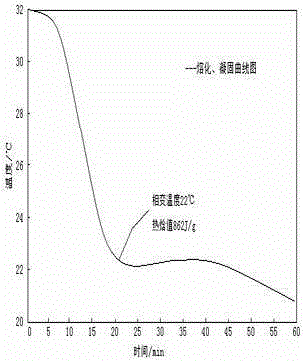

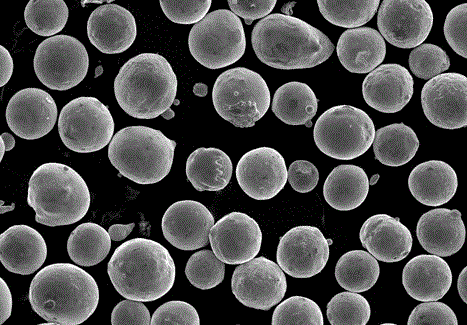

Phase change energy storage composite microcapsule and manufacturing method thereof

ActiveCN105219352AHarden fastNo supercoolingHeat-exchange elementsMicroballoon preparationHeat conservationCalcium chloride hydrate

The invention discloses a preparation method of a phase change energy storage composite microcapsule and belongs to the technical field of building low carbon and energy saving. The phase change energy storage composite organic-inorganic microcapsule is processed by using inorganic calcium carbonate as a wall material to encapsulate liquid paraffin and a calcium chloride hydrate core material. The phase change temperature is 22 DEG C. The phase change energy storage composite microcapsule is mainly used for building heat preservation, heat insulation and energy storage.

Owner:贵州华益能环保科技有限公司

Quantitative kit for detecting dog IL-6 by adopting homogeneous chemiluminescent immunoassay and use method thereof

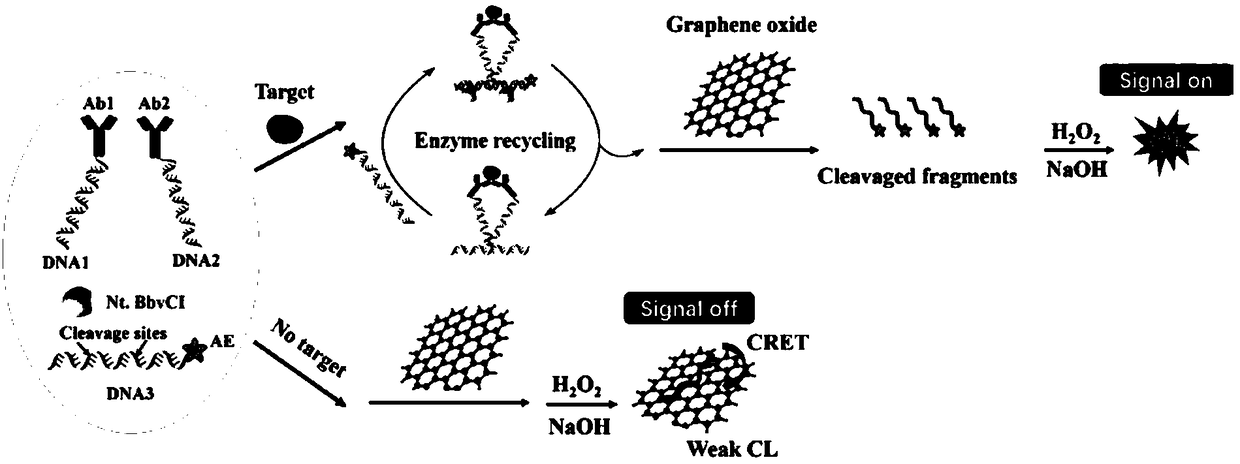

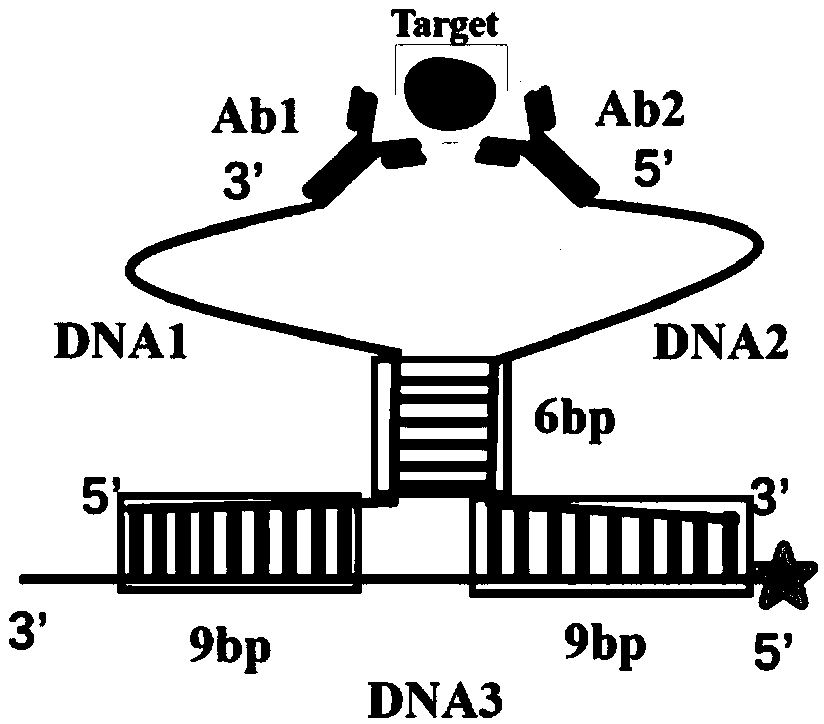

InactiveCN109030829AEasy to operateShort analysis timeChemiluminescene/bioluminescenceBiological testingEnzyme digestionChemiluminescent immunoassay

The invention relates to the chemiluminescent immunoassay, in particular to a quantitative kit for detecting dog IL-6 by adopting homogeneous chemiluminescent immunoassay and a use method thereof. A detection solution adopted by the kit contains DNA1-IL-6 antibody1 conjugate, DNA2-IL-6 antibody2 conjugate, DNA3 for marking acridinium ester (AE), restriction enzyme and graphene oxide; DNA1 and DNA2have six complementary bases, the DNA3 contains two enzyme digestion sites, and has nine bases to complementarily pair with the DNA1 and the DNA2; the DNA3 is adsorbed on the surface of the grapheneoxide through the Pai-Pai stacking effect, and the chemiluminiscence of the AE marked at the tail end is quenched due to the occurring of the CRET. The method is the homogeneous immunoassay method, the operation is simple, and the analysis time is greatly shortened, the measure of the single sample can be accomplished in 5-10min, by combining the ortho-bunting effect and a chemiluminescent molecular beacon, a switch of the graphene quenching mechanism is induced through immunoreaction, thereby releasing a chemiluminiscence signal without washing, separation and purification steps.

Owner:南京浦光生物科技有限公司

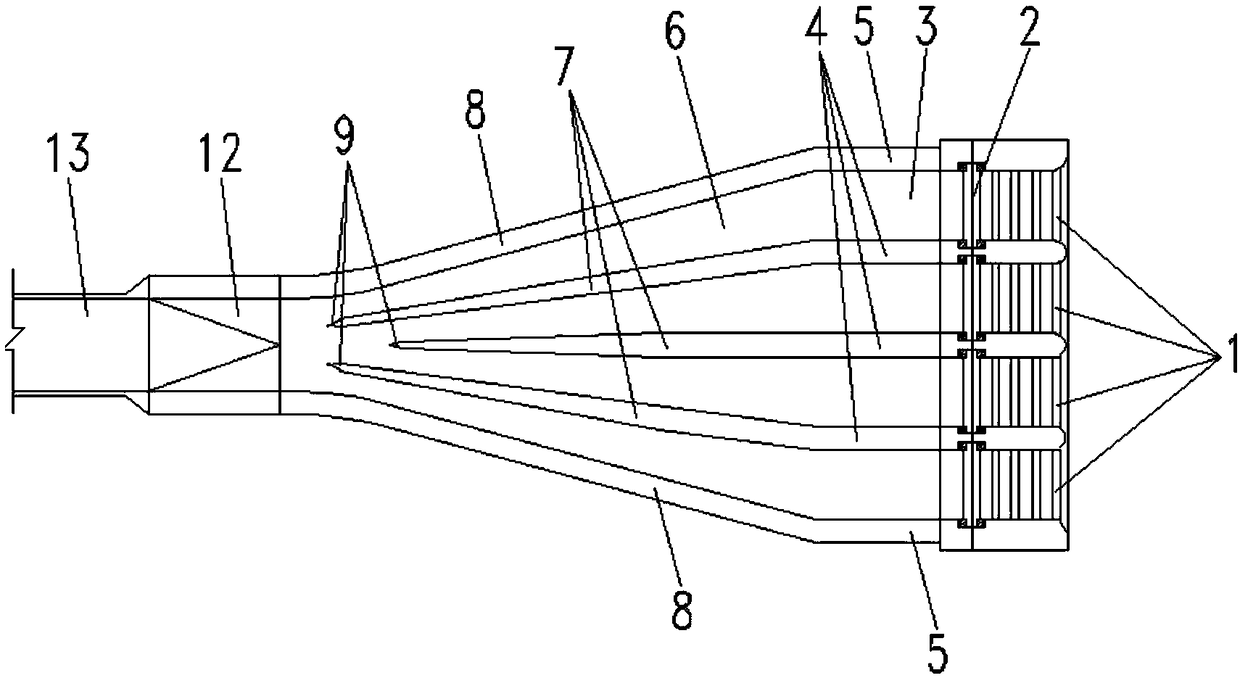

Water-fertilizer-gas integrated irrigation control system and control method

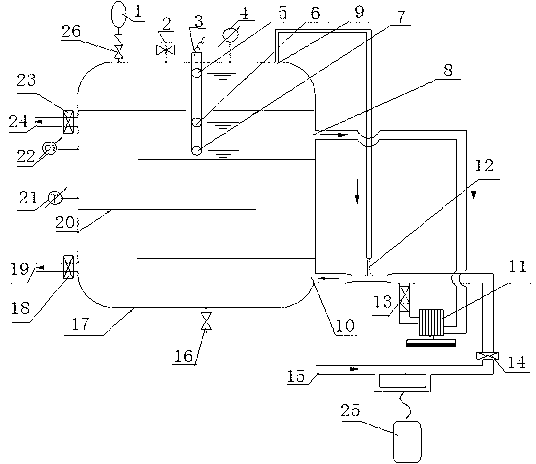

InactiveCN103314697AIntegrated Irrigation RealizationA wide range of incorporation ratiosClimate change adaptationWatering devicesAir cycleOxygen controller

The invention discloses a water-fertilizer-gas integrated irrigation control system and control method. The control system comprises a pressure-bearing water tank (17), wherein the pressure-bearing water tank (17) is provided with a pressure safety valve (2), a water level controller (3), a pressure controller (4), an inner circulating water gap (8), an air circulation port (9), a water inlet (10), a drain outlet (16), a low-post water outlet (19), a guide plate (20), a temperature transmitter (21), a dissolved oxygen controller (22) and a high-post water outlet (24), and a fertilization and air-entrapping device is arranged outside the pressure-bearing water tank (17); through the control of water inlet and outlet and aeration, a function of carrying out automatic aeration on liquid in the pressure-bearing water tank (17) can be achieved so as to achieve a preset water-gas mixing ratio. The system can realize water-fertilizer-gas integrated irrigation, thereby greatly increasing the water and fertilizer utilization efficiencies of crops.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Formula of peanut paste and preparation method thereof

The invention belongs to the technical field of peanut food deep processing and relates to a formula of peanut paste, which is characterized by comprising pulverized skimmed peanut protein particles, pulverized soybean, pulverized garlic, additive, stabilizer and emulsifier, wherein the mass ratio of the skimmed peanut protein particles to the soybean to the garlic is 10:2:1; and the additive, the stabilizer and the emulsifier account for 1.5 percent, 0.2 percent and 0.1 percent of the mass of the mixture of the peanut protein, the soybean and the garlic respectively. The invention also discloses a preparation method of the peanut paste. The peanut paste prepared by the method has the advantages of preventing the paste from separating from fat and oil, along with fine mouthfeel, pure flavor, high stability, long quality guarantee period and the like. Meanwhile, the peanut paste offers a very excellent mouthfeel and can be spread easily. The production method of the peanut paste is simple and the production cost of the peanut past is low, so the peanut paste is suitable for industrial production and can create obvious economic and social benefit.

Owner:SHANDONG PEANUT RES INST

Cement mortar composition for grout and grout mortar obtained from the same

A cement mortar composition for grouts which retains satisfactory flowability, is free from bleeding and material separation, has an anti-cracking ability due to high strength, high durability, and reduction in dry shrinkage, and is for use in applications such as foundations for machines; and a grout mortar obtained from the composition. The cement mortar composition for grouts comprises a binder, a setting retarder, a water-reducing agent, and a fine aggregate. It is characterized in that the binder comprises a quick hardening material comprising a cement, calcium aluminosilicate glass, and plaster and a fine pozzolan powder, the water-reducing agent comprises at least a polycarboxylate-type water-reducing agent, and the fine aggregate is a heavy aggregate having a density of 3.0 g / cm<3> or higher. The grout mortar is obtained by kneading the cement mortar composition together with water.

Owner:DENKA CO LTD

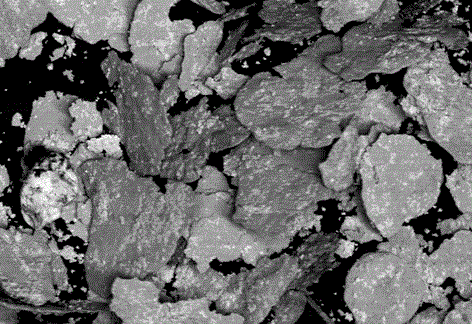

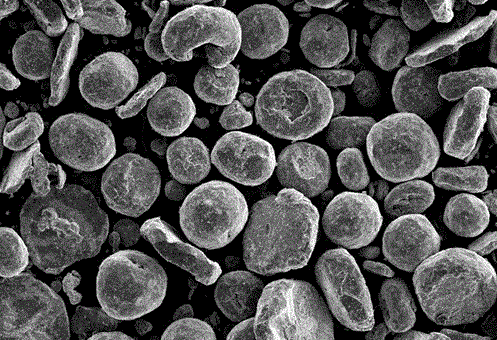

Preparation method for tin-coated copper composite powder

The invention relates to a preparation method for tin-coated copper composite powder. The composite powder comprises primary particles and secondary particles, wherein the primary particles mainly comprise copper powder; and the secondary particles mainly comprise small particle tin powder. The preparation method comprises the steps as follows: weighing a certain amount of the copper powder and the tin powder respectively; placing the weighed powder in a ball mill, and preprocessing for a period of time to prepare sheet powder; annealing the preprocessed powder under a protective atmosphere; and adding the annealed powder into spheroidizing equipment, and compounding and spheroidizing to prepare the tin-coated copper composite powder. According to the tin-coated copper composite powder, the copper powder can be uniformly coated with tin, the particle size of the powder is uniform, and the flowability is good. The preparation process is simple, the cost is lower, and the prepared oil bearing powder is good in flowability and easy to press.

Owner:JIANGSU YINGQIU GRP CO LTD

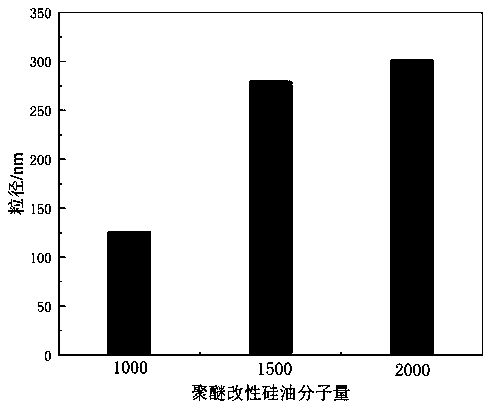

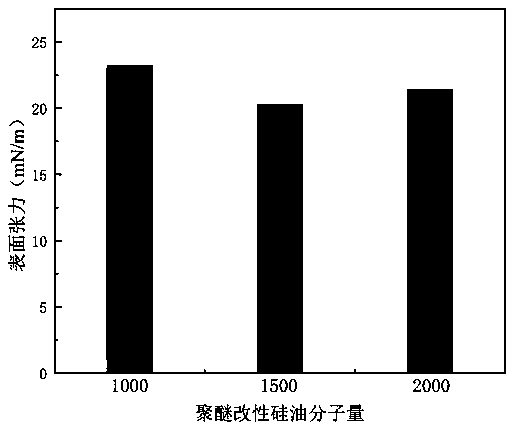

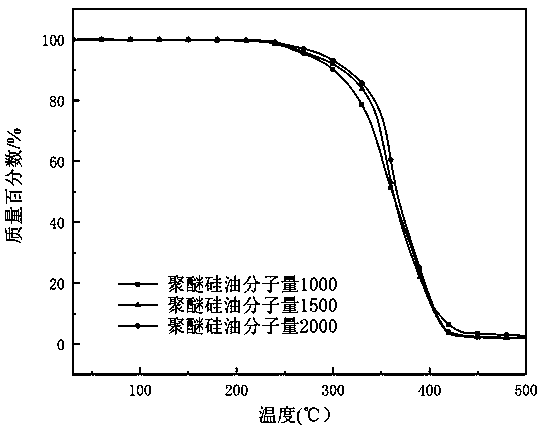

Preparation method of isocyanate modified polyether silicone oil nonionic emulsion and product and application thereof

ActiveCN110042667ASolve yieldSolve problems such as purification difficultiesCarbon fibresFiberCarbon fibers

The invention provides a preparation method of an isocyanate modified polyether silicone oil nonionic emulsion and a product and application thereof. The method comprises the steps of synthesizing double-end containing hydrogen silicone oil, synthesizing double-end hydroxyl modified silicone oil, synthesizing isocyanate modified polyether silicone oil, adding a proper amount of water for emulsifying, performing co-emulsifying with cationic amino modified epoxy silicone oil, and performing compounding to prepare a carbon fiber precursor oil agent. The technical problems met during an addition reaction of polyether modified silicone oil and high molecular weight polyethylene glycol monoallyl ether through containing hydrogen silicone oil that the reaction is difficult, the yield is low, theseparation purification is hard, and the color is dark are solved, and meanwhile the problems that the storage stability of amino modified silicone oil in the weak acid water phase is poor, compounding with cationic amino modified epoxy silicone oil is performed to prepare the carbon fiber precursor oil agent, after oiling, the carbon fiber precursor is stuck to rollers in the high-temperature drying and rolling process are solved.

Owner:吉林乾仁新材料有限公司

Exterior decoration mortar and productive construction technology thereof

InactiveCN101224970AImprove compactnessImprove waterproof performanceSolid waste managementEmulsionShrinkage rate

The invention discloses an exterior wall decoration mortar which comprises white cement, fly ash and granulating slag. Each constituent comprises the following components by weight per 1,000 portion of mortar: 110-150 of fly ash, 185-285 of white cement, 220-290 of granulating slag for Phi 0.1-0.7 mm, 190-240 for Phi 0.2-0.6 mm, 100-160 for Phi 0.4-1.0 mm, 50-100 for Phi 1.2-1.6 mm. The invention adopts the homogeneous materials of decoration mortar and base layer of the wall surface, both mortars have identical dry shrinkage rate and physical and chemical index; the decoration mortar has good compactness once being finished according to the requirement of construction characteristics, thus the water proof performance is good; adequate redispersible emulsion powder allowing for anti-cracking requirement is blended when the mortar is prepared to lead the mortar to have a certain flexibility to overcome the disadvantage that the anti-cracking performance is not satisfactory when the mortar is resisting the cement material with high rigidity, thus the weatherability of the mortar is greatly enhanced. The test result indicates that the invention provides a mortar that can be fadeless and can not be damaged for 50 years.

Owner:GESHAN CONSTR GROUP

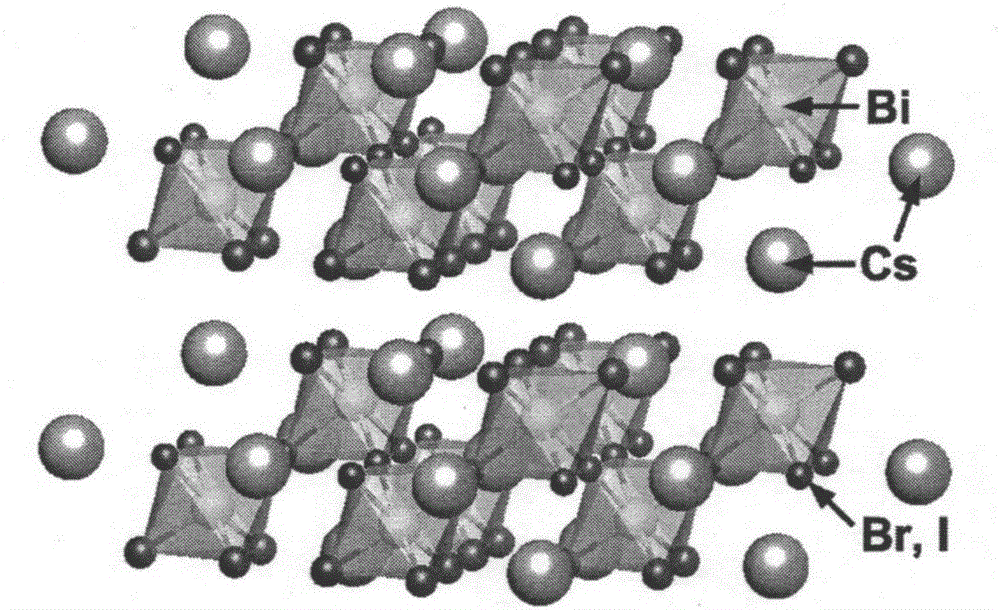

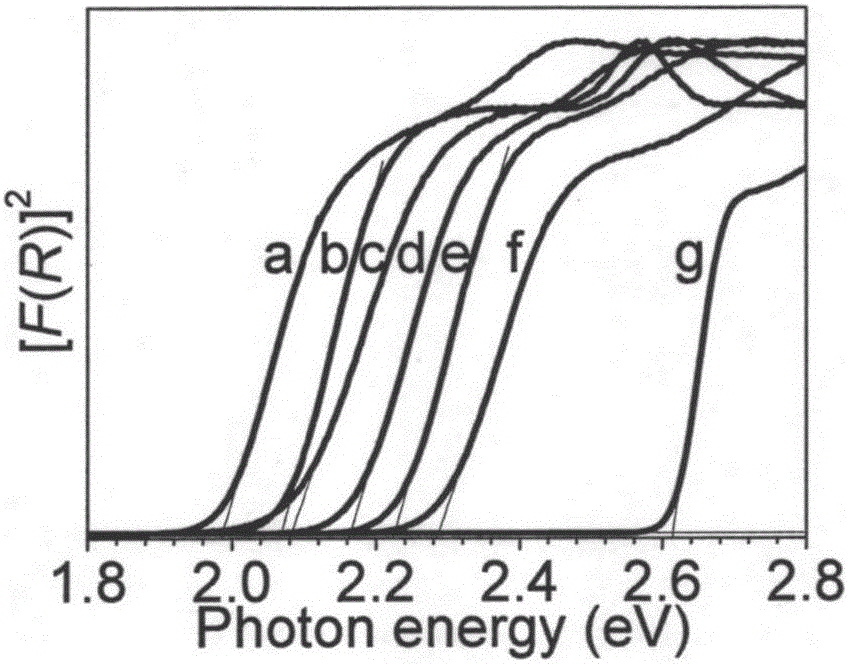

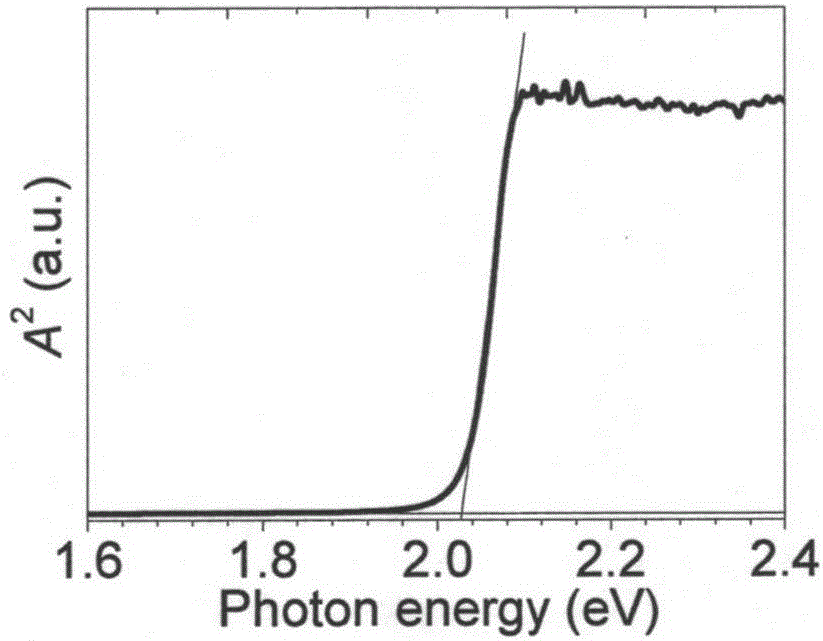

Semiconductor material containing bismuth and halogen and preparation and analysis method thereof

ActiveCN106082329ATunable direct bandgap energyStable and controllableChemical analysis using titrationBismuth compoundsHalogenSemiconductor materials

The invention provides a semiconductor material containing bismuth and halogen and a preparation and analysis method thereof. The semiconductor material containing bismuth and halogen is characterized in that it has a chemical formula of Cs3Bi2BrxI9-x, wherein x=1-6.85. The semiconductor material with a general formula of Cs3Bi2BrxI9-x provided by the invention has adjustable direct bandgap energy, in an embodiment of the invention, the adjustable direct bandgap energy can be adjusted to a minimum of 1.99eV, which is lower than that of existing material Cs3Bi2Br9 or Cs3Bi2I9, so that the semiconductor material has a wider absorption wavelength range in a visible spectrum.

Owner:SHANGHAI TECH UNIV

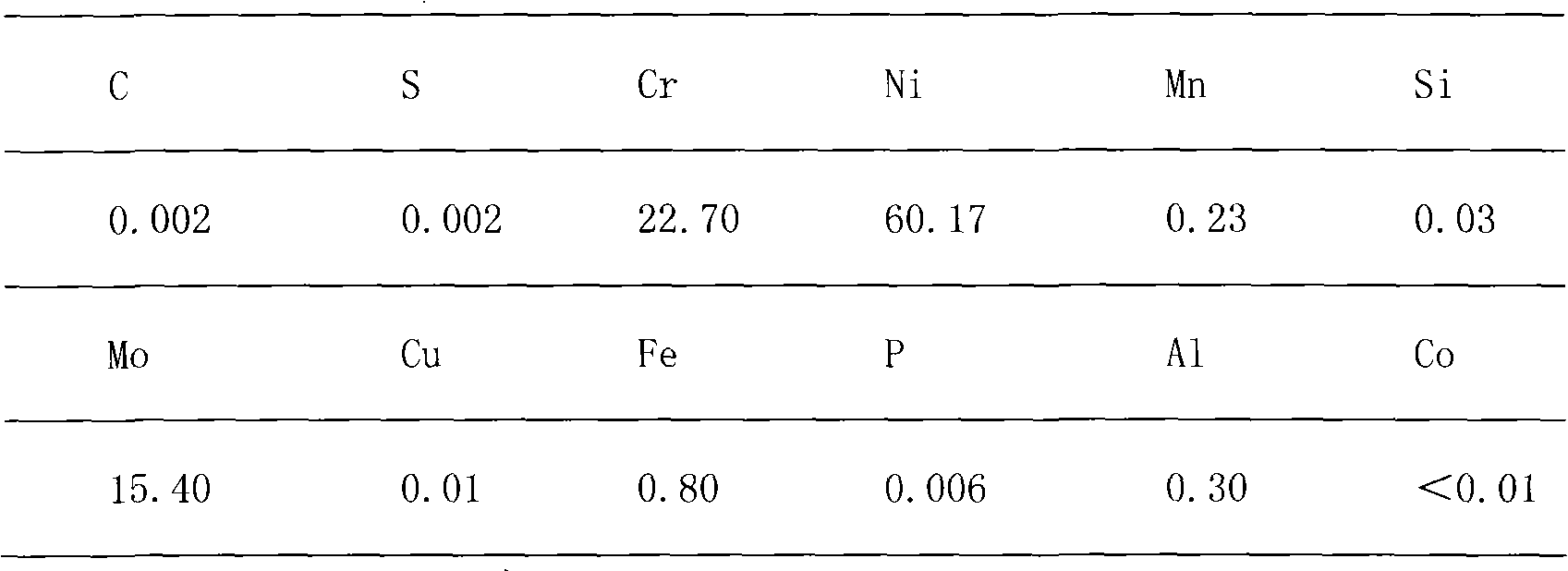

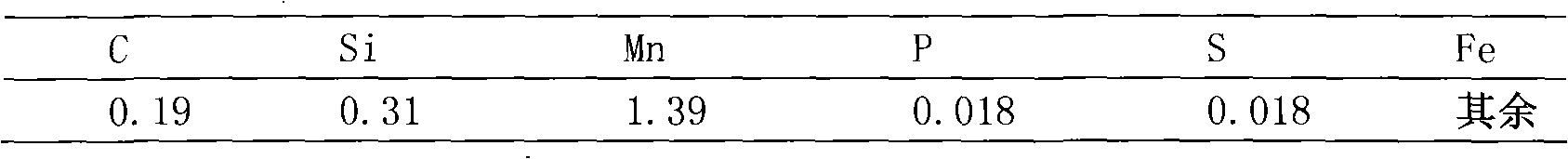

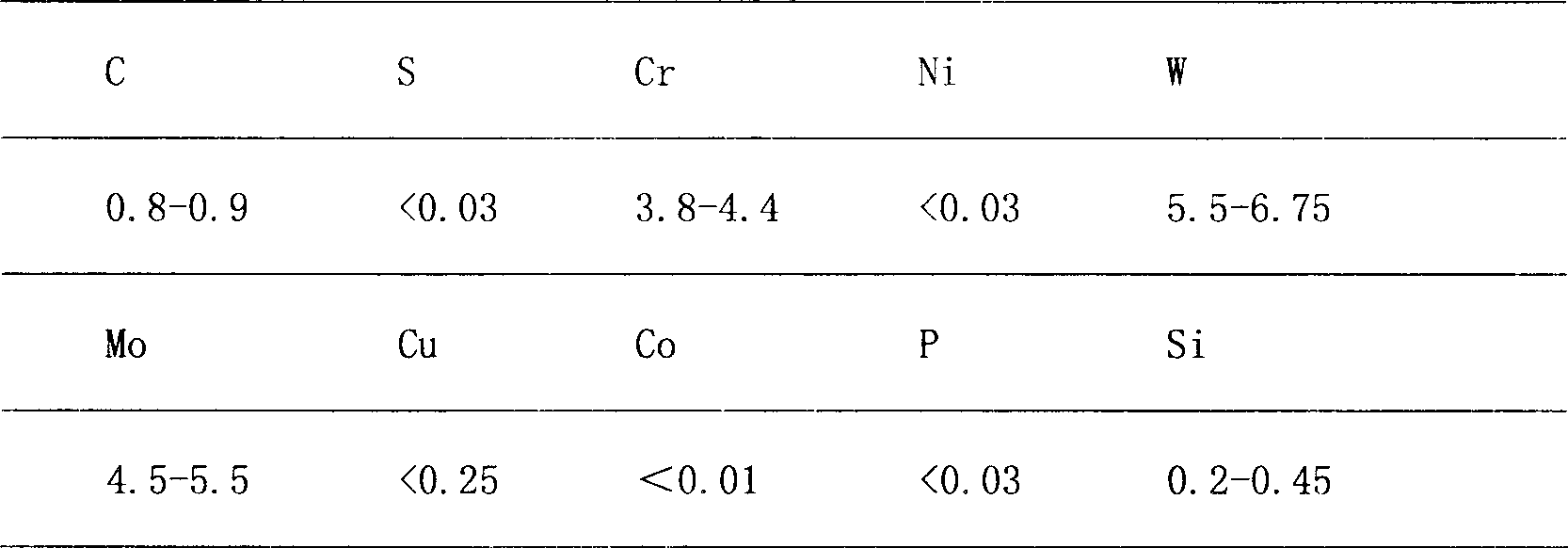

Ultra-low carbon Ni-Cr-Mo5923hMo steel alloy explosion welding high corrosion resistance composite material

ActiveCN101293305AEliminate the detonatorEliminate both sidesNon-electric welding apparatusCrack resistanceStress corrosion cracking

The invention relates to a novel compound material which is formed by an explosion welding technique and a common low alloy steel Q345B as well as by adopting the ultra-low-carbon Ni-Cr-Mo 5923hMo alloy steel as a high anti-corrosion layer. The manufacture method of the invention includes the techniques of surface pre-treatment, explosion welding compounding and annealing for removing a stress. The structure of the invention is that the common low alloy steel is combined with the metallurgy of a 5923hMo anti-corrosion steel multiple layer on the common low alloy steel. The compound material of the invention has the advantages that the multiple layer has excellent anti-corrosion property to most corrosion properties and extremely excellent properties of pit corrosion resistance, crevice corrosion resistance and stress corrosion cracking resistance caused by chlorides; while a basic layer plate has excellent mechanical property to fully play the excellent physical and chemical properties of two metals. The novel compound material can not have the phenomena of cracking or separation on the interface between the basic layer and the composite layer after being processed by the hot and cold techniques such as annealing, leveling and cutting, etc. Analyzed by a physical test and a chemical test, the property index of the novel compound material is completely in accordance with the standard of JB4748-2002 and can meet the property requirements of a device to special materials under execrable working conditions.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

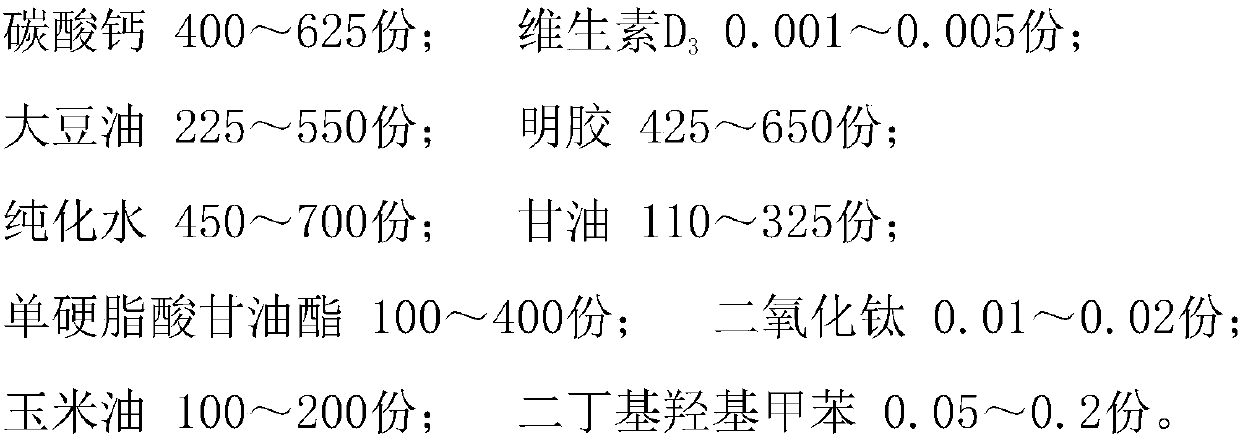

Vitamin D soft capsule and making method thereof

ActiveCN109662953AWell mixedStable mixOrganic active ingredientsMetabolism disorderButylated hydroxytolueneCalcium carbonate precipitation

The invention discloses a vitamin D soft capsule and a making method thereof. The vitamin D soft capsule is prepared from, by mass, 400-625 parts of calcium carbonate, 0.001-0.005 part of vitamin D3,225-550 parts of soybean oil, 425-650 parts of gelatin, 450-700 parts of purified water, 110-325 parts of glycerin, 100-400 parts of glyceryl monostearate, 0.01-0.02 part of titanium dioxide, 100-200parts of corn oil and 0.05-0.2 part of butylated hydroxytoluene. The making method of the soft capsule comprises the steps of making capsule content; making glue; making the soft capsule containing the capsule content; processing the vitamin D soft capsule after preparation. The vitamin D soft capsule has few additives, and allergic reactions or other discomfort caused by the additives can be avoided; the capsule content is more uniformly and stably mixed, and the phenomena of oil layer separation or calcium carbonate precipitation or the like cannot occur; a capsule shell of the soft capsulehas a water retaining effect.

Owner:威海金思力生物科技股份有限公司

Environment-friendly wear-resisting semi-rigid heat-shrinkable tube for protecting car metal pipeline and preparation method thereof

InactiveCN104788776AAct as stressPlay a protective effectPipe protection against damage/wearLow-density polyethyleneAntioxidant

The invention discloses an environment-friendly wear-resisting semi-rigid heat-shrinkable tube for protecting a car metal pipeline and a preparation method thereof. The heat-shrinkable tube is mainly prepared from the following ingredients in parts by weight: 50-75 parts of low-density polyethylene, 25-50 parts of an ethylene-vinyl acetate copolymer, 20-30 parts of an inorganic filler, 1.5-2.0 parts of an antioxidant, 1.0-2.0 parts of a lubricant and 3-6 parts of carbon black masterbatch. The preparation method comprises the following steps: granulation, extrusion, irradiation and expansion with a two-step mixing method. The heat-shrinkable tube has good adhesive strength with the car pipeline, the phenomena of separation from the pipeline and pleating of the heat-shrinkable tube cannot occur in the bending operation, and the sealing is ensured. Meanwhile, the environment-friendly wear-resisting semi-rigid heat-shrinkable tube has the characteristics of being easy and convenient to mount, high in performance cost ratio, safe and durable and can effectively prolong the service life of the car pipeline and reduce the potential safety hazards of vehicles during use.

Owner:大连联合高分子材料有限公司

Method and device used for recovering floating oil on water surface

InactiveCN1651340AEfficient recyclingNew technologyFatty/oily/floating substances removal devicesLiquid separationDihydrogen oxideFuel tank

An apparatus for recovering the oil floating on water surface is composed of oil deivering pump, water draining pump and oil collecting tank with oil-water inlet and curved guide plate. Its method includes filling water in oil collecting tank, putting it in the polltued water region, using water draining pump to discharge water from it while oil-water mixture flowing in it via said curved guide plate for separating oil layer from water layer, and pumping the oil to a storage position by oil pump.

Owner:侯解民

Snowy moon cake at room temperature

Owner:HUNAN JINZHIYUAN FOOD

W6Mo5Cr4V2/Q345 explosive welding composite material

InactiveCN103009702AHigh bonding strengthInvariant physicsExplosivesMetal layered productsMetallic materialsMechanical property

The invention discloses a novel composite material which takes W6Mo5Cr4V2 high-speed steel as a high wear-resistance, high hardness and high strength covering layer, and adopts Q345 and an explosive welding process. The unique production process comprises the following steps of: selecting researched main body explosive RB53 and denotation explosive cyclonite; overlapping three layers of explosive at a denotation point and peripheral parts, wherein the total thickness is increased by 10-15mm compared with that of other areas; and carrying out a secondary sectional annealing thermal treatment process. The composite material provided by the invention has the advantages that the covering layer has the complete advantages of the high-speed steel W6Mo5Cr4V2, and the substrate layer Q345 has a good mechanical property, so that the perfect combination of the two metal materials of different properties is realized, the property advantages of one single material is brought into full play, and particularly the composite material has wide application prospect in fields requiring cost conservation and producing knives, dies and the like of irregular structures.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

Moisturizing banishing essence containing beta-glucan and preparation method of moisturizing banishing essence

ActiveCN110075003AGood moisturizing effectImprove dullnessCosmetic preparationsToilet preparationsSaccharomycopsisBeta-glucan

The invention discloses moisturizing banishing essence containing beta-glucan and a preparation method of the moisturizing banishing essence, and belongs to the technical field of skin care products.The components of the moisturizing banishing essence containing the beta-glucan contain hematic acid, yeast peptide, saccharomycopsis ferment filtrate, rice ferment filtrate, saussurea involucrata fermentation liquor, nicotinamide, beta-glucan, a tremella fuciformis fruit body extract, and the like; natural organic efficient healthy and safe spot-fading components of the yeast peptide, the rice ferment filtrate and the saussurea involucrata fermentation liquor are added into a formula of the moisturizing banishing essence, the safety is high, and skin melanin and color spots can be effectivelyconfronted; the mass ratio of the beta-glucan to the tremella fuciformis fruit body extract is controlled in an implementation process, so that the prepared moisturizing banishing essence has excellent moisturizing property.

Owner:湖南美媛本草生物工程有限公司

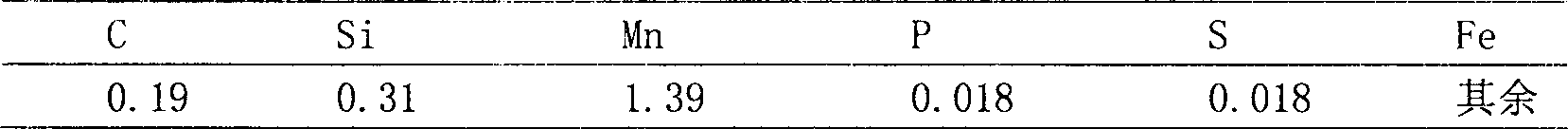

W/O emulsified cosmetic, preparation method thereof, and application of quaternary ammonium salt-18 bentonite

InactiveCN104287978ASolve the phenomenon that there is always instabilityNo separabilityCosmetic preparationsMake-upQuaternium 18-bentoniteQuaternary ammonium cation

The invention provides a W / O emulsified cosmetic, a preparation method thereof, and application of quaternary ammonium salt-18 bentonite. By adding quaternary ammonium salt-18 bentonite (QUATERNIUM-18 BENTONITE) into the W / O emulsified cosmetic product containing oil phases, water phases and powder, thickening can be realized, and accordingly the cosmetic can maintain long-term stability and does not cause oil-water separation or powder coacervation phenomenon, the emulsification stability is enhanced, and the problem that powder added W / O emulsified cosmetics are always unstable can be solved.

Owner:SHENZHEN SANDA COSMETICS

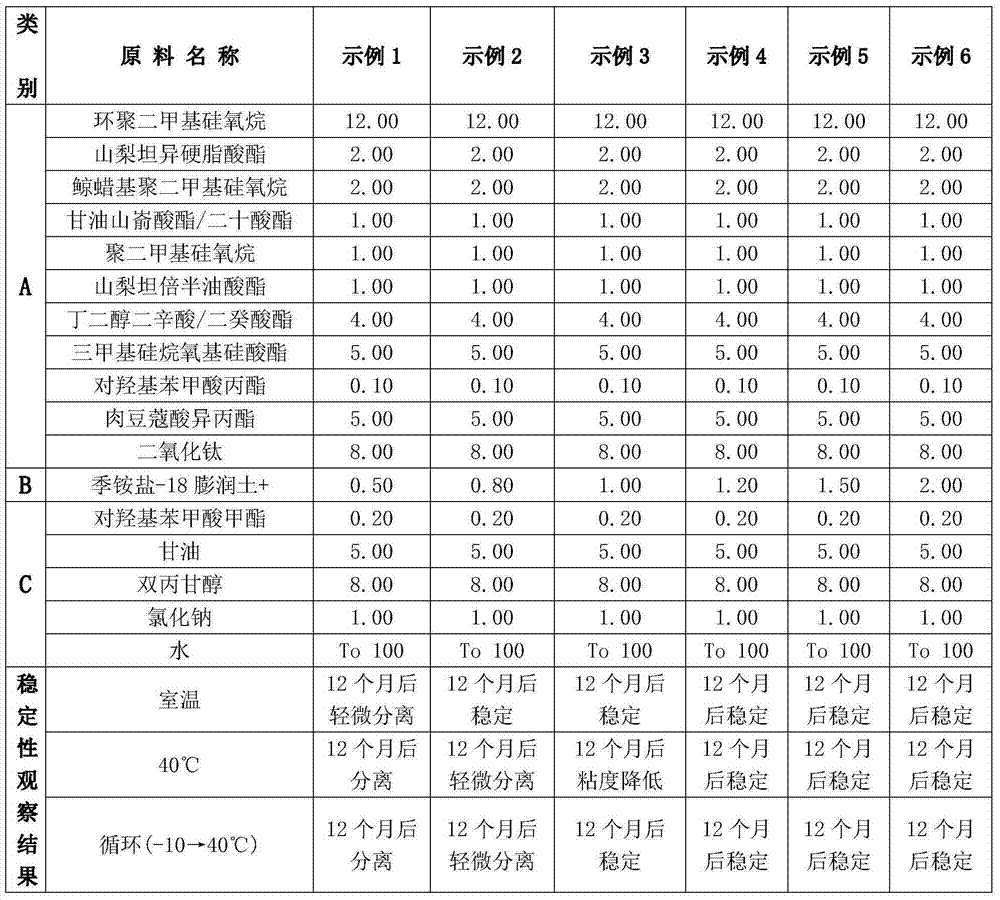

Homocysteine (HCy) kit based on aptamer fluorescence probe and detection method for concentration of homocysteine (HCy) by using homocysteine (HCy) kit

InactiveCN104677868ANo workabilityNo separabilityFluorescence/phosphorescenceMedical testingStandard samples

The invention relates to a homocysteine (HCy) kit based on an aptamer fluorescence probe and a method for measuring the concentration of homocysteine (HCy) as well as the composition and components of a measuring reagent, and belongs to the technical field of medical examination and measurement. The kit provided by the invention mainly comprises erythrocyte lysate, a phosphate buffer solution PBS, a standard sample of homocysteine and the homocysteine aptamer fluorescence probe. The concentration of the homocysteine is measured through blood sample cracking and mixed incubation treatment in combination with fluorospectrophotometer detection. The kit and the method provided by the invention have the advantages of easiness in sample treatment, easiness in operation, short detection time, high detection specificity, high sensitivity, high repeatability of detection result, and the like.

Owner:陈燕婷 +2

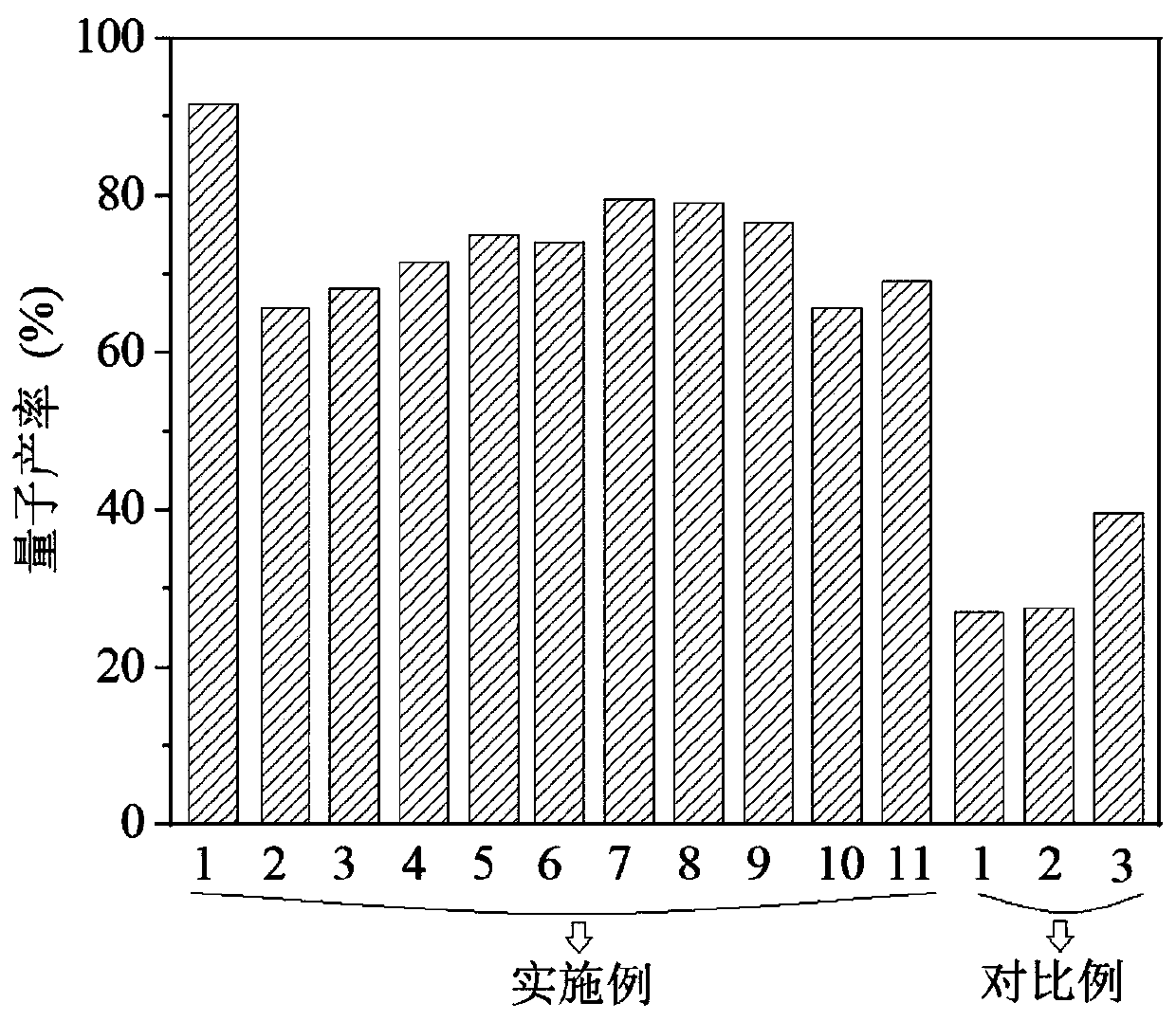

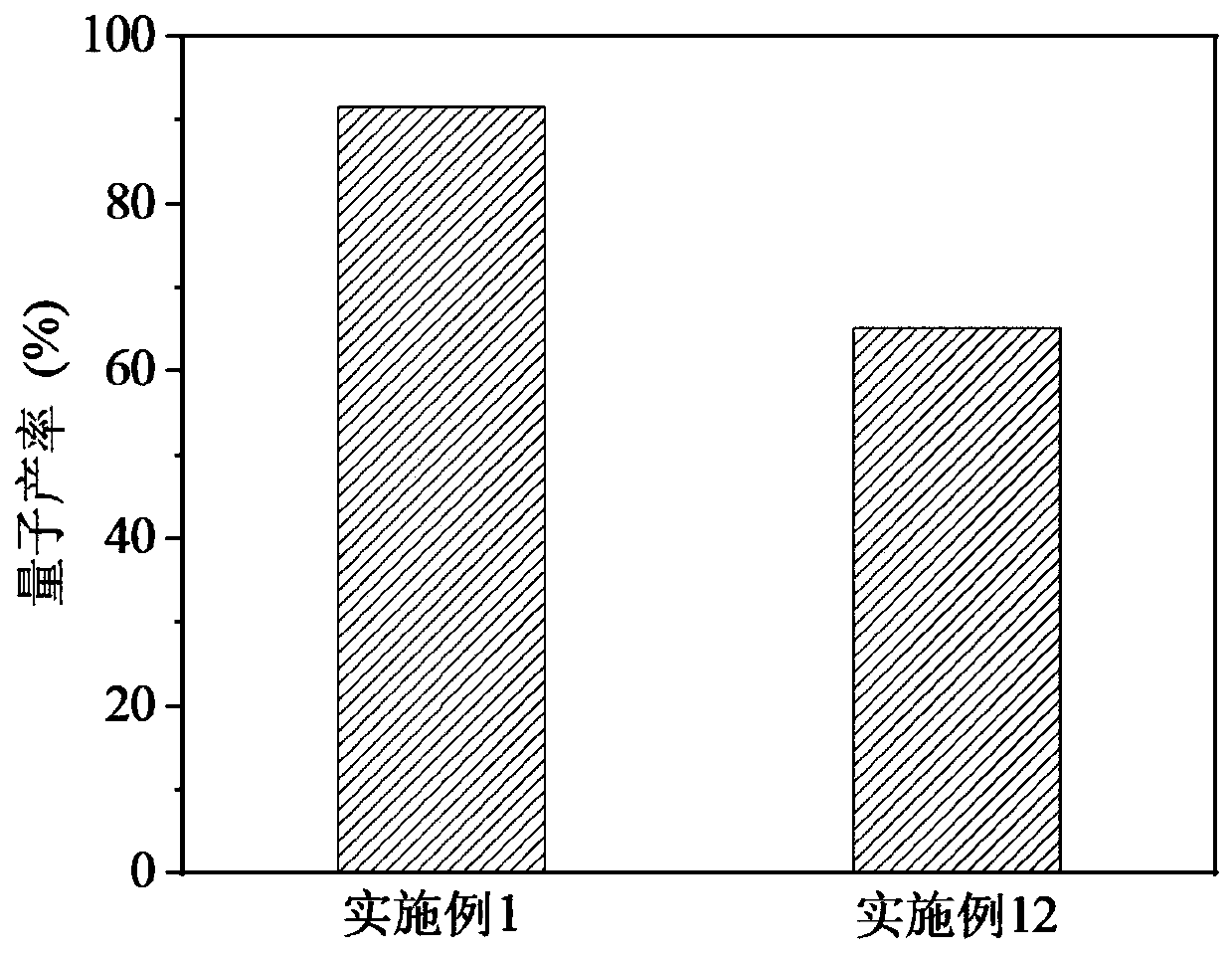

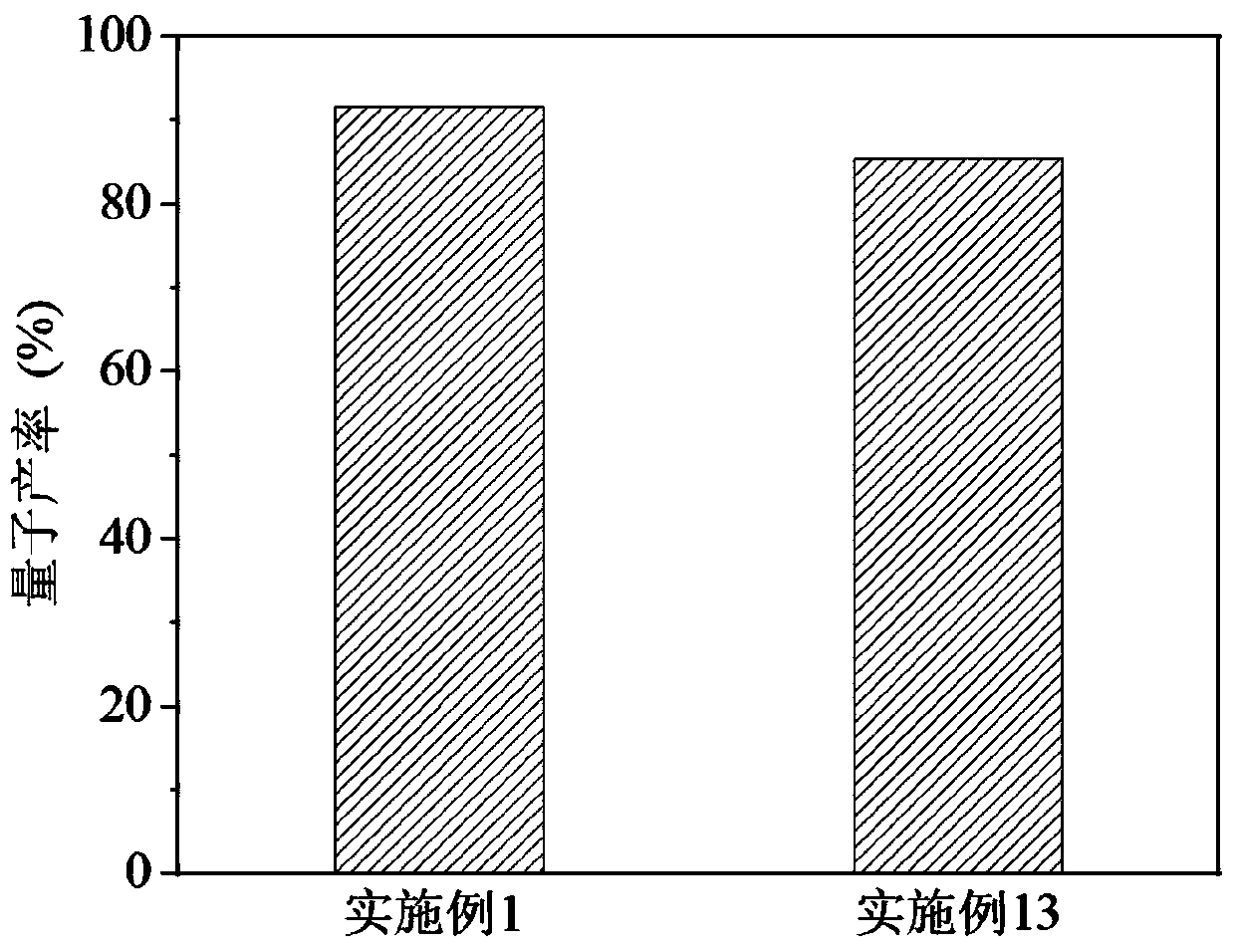

Preparation method of carbon quantum dots with high quantum yield

ActiveCN110877904AFriendlyCause secondary pollutionNanoopticsNano-carbonPhysical chemistryEthylenediamines

The invention discloses a preparation method of carbon quantum dots with high quantum yield. The preparation method comprises the following steps: firstly, mixing a carbon source composed of citric acid and ascorbic acid, and an alkali source composed of ethylenediamine and o-phenylenediamine, adding an obtained mixture into a solvent to obtain a mixed solution, and then performing microwave heating on the mixed solution for preset time to obtain the carbon quantum dots. The preparation method of the carbon quantum dot with high quantum yield can solve the technical problems of complex preparation method, long time consumption, high preparation cost and the like in the existing carbon quantum dot preparation process.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

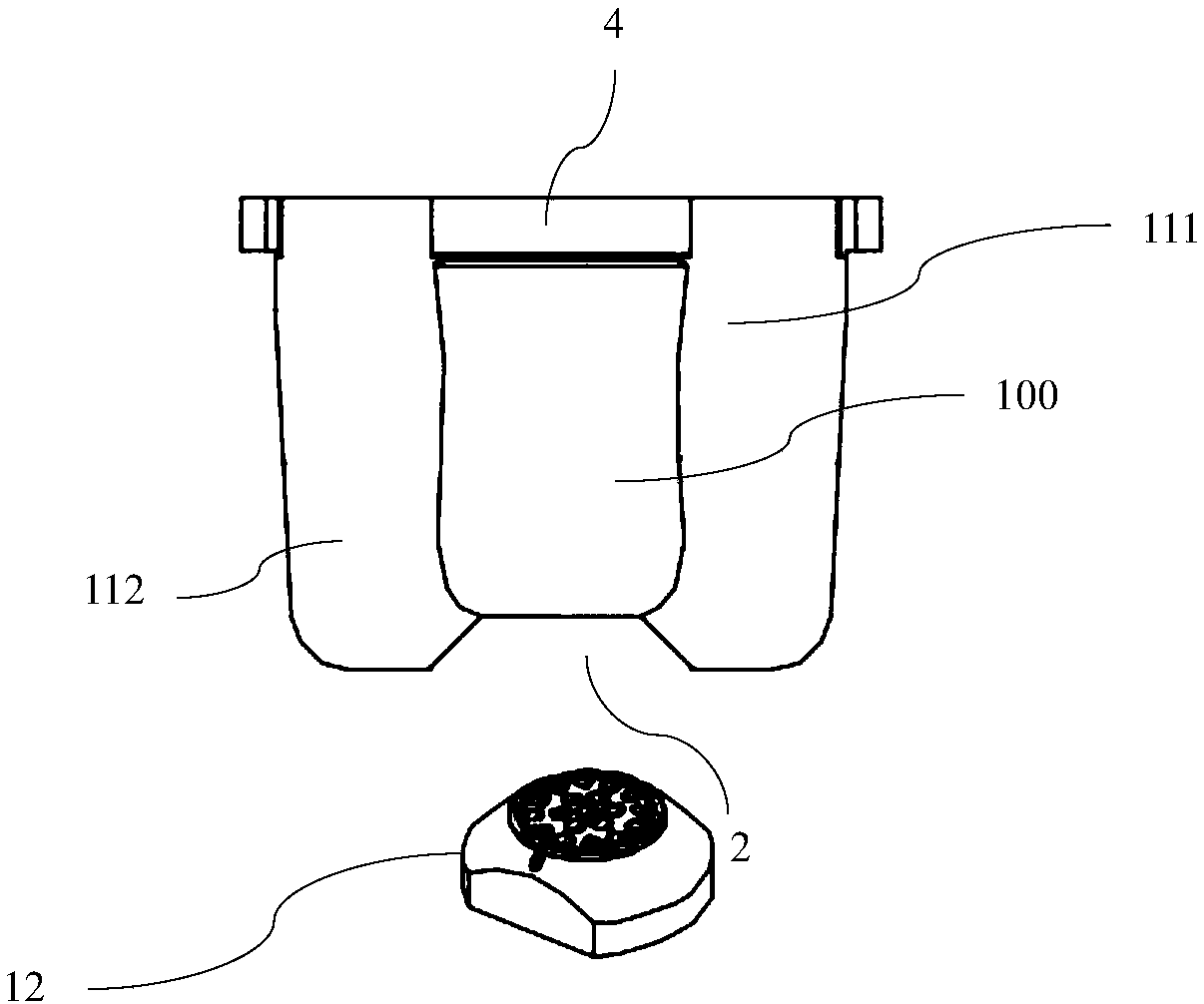

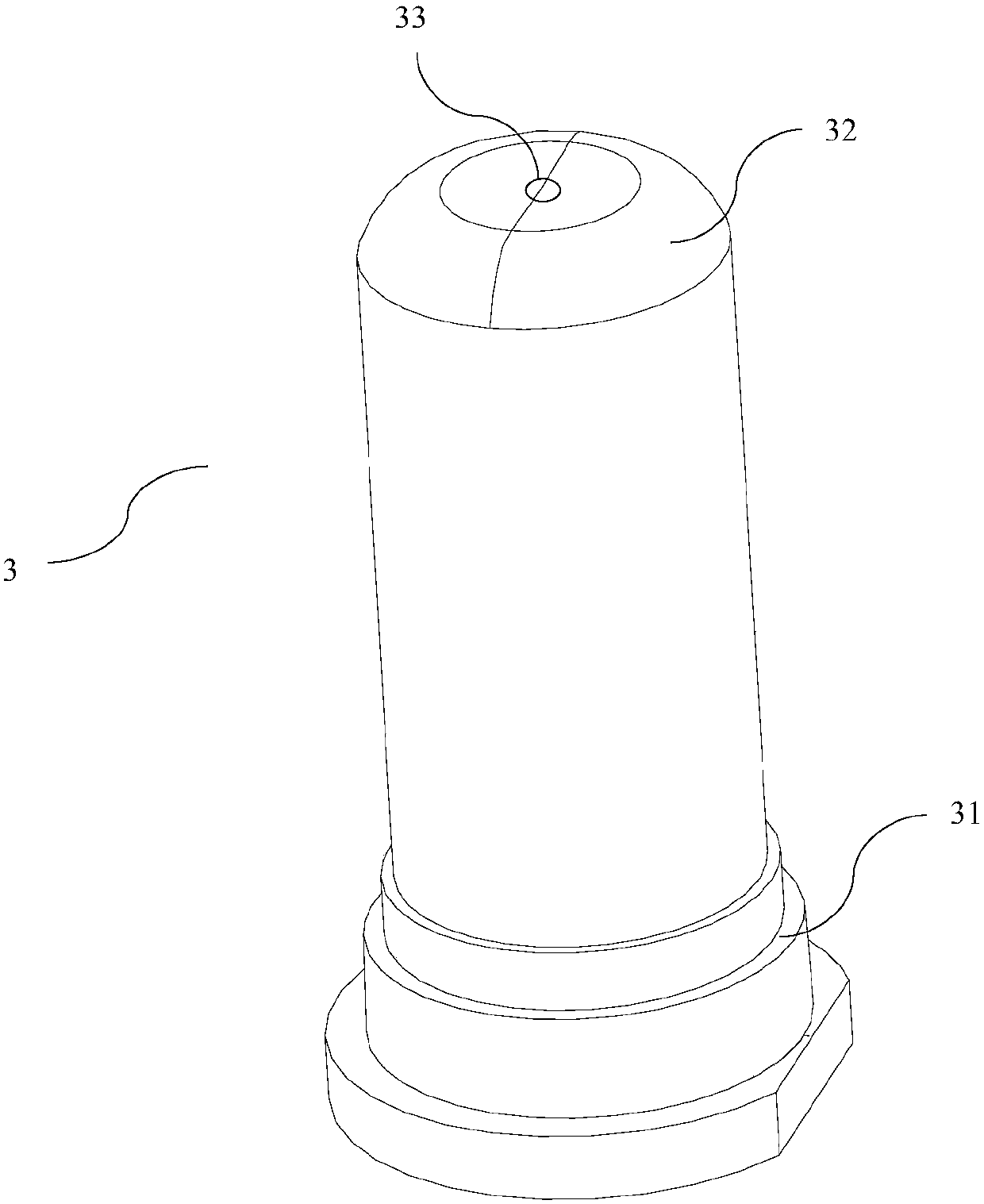

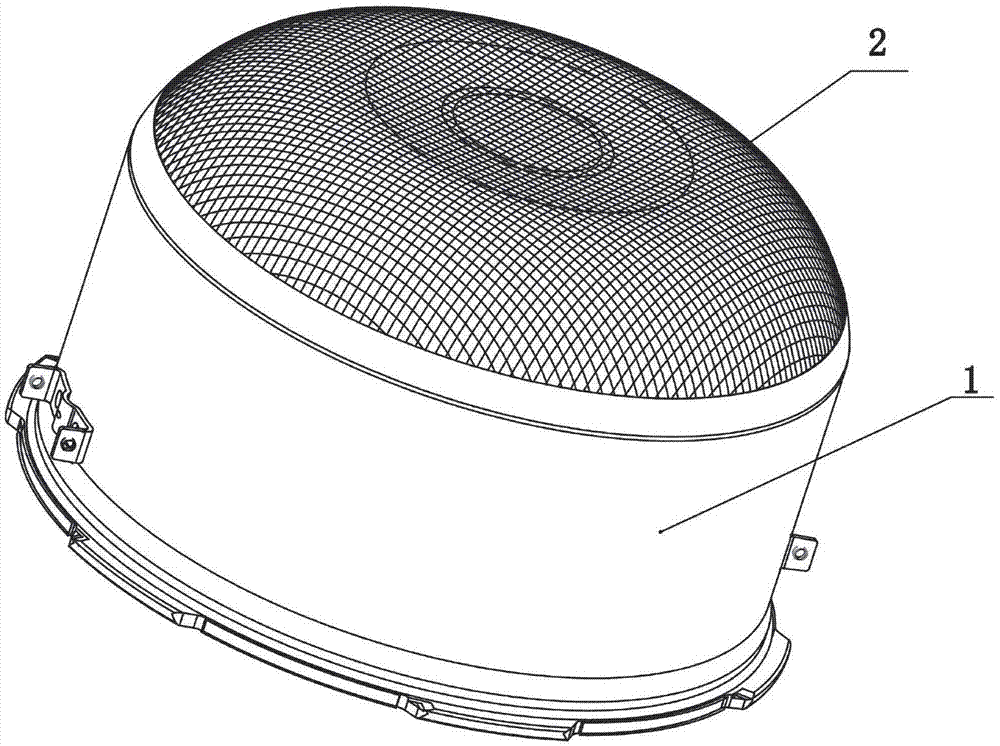

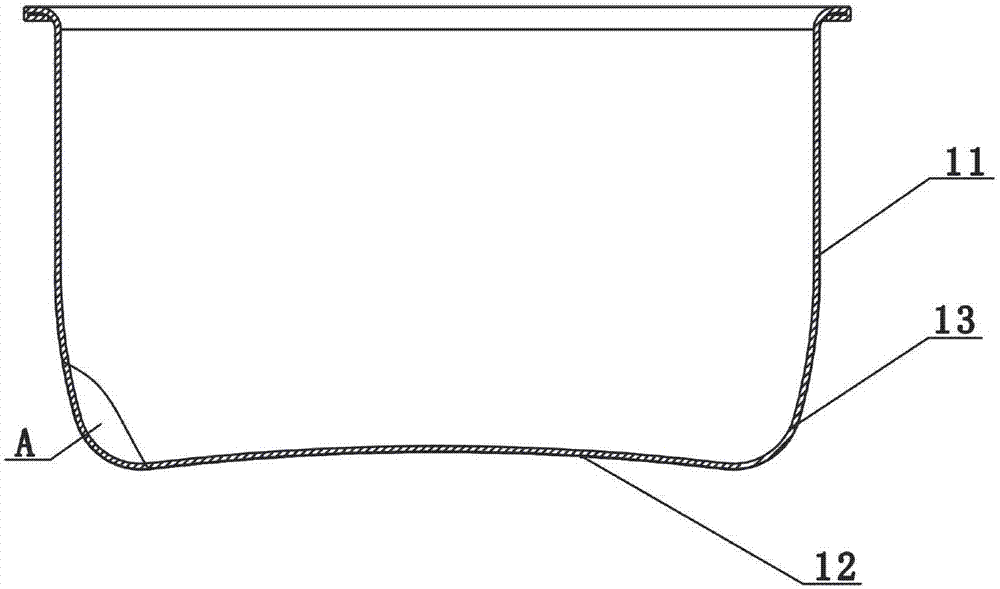

Electromagnetic heating cookware and three-dimensionally heated electromagnetic cooking appliance

ActiveCN102920310AFirmly connectedNo cracksCooking-vessel materialsPressure-cookersEngineeringElectromagnetic heating

The invention relates to an electromagnetic heating cookware and a three-dimensionally heated electromagnetic cooking appliance. The electromagnetic heating cookware is formed by stretching aluminum plates and is a cylindrical cookware with a bottom. The cookware comprises a pot body, a pot bottom, a transition part and a magnetic conduction heating element which is embedded into the outer side of the transition part, wherein the transition part is connected with the pot body and the pot base; the transition part is arc; the heat conduction heating element is a metal stretching net with a high extending property; the metal stretching net is compressed and connected to the corresponding part of the aluminum plate in advance and is stretched and formed into a cookware together with the aluminum plate. The three-dimensionally heated electromagnetic cooking appliance comprises a shell, the cookware and an electromagnetic wire coil for inducing the cookware to be heated three-dimensionally; the cookware is the cookware for electromagnetic heating; and the electromagnetic cooking appliance is an electric cooker, or an electric pressure cooker or an electric stewpan.

Owner:JOYOUNG CO LTD

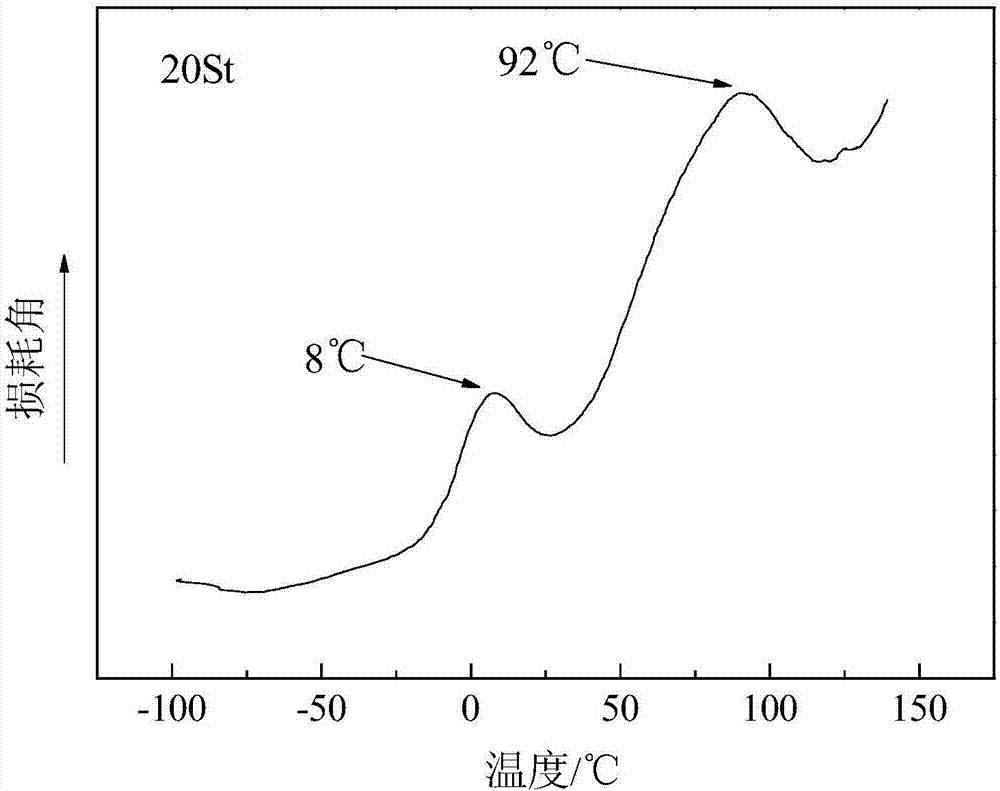

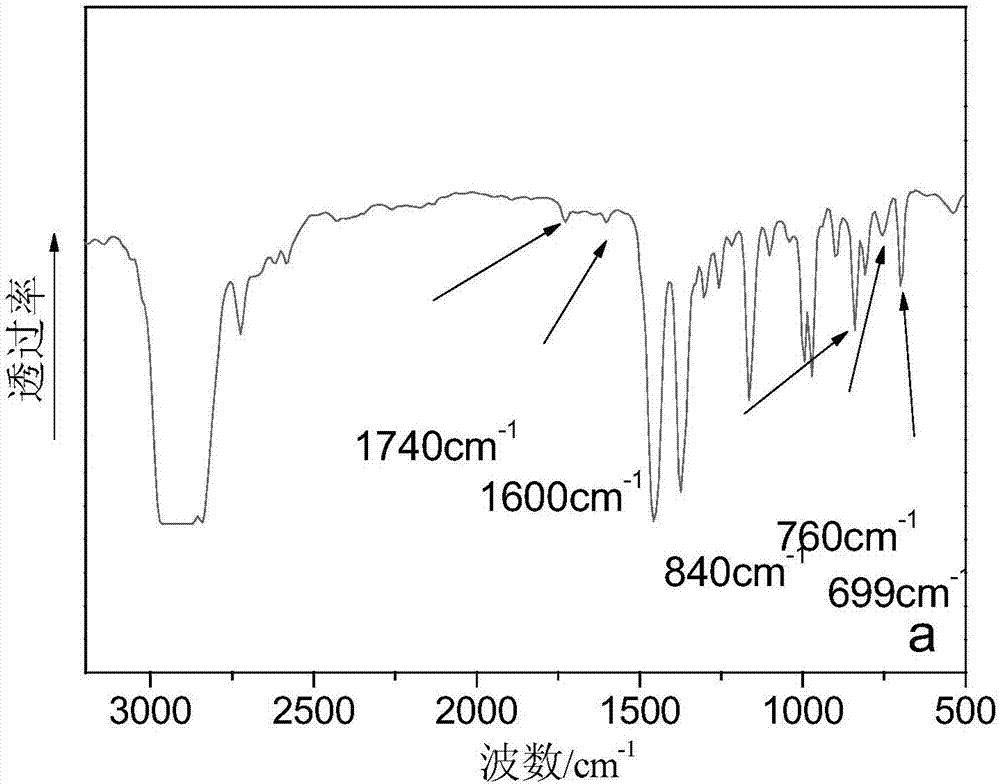

Compatilizer for PP/PS extrusion molding and preparation method thereof

ActiveCN107286294APrevent volatilizationImprove mechanical propertiesOxygenUltimate tensile strength

The invention relates to a compatilizer for PP / PS extrusion molding and a preparation method thereof. The compatilizer is prepared from the following components in percentages by mass: 65-80% of PP powder, 10-30% of a styrene monomer, 0-30% of a polar monomer, 0.05-0.25% of an initiator, 2-5% of a thickener and 0.1-0.4% of an anti-thermal oxygen stabilizer through reactive extrusion pelletization. The prepared compatilizer for PP / PS extrusion molding has good mechanical property and extrusion property, the compatibility of the PP / PS blend can be well improved, the mechanical strength of the blend can be effectively improved, the current situation of PP / PS extrusion molding is improved and the compatilizer has a wide application prospect.

Owner:CHANGZHOU UNIV

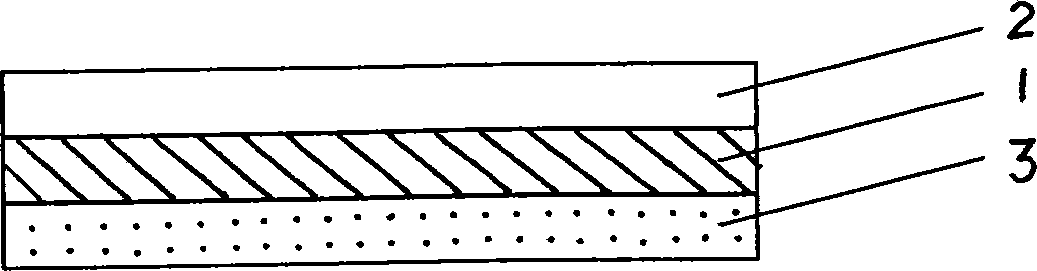

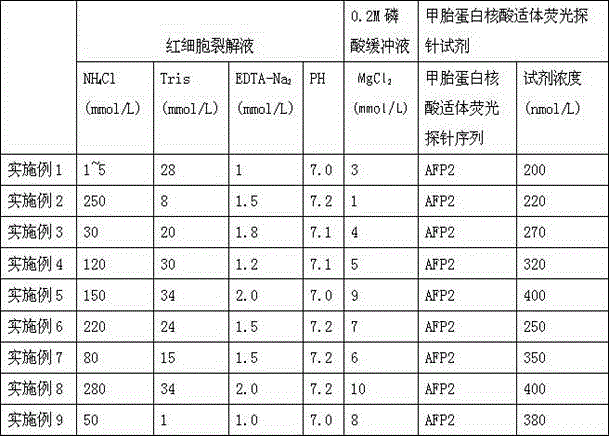

Alpha fetal protein kit based on aptamer fluorescent probe AFP3 and detection method thereof

InactiveCN105785034ANo workabilityNo separabilityBiological material analysisBiological testingRed blood cellBiology

The invention relates to an alpha fetal protein (AFP) kit based on an aptamer fluorescent probe, further relates to a method for measuring AFP concentration and reagent composition and components, and belongs to the technical field of medical detection and measurement. The kit mainly comprises the components of red blood cell lysis buffer, a phosphate buffer solution (PBS), an AFP standard and the AFP aptamer fluorescent probe. The AFP concentration is measured through blood sample splitting and mixed egg cultivation in conjunction with a fluorescent spectrophotometer. The alpha fetal protein kit has the advantages of simple sample treatment, easiness and convenience in operation, short detection time, high detection specificity, high flexibility, high detection result repeatability and the like.

Owner:GUANGZHOU HIGHER EDUCATION MEGA CENT HEALTH IND SCI & TECH PARK INVESTMENT MANAGEMENT

Waterproof neutral ink with nanometer level pigment and its prepn

The waterproof neutral ink with nanometer level pigment consists of nanometer level material liquid 40 wt%, thickener 40-50 wt% and diluent 10-20 wt%, and has average size of 100-200 nm. The preparation process includes the following steps: setting the nanometer level material liquid in the compounding pot, adding the diluent while stirring, and stirring for further 30-90 min, adding the thickener, stirring for further 1-3 hr, and discharging. The neutral ink has bright color, stable quality, writing fluency and other advantages, and may be filled into different kinds of pens.

Owner:苏州三威纳米科技有限公司

Microcapsule with effect of after-sun repairing and sunscreen cream containing microcapsule

ActiveCN105213205ARelieves redness and heatGood after-sun repairCosmetic preparationsToilet preparationsLanolinJojoba wax

The invention discloses a microcapsule with an effect of after-sun repairing and a sunscreen cream containing the microcapsule. The capsule wall material of the microcapsule comprises maltodextrin, Arabic gum and hydroxyethyl cellulose; the capsule core material of the microcapsule comprises coconut oil, sea buckthron oil, jojoba wax, squalane, vitamin E, witch hazel alcohol extract, purslane alcohol extract, paeoniflorin, green tea alcohol extract, L-cysteine and span; and the sunscreen cream is prepared from the microcapsule with the after-sun repairing effect, coconut oil, lanolin, ethanol, zinc oxide, titanium dioxide, iso-octyl p-methoxycinnamate, butyl methoxydibenzoylmethane, 2-ethylhexyl 2-cyano-3,3-diphenyl-acrylate, vitamin E, deionized water, xanthan gum and span 20. An after-sun repairing ingredient is embedded by a microcapsule technology and is added into the sunscreen cream, so that the sunscreen cream has sunscreen and after-sun repairing double functions, and adverse mutual competition caused by coexistence of the sunscreen and after-sun repairing ingredients can be effectively avoided.

Owner:CHONGQING PELLETS TECHN & TRADE

Green black paint and its prepn and use

InactiveCN101089060AAvoid shadesImprove adsorption capacityLiquid surface applicatorsCoatingsOrganic solventPolystyrene

The present invention relates to liquid polymer, and is especially one kind of environment friendly black paint specially for shading PVC film and its preparation process and use. The environment friendly black paint consists of dye 8-12 wt%, butyl acrylate 15-25 wt%, chlorosulfonated polypropylene 5-10 wt%, Teflon 15- 25 wt%, polystyrene 4-6 wt%, assistant 0.05-0.15 wt%, and organic solvent for the rest. Its preparation process includes the following steps: 1. adding butyl acrylate, chlorosulfonated polypropylene, Teflon and polystyrene into the organic solvent, and dissolving butyl acrylate completely; 2. adding dye and stirring; 3. adding assistant to form thick slurry; and 4. grinding and filtering. The environment friendly black paint is coated onto PVC film to form shading film.

Owner:上海富顺单向透视材料有限公司

Nucleic acid aptamer fluorescent probe based alpha-fetoprotein AFP2 kit and detection method

InactiveCN105651754ANo workabilityNo separabilityBiological testingFluorescence/phosphorescenceLysisRed blood cell

The invention relates to a nucleic acid aptamer fluorescent probe based alpha-fetoprotein AFP2 kit. Simultaneously, the invention also relates to a method for determining concentration of alpha-fetoprotein AFP and determination on composition and ingredients of reagents and belongs to the technical field of medical detection and determination. The kit provided by the invention comprises the main ingredients, i.e., a red blood cell lysis solution, a phosphate buffer solution PBS, an alpha-fetoprotein AFP standard and an alpha-fetoprotein AFP nucleic acid aptamer fluorescent probe; the size of concentration of the alpha-fetoprotein AFP is measured through carrying out blood sample lysis, carrying out mixed egg breeding treatment and carrying out detection by a fluorescence spectrophotometer. The nucleic acid aptamer fluorescent probe based alpha-fetoprotein AFP2 kit and the method have the advantages of simplicity in sample treatment, simplicity and convenience in operation, short detection time, high detection specificity, high sensitivity, high detection result repeatability and the like.

Owner:徐大鹏

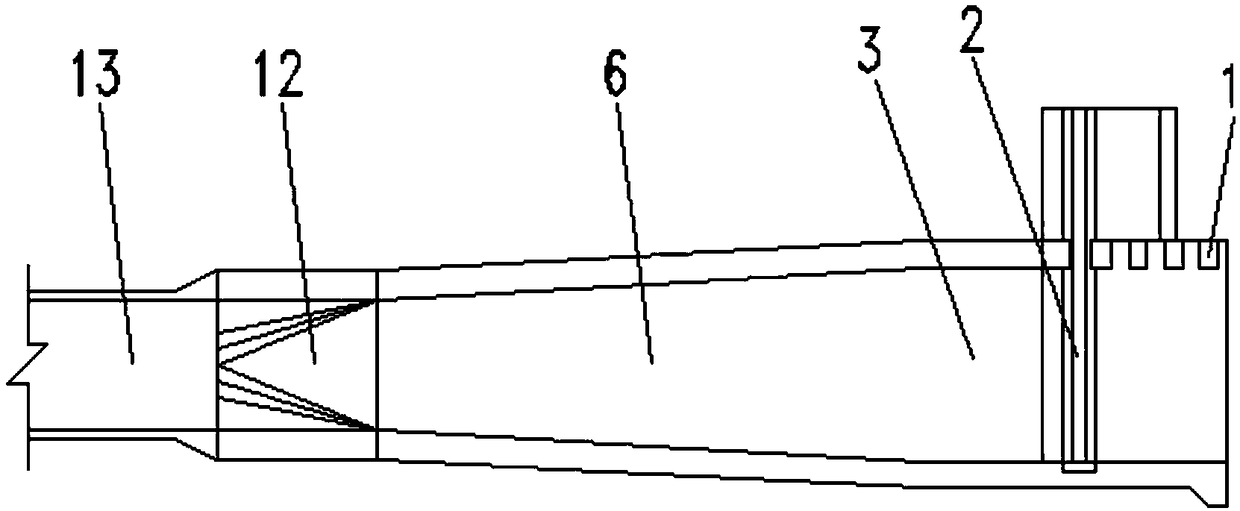

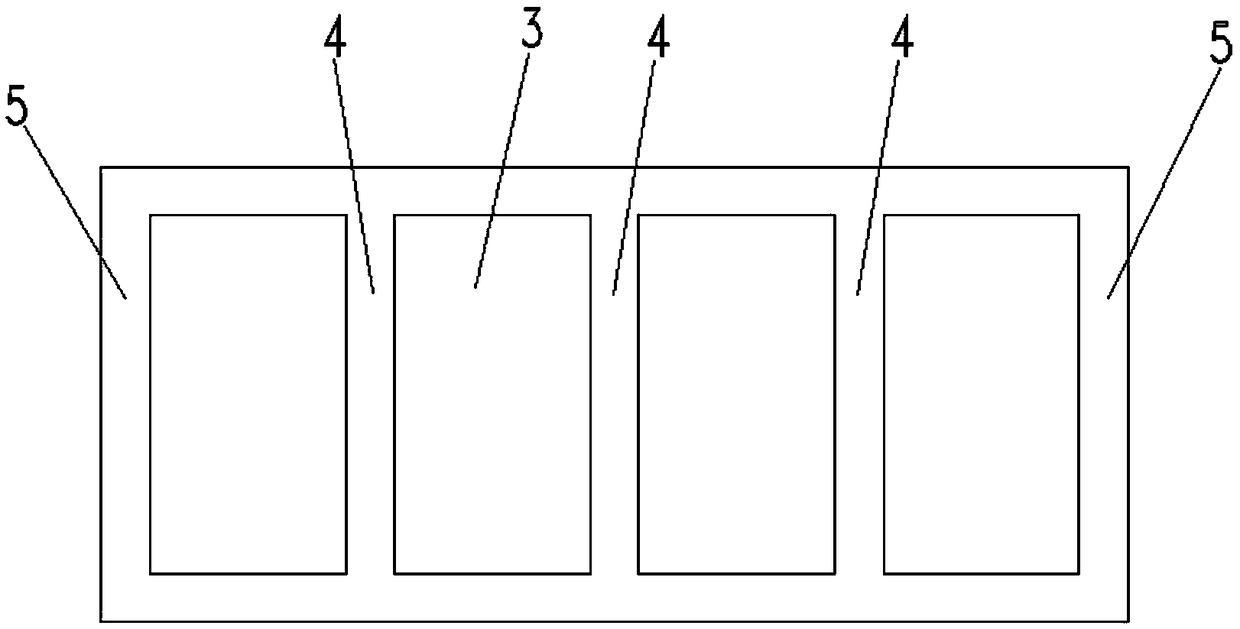

Method for improving hydraulic properties of water inlet/outlet of lower storage reservoir of pumped storage power station

PendingCN109056672AImprove water flowImprove running stabilityWater-power plantsHydro energy generationPower stationSurface pressure

The invention relates to a method for improving the hydraulic properties of a water inlet / outlet of a lower storage reservoir of a pumped storage power station. According to the method, by taking a series of engineering measures such as arranging a vortex prevention beam section, an adjustment section, a diffusion section and a round-to-square transition section, the distribution conditions of flow fields of the water inlet / outlet are improved, the hydraulic parameters such as the flow rate nonuniform coefficient, the flow distribution coefficient, head loss and the head loss coefficient are controlled within the reasonable range, and harmful backflow and ring current and fracture surface negative pressure are eliminated, so that the fracture surface pressure changes stably along the river, and the hydraulic conditions of the water inlet / outlet are improved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Synthesis method of dimer acid emulsifier

PendingCN113441079AImprove stabilityGood emulsifying effectTransportation and packagingMixingPtru catalystExplosive Agents

The invention discloses a synthesis method of a dimer acid emulsifier, the synthesis method comprises the following steps: (1) adding dimer acid into a reactor, stirring and heating to 80 DEG C, and starting a vacuum pump; (2) adding polyol and a catalyst solution, continuously heating to 150-190 DEG C, stirring and reacting for 2-5 hours, and controlling the heating speed at 20-30 DEG C / h to obtain an intermediate containing a lipid group; (3) cooling the intermediate containing the lipid group in the step (2) to 120 DEG C, adding a diluent, then adding polyamine or alcohol amine, controlling the temperature to be 120-180 DEG C for reaction, stirring and reacting for 1-2 hours in a vacuum state, controlling the heating speed to be 10-20 DEG C / h, and stopping the reaction after all water generated by the reaction is evaporated; and (4) cooling and discharging to obtain the emulsifier with the content of 70% or above. The emulsifier is used for industrial colloidal explosives, the emulsibility in the product preparation process is greatly improved, the emulsifier can be smoothly emulsified under the condition that the stirring strength in the emulsion preparation process is reduced, the emulsifier has a certain self-emulsifying function, and the stability of colloid is greatly improved after the emulsification is finished.

Owner:昆明澳融科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com