Technological method for forming silica gel layers on surfaces of glass bottles by means of injection molding

A process method and glass bottle technology, applied in the direction of coating, etc., can solve the problems of inconvenient use, fragile glass bottles, poor user experience, etc., and achieve the effects of good safety, firm effect, and high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

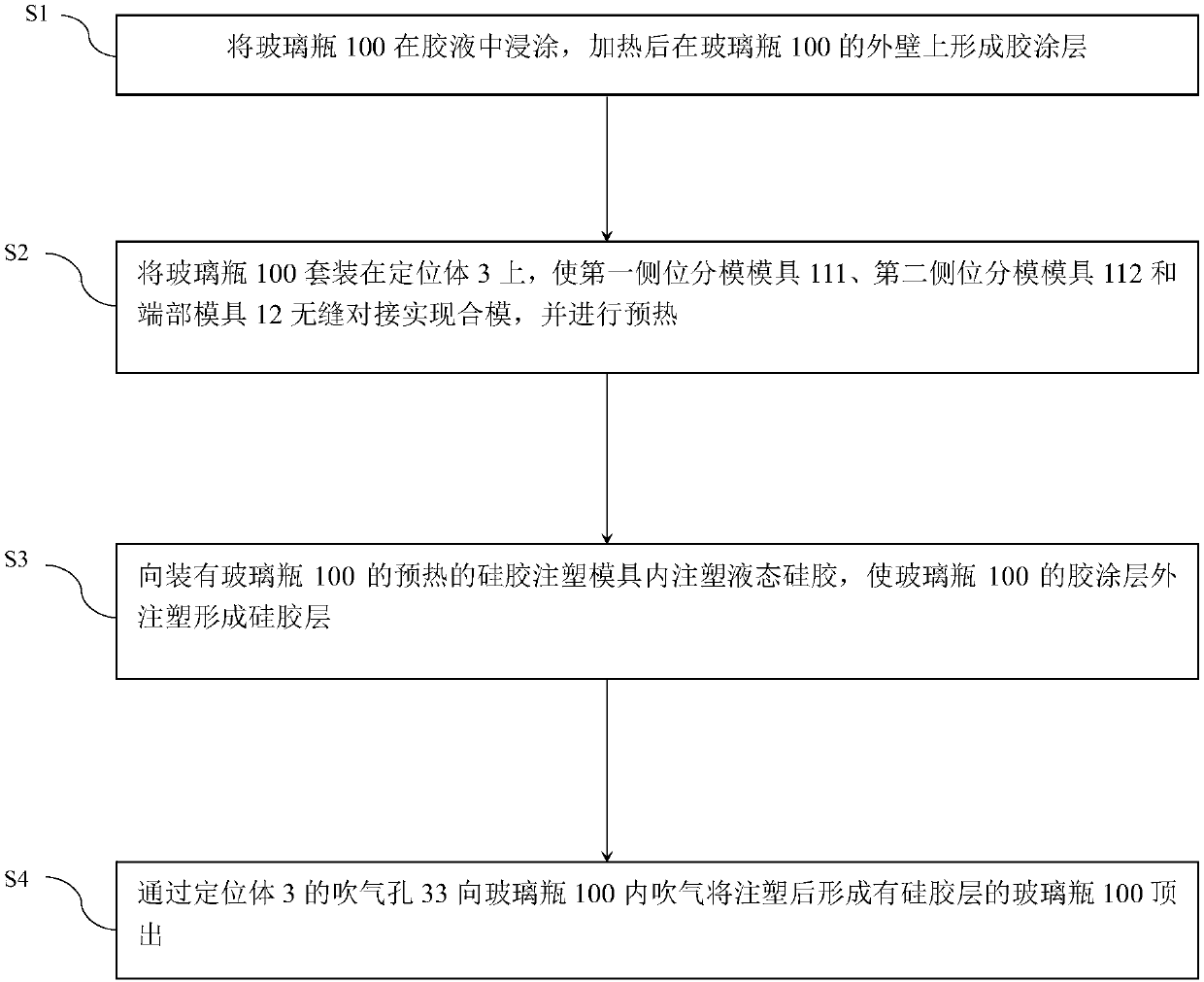

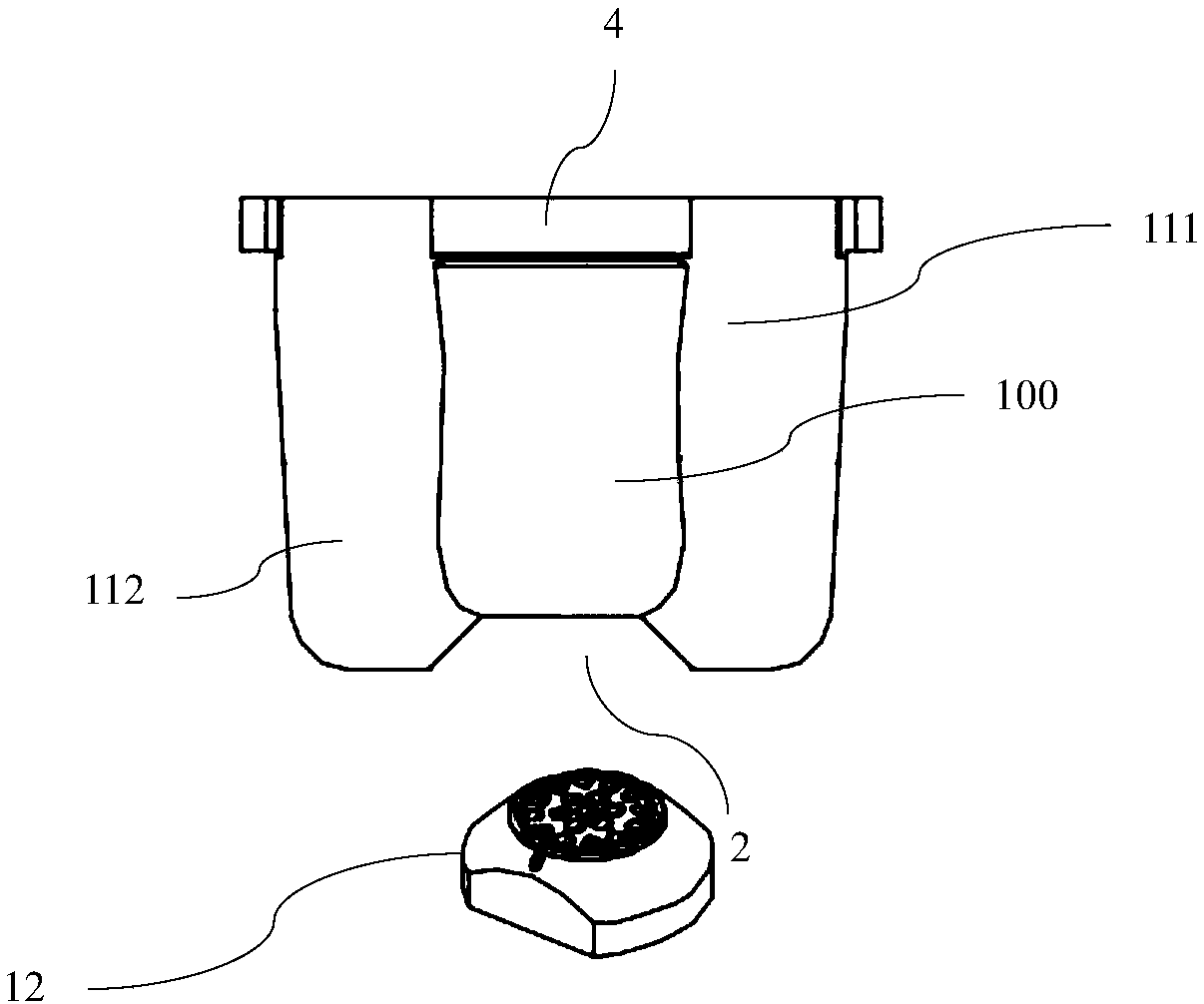

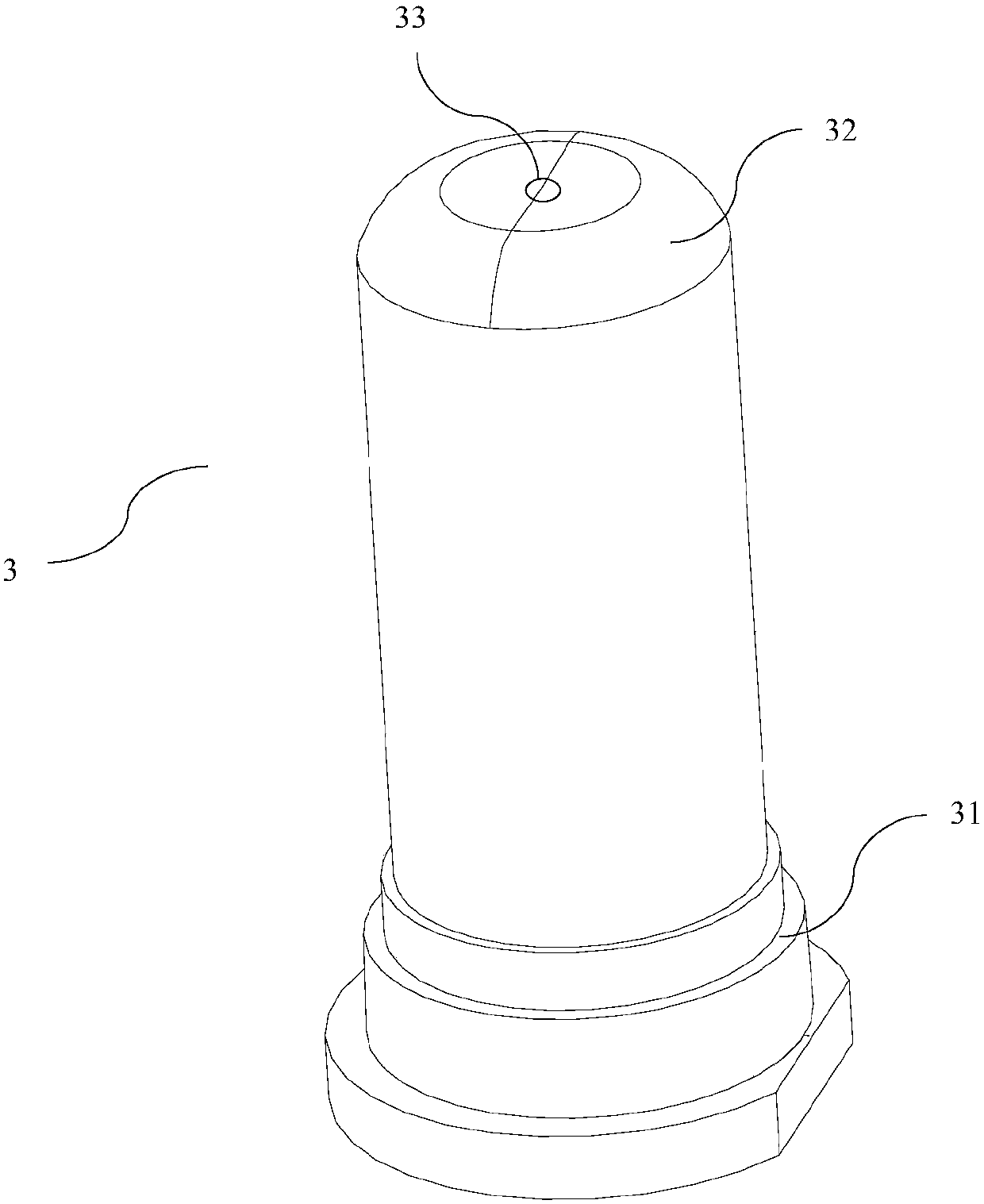

[0035] Such as Figure 2-3 As shown, the silicone injection mold includes a positioning body 3 for setting the glass bottle 100, and a first side parting mold for encapsulating the glass bottle 100 from the outer periphery of the side wall of the glass bottle 100 is arranged on both sides of the positioning body 3 111 and the second side parting mold 112 , an end mold 12 for encapsulating the glass bottle 100 towards the outer bottom wall of the glass bottle 100 is provided at the end of the positioning body 3 . Wherein, the first side parting mold 111, the second side parting mold 112 and the end part mold 12 form the inner injection molding space 2 after the joint molds are seamlessly connected. At this time, the positioning body 3 is located at the center of the injection molding space 2. And after the glass bottle 100 is set on the positioning body 3 for positioning, the outer wall of the glass bottle 100 has a stable contact with the inner wall of the first side parting m...

Embodiment 2

[0049] Dip-coat the surface of the glass bottle 100 in the glue solution, avoid dipping the external thread of the glass bottle 100, put the dip-coated glass bottle 100 into an oven and bake at 100°C for 20 minutes to form a thick layer on the outside of the glass bottle 100. 0.07mm glue coating, and use a clean cloth to wipe off the glass bottle 100 forming the glue coating or blow it clean; after the protective shell 4 and the protective ring are set on the glass bottle 100, the glass bottle 100 is set on the positioning body 3. Make the first side parting mold 111, the second side parting mold 112 and the end part mold 12 seamlessly connected to realize mold closing, and preheat. The preheating temperature is 130°C, keeping the temperature of the silicone injection mold At a temperature of 130°C, through the two injection ports 123 of the silicone injection mold, inject liquid silicone into the silicone injection mold from both sides toward the bends of the side wall and the...

Embodiment 3

[0051] Dip-coat the surface of the glass bottle 100 in the glue solution, avoid dipping the external thread of the glass bottle 100, put the dip-coated glass bottle 100 into an oven and bake at 125°C for 45 minutes to form a thick layer on the outside of the glass bottle 100. 0.1mm glue coating, and use a clean cloth to clean the glass bottle 100 that has formed the glue coating or blow it clean; after the protective shell 4 and the protective ring are set on the glass bottle 100, the glass bottle 100 is set on the positioning body 3. Make the first side parting mold 111, the second side parting mold 112 and the end part mold 12 seamlessly connected to realize mold closing, and preheat. The preheating temperature is 145°C, keeping the temperature of the silicone injection mold At a temperature of 145°C, through the two injection ports 123 of the silicone injection mold, inject liquid silicone into the silicone injection mold from both sides toward the bends of the side wall and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com