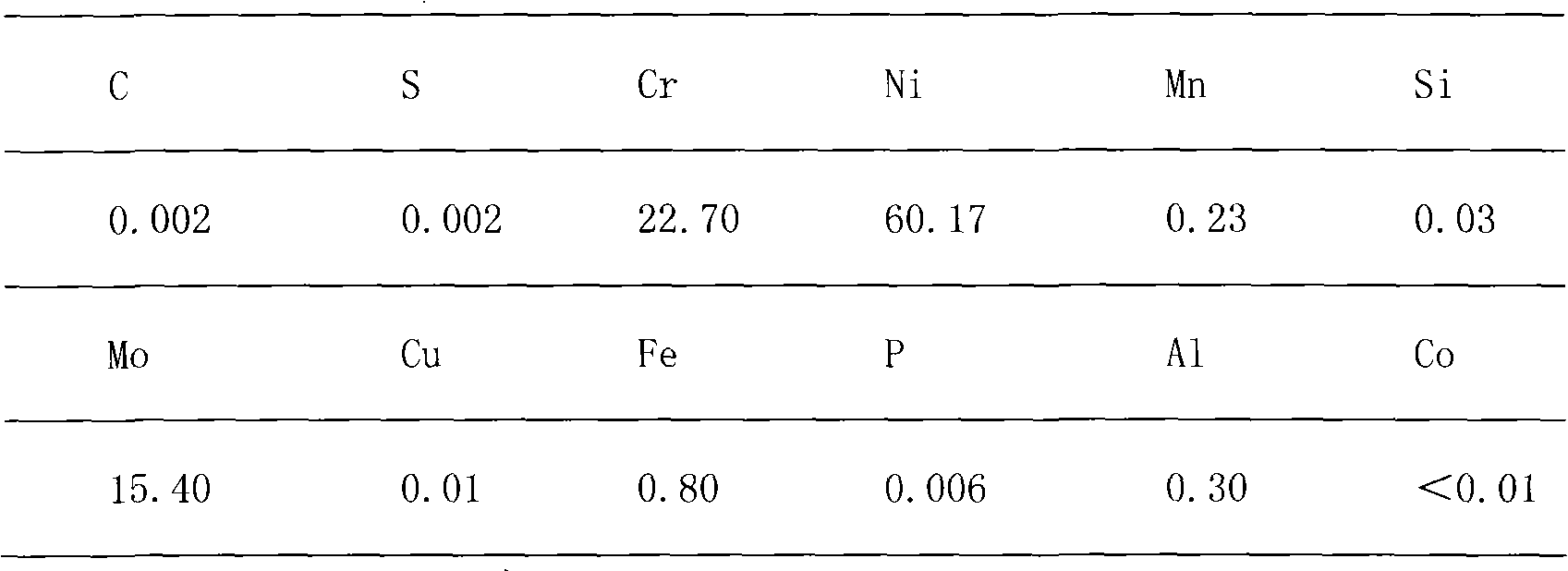

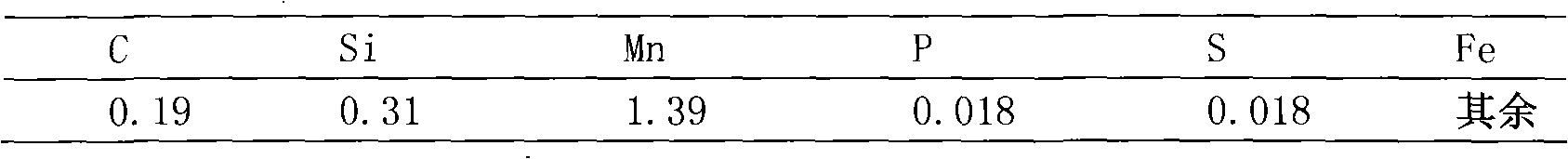

Ultra-low carbon Ni-Cr-Mo5923hMo steel alloy explosion welding high corrosion resistance composite material

A cr-ni-mo5923hmo, explosive welding technology, which is applied in the fields of molybdenum alloy steel, chromium and nickel, can solve the problem of explosive welding of Cr-Ni-Mo alloy composite materials that has not been reported in literature and does not involve Cr-Ni-Mo alloy steel. Technology and other issues to achieve the effect of reducing the cost of explosive welding, high bonding strength, and weakening shock waves and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Industrial scale production of ultra-low carbon Cr-Ni-Mo5923hMo alloy steel explosion welding high corrosion resistance composite material, the production method is as follows:

[0020] 1. Pretreatment process before explosion: 1. Grinding and polishing the bonding interface with grinding wheel and cloth wheel to remove the oxide layer on the surface to achieve the purpose of flatness, lightness and cleanliness. 2. Determination of the size of base, doubler board and drug distribution; the doubler board is 40mm longer than the four sides of the base plate, and the size of the drug distribution is the same as that of the doubler board. 3. Before installing the base and double board, wash the two joint surfaces with acetone to remove dust and oil stains on the surface.

[0021] 2. Explosive welding composite process: select powdered ammonium oil emulsion explosive with low detonation velocity, and add powdered industrial salt accounting for 25% of the total mass, 3-4% per...

Embodiment 2

[0025] Industrial scale production of ultra-low carbon Cr-Ni-Mo5923hMo alloy steel explosion welding high corrosion resistance composite material, the production method is as follows:

[0026] 1. Pretreatment process before explosion: 1. Grinding and polishing the bonding interface with grinding wheel and cloth wheel to remove the oxide layer on the surface to achieve the purpose of flatness, lightness and cleanliness. 2. Determination of the size of the base, compound board and drug distribution; the compound board is 20mm longer than the four sides of the base plate, and the drug distribution size is the same as that of the compound board. 3. Before installing the base and double board, wash the two joint surfaces with acetone to remove dust and oil stains on the surface.

[0027] 2. Explosive welding complex process: select powdered ammonium oil emulsion explosive with low detonation velocity, and add powdered industrial salt accounting for 30% of the total mass, 3-4% perli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com