Green black paint and its prepn and use

A black paint, environmentally friendly technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problem of insufficient shading method of PVC film, and achieve the effect of solving shading problem, avoiding harm and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

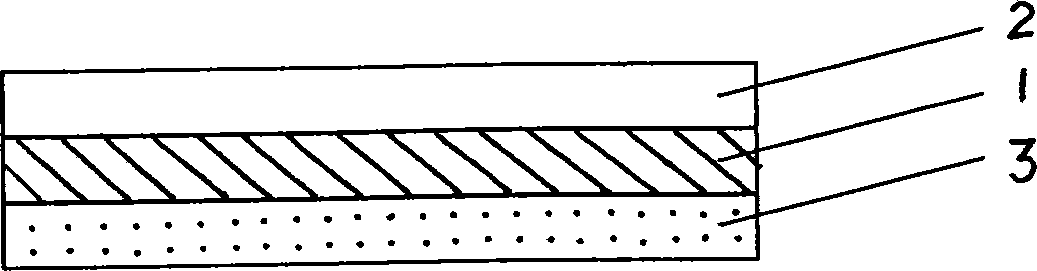

Image

Examples

Embodiment 1

[0038] A kind of environment-friendly type black paint, each component is calculated as by weight percentage:

[0039] Dye 8.4%

[0040] Butyl Acrylate 15.2%

[0041] Chlorosulfonated Polypropylene 8.2%

[0042] PTFE 23.6%

[0043] Polystyrene 4.1%

[0044] Glycerin 0.05%

[0045] Polyethylene 0.02%

[0046] Polyacrylate 0.03%

[0047] Amine antioxidant 0.02%

[0048] Epoxy resin 0.01%

[0049] Toluene 40.37%.

[0050] The preparation method of environment-friendly type black paint comprises the following steps:

[0051] Step 1: Put the butyl acrylate, chlorosulfonated polypropylene, polytetrafluoroethylene and polystyrene of the above formula in toluene according to the formula, and fully dissolve the butyl acrylate under normal pressure at 20-36°C;

[0052] Step 2: After 1 hour, add the dye, stir and decompose for 20-40 minutes;

[0053] Step 3: Add polyethylene, polyacrylate, amine antioxidant and epoxy resin to make a viscous slurry;

[0054] Step 4: Grind in a...

Embodiment 2

[0057] A kind of environment-friendly type black paint, each component is calculated as by weight percentage:

[0058] Dye 9.5%

[0059] Butyl Acrylate 20.1%

[0060] Chlorosulfonated Polypropylene 7%

[0061] PTFE 18.2%

[0062] Polystyrene 5.1%

[0063] Glycerin 0.03%

[0064] Polyethylene 0.02%

[0065] Polyacrylate 0.03%

[0066] Amine antioxidant 0.01%

[0067] Epoxy resin 0.01%

[0068] Toluene 40%.

[0069] The preparation method and application of the environment-friendly black paint in this embodiment are the same as those in Embodiment 1.

Embodiment 3

[0071] A kind of environment-friendly type black paint, each component is calculated as by weight percentage:

[0072] Dye 10.1%

[0073] Butyl Acrylate 24.6%

[0074] Chlorosulfonated Polypropylene 6.2%

[0075] PTFE 16.7%

[0076] Polystyrene 4.9%

[0077] Glycerin 0.04%

[0078] Polyethylene 0.01%

[0079] Polyacrylate 0.03%

[0080] Amine antioxidant 0.01%

[0081] Epoxy resin 0.02%

[0082] Toluene 37.39%.

[0083] The preparation method and application of the environment-friendly black paint in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com