Novel laser engraving unit equipment

A new type of laser engraving technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficult cleaning, engraving machine failure, easy aging, etc., to eliminate surrounding static electricity, save cleaning time, and avoid static electricity interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

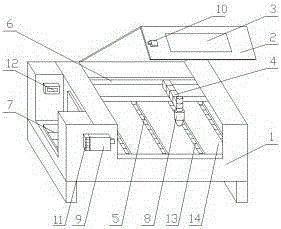

[0009] A new type of laser engraving unit equipment, including: body 1, machine cover 2, observation port 3, telescopic frame 4, slag collection tank 5, guide rail 6, console 7, laser transmitter 8, photoelectric receiver 9, photoelectric transmitter Device 10, buzzer 11, automatic static eliminator 12, exhaust fan 13, engraving table 14, machine cover 2 is installed on the top of the body 1, an observation port 3 is opened on the machine cover 2, and a photoelectric transmitter is installed on one side of the observation port 3 10. A console 7 is installed on one side of the fuselage 1, a fully automatic static eliminator 12 is installed on one side of the console 7, a photoelectric receiver 9 is installed on one side of the console 7, a buzzer 11 is installed on one side of the photoelectric receiver 9, the fuselage 1 The engraving table 14 is installed at the bottom, the slag collection tank 5 is set on the engraving 14 table, the exhaust fan 13 is installed in the slag coll...

Embodiment 2

[0011] Place the metal to be engraved on the engraving table 14, close the machine cover 2, start engraving after setting the engraving pattern through the console 7, and the laser emitter 8 emits laser light to engrave the metal surface on the engraving table 14. If the machine cover 2 is not If it can be completely closed, the photoelectric receiver 9 cannot receive the photoelectric signal emitted by the photoelectric transmitter 10, triggering the buzzer 11 to sound an alarm. During the engraving process, the exhaust fan 13 sucks the generated debris and dust into the slag collection tank 5 , Fully automatic static eliminator 12 can automatically remove static electricity around to avoid static interference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com