Preparation method of carbon quantum dots with high quantum yield

A carbon quantum dot, high-quantum technology, applied in the field of new functional materials, can solve the problems of long time consumption, complicated preparation method, high production cost, etc., and achieve the effect of reducing production cost, simple preparation method and short preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

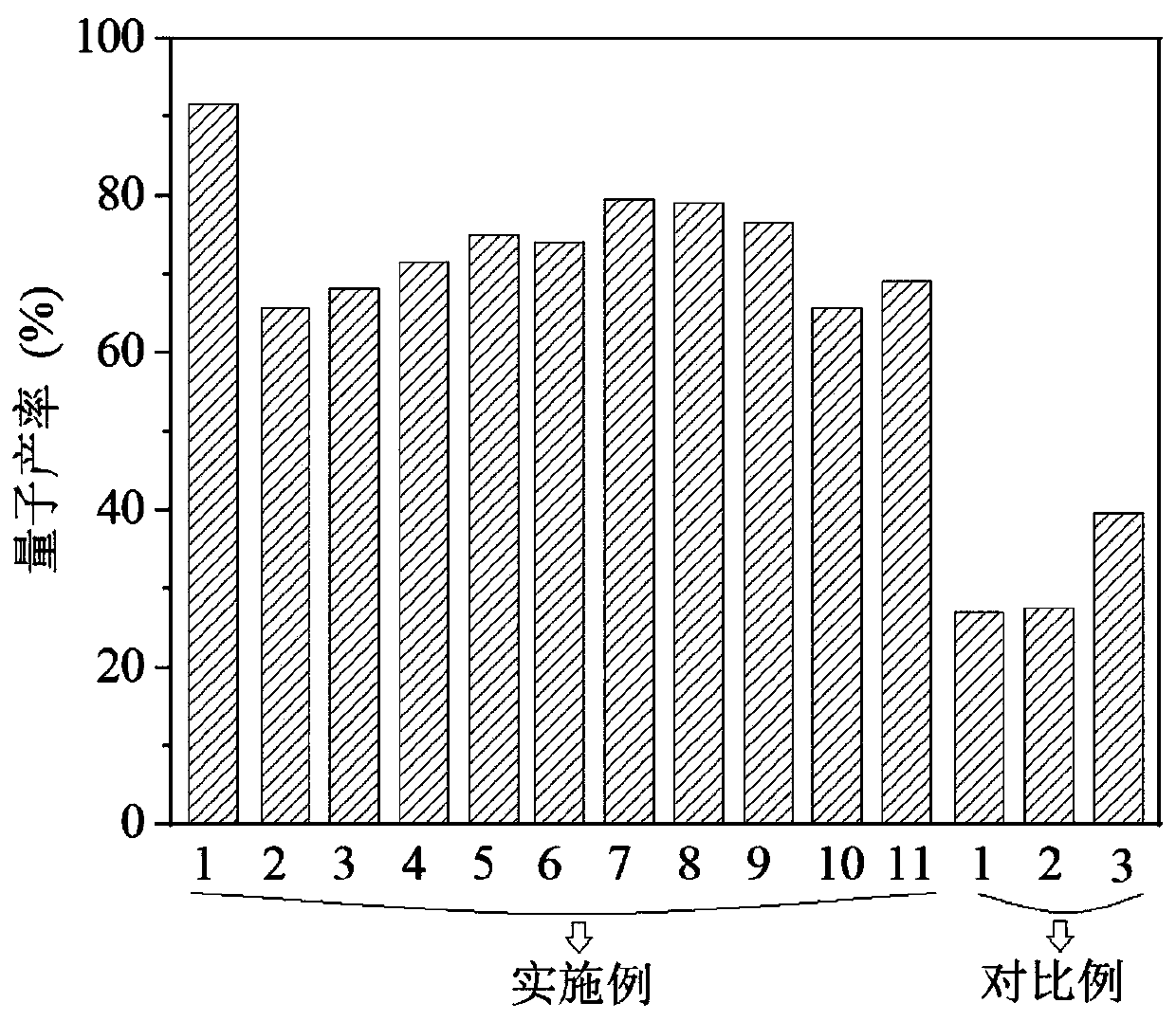

Examples

preparation example Construction

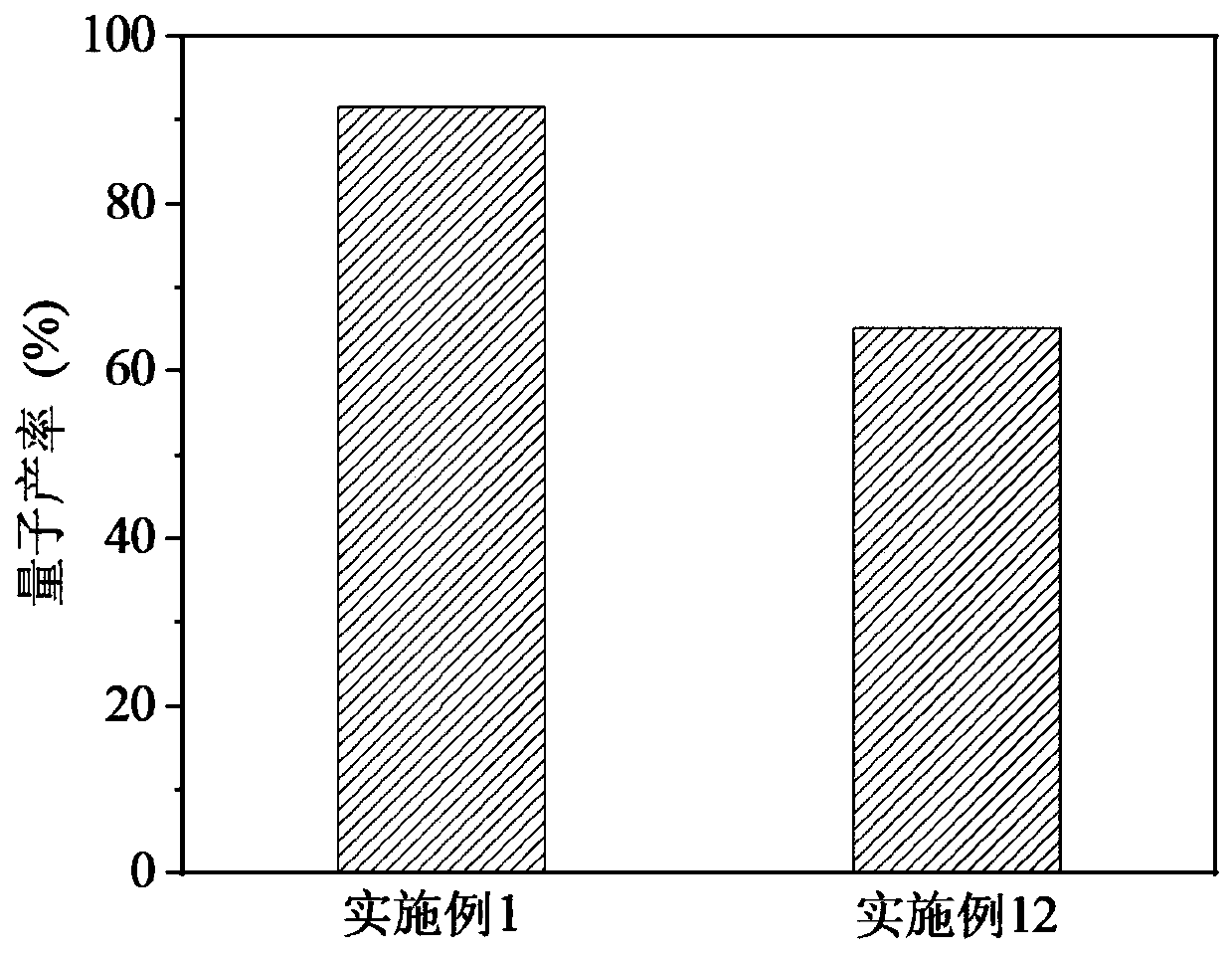

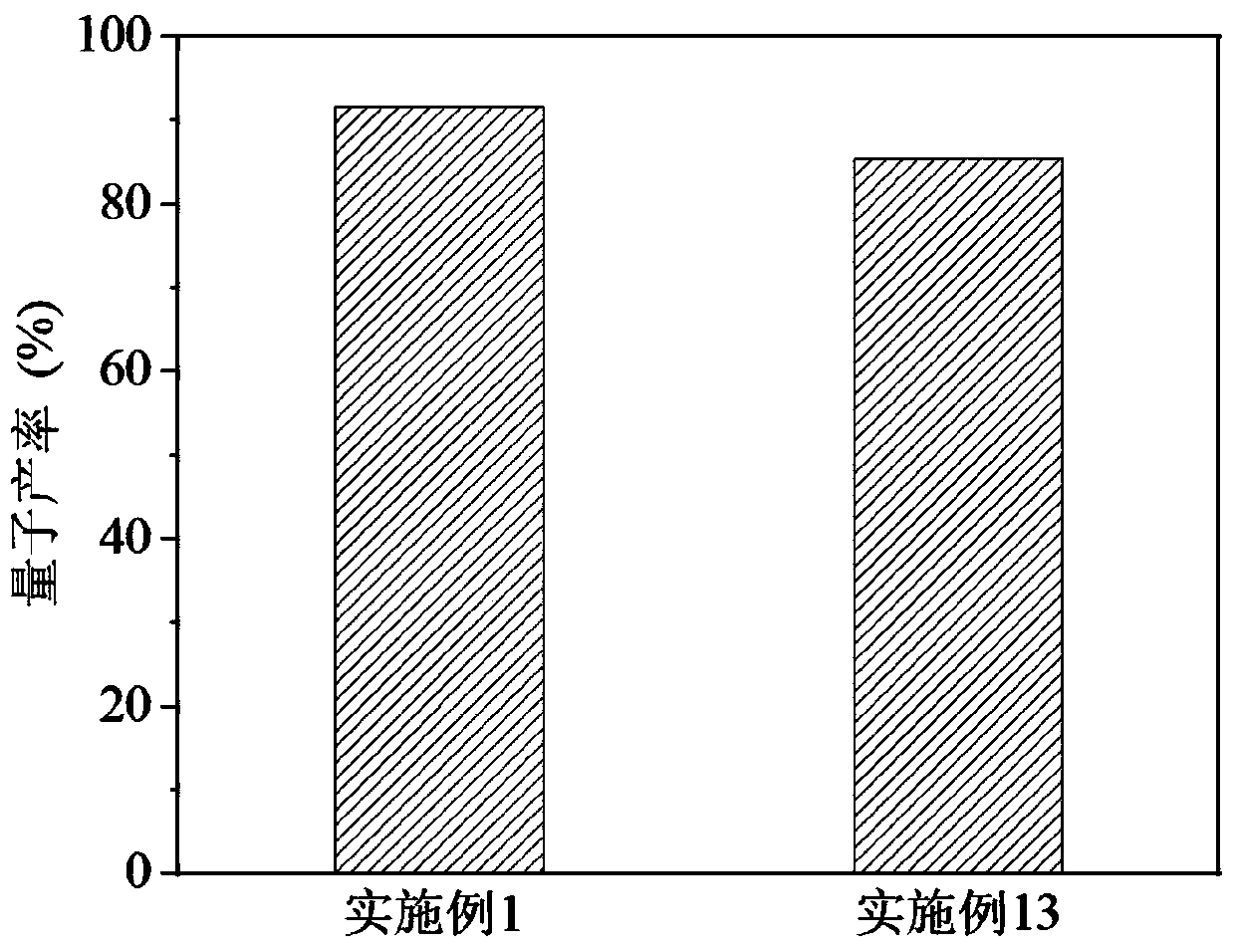

[0035] A preferred embodiment of the present invention provides a method for preparing carbon quantum dots with a high quantum yield, comprising: first mixing a carbon source composed of citric acid and ascorbic acid with an alkali source composed of ethylenediamine and o-phenylenediamine A mixed solution is obtained in a solvent, and then the mixed solution is microwave-heated for a preset time to prepare carbon quantum dots.

[0036] In a specific embodiment, the molar ratio of citric acid and ascorbic acid forming the carbon source is (0.5~2):1, preferably 1:1, and the molar ratio of ethylenediamine and o-phenylenediamine forming the alkali source is ( 0.25~1):1, preferably 0.5:1; the molar ratio of carbon source and alkali source is (1~20):1, preferably 5:1; the volume of solvent is 1~50ml, preferably 10~30ml; The concentration of the carbon source in the mixed solution is 0.3-0.7mol / L, preferably 0.5mol / L; the microwave intensity during microwave heating is 100-700W; the ...

Embodiment 1

[0039] A carbon source composed of citric acid and ascorbic acid (the molar ratio of citric acid and ascorbic acid is 1:1) and an alkali source composed of ethylenediamine and o-phenylenediamine (the molar ratio of ethylenediamine and o-phenylenediamine is 1 :2) According to the molar ratio of carbon source and alkali source being 5:1, mix and add in 10ml ethylene glycol solvent, wherein the concentration of carbon source is 0.5mol / L, place it in a microwave oven, set the power of the microwave oven to 700W, and react Take it out after 3 minutes to obtain carbon quantum dots.

Embodiment 2

[0041] The only difference from Example 1 is that the molar ratio of carbon source to alkali source is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com