Modified biomass adsorber as well as preparation method and application thereof

A biomass adsorbent and modified technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of high price, difficult to recycle, large amount of consumption, etc., and achieve low price and adsorption speed. The effect of fast and improving reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

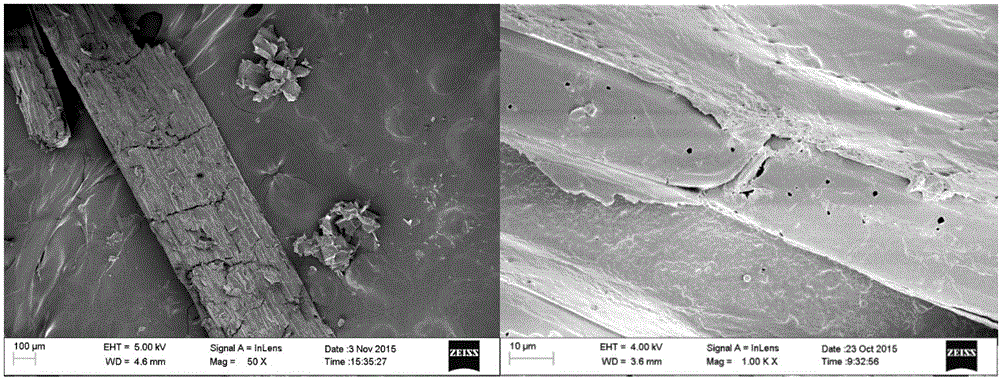

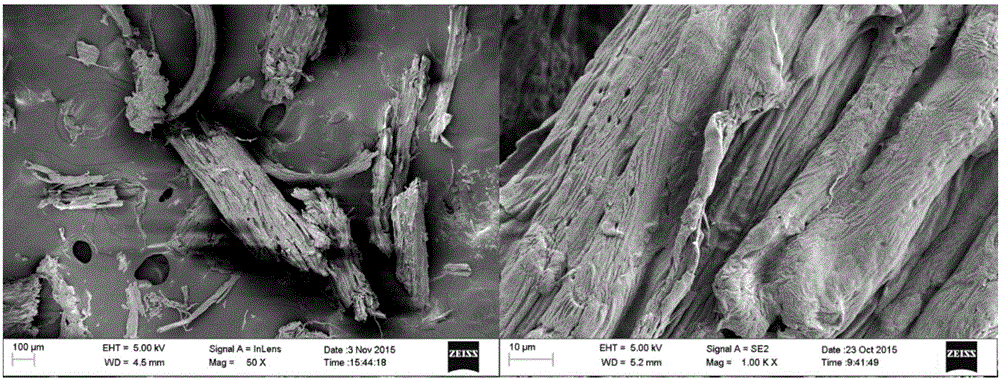

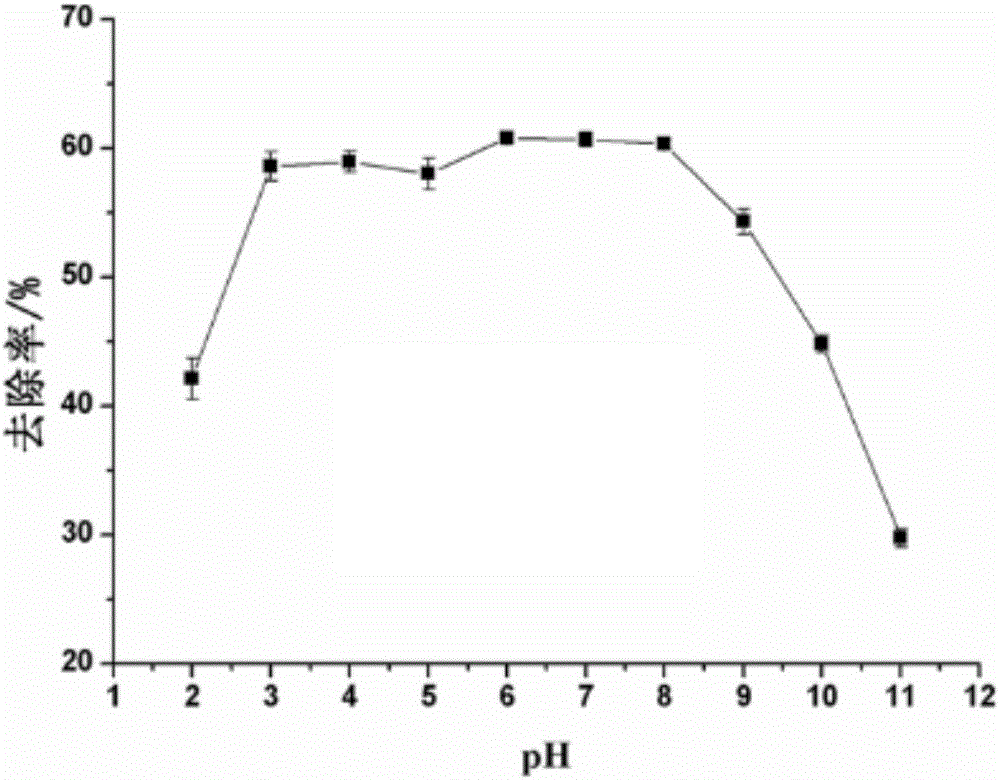

[0042]Wash, soak and dry the raw material of corn stalks, and crush them for later use. Weigh 6g of crushed corn stalks (40-80 mesh) into a beaker, add 200mL of 10% NaOH aqueous solution, and carry out alkalization pretreatment at room temperature for 3 hours. . The pretreated straw was dehydrated by suction filtration, and transferred to a three-necked flask, 60 mL of epichlorohydrin was added, and the cross-linking reaction was carried out in a constant temperature water bath at 65° C. and mechanical stirring for 6 hours. After the cross-linking reaction, excess epichlorohydrin in the straw was removed by filtration, and 60 mL of 33% trimethylamine aqueous solution was added to react for 3 h under the conditions of constant temperature water bath at 80° C. and mechanical stirring. The solidified product obtained by the reaction was washed successively with 100 mL of ethanol aqueous solution with a volume ratio of 1:1, 0.1 mol / L NaOH aqueous solution, and 0.1 mol / L NaCl aqueo...

Embodiment 2

[0047] Wash, soak and dry the raw material of corn stalks, and crush them for later use. Weigh 10g of crushed corn stalks (40-100 mesh) into a beaker, add 300mL of 10% NaOH aqueous solution, and carry out alkaline pretreatment at room temperature for 2 hours. . The pretreated straw was dehydrated by suction filtration, and transferred to a three-necked flask, where 100 mL of epichlorohydrin was added, and the crosslinking reaction was carried out in a constant temperature water bath at 65° C. and mechanical stirring for 6 hours. After the cross-linking reaction, excess epichlorohydrin in the straw was removed by filtration, and 100 mL of 33% trimethylamine aqueous solution was added to react for 3 h under the conditions of constant temperature water bath at 80° C. and mechanical stirring. The solidified product obtained by the reaction was washed successively with 100 mL of ethanol aqueous solution with a volume ratio of 1:1, 0.1 mol / L NaOH aqueous solution, and 0.1 mol / L NaCl...

Embodiment 3

[0050] The rice straw raw material was cleaned, soaked, dried, and crushed for later use. Weighed 6 g of crushed rice straw (40-80 mesh) into a beaker, added 200 mL of 10% NaOH aqueous solution, and alkalized for 3 hours at room temperature. The pretreated straw was dehydrated by suction filtration, and transferred to a three-necked flask, 60 mL of epichlorohydrin was added, and the cross-linking reaction was carried out in a constant temperature water bath at 65° C. and mechanical stirring for 6 hours. After the cross-linking reaction, excess epichlorohydrin in the straw was removed by filtration, and 100 mL of 33% trimethylamine aqueous solution was added to react for 3 h under the conditions of constant temperature water bath at 85° C. and mechanical stirring. The solidified product obtained by the reaction was washed successively with 100 mL of ethanol aqueous solution with a volume ratio of 1:1, 0.1 mol / L NaOH aqueous solution, and 0.1 mol / L NaCl aqueous solution, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com